Professional Documents

Culture Documents

Jay Holland Detailed

Uploaded by

Jay Nova0 ratings0% found this document useful (0 votes)

189 views5 pagesI'm looking for work if you need someone certified please feel free to contact me at the numbers and addresses included in this document

Original Title

Jay.holland.detailed

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentI'm looking for work if you need someone certified please feel free to contact me at the numbers and addresses included in this document

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

189 views5 pagesJay Holland Detailed

Uploaded by

Jay NovaI'm looking for work if you need someone certified please feel free to contact me at the numbers and addresses included in this document

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

Jay Holland

Level 1 Quality Inspector, Certified Welder, IW 736 Member

Saskatchewan: 306.690.6667

xlnts@outlook.com

54 Upper Mount Albion Road

Stoney Creek, Ontario

L8J-2S1

Work Experience

Current Job No

Start Date Jan 1993

End Date Jan 1997

Employer Lancing Fabricators

Job Title Welder

Responsibilities Perform welding from various departments with help of

welding torches and arcs. Taking direction, basic shop

and detailed drawings. Analyze defective equipments and

identify appropriate defective equipments and inform

supervisors. Manage work with help of manual welding

machines. Monitor all welding processes and ensure

absence of any shrinkage and distortion to materials.

Manage welding work and ensure compliance to all

specifications. Ensure clean weld joint to obtain smooth

look. Maintain disc grinder and perform all cleaning and

grinding of metals. Operate various manual and

automated welding equipment for welding work. Analyze

speed and length of welding arc for all welding process.

Assemble all components with help of power and hand

tools.

Start Date Jan 1996

End Date Jan 1997

Employer Butty Manufacturing

Job Title Welder Fitter

Responsibilities

Blueprints, taking directions, operating safety working

equipments and applying safety practice at work while

performing duties. Welding spare parts in various

directions: flat, horizontal, vertical or overhead, etc.

Igniting flame or striking an arc while welding or

performing other electricity-related work to weld part of a

metal structure. Identifying any fault in operating the

equipment or in relation to any material or equipment,

then notifying the supervisor. Clamping, holding, tack-

welding, heat-bending, bolting, or grinding spare parts as

necessary to satisfy the technical requirements and create

a welded final product. Operating other accessory

equipments and performing some tasks necessary for

welding metal, such as fusing metal segments, using gas

tungsten arc, metal arc, flux-cored arc, and other types of

welding arcs. Control the processes of fitting, burning and

welding to avoid problems in relation to overheat,

distortion, expansion or shrink of spare parts. Examining

finish products and spare parts and comparing them with

samples to check whether the specifications are met.

Preparing and setting up necessary tools and equipments

for welding job such as shielded metal arc, gas metal arc

or other welding equipments. Arranging and assuring the

welded parts to be arranged in order before being

assembled into final products; Using such tools as square,

caliper or ruler for this task.

Start Date Jan 1997

End Date Jan 2000

Employer Edge Advertising Operations and Account Manager

Job Title Account Manager

Responsibilities Responsible for obtaining profitable results through the

sales team by developing the team through motivation,

counseling, skills development and product knowledge

development. Manage the sales administration function,

operational performance reporting, streamlining

processes and systems wherever possible, and advising

senior management on maximizing business relationships

and creating an environment where customer service can

flourish. Manage the sales team, developing a business

plan covering sales, revenue, and expense controls,

meeting agreed targets, and promoting the organizations

presence throughout Southern Ontario. Assist in the

development of the annual marketing plan, specifically

advising on: realistic forecasts for each product and

territory (based on historical data, market trends,

competitive activity, promotional strategy and sales effort),

realistic costs of operating the sales force; and sales

promotion programme plans. Ensure recruitment,

direction, organization and control of sales managers and

sales representatives to accomplish specific objectives.

Responsible for monitoring the performance of the sales

team by establishing a system of reports and

communications involving sales reports, cyclical sales

meetings. Plan and implement a specific appraisal system

that describes the responsibilities and performance

standards for each member of the sales team, set

individual territory sales and commission targets and

administer the commission plan. Personally observe the

performance of representatives in the field on a regular

basis. Provide high standards of training for

representatives so that they possess sufficient technical

knowledge

Start Date Jan 2003

End Date Apr 2012

Employer Hamilton-Welding.com

Job Title Project Coordinator, Metal Fabricator, Weld Quality

Control

Responsibilities Blueprints, direct work, implementation and auditing of

welding guidelines. Blueprints, Consulting BUs / Areas

concerning Welding Questions. Development and

implementation of best practices in welding technology.

Optimization of welding production processes in terms of

quality and cost. Perform audits, analysis and

improvement projects. Creation and implementation of

preventive measures to enforce the Group-wide welding

technology standards. Independent implementation of

strategic welding projects.

Start Date Apr 2012

End Date Current

Employer Ironworkers Local 736

Job Title Ironworker/Welder

Responsibilities Blueprint reading, weld specifications, quality control,

raise, place, and also unite girders, columns, and also

other structural-steel members to form completed

structures or structure frameworks, working as member of

crew. Sets up hoisting equipment for raising placing

structural-steel members. Fastens steel members to cable

of hoist, using chain, cable, or rope. Signals worker

operating hoisting equipment to lift and place steel

member. Guides member, using tag line rope in order to

guide it into position. Pulls, pushes, or pry steel members

into approximate position while member is supported by

hoisting device. Forces members into final position, using

turnbuckles, crowbars, jacks, and also handtools. Aligns

holes in member with corresponding holes in previously

placed member by driving drift pins or handle of wrench

through holes. Verifies vertical as well as horizontal

alignment of members, using plumb bob level; Bolts

aligned members to keep them in position until they can

be permanently bolted, or welded in place. Cuts welds

steel members to make alterations, using oxyacetylene

welding equipment. Structural-Steel-Equipment Erector.

Erect wind turbines, refinery modules, retrofits, new

construction of transmission line towers

Education

Education Level Technical Degree / Diploma

Institution CWB Group

Program Welding Quality Inspector Level 1

Major Welding

Minor Quality Inspection

Start Date May 2013

Graduation Date Jun 2014

Certifications

Certification Cardiopulmonary Resuscitation (CPR)

Issuing Organization Red Cross

Issue Date Nov 1996

Certification Apply First Aid (Senior First Aid or Level II First Aid)

Issuing Organization Red Cross

Issue Date Nov 1996

Certification Water Rescue Level 1

Issuing Organization CSA

Issue Date Jul 1997

Certification Level 2 Water Rescue

Issuing Organization CSA

Issue Date Jun 1998

Certification Confined Space Worker

Issuing Organization Inward Safety

Issue Date Jul 2007

Certification Confined Space Supervisor

Issuing Organization Inward Safety

Issue Date Jul 2007

Certification WHMIS

Issuing Organization Ironworkers Union

Issue Date Apr 2012

Certification ZoomBoom (Telehandler)

Issuing Organization Ironworkers Union

Issue Date Apr 2012

Certification Construction Safety Training Systems

Issuing Organization Alberta Construction Safety Association

Issue Date May 2012

Certification Rights and Responsibilities

Issuing Organization Construction Opportunities Development Council Inc

Issue Date May 2012

Certification Safety, Risk and Error

Issuing Organization Safe Start

Issue Date Apr 2013

Certification Defensive Driving

Issuing Organization SafeStart

Issue Date Apr 2013

Certification Critical Error Reduction

Issuing Organization SafeStart

Issue Date Apr 2013

Certification Ground Disturbance Level 2 Supervisor

Issuing Organization Ecompliance

Issue Date May 2013

Certification H2S Alive Course

Issuing Organization Enform

Issue Date Mar 2014

Certification OSSA Fall Protection

Issuing Organization OSSA

Issue Date Mar 2014

Certification W47.1 Manual Welding Certificate CWB

Flat,Horizontal,Vertical,Overhead

Issuing Organization CWB Group

Issue Date May 2014

Certification CWB Certified Welding Inspector Level 1 B31.3, W178.2

Issuing Organization CWB Group

Issue Date Jun 2014

References

James (Jamie) Butler OE955 Member

780.722.4855

Rick Brunaccioni Weld-Tech

905.664.5088 Manager

Peter Clark Project Manager for Safeway (Carpenters Union)

905.928.9034

Portfolio of some work available upon request

You might also like

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Diamond Chemical Vapor Deposition: Nucleation and Early Growth StagesFrom EverandDiamond Chemical Vapor Deposition: Nucleation and Early Growth StagesNo ratings yet

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationFrom EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Car Maintainer, Group B: Passbooks Study GuideFrom EverandCar Maintainer, Group B: Passbooks Study GuideNo ratings yet

- Metal-Catalyzed Oxidations of Organic Compounds: Mechanistic Principles and Synthetic Methodology Including Biochemical ProcessesFrom EverandMetal-Catalyzed Oxidations of Organic Compounds: Mechanistic Principles and Synthetic Methodology Including Biochemical ProcessesNo ratings yet

- Electrolysis Process Removes Formate Salts from Pentaerythritol SolutionDocument6 pagesElectrolysis Process Removes Formate Salts from Pentaerythritol SolutionRuchita Poilkar100% (1)

- Hot vs Cold Zinc Phosphating BenefitsDocument2 pagesHot vs Cold Zinc Phosphating BenefitsNaveen Kanchi100% (1)

- Structure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsFrom EverandStructure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsNo ratings yet

- Result Page: Description of EP2309028 Print Copy Contact Us CloseDocument26 pagesResult Page: Description of EP2309028 Print Copy Contact Us CloseKaveri JainNo ratings yet

- Extrusion of PlasticsDocument49 pagesExtrusion of PlasticsDenys MoralesNo ratings yet

- Evaluation of Commercially Available Flame Retardants for Production of Carbon FabricFrom EverandEvaluation of Commercially Available Flame Retardants for Production of Carbon FabricNo ratings yet

- SolidWorks 2017 Black Book: SolidWorks Black BookFrom EverandSolidWorks 2017 Black Book: SolidWorks Black BookRating: 3.5 out of 5 stars3.5/5 (3)

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaFrom EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneFrom EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneNo ratings yet

- Advances in Research on the Strength and Fracture of Materials: An OverviewFrom EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD M R TaplinNo ratings yet

- Current Topics in Amorphous Materials: Physics & TechnologyFrom EverandCurrent Topics in Amorphous Materials: Physics & TechnologyY. SakuraiRating: 5 out of 5 stars5/5 (1)

- Preparation and Characterization of MaterialsFrom EverandPreparation and Characterization of MaterialsJ HonigNo ratings yet

- Analysis of Organoaluminium and Organozinc Compounds: International Series of Monographs in Analytical ChemistryFrom EverandAnalysis of Organoaluminium and Organozinc Compounds: International Series of Monographs in Analytical ChemistryNo ratings yet

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsFrom EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- TungstenDocument49 pagesTungstenahmed samyNo ratings yet

- Strength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985From EverandStrength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985H. J. McQueenNo ratings yet

- Plastic Deformation of Materials: Treatise on Materials Science and Technology, Vol. 6From EverandPlastic Deformation of Materials: Treatise on Materials Science and Technology, Vol. 6R. J. ArsenaultNo ratings yet

- Permanent Magnet Materials and Current Challenges: Arnold Knowledge BaseDocument18 pagesPermanent Magnet Materials and Current Challenges: Arnold Knowledge BaseRares Valentin100% (1)

- Diamond Like Carbon DLCDocument5 pagesDiamond Like Carbon DLCjbertralNo ratings yet

- M17a3 PDFDocument14 pagesM17a3 PDFErika Lorena Gonzalez PeñaNo ratings yet

- Polymer Blends and CompositesDocument25 pagesPolymer Blends and CompositesHamza ChelaliNo ratings yet

- MT-II LabDocument7 pagesMT-II LabAjay Vikram0% (1)

- Handbook of Ballistic and Engineering Data For Ammunition, Vol 1Document261 pagesHandbook of Ballistic and Engineering Data For Ammunition, Vol 1Vlad VladNo ratings yet

- Navy MIC PrimerDocument29 pagesNavy MIC PrimerDANIEL RONTEYNo ratings yet

- BB003 Parts ListingDocument9 pagesBB003 Parts ListingKeetykatNo ratings yet

- GL Venturi DesignDocument6 pagesGL Venturi DesignRoland GarciaNo ratings yet

- History and Applications of Diamond-Like CarbonDocument7 pagesHistory and Applications of Diamond-Like CarbonRaul RodríguezNo ratings yet

- Active Metal BrazingDocument14 pagesActive Metal BrazingAdam GeorgeNo ratings yet

- Gamma Irradiation PEEKDocument7 pagesGamma Irradiation PEEKanilsamuel0077418No ratings yet

- High Standard-MagazinesDocument3 pagesHigh Standard-MagazinesBob WilliamsNo ratings yet

- Recent Advances in Sand CastingDocument25 pagesRecent Advances in Sand Casting9591007896No ratings yet

- Occupational Health and Safety Act - O. Reg. 632 - 05Document10 pagesOccupational Health and Safety Act - O. Reg. 632 - 05Jay NovaNo ratings yet

- Jay Holland - Inspector-Supervisor-WelderDocument3 pagesJay Holland - Inspector-Supervisor-WelderJay NovaNo ratings yet

- Jason Smith Completes Supervisor Safety CourseDocument1 pageJason Smith Completes Supervisor Safety CourseJay NovaNo ratings yet

- Experienced Welder and Inspector Seeking New OpportunitiesDocument5 pagesExperienced Welder and Inspector Seeking New OpportunitiesJay NovaNo ratings yet

- Site Quality ManualDocument366 pagesSite Quality ManualJay Nova92% (13)

- Site Quality ManualDocument366 pagesSite Quality ManualJay Nova92% (13)

- Rights and ResponsibilitiesDocument1 pageRights and ResponsibilitiesJay NovaNo ratings yet

- Seed FilesDocument1 pageSeed Filesارسلان علیNo ratings yet

- General Education September 2016Document195 pagesGeneral Education September 2016Ronalyn AndaganNo ratings yet

- Excellent Hex Key Wrench: English VersionDocument54 pagesExcellent Hex Key Wrench: English Versionmg pyaeNo ratings yet

- ) (Significant Digits Are Bounded To 1 Due To 500m. However I Will Use 2SD To Make More Sense of The Answers)Document4 pages) (Significant Digits Are Bounded To 1 Due To 500m. However I Will Use 2SD To Make More Sense of The Answers)JeevikaGoyalNo ratings yet

- Nimt Institute of Method & Law, Greater Noida: "Legal Bases and Issues in Scrapping Article 370"Document12 pagesNimt Institute of Method & Law, Greater Noida: "Legal Bases and Issues in Scrapping Article 370"Preetish Sahu100% (1)

- Rapidcure: Corrosion Management Products Rapidcure UwDocument1 pageRapidcure: Corrosion Management Products Rapidcure UwHeramb TrifaleyNo ratings yet

- Nursing Grand Rounds Reviewer PDFDocument17 pagesNursing Grand Rounds Reviewer PDFAlyssa Jade GolezNo ratings yet

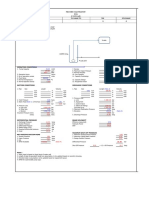

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- Indian Pharmaceutical Industry: The Changing Dynamics: April 2016Document26 pagesIndian Pharmaceutical Industry: The Changing Dynamics: April 2016payal joshiNo ratings yet

- SRX835 Spec Sheet - 11 - 11 - 19Document4 pagesSRX835 Spec Sheet - 11 - 11 - 19Eric PageNo ratings yet

- Unit 4:: Incident Commander and Command Staff FunctionsDocument16 pagesUnit 4:: Incident Commander and Command Staff FunctionsAntonio Intia IVNo ratings yet

- Zodiac Working Boat MK6HDDocument4 pagesZodiac Working Boat MK6HDdan antonNo ratings yet

- Company Law PPT on Types of CompaniesDocument8 pagesCompany Law PPT on Types of CompaniesAbid CoolNo ratings yet

- Theory of Planned Behaviour (TPB)Document18 pagesTheory of Planned Behaviour (TPB)Afiq Wahyu AjiNo ratings yet

- High-Energy Fuels For Cruise MissilesDocument4 pagesHigh-Energy Fuels For Cruise Missilesgrindormh53No ratings yet

- Problem Solving 5Document4 pagesProblem Solving 5Raphael Pizarro ArceoNo ratings yet

- Water Supply NED ArticleDocument22 pagesWater Supply NED Articlejulie1805No ratings yet

- Apollo Experience Report Lunar Module Landing Gear SubsystemDocument60 pagesApollo Experience Report Lunar Module Landing Gear SubsystemBob Andrepont100% (3)

- UmehDocument2 pagesUmehAdeleke AyobamiNo ratings yet

- Stenhoj ST40 ST50 ST60 Wiring Diagram T53065 ST40 60 230 400V 50HzDocument21 pagesStenhoj ST40 ST50 ST60 Wiring Diagram T53065 ST40 60 230 400V 50HzLucyan IonescuNo ratings yet

- Design Thinking ReflectionDocument3 pagesDesign Thinking ReflectionNeil PerlasNo ratings yet

- As 2669-1983 Sulphuric Acid For Use in Lead-Acid BatteriesDocument7 pagesAs 2669-1983 Sulphuric Acid For Use in Lead-Acid BatteriesSAI Global - APACNo ratings yet

- Numerical Investigation of The Effect of Nappe Non Aeration On Caisson Sliding Force During Tsunami Breakwater Over Topping Using OpenFOAM Akshay PatilDocument73 pagesNumerical Investigation of The Effect of Nappe Non Aeration On Caisson Sliding Force During Tsunami Breakwater Over Topping Using OpenFOAM Akshay PatilSamir BelghoulaNo ratings yet

- EJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPEDocument4 pagesEJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPESARAVANAN ARUMUGAMNo ratings yet

- Process Costing-FifoDocument8 pagesProcess Costing-FifoMang OlehNo ratings yet

- Assignment 2Document21 pagesAssignment 2api-445531772No ratings yet

- DMC Bored Cast in Situ Pile ConcretingDocument38 pagesDMC Bored Cast in Situ Pile Concretingmaansi jakkidi100% (1)

- Port Er's Nat Iona L Dia Mon D Co Mpe Titiv Ea Dva Ntag Eof Natio NS'Document45 pagesPort Er's Nat Iona L Dia Mon D Co Mpe Titiv Ea Dva Ntag Eof Natio NS'Soha KhanNo ratings yet

- NOC Hardware Management SO.P. Derricks FormattedDocument3 pagesNOC Hardware Management SO.P. Derricks Formattedapi-27532183No ratings yet

- PSC Vacancy Government SpokespersonDocument3 pagesPSC Vacancy Government SpokespersonMoreen WachukaNo ratings yet