Professional Documents

Culture Documents

Inbuilt Hydraulic Jack System for Automobiles

Uploaded by

xperiaz12Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inbuilt Hydraulic Jack System for Automobiles

Uploaded by

xperiaz12Copyright:

Available Formats

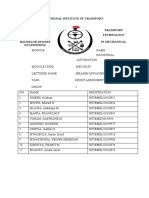

Inbuilt Hydraulic J ack in Automobile Vehicles

Mohammed Abuzaid

Department of Mechanical Engineering

Satyam Education and Social Welfare Sociaty Group of Institutions, Bhopal, MP, India

Mohammad Hasnain

Department of Mechanical Engineering

Satyam Education and Social Welfare Sociaty Group of Institutions, Bhopal, MP, India

Shabaj Alam

Department of Mechanical Engineering

Satyam Education and Social Welfare Sociaty Group of Institutions, Bhopal, MP, India

Sohail khan

Department of Mechanical Engineering

Satyam Education and Social Welfare Sociaty Group of Institutions, Bhopal, MP, India

Prof. Surendra Agarwal

Department of Mechanical Engineering

Satyam Education and Social Welfare Sociaty Group of Institutions, Bhopal, MP, India

Abstract- An inbuilt hydraulic jack system is attached to automobile vehicle on front and rear par of the chassis. An

automobile hydraulic jack system can be easily attached to all currently manufacture automobile chassis and frames.

There is a front suspension hydraulic jack that is mounted centrally to the front suspension of an automobile between its

front wheels. There is also a rear suspension hydraulic jack that is mounted centrally to the rear suspension of the

automobile between its rear wheels. The system operates from a compressed fluid reservoir tank that has connections for

the front and rear car jack outlets. Additional outlets can be added to the compressed fluid reservoir tank for connecting

a hydraulic lug wrench and another for a tire inflating hose.

The Major Project entitled Inbuilt hydraulic jack in automobile vehicle Worked on the principal of hydraulic power

and operated by 12 Volt DC current, solves the all major problem of maintenance of all automobiles specially the heavy

vehicles like truck and bus.

This work, if implemented, would definitely help in the maintenance of automobiles and also in saving of time.

I. INTRODUCTION

Hydraulic jacks work on the basis of Pascal's Principle, named for Blaise Pascal, who lived in the seventeenth

century. Basically, the principle states that the pressure in a closed container is the same at all points. Pressure is

described mathematically by a Force divided by Area. Therefore if you have two cylinders connected together, a

small one and a large one, and apply a small Force to the small cylinder, this would result in a given pressure. By

Pascal's Principle, this pressure would be the same in the larger cylinder, but since the larger cylinder has more area,

the force emitted by the second cylinder would be greater. This is represented by rearranging the pressure formula P

=F/A, to F =PA. The pressure stayed the same in the second cylinder, but Area was increased, resulting in a larger

Force. The greater the differences in the areas of the cylinders, the greater the potential force output of the big

cylinder. A hydraulic jack is simply two cylinders connected. An enclosed fluid under pressure exerts that pressure

throughout its volume and against any surface containing it. That's called 'Pascal's Principle', and allows a hydraulic

lift to generate large amounts of FORCE from the application of a small FORCE. For lifting cars in car service

station hydraulic jacks are used. High pressure liquid is filled in the jack cylinder by hydraulic pump, due to the

pressure the piston moves up. To lower the piston valve is provided by which the liquid returns to the hydraulic

tank. Hydraulic J acks are portable devices used for raising heavy objects by means of force applied with a lever or

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 76 SSN: 2319 1058

screw. The hydraulic jacks are compact and lightweight units that are used for lifting capacities. They offer easy

operation and are fast acting components. The hydraulic jacks come with inbuilt release pedal for rapid lowering and

lugs that make it easy to mount. The heavy duty chassis prevents the jack from twisting or bending and foot pump

provides fast lift to the load. It also has a safety overload valve that prevents overloading beyond rated capacity.

Unlike the traditional screw type jack which has to be turned with a long handle, the hydraulic jack uses oil pressure

to displace (lift) the vehicle by mere moving a lever or handle up and down. This is very easy to operate and with

this even a child can operate and lift a vehicle using the hydraulic jack.

\

II. HYDRAULIC J ACK

2.1 HYDRAULIC FLUID

Hydraulic fluids are a large group of fluids used as the motive medium in hydraulic machinery. Fluid types include

synthetic compounds, mineral oil, water, and water-based mixtures. The fluids are found in machinery and

equipment ranging from brakes, power steering systems, and transmissions to backhoes, excavators, garbage trucks

and industrial shredders. Hydraulic systems are very common in aircraft flight control systems.

Hydraulic fluids can contain a wide range of chemical compounds, including: oils, butanol, esters (e.g.

phthalates, like DEHP, and adipates, like bis (2-ethylhexyl) adipate), polyalkylene glycols (PAG), phosphate esters

(e.g. tributylphosphate), silicones, alkylated aromatic hydrocarbons, polyalphaolefins (PAO) (e.g. polyisobutenes),

corrosion inhibitors, etc.

2.2 HYDRAULIC CYLINDER

A Hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a linear force

through a linear stroke. It has many applications, notably in engineering vehicles.

2.3 OPERATION

Hydraulic cylinders get their power from pressurized hydraulic fluid, which is typically oil. The cylinder consists of

a cylinder barrel, in which a piston connected to a piston rod is moving. The barrel is closed by the cylinder bottom

and by the cylinder head where the piston rod comes out of the cylinder. The piston has sliding rings and seals. The

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 77 SSN: 2319 1058

piston divides the inside of the cylinder in two chambers, the bottom chamber and the piston rod side chamber. The

hydraulic pressure acts on the piston to do linear work.

A hydraulic cylinder is the actuator or "motor" side of this system. The "generator" side of the hydraulic system is

the hydraulic pump that brings a fixed or regulated flow of oil into the system. Mounting brackets or clevises are

mounted to the cylinder bottom as well as the piston rod.

By pumping hydraulic oil to the bottom side of the hydraulic cylinder, the piston rod starts moving upward. The

piston pushes the oil in the other chamber back to the reservoir. If we assume that the oil pressure in the piston rod

chamber is zero, the force on the piston rod equals the pressure in the cylinder times the piston area. If the oil is

pumped into the piston rod side chamber and the oil from the piston area flows back to the reservoir without

pressure, the pressure in the piston rod area chamber is Pull Force/(piston area - piston rod area). In this way the

hydraulic cylinder can both push and pull.

Parts of a hydraulic cylinder

(1). A hydraulic cylinder consists of the following parts:

(2). Cylinder barrel

(3). Cylinder bottom

(4). Cylinder head

(5). Piston

(6). Cylinder bottom connection

(7). Piston rod connection

(8). Feet for mounting of the barrel

A hydraulic cylinder should be used for pushing and pulling and no bending moments should be transmitted to the

cylinder. For this reason, the ideal connection of a hydraulic cylinder is a single clevis with a ball bearing.

2.4 ADVANTAGES OF HYDRAULIC

fluid does not absorb any of the supplied energy.

It is capable of moving much higher loads and providing much higher forces due to the

incompressibility.

The hydraulic working fluid is basically incompressible, leading to a minimum of spring action. When

hydraulic fluid flow is stopped, the slightest motion of the load releases the pressure on the load; there is no

need to "bleed off" pressurized air to release the pressure on the load.

2.5 DESIGNING OF INBUILT HYDRAULIC JACK IN AUTOMOBILE

The research project is carried out for Maruti-Alto car, where two hydraulic jacks are fixed on the front and rear

portion of chassis. Figure 4.1 shows the model of project in details. J acks work on the principle of hydraulic power

and operated by a battery.

2.6 SPECIFICATION OF COMPONENTS USED

Battery:

Voltage: 12V

Type: D.C. Generator

Jacks:

No.: Two hydraulic jacks

Capacity: Depends on the vehicle type (for Maruti-Alto, 500 Kg each)

Type: Hydraulic

Principle of operation: Hydraulic Power

Paddle:

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 78 SSN: 2319 1058

No.: Two

Shape Rectangular (may be circular also)

Size: Depend on vehicle type (for Maruti-Alto, 30cm X 30cm)

Weight

Depend on vehicle type (for Maruti-Alto, 15 Kg)

Cost: 15,000/- for Maruti-Alto

2.7 DESIGN OF HYDRAULIC JACK

This work describes a procedure for determining the mechanical advantage and efficiency of a small hydraulic jack.

The testing procedure and required calculations demonstrate how the efficiency of a simple machine can be

determined, and how multiple mechanical advantages in a simple machine have a multiplying effect, rather than an

adding effect. The cost to set up the experiment is relatively low, yet very informative for the students.

Hydraulic jacks provide a means of lifting loads that otherwise could not be lifted by conventional mechanical

(screw and scissors) jacks. A common hydraulic jack with a lever arm and pump has two Mechanical Advantages

(MA) built into it. One MA is due to the lever arm and the other is due to the ratio of the ram piston diameter

squared (D2) to the pump piston diameter squared (d2), D2 / d2. The two MAs combine in a manner that results in

a multiplying effect rather than an adding effect, which yields a much larger overall MA. The efficiency of a jack

can be determined from the basic definition of efficiency, which is output / input.

A hydraulic jack has a relatively large overall MA due to the lever arm and the ratio of the ram piston diameter

squared to the pump piston diameter squared.

The MA due to the lever arm can be demonstrated and determined by analyzing the simple lever arm shown in

Figure 4.1.

Point A is the lever arm pivot point, Point B is where the lever arm applies an output force (FOLA =force out, lever

arm) to the jacks pump and Point C is where the input force (FILA =force in, lever arm) to the system is applied,

usually by hand.

2.8 HYDRAULIC JACK LEVER ARM

Summing moments about Point A yields;

M

A

=0 =(FO

LA

* l

1

) (FI

LA

* l

2

)

or

(FO

LA

* l

1

) =(FI

LA

* l

2

)

or

FO

LA

/ FI

LA

=l

2

/ l

1

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 79 SSN: 2319 1058

The mechanical advantage due to the lever arm is either of the above ratios, or

MA lever arm =FOLA / FILA =l2 / l1. Eqn. (1)

It is usually difficult to determine FOLA, but easy to measure l1 and l2, and therefore possible to calculate MA lever

arm.

The mechanical advantage due to the ratio of the ram diameter squared to the pump diameter squared can be

developed by analyzing the basic fluid principles of the jack. A simplified hydraulic jack is shown in Figure 4.2.

Point A is where the force into the system is applied (FILA) and Point B is where the force out of the system (FOHS

=force out, hydraulic system) is used to lift a load. In the case of a jack the force out of the lever arm (FOLA) is

equal to the force into the hydraulic system (FIHS) at the pump.

The definition of fluid pressure is a force per unit area, or in equation form,

P =F / A EQN. (2)

Where

P =pressure (N/m2),

F =force (N), and

A =area (m2)

Simple hydraulic jack system

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 80 SSN: 2319 1058

The pressure throughout the hydraulic fluid is assumed to be constant, and for Figure 2 the following applies,

P =FOHS / AD =FIHS / Ad

Where

P =the pressure of the hydraulic fluid in the jack (N/m2)

AD =the area of the ram piston (m2) and

Ad =the area of the pump piston (m2)

Rearranging the above yields

FOHS / FIHS =AD / Ad =(p D2/4) / (p d2/4) =D2 / d2

The mechanical advantage of the hydraulic system is any of the above ratios, or

MA hydraulic system =FOHS / FIHS =AD / Ad =D2 / d2 Eqn (3)

Measuring the piston diameters is usually easier than measuring the forces into and out of the hydraulic system.

Total mechanical advantage

Figure 4.3, demonstrates how two MAs, MA1 and MA2, can be manipulated to determine the overall MA total.

One systemwith two mechanical advantages

MA

total

=Out / In =30 / 5 =2 * 3 =6

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 81 SSN: 2319 1058

Figure shows that the total system MA is determined by taking the ratio of the output to the input, or by multiplying

the individual MAs.

For the topic at hand, the total mechanical advantage of the hydraulic jack would be determined by multiplying the

MA of the lever arm by the MA of the hydraulic system,

or

MAtotal =MAlever arm * MAhydraulic system

The efficiency of the hydraulic jack can now be determined from the following,

=(Output / Input) * 100 =(Output Force / (Input Force * MAtotal)) * 100

=(FOHS / (FILA * MAtotal)) * 100 Eqn. (4)

Where

=the jack efficiency (%)

The testing apparatus can be constructed out of readily available materials. A testing apparatus that could be used is

shown in Figure 4.4.

Testing apparatus example

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 82 SSN: 2319 1058

2.9 PROCEDURE FOR TESTING

Weigh the weight hanger.

Weigh the assorted small weights.

Determine the mechanical advantage due to the lever arm on the jack by measuring the lengths l1 and l2,

and calculating the ratio l2 / l1.

Determine the mechanical advantage due to the ratio of the piston diameters squared by measuring the

pump piston and ram diameters, and calculating the ratio D2 / d2. The instructor may choose to

disassemble the jack and measure the diameters before the experiment actually takes place to save time.

Determine the total mechanical advantage of the jack by multiplying the individual MAs together.

Place the jack in the testing apparatus.

Place the weight hanger on the end of the hydraulic jacks lever arm.

Add weights to the weight hanger until the jack just starts to lift the beam. Record the amount of weight on

the weight hanger and the load cell force.

Add large weight(s) to the beam.

Adjust the position of the lever arm so that it remains horizontal as the hanger weights are applied to

simplify the calculations.

Repeat steps 8-10 eight to ten times throughout the load range of the jack.

2.10 PRINCIPLE OF OPERATION

Both hydraulic jacks are pivoted on the rectangular struts. The one end of jack is fixed to frame. The rectangular

struts are kept hollow for reducing the weight. The rectangular paddles are also pivoted on the other end of struts.

Hydraulic jacks are operated by 12 volt DC battery. At a single time, one and two both jacks can work and vehicle

can lift from one side and also from two sides as per the requirement.

2.11 APPLICATIONS

The inbuilt hydraulic jacks system can be incorporate in any type of motor vehicle such as:

In small cars

In heavy loading vehicle like trucks and buses

In heavy vehicles like crane and harvester

2.12 ADVANTAGES

The maintenance of vehicle will be very easy.

The servicing of vehicle will be easy and cheap.

This type of system is very useful for ladies since during the problem of puncher of tyres, they can easily

change the wheel.

Time saving of maintenance.

This is also very useful for heavy vehicles such as trucks and buses, since there is a common problem of

breaking leaf spring plates, this system will help in changing of leaf spring plates.

A single person can go on a long drive.

Since whole system is operated by battery, jacks will also work when vehicle will not in starting condition.

Both jacks can work at a single time also.

Vehicle can easily wash at home also.

2.13 DISADVANTAGES

Cost will increase slightly.

Weight of vehicle will increase slightly.

System can not work without 12 volt DC current.

System required maintenance also

2.14 FUTURE SCOPE

The arrangement of inbuilt hydraulic jack system is designed for small car in this project work, but this

arrangement can be widely use in future for heavy vehicles also by making some small modifications in current

project.

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 83 SSN: 2319 1058

III. CONCLUSION

An inbuilt hydraulic jack system can be easily attached to all currently manufacture automobile chassis and frames.

There is a front suspension hydraulic jack that is mounted centrally to the front suspension of an automobile

between its front wheels. There is also a rear suspension hydraulic jack that is mounted centrally to the rear

suspension of the automobile between its rear wheels. The system operates on the hydraulic power. This

arrangement has many advantages such as maintenance and servicing of vehicle. With the help of this system the

driving of vehicles will be easy especially for ladies. Arrangement is also very useful for heavy loading vehicles and

a single person can go on a long drive. Whole system is operated by 12 volt DC battery; hence jacks will also work,

when vehicle will not in starting condition. Both jacks can work simultaneously at a single time also.

REFERENCES

[1] www.howstuffworks.com.

[2] www.google.com.

[3] www.bharatwirerope.com.

[4] www.wikipedia.com.

[5] www.techsourcer.com.

[6] www.engineering.com.

[7] www.globalspec.com.

[8] A Textbook of Machine Design by R.S.Khurmi & J .K.Gupta.

[9] A Textbook of Automobile Engineering by Dr. Kirpal Singh.

nternational Journal of nnovations in Engineering and Technology (JET)

Vol. 2 ssue 2 April 2013 84 SSN: 2319 1058

You might also like

- Inbuilt Hydraulic Jack in Automobile Vehicles: Mohammed AbuzaidDocument9 pagesInbuilt Hydraulic Jack in Automobile Vehicles: Mohammed Abuzaidbhagwan kendreNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Inbuilt Hydraulic Jack in Automobile VehiclesDocument14 pagesInbuilt Hydraulic Jack in Automobile VehiclesrajaNo ratings yet

- Automatic Hydraulic Car Jack DesignDocument44 pagesAutomatic Hydraulic Car Jack Designinfo svmelectromechNo ratings yet

- Automated Hydraulic Jack With Air SystemDocument35 pagesAutomated Hydraulic Jack With Air SystemAsghar KhalilNo ratings yet

- Compact Button Operated Hydraulic JackDocument9 pagesCompact Button Operated Hydraulic JackxyzNo ratings yet

- Jojo 1 PDFDocument6 pagesJojo 1 PDFandoma bahtaNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Hydraulic Rod Bending MachineDocument14 pagesHydraulic Rod Bending Machinek.santhosh kumar50% (2)

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Hydraulic Jack Chap 1Document14 pagesHydraulic Jack Chap 1Ab AnNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Designing a Hydraulic Car JackDocument17 pagesDesigning a Hydraulic Car Jacksamuel fekadeNo ratings yet

- Pounder's Marine Diesel Engines and Gas TurbinesFrom EverandPounder's Marine Diesel Engines and Gas TurbinesRating: 4 out of 5 stars4/5 (15)

- Fabrication of Hydraulic Fork LiftDocument41 pagesFabrication of Hydraulic Fork LiftElakkiya Karthic50% (2)

- Modificationofan Existing Small Hydraulic Jackfor Lifting Light DutyDocument7 pagesModificationofan Existing Small Hydraulic Jackfor Lifting Light DutyAbhishek GadhwalNo ratings yet

- Automated inbuilt hydraulic jack improves vehicle maintenanceDocument5 pagesAutomated inbuilt hydraulic jack improves vehicle maintenancePaul deshmukhNo ratings yet

- 13. 74-78Document5 pages13. 74-78Alok Kumar YadavNo ratings yet

- Irjet V5i2303 PDFDocument5 pagesIrjet V5i2303 PDFAnonymous ytZsBOVNo ratings yet

- Hmcproject 180124134619Document27 pagesHmcproject 180124134619johnnie okoromaNo ratings yet

- Hydraulic Jack Design and Analysis ReportDocument48 pagesHydraulic Jack Design and Analysis ReportParmesh94% (16)

- Literature Review Hydraulic JackDocument6 pagesLiterature Review Hydraulic Jackdrnpguwgf100% (1)

- Project Hydraulic JacDocument26 pagesProject Hydraulic JacPrince RajNo ratings yet

- Hydraulic Jack or Hydraulic PressDocument8 pagesHydraulic Jack or Hydraulic PressAnand HaseNo ratings yet

- Fabrication of Hydraulic Pipie Bending MachineDocument50 pagesFabrication of Hydraulic Pipie Bending MachineElakkiya Karthic100% (4)

- RayDocument17 pagesRayrayiz shameerNo ratings yet

- MEC69 - Design & Fabrication of Mini Hydraulic Jack ReportDocument42 pagesMEC69 - Design & Fabrication of Mini Hydraulic Jack ReportraviakashmurtyNo ratings yet

- Irjet V8i5403Document5 pagesIrjet V8i5403Mohammed AlfazNo ratings yet

- Hydraulic LiftDocument6 pagesHydraulic LiftRkNo ratings yet

- Hydraulic Jack Research PaperDocument6 pagesHydraulic Jack Research Papervstxevplg100% (1)

- hydraulic jackDocument16 pageshydraulic jackajinkyawj01No ratings yet

- FinalcopytddDocument6 pagesFinalcopytddapi-302628110No ratings yet

- Name: A Rghya de Roll No.: Stream: Subject: Subject Code: 1690071 5020 Mechanical Engineering Design of Mechanical System ME 881Document65 pagesName: A Rghya de Roll No.: Stream: Subject: Subject Code: 1690071 5020 Mechanical Engineering Design of Mechanical System ME 881Yummy BeatsNo ratings yet

- Seminar ReportDocument14 pagesSeminar ReportArjun LalitNo ratings yet

- Pipe Clamp Pressing MC 2013Document49 pagesPipe Clamp Pressing MC 2013Chockalingam AthilingamNo ratings yet

- Full Report PDFDocument30 pagesFull Report PDFDarshiKrishnaNo ratings yet

- Hydraulic JackDocument29 pagesHydraulic JackTanvi0% (1)

- Industrial Applications of Hydraulic SystemsDocument18 pagesIndustrial Applications of Hydraulic SystemsAkshajNo ratings yet

- National Institute of TransportDocument12 pagesNational Institute of TransportROYALNEWSSNo ratings yet

- Hydraulic SystemsDocument63 pagesHydraulic SystemsBhaskar ReddyNo ratings yet

- Mini Project Report On QwertDocument42 pagesMini Project Report On QwertraviakashmurtyNo ratings yet

- Design and Fabrication of Inbuilt Hydraulic Jack For Four WheelersDocument11 pagesDesign and Fabrication of Inbuilt Hydraulic Jack For Four WheelersManuNo ratings yet

- Literature Review of Hydraulic JackDocument5 pagesLiterature Review of Hydraulic Jackafmzfxfaalkjcj100% (1)

- Design of Hydraulic Platform LiftDocument31 pagesDesign of Hydraulic Platform LiftzetseatNo ratings yet

- Defination of Hydraulic JackDocument6 pagesDefination of Hydraulic JackSaravanan ViswakarmaNo ratings yet

- Chapter-1 Introduction To Project PlanningDocument32 pagesChapter-1 Introduction To Project PlanningjosephfelixNo ratings yet

- A Case Study On Implementation of Hydraulic Jack To Heavy Loaded VehiclesDocument8 pagesA Case Study On Implementation of Hydraulic Jack To Heavy Loaded VehiclesmamaNo ratings yet

- Dil - Iii-1Document37 pagesDil - Iii-1Nikhil SreenivasanNo ratings yet

- Design and Fabrication of A Remote ContrDocument14 pagesDesign and Fabrication of A Remote ContrAbdulkarim Odeh MuhammadNo ratings yet

- Hydrulic Power PackDocument3 pagesHydrulic Power PackNaveen RaiNo ratings yet

- Accelerating research globallyDocument15 pagesAccelerating research globallyUğur KoyunNo ratings yet

- Hydraulic System (B 60)Document21 pagesHydraulic System (B 60)Gaurav SinghNo ratings yet

- Hydraulic drive system basicsDocument6 pagesHydraulic drive system basicsyamnul khairNo ratings yet

- Design of Mechanical Hydraulic JackDocument14 pagesDesign of Mechanical Hydraulic JackAbel MelesseNo ratings yet

- Certificate: Maharashtra State Board of Technical Education, Mumbai Government Polytechnic, SolapurDocument10 pagesCertificate: Maharashtra State Board of Technical Education, Mumbai Government Polytechnic, SolapurOm KalkeriNo ratings yet

- PMV Grease Pump: Installation InstructionsDocument12 pagesPMV Grease Pump: Installation InstructionsGopi GopiNo ratings yet

- Testing 320clDocument60 pagesTesting 320clRaul Rodriguez100% (4)

- Bosch Prop VLVDocument157 pagesBosch Prop VLVHdhm TdhNo ratings yet

- 45INDPRDocument104 pages45INDPRpapum2013No ratings yet

- Filter Elements For Installation in Hydac Filter Housings: FeaturesDocument14 pagesFilter Elements For Installation in Hydac Filter Housings: FeaturesMohamed HusseinNo ratings yet

- Cat Forklift Nr16n2 Nr16n2h Nr16n2s Nr16n2c Nr14n2hs Nr14n2hc Nr20n2h Nr20n2x Nr25n2x Service Operation Maintenance ManualDocument29 pagesCat Forklift Nr16n2 Nr16n2h Nr16n2s Nr16n2c Nr14n2hs Nr14n2hc Nr20n2h Nr20n2x Nr25n2x Service Operation Maintenance Manualrodneycox060901aqk100% (125)

- Thuy Luc Drd420Document40 pagesThuy Luc Drd420ANH LÊNo ratings yet

- Motoare Hidraulice-1 Cilindree-Hc3-ItalgroupDocument60 pagesMotoare Hidraulice-1 Cilindree-Hc3-ItalgroupANTON NEAGUNo ratings yet

- 08D BubenzerHydraulic Unit PB-3421285-E4Document20 pages08D BubenzerHydraulic Unit PB-3421285-E4Edward Erney Salas ValenzuelaNo ratings yet

- Dynaset HKR - Data - Sheet - v1.1Document8 pagesDynaset HKR - Data - Sheet - v1.1gulam husseinNo ratings yet

- MT 030 60 F PDFDocument198 pagesMT 030 60 F PDFDiego Ramirez100% (1)

- Hyspin DSP RangeDocument2 pagesHyspin DSP RangeMoutaz IsmailNo ratings yet

- DRF450 Workshop Manual VDRF03 - 02GB PDFDocument128 pagesDRF450 Workshop Manual VDRF03 - 02GB PDFANH LÊ100% (1)

- JD 750c 850c Dozer Operator Sec WatDocument20 pagesJD 750c 850c Dozer Operator Sec Watlakeisha100% (46)

- Relief Valve (Load Sensing Signal) 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument6 pagesRelief Valve (Load Sensing Signal) 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- Aeroquip Fluid Compatibility InfoDocument5 pagesAeroquip Fluid Compatibility Infos2000ratNo ratings yet

- Best Gear PumpDocument72 pagesBest Gear PumpbiabamanbemanNo ratings yet

- Ficha Tecnica Valvula Reguladora de Caudal Z2FS10 Bosch RexrothDocument12 pagesFicha Tecnica Valvula Reguladora de Caudal Z2FS10 Bosch RexrothRonald Aldair arturo Fajardo ramosNo ratings yet

- Re 29106 - 2022-11Document24 pagesRe 29106 - 2022-11Luis Alberto Zapata OjedaNo ratings yet

- D20x22 Series II: Navigator® Horizontal Directional Drill Maintenance ManualDocument78 pagesD20x22 Series II: Navigator® Horizontal Directional Drill Maintenance ManualAbraham JohnsonNo ratings yet

- Intermot - Iam Complete CatalogueDocument111 pagesIntermot - Iam Complete CatalogueChristian StalinNo ratings yet

- HandS Hydraulics Safety AwarenessDocument39 pagesHandS Hydraulics Safety Awarenessvikram_007100% (1)

- Parker Denison Approved Fluids List: CNOOC Energy Technology & Services - Petrochemicals CoDocument4 pagesParker Denison Approved Fluids List: CNOOC Energy Technology & Services - Petrochemicals CoYanu IsmadiNo ratings yet

- Sauer Danfoss 520L0603 - Series 90 HST - TI - REV F PDFDocument68 pagesSauer Danfoss 520L0603 - Series 90 HST - TI - REV F PDFluis sarmientoNo ratings yet

- Labrie Optimizer Maintenance Manual PDFDocument81 pagesLabrie Optimizer Maintenance Manual PDFstainless31620039126100% (1)

- 4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckDocument2 pages4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckGaneshkumar Enkili SundarvasanNo ratings yet

- Cat Forklift Pd10000 Pd11000 Pd12000 Pd8000 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Pd10000 Pd11000 Pd12000 Pd8000 Schematic Service Operation Maintenance Manualmichellemacias080283gfz100% (49)

- 300DMonitorOperationManual v15Document129 pages300DMonitorOperationManual v15SerkanAl100% (2)

- P0713Document6 pagesP0713SenaMecánicaElectrónicaNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansFrom EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerRating: 4 out of 5 stars4/5 (1)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)