Professional Documents

Culture Documents

Sysweld CCT Description

Uploaded by

prakashg2210Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sysweld CCT Description

Uploaded by

prakashg2210Copyright:

Available Formats

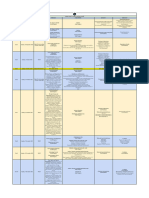

SYSWELD database

heat_treatment_quenching

Material

17CrNiMo6

Additional info from the database

NOM : HT 17CrNiMo6 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 19-02-06

Composition - basic material:

% C 0.17

% Si 0.29

% Mn 0.54

% Ni 1.62

% Cr 1.68

% Mo 0.28

% V 0.01

Phases:

1: Ferrite / Pearlite

2: Upper Bainite (soft)

3: Martensite

4: Lower Bainite (hard)

5: Not used - reserved for tempering

6: Austenite

TS = 1450, TL = 1507, LF = 250000 J/kg

Typical applications:

Case hardening steel

Steel for cold extrusion

About the properties:

Enthalphy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: Individual properties

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

Heating: Individual AC1 and AC3

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test

Properties formatted for wizards usage

Composition

% C 0.17

% Si 0.29

% Mn 0.54

% Ni 1.62

% Cr 1.68

% Mo 0.28

% V 0.01

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

EndPhases

SYSWELD database

heat_treatment_quenching

Material

18CD4

Additional info from the database

NOM : HT 18CD4 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 19-02-06

Composition:

0.15-0.22 % C

0.80-1.20 % Cr

0.60-0.90 % Mn

0.15 % Ni

0.10-0.40 % Si

0.15-0.25 % Mo

<0.035 % S

<0.035 % P

Phases:

1: Ferrite + Pearlite

2: Bainite

3: Martensite

4: Not used - reserved for tempering

5: Not used - reserved for tempering

6: Austenite

Typical applications:

Case hardening steel

Heat treatable steel

About the properties:

Enthalphy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: Individual properties

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

Heating: Individual AC1 and AC3

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test

Properties formatted for wizards usage

Composition

% C 0.18

% Si 0.25

% Mn 0.75

% Ni 0.15

% Cr 1.00

% Mo 0.20

% V 0.00

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

SYSWELD database

heat_treatment_quenching

Material

18CrNiMo7-6

Additional info from the database

NOM : HT 18CrNiMo7-6 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 19-02-06

Composition - basic material:

0.17-0.18 % C

0.50-0.58 % Mn

0.26-0.32 % Si

1.55-1.68 % Ni

1.63-1.71 % Cr

0.26-0.29 % Mo

0.005-0.009 % V

Phases:

1: Ferrite / Pearlite

2: Upper Bainite (soft)

3: Martensite

4: Not used - reserved for tempering

5: Not used - reserved for tempering

6: Austenite

TS = 1450, TL = 1507, LF = 250000 J/kg

Typical applications:

Case hardening steel

Steel for cold extrusion

About the properties:

Enthalphy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: Individual properties

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

Heating: Individual AC1 and AC3

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test

Properties formatted for wizards usage

Composition

% C 0.18

% Si 0.29

% Mn 0.54

% Ni 1.62

% Cr 1.68

% Mo 0.28

% V 0.01

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

EndPhases

SYSWELD database

heat_treatment_quenching

Material

100Cr6

Additional info from the database

NOM : HT 100Cr6 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 19-02-06

Composition:

% C 1.04

% Si 0.26

% Mn 0.33

% Ni 0.31

% Cr 1.53

% Mo 0.01

% V 0.01

Phases:

1 : Pearlite (Ferrite)

2 : Bainite

3 : Martensite

4 : Not used - reserved for tempering

5 : Not used - reserved for tempering

6 : Austenite

TS = 1320, TL = 1450, LF = 210000 J/kg

Typical applications:

Ball and roller bearing steel

About the properties:

Enthalphy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: Individual properties

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test

Properties formatted for wizards usage

Composition

% C 1.04

% Si 0.26

% Mn 0.33

% Ni 0.31

% Cr 1.53

% Mo 0.01

% V 0.01

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

EndPhases

Initial hardness

EndInitial hardness

EndProperties formatted for wizards usage

SYSWELD database

heat_treatment_surface

Material

38MnSiVS5

Additional info from the database

NOM : HT 38MnSiVS5 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 19-02-06

Chemical Composition

38MnSiVS5

0.37 % C

0.22 % Cr

1.38 % Mn

0.01 % Ni

0.58 % Si

0.01 % Mo

0.018 % P

0.023 % Al

0.20 % Cu

0.044 % S

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 : Not used, reserved for tempered phases

5 : Not used, reserved for tempered phases

6 : Austenite

About the properties:

Enthalphy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: As 16MnCr5, needs improvement

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

Heating: Individual AC1 and AC3

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test, in case more then a

martensite transformation is expected

Properties formatted for wizards usage

Composition

% C 0.37

% Si 0.58

% Mn 1.38

% Ni 0.01

% Cr 0.22

% Mo 0.01

% V 0.00

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

EndPhases

SYSWELD database

heat_treatment_surface

Material

42CrMo4

Additional info from the database

NOM : HT 42CrMo4 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 19-02-06

Composition:

% C 0.38

% Si 0.23

% Mn 0.64

% Ni 0.08

% Cr 0.99

% Mo 0.16

% V 0.01

Phases:

1 : Ferrite

2 : Pearlite

3 : Bainite

4 : Martensite

5 : Not used, reserved for tempered martensite

6 : Austenite

Typical applications:

Casting steel

Structural steel

About the properties:

Enthalpy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: Individual properties

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

Heating: Individual AC1 and AC3

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test, in case more then a

martensite transformation is expected

Properties formatted for wizards usage

Composition

% C 0.38

% Si 0.23

% Mn 0.64

% Ni 0.08

% Cr 0.99

% Mo 0.16

% V 0.01

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

EndPhases

SYSWELD database

heat_treatment_surface

Material

CF35

Additional info from the database

NOM : HT CF35 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 11-01-07

Composition:

0.35 % Carbone

0.65 % Mn

0.25 % Si

Phases:

1 : Ferrite / Pearlite

2 : Bainite

3 : Martensite

4 : Not used, reserved for tempered bainite

5 : Not used, reserved for tempered martensite

6 : Austenite

Typical applications:

Heat treatable steel

High temperature construction steel

About the properties:

Enthalpy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: Individual properties

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

Heating: Individual AC1 and AC3

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test, in case more then a

martensite transformation is expected

Properties formatted for wizards usage

Composition

% C 0.35

% Si 0.325

% Mn 0.65

% Ni 0.0

% Cr 0.0

% Mo 0.00

% V 0.00

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

EndPhases

SYSWELD database

heat_treatment_surface

Material

CK45

Additional info from the database

NOM : HT CK45 thermometal_enth mm

COMMENTAIRES :

Disclaimer:

Whilst this database has been carefully written and subject to intensive review,

it is the users responsibility to take all necessary steps to ensure that

the assumptions and results from any finite element analysis which is made

as a result of using this data are correct. Neither ESI GROUP nor the authors

can accept any liability for incorrect analysis.

Date: 19-02-06

Composition:

0.45 % Carbone

<0.4 % Cr % Va

0.65 % Mn % Al

<0.4 % Ni % Co

<0.40 % Si % Cu

<0.10 % Mo 0.035 % S

0.035 % P

Phases:

1 : Ferrite

2 : Pearlite

3 : Bainite

4 : Martensite

5 : Not used, reserved for tempered martensite

6 : Austenite

Typical applications:

Heat treatable steel

High temperature construction steel

About the properties:

Enthalpy: Average values of not and low alloyed steels

Unit J/kg

Phase transformation enthalphy included

Melting enthalphy included

Thermal conductivity: Individual properties

Unit W/mm

Austenite: Average values of austenitic steels

Density: Average values of not and low alloyed steels

Unit kg/mm3

Austenite: Average values of austenitic steels

Heating: Individual AC1 and AC3

CCT-diagram: Heat Treatment CCT diagram. It is important to understand that

the CCT diagram needs to be adjusted with a Jominy test, in case more then a

martensite transformation is expected

Properties formatted for wizards usage

Composition

% C 0.45

% Si 0.30

% Mn 0.65

% Ni 0.35

% Cr 0.35

% Mo 0.05

% V 0.00

EndComposition

Phases

1 : Ferrite

2 : Bainite

3 : Martensite

4 :

5 :

6 : Austenite

EndPhases

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Kondo ScatteringDocument8 pagesKondo ScatteringPRIYA MANDALNo ratings yet

- Thermodynamics UnacademyDocument6 pagesThermodynamics UnacademyAdvyth Vaman AkalankamNo ratings yet

- Ayu Anjelia CH - 43219055 - 4B Alih Jenjang - Heat Treament of SteelDocument4 pagesAyu Anjelia CH - 43219055 - 4B Alih Jenjang - Heat Treament of SteelAnanda WulandariNo ratings yet

- StressHead Technical Documentation en 160318Document26 pagesStressHead Technical Documentation en 160318Juan ManuelNo ratings yet

- Seismic Analysis of Multi Storey RC Building With and Without Fluid Viscous DamperDocument7 pagesSeismic Analysis of Multi Storey RC Building With and Without Fluid Viscous DamperEditor IJTSRDNo ratings yet

- Test Planner - Lakshya NEET 3.0 2024Document2 pagesTest Planner - Lakshya NEET 3.0 2024pj9482No ratings yet

- Biochemistry 6th Edition Garrett Test BankDocument29 pagesBiochemistry 6th Edition Garrett Test Banklantautonomyurbeiu100% (43)

- Coir Fibre Used in Reinforced ConcreteDocument6 pagesCoir Fibre Used in Reinforced ConcreteVIVA-TECH IJRINo ratings yet

- Sa 335 PDFDocument12 pagesSa 335 PDFAnilNo ratings yet

- Progress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidDocument14 pagesProgress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidFarahatNo ratings yet

- Insulator Prorox Ma 520 AluDocument1 pageInsulator Prorox Ma 520 AluNadia DaokajaiNo ratings yet

- Passive Energy Dissipation Systems For StructuralDocument12 pagesPassive Energy Dissipation Systems For StructuralMichael Jhoan Rodriguez RomeroNo ratings yet

- Design & Constructio N Errors: Building Maintenance & RepairsDocument43 pagesDesign & Constructio N Errors: Building Maintenance & RepairsarunNo ratings yet

- Anisotropy of Additively Manufactured 18ni 300 Maraging Steel - 2020 - ProcediaDocument11 pagesAnisotropy of Additively Manufactured 18ni 300 Maraging Steel - 2020 - ProcediaajayvgNo ratings yet

- EM Waves Concept MapDocument8 pagesEM Waves Concept MapAaron AsneNo ratings yet

- Wa0005.Document35 pagesWa0005.maryam zafarNo ratings yet

- Sensors SyllabusDocument2 pagesSensors Syllabusdirector.sportssrmistNo ratings yet

- Dental Materials m1Document2 pagesDental Materials m1Rosette GoNo ratings yet

- Factor (E-6-3) - Report Earthing System For Apt FactorDocument4 pagesFactor (E-6-3) - Report Earthing System For Apt FactorOssama Al-sayed HelalNo ratings yet

- Department of Mechanical Engineering Machine Design Objective QuestionDocument211 pagesDepartment of Mechanical Engineering Machine Design Objective QuestionSushant TiwariNo ratings yet

- List of Chemical Engineering EbooksDocument50 pagesList of Chemical Engineering EbooksSyarif HidayatNo ratings yet

- A Review Paper On Photovoltaic TextilesDocument13 pagesA Review Paper On Photovoltaic TextilesShradha Shinde DongreNo ratings yet

- TM4101 IfmDocument2 pagesTM4101 IfmJuvenal Filipe CamposNo ratings yet

- CalculatorDocument7 pagesCalculatorBesan LaduNo ratings yet

- IS 3370 (Part 3) 1967 R 1999Document14 pagesIS 3370 (Part 3) 1967 R 1999Nayag Singh100% (1)

- X-Ray DiffractionDocument30 pagesX-Ray DiffractionMerve Ayvaz KöroğluNo ratings yet

- AluminumDocument4 pagesAluminumMartyn PereiraNo ratings yet

- Shimadzu Shear Test ASTM D5379 ReportDocument4 pagesShimadzu Shear Test ASTM D5379 ReportRian Suari AritonangNo ratings yet

- Fundamentals of Modern Manufacturing 6th Edition Groover Solutions ManualDocument3 pagesFundamentals of Modern Manufacturing 6th Edition Groover Solutions ManualJacobTorresbipkz100% (14)

- Nanotechnology and Product Liability: Rod Freeman - Partner Product Liability Group Lovells LLPDocument38 pagesNanotechnology and Product Liability: Rod Freeman - Partner Product Liability Group Lovells LLPHaritz Atika ANo ratings yet