Professional Documents

Culture Documents

06353243

Uploaded by

Ahmad Diyanal ArifinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06353243

Uploaded by

Ahmad Diyanal ArifinCopyright:

Available Formats

340 IEEE TRANSACTIONS ON SUSTAINABLE ENERGY, VOL. 4, NO.

2, APRIL 2013

Optimization of Subcell Interconnection for

Multijunction Solar Cells Using Switching

Power Converters

Mohammed Khorshed Alam, Student Member, IEEE, Faisal Khan, Member, IEEE, and

Abusaleh M. Imtiaz, Student Member, IEEE

AbstractA multijunction solar cell can extract higher solar en-

ergy compared to a single junction cell by splitting the solar spec-

trum. Although extensive research on solar cell efciency enhance-

ment is in place, limited research materials are available to iden-

tify the optimum interconnection of multijunction solar subcells

using power electronic circuits. Multijunction solar cells could be

grouped into two main categories: vertical multijunction (VMJ)

solar cells and lateral multijunction (LMJ) solar cells. In this paper,

a detailed study to identify the optimum interconnection method

for various multijunction solar cells has been conducted. The au-

thors believe that the conducted research in this area is very lim-

ited, and an effective power electronic circuit could substantially

improve the efciency and utilization of a photovoltaic (PV) power

systemconstructed frommultijunction solar cells. Amultiple input

dc-to-dc boost converter has been used to demonstrate the advan-

tage of the proposed interconnection technique. In order to ensure

maximum power point (MPP) operation, a particle swarm opti-

mization (PSO) algorithm has been applied needing only one MPP

control for multiple solar modules resulting in cost and complexity

reduction. The PSO algorithm has the potential to track the global

maxima of the system even under complex illumination situations.

A complete functional system with the implementation of the pro-

posed algorithm has been presented in this paper with relevant ex-

perimental results.

Index TermsInterconnection, maximum power point tracking

(MPPT), multijunction solar cell.

I. INTRODUCTION

S

INGLE junction solar cells utilize a fraction of the solar

spectrum depending on the band gap of the material used.

On the other hand, multijunction (MJ) solar cells have evolved

to extract energy froma larger energy band of the solar spectrum

[1][23]. Multijunction solar cells could be grouped into two

main categories depending on the spectrum splitting technique

and orientation of the intermediate junctions: vertical multijunc-

tion (VMJ) solar cells and lateral multijunction (LMJ) solar cells

[7], as illustrated in Fig. 1. In VMJ solar cells, beam splitting is

performed by the subcells itself and the efciency can be as high

as 40.7% under concentrated illumination [3]. VMJ solar cells

Manuscript received October 26, 2011; revised August 05, 2012; accepted

September 29, 2012. Date of publication November 16, 2012; date of current

version March 18, 2013.

The authors are with the University of Utah, Salt Lake City, UT

84112 USA (e-mail: khorshed.alam@utah.edu; faisal.khan@utah.edu;

as.imtiaz@utah.edu).

Color versions of one or more of the gures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identier 10.1109/TSTE.2012.2223493

Fig. 1. (a) VMJ solar cell. (b) LMJ solar cell structure.

can be either monolithically grown or mechanically stacked. In

general, VMJ solar cells are more expensive compared to single

junction cells due to the expensive fabrication steps involved in

growing layers of materials with substantial lattice mismatch.

Moreover, strain and interface defects signicantly affect the

fabrication yield and performance of the VMJ solar cells [16].

Monolithically grown VMJ solar cells suffer from current

mismatch, and mechanically stacked VMJ solar cells may over-

come this limitation by inserting nonconductive tunnel junc-

tions between subcells. On the other hand, optical splitter such

as dichroic beam splitting technique is used in LMJ solar cells

in order to split the beam. The subcells in an LMJ solar cell

may be connected externally; therefore, LMJ solar cells and me-

chanically stacked VMJ solar cells provide greater exibility in

terms of interconnection of subcells and material choice issues

and yield higher efciency.

The power output from the solar cells varies with tempera-

ture, illumination, and the electric load connected to the cell.

Therefore, maximum power point tracking (MPPT) is almost

an indispensible part of an efcient solar cell system [24].

Multijunction solar cells are already very expensive, and a

photovoltaic (PV) system designed around multijunction cells

without having an MPPT system is far from an economically

viable solution. It should be noted that the interconnection

technique presented here is applicable for crystalline MJ solar

cells. Therefore, throughout this paper, the term MJ solar cell

will refer to the crystalline MJ solar cell only. A particle swarm

optimization (PSO)-algorithm-based MPPT technique has been

used in this paper where the duty cycles of the dc-to-dc con-

verters are periodically updated with a single MPPT controller

to track the global maximum power point (MPP) of the system.

This paper presents the advancement of the concept de-

scribed in [1] and [2]. In addition, a modied MPPT technique

that signicantly improves the overall system performance

has been implemented. Therefore, this paper is organized in

1949-3029/$31.00 2012 IEEE

ALAM et al.: OPTIMIZATION OF SUBCELL INTERCONNECTION FOR MULTIJUNCTION SOLAR CELLS 341

the following manner: a) present state-of-the-art LMJ solar

cells and VMJ solar cells is presented in Sections II and III,

respectively; b) the proposed interconnection technique for

MJ solar cells is presented in Section IV; c) the detail of the

PSO technique is discussed in Section V; d) the simulation

and experimental results are presented in Sections VI and VII,

respectively; e) a brief comparison with conventional solutions

is shown in Section VIII; f) the effect of partial shading is

discussed in Section IX; and g) the summary of the paper is

presented in Section X.

II. LMJ SOLAR CELL INTERCONNECTION

The design of the subcells in the LMJ solar cell can be in-

dependent [7], [12][15] or interconnected [6]. Two indepen-

dent solar cells with their characteristics under full spec-

tral illumination and with split beam illumination are shown in

Fig. 2. The GaAs solar cell has higher energy band gap than

the silicon solar cell. Therefore, the GaAs solar cell is intended

to absorb the energy from the higher energy photons and Si

solar cell absorbs the lower energy photons. The amount of

power gain achieved using the beam splitting technique is also

shown in Fig. 2. An LMJ solar cell fabrication process using

Zn Cd S Se has been demonstrated in [6], and a spatial

composition grading is achieved across a single wafer (

, ). This resulted in a band gap from 1.7 eV(CdSe)

to 3.6 eV (ZnS).

As the beam splitting is performed by the optical instruments,

the LMJ solar cell is free from lattice and current mismatches.

The theoretical absorption efciency could be 100% with in-

nite band splitting. The efciency could be as high as 69% for

three subcells, and this efciency gure is astonishingly 86%

for ten subcells. Because the efciency does not increase in pro-

portion with the number of subcells, a compromise is made be-

tween the efciency and cost ($/W). However, the lateral split-

ting is more feasible in space applications if combined with solar

ux concentration techniques [14]. Due to the logarithmic rela-

tionship between the increase in efciency and solar concen-

tration, it is possible to achieve reasonable efciency with the

same number of subcells even at low concentration (between

10 and 100 ) [12], and the optical splitter may be integrated

with the static solar concentrator [7]. In addition, the need for

tunnel junction is eliminated as the subcells in the LMJ solar

cell can be connected independently.

Because unique contact metallurgy is required for each ele-

ment, the design-complexity could be greatly reduced by elimi-

nating tunnel junctions. Despite these advantages, the intercon-

nection technique for LMJ solar cell has not been optimized

yet, and this is possibly because of the lack of information ex-

change between the solar cell designers and researchers in the

power electronics community. In [15] and [25], an interconnec-

tion technique has been proposed where subcells constructed

from the same materials are connected in series strings, and

strings of subcells constructed from different materials are con-

nected in parallel to achieve a nearly voltage-matched intercon-

nection. In spite of achieving several advancements, this solu-

tion does not optimize the MPPT operation.

Fig. 2. (a) characteristics and (b) power curve of a GaAs subcell. (c)

characteristics and (d) power curve of a Si subcell. (e) Photograph of the actual

multijunction cell assembly (courtesy of Prof. R. Menon and his research group

at University of Utah).

Through the length of this paper, the interconnection issues

will be explained with greater detail. Although researchers have

342 IEEE TRANSACTIONS ON SUSTAINABLE ENERGY, VOL. 4, NO. 2, APRIL 2013

Fig. 3. VMJ structures (a) monolithically stacked and (b) mechanically

stacked.

already fabricated LMJ cells in the laboratory environment, a

complete optimal solution with an efcient power electronic so-

lution has not been reported yet.

III. VMJ SOLAR CELL INTERCONNECTION

VMJ solar cells can be fabricated in two different ways: either

mechanically stacked or monolithically, as shown in Fig. 3 [19],

[20]. In mechanically stacked VMJ solar cells, multiple subcells

of different materials are manufactured on separate substrates,

and they are stacked vertically resulting in a multiterminal de-

vice. Monolithically grown VMJ solar cells have a series of sub-

cells directly grown on one substrate, and interconnected in se-

ries by electrically conductive tunnel junctions [3][5], [8], [9],

[11].

A monolithically grown VMJ solar cell can be either lattice

matched or metamorphic in design [3], [8], [9]. The metamor-

phic structure provides higher current matching among the dif-

ferent subcells in the VMJ cell structure. However, a better cur-

rent matched structure has been reported in the form of an in-

verted metamorphic structure in [11]. Despite of the above facts,

a complete current matching is unattainable because the subcells

of different materials are connected in series. Moreover, there

are a few combinations of group IIIIV materials that are suit-

able for monolithic VMJ solar cells. It is apparent that the me-

chanically stacked structure provides more exibility in terms

of material selection and interconnection of subcells where MPP

can be achieved for individual subcells. Therefore, this arrange-

ment would be more efcient than the monolithic structure at the

expense of greater system complexity [19], [20]. The complex

fabrication steps involved in mechanically stacked VMJ solar

cells and recent advancement of the key fabrication processes

for monolithically stacked cells have led researchers towards

the monolithic structures. However, the mechanically stacked

VMJ solar cell is still a promising technology and the subcells

can be connected in a similar fashion as in LMJ subcells where

the greatest advantage would be the exclusion of optical splitter

which incorporates a signicant cost for the LMJ structure [7].

Fig. 4. Hybrid MJ structures.

Combining the advantages of both LMJ and VMJ solar cells,

a hybrid structure has been proposed in [12], [17], [22], [23], and

[37]. In these structures, the beam splitting may be performed in

different stages, as shown in Fig. 4. The hybrid structure individ-

ually facilitates the optimization needed for the monolithically

grown VMJ solar cells and the optical elements. The efciency

can be as high as 50% because optical losses and the fabrication

constrains are optimized in this hybrid layout [12]. Moreover,

the interconnection can also be optimized in system level where

the subcells are mechanically stacked as presented in [22].

Although, a substantial effort is in place to improve the ef-

ciency of multijunction solar cells, only a few research ini-

tiatives were taken to identify the most efcient interconnec-

tion of the subcells using suitable power electronic converters.

Multijunction solar cells having independent subcells can be in-

terconnected to accomplish a completely matched interconnec-

tion. In addition, subcells made from similar materials can be

connected in series to form a string to build up the voltage for

suitable power electronic conversion, and identical strings can

be connected in parallel to increase the power output.

In this paper, an MJ solar cell with four different subcells

consisting of GaInP, GaAs, GaInAsP, GaInAs have been con-

sidered, and this paper presents a completely matched intercon-

nection in terms of terminal voltage and string current using a

multiple input dc-to-dc boost converter. Although the design has

been considered for four specic subcells, it is compatible with

any number of subcells, and can be extended for higher num-

bers of subcells without any apparent limitations.

IV. PROPOSED INTERCONNECTION TECHNIQUE

Solar cells in a power generation system are usually inter-

connected to achieve the desired open circuit voltage and

short circuit current compatible with the power converters

used [31]. Typically, solar cells are connected in series (typically

3650 cells) to form a string, and multiple strings are connected

in parallel to form a higher current rating module, as shown in

Fig. 5. The output voltage and current of the module are very

sensitive to solar cell mismatches and partial shading. The main

ALAM et al.: OPTIMIZATION OF SUBCELL INTERCONNECTION FOR MULTIJUNCTION SOLAR CELLS 343

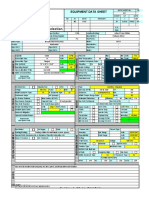

TABLE I

SUBCELL MATERIAL, BAND GAP ENERGY, AND SUMMERY OF THE PROPOSED INTERCONNECTION

Fig. 5. (a) String and module formation; (b) interconnection of modules for

higher power output.

disadvantage of series connection of solar cells is the inability to

operate at optimum point during partial shading, and the perfor-

mance of the module signicantly degrades. As an example, if

3650 solar cells are connected in series as shown in Fig. 5, and

only one cell is partially shaded by 50%, the overall power may

decrease to 50% [38]. However, the insertion of bypass diodes

gives some advantages of protecting the shaded cell from ex-

cessive heating that may cause a permanent damage to the cell.

Usually one bypass diode is connected across every 510 solar

cells in the string [32].

Power generated from the nonshaded cells can pass across

the shaded cells through the bypass diode arrangement [41].

Although this method provides protection to a certain level

and helps to prevent drastic rise in temperature in that string,

it is not completely immune to partial shading, and therefore

suffers from degraded module performance. Several methods

to address this problem have been demonstrated in [32][34].

Although highly paralleled congurations exhibit superior per-

formance in partial shading or uctuating irradiance conditions,

the comparatively low open circuit voltage or MPP

voltage is not suitable for efcient power conversion

for power generation, and their use is typically limited to

portable or low power systems. Therefore, the interconnection

shown in Fig. 5(a) is capable of supplying small amount of

power suitable for standalone operation or charging a battery.

In order to produce higher power from a PV system, the PV

modules are interconnected in a series-parallel combination to

boost the output power, and this concept is similar to intercon-

necting solar cells [31], [32]. There may be number of PV

modules in series in each of number of parallel connections

in a solar panel as shown in Fig. 5. In case of a completely

matched situation, the terminal voltage would be times the

voltage across each module, the current would be times of

each module, and the power would be times each

modules power. However, this theoretical limit is not typically

achieved in practice. There is a diode in series of each string

of the modules to conrm unidirectional power ow, and it

prevents power ow from one string of modules to another.

These diodes introduce conduction loss and degrade the overall

efciency.

In [22], the individual subcell characteristics of an MJ solar

cell system are given. Based on this reference and considering

a 20-cm surface area of each subcell, Table I has been formed.

If all subcells with different band-gap energies are connected in

series, current mismatch will reduce the efciency and will re-

sult in a low short-circuit current of the system ( 0.1616 A). In

addition, connecting all subcells in parallel will cause voltage

mismatch and very low output voltage for power conversion

( 0.336 V). In order to avoid current mismatch and to achieve

higher terminal voltage, the subcells constructed from the same

material can be connected in series to form a string and the

strings with similar characteristics can be connected in

parallel without any mismatch, and therefore a module can be

formed. This interconnection will end up having completely

matched modules. Moreover, a highly parallel conguration is

desired [25] to compensate for the effect of partial shading.

Therefore, similar modules should be connected in series-par-

allel combination as shown in Fig. 5(b) for higher power output.

In order to ensure the MPPT operation of individual modules,

multiple dc-to-dc converters are needed to dynamically main-

tain the operating point of the converters when external condi-

tions (temperature, illumination, and loading) are altered. Fig. 6

shows the proposed conguration with four modules connected

to a four input dc-to-dc boost converter ensuring global maxima

of the system, and the multiple input dc-to-dc converter shown

in this gure can be designed for any number of modules. This

feature is important for an LMJ, mechanically stacked or hybrid

MJ solar cell systems. Moreover, this conguration allows sim-

pler gate drive circuit for the switches.

Similar interconnection systems for connecting conventional

solar panels have been discussed in [26][30], and they are

termed as multistring systems. A high efciency (95%) multi-

string converter using similar multiple input dc-to-dc boost con-

verter topology is commercially available [29], [42]. However,

344 IEEE TRANSACTIONS ON SUSTAINABLE ENERGY, VOL. 4, NO. 2, APRIL 2013

Fig. 6. Proposed interconnection: each module is connected to a separate input of the multiple input dc-to-dc converter.

the interconnection of the subcells of MJ solar cell with suitable

power electronic solution has not been reported yet.

V. THE PSO ALGORITHM

The output characteristics of a PV array depend on several

factors such as temperature, insolation, and the electrical load

connected across the array. Therefore, an MPPT circuit is es-

sential to maximize the power extraction from a PV array, es-

pecially for already expensive MJ solar cells. In conventional

MPP tracking circuits, separate MPP trackers are usually im-

plemented for each dc-to-dc converters. In [24], various MPPT

techniques have been discussed with a comparative study. Most

of the MPPT circuits work with a single converter, and this pro-

posed interconnection will require four MPPT circuits to har-

ness power from four modules of subcells. Eventually, these

multiple MPPT circuits would require four current sensors to

localize the individual MPPs. In order to reduce the cost and

complexity of the system, the global MPP can be achieved by

using only one current sensor at the nal output rather than in-

dividual sensors located at the output of each module. This can

be achieved by using advanced control algorithms. PSO is a

member of swarm intelligence (SI) and appropriate for global

optimization over an -dimensional surface of possible solu-

tions. A PSO approach using only one MPPT instead of two

has been discussed in [36], where the voltage information of

the dc-to-dc converters is continuously updated. Moreover, PSO

has the capability of bypassing the local MPPs and tracking the

global MPP under complex illumination [36]. The PSO algo-

rithm used here can be applied for interconnections among sub-

cells of LMJ solar cells, mechanically stacked VMJ solar cells

and hybrid MJ solar cells.

The PSO algorithm applied in the proposed circuit updates

the duty cycle of four single input dc-to-dc converters (indi-

vidual inputs of a multiple input dc-to-dc converter) connected

to the corresponding modules, and each module consists of sub-

cells with matching characteristics. Although the subcells

in a module are electrically matched, the characteristics of

individual modules could widely vary, and the multiple input

dc-to-dc converter is used to address this variation. The duty ra-

tios ( ) of the single input dc-to-dc converters are varied so that

the global maxima of the system can be tracked. PSO is a com-

putational technique, where global maximum is searched by a

number of agents with a continually updated velocity controlled

by previous search of that agent and social interaction among

the agents. Therefore, every PSO implementation requires ex-

tensive and iterative computations to decide the number of re-

quired agents and the weights to be used to update the velocity

of the agents.

The owchart of the PSO algorithm used in the proposed

system is shown in Fig. 7. Five agents are used to search the

global maxima. The initialization of the agents is shown in

Table II.

Duty cycles of an agent are grouped in a position vector

as follows:

(1)

The subscript indicates the duty cycles of the th agent at

the th iteration and is the duty cycle of the th converter for

agent , and is the total number of agents. Equation (2) has

been used to update the position of the th agents:

(2)

where is the position vector corresponding to the

maximum power achieved by the agent , and is the

position vector corresponding to the maximum power ever

achieved by any agent. are weight constants and

are random values (0 to 1). is the inertia coefcient

of the agent, and and are factors that decide how fast

the agents will move towards the agents maximum point and

ALAM et al.: OPTIMIZATION OF SUBCELL INTERCONNECTION FOR MULTIJUNCTION SOLAR CELLS 345

Fig. 7. PSO algorithm.

TABLE II

INITIAL DUTY CYCLES FOR DIFFERENT AGENTS

the global maximum point. Therefore, assigning values for

constant is crucial for searching global maxima and

convergence of the algorithm. Variation in duty cycle is limited

to 0.2 to 0.8, and the global as well as agents maximum values

are updated once the change in the output power is larger than

the allowed maximum power variation.

VI. SIMULATION RESULTS

Simulation is performed for four solar modules in PSIM with

a functional model of solar cells as demonstrated in Table I. The

MPP voltages and currents are estimated by matching the ll

factor of the corresponding subcells. The MPPT algorithm is

written in inside PSIM using the simplied block, and the

obtained simulation results are shown in Fig. 8. In this simula-

tion, the values of the constants are set as shown in Table III. The

parameters of different components of the power converter were

taken fromthe datasheet of the components used for building the

prototype. From Fig. 8(a), it is apparent that all the agents are

moving towards the peak power and they settle down near the

global maxima. The duty cycle variation of the dc-to-dc con-

verters is also shown in Fig. 8(b).

Fig. 8. Simulation results: (a) variation of output power versus time; (b) vari-

ation of duty ratio of the dcdc converters versus time.

TABLE III

CONSTANTS FOR PSO ALGORITHM

VII. EXPERIMENTAL SETUP

As a proof of concept, four solar modules were built using

commercially available crystalline silicon solar cells to mimic a

four-junction MJ cell system. The experimental setup is shown

in Fig. 9. A 60-V 3-A Schottky diode (MBR360) was placed in

series of each of these four modules to block the reverse current

ow, and synchronous rectication topology was used to min-

imize the power loss across the diode of the boost converters.

IRFI4410ZPbF MOSFETs and MBR360 diodes were used as

switching devices in the proposed circuit, and an IRS2108 boot-

strap gate driver provided the necessary gate signals for the

high and low side MOSFETs in each switching pair. Inductors

and in Fig. 6 were implemented using 390 H induc-

tors, and both and were 780 H in order to ensure con-

tinuous conduction. All the inductors were implemented using

2100LL-391-H-RC.

The algorithm was implemented in dSPACE 1104 system,

and the switching frequency of the converters was set at 5 kHz.

The duty ratio was updated every 0.2 s. The output voltage was

kept constant at 6.5 V using a switch mode power supply, and a

xed resistor of 2.5 was used as the load. In this way, a dc bus

was created with two sources and a load. The output current of

the converter was measured using an LTS 6 current transducer,

and the experimental results are shown in Fig. 10. The mea-

sured voltages and currents of the solar modules are listed in

Table IV, and the maximum power delivered by all four mod-

ules was 14.28 W. It should be noted that the straight line shown

in Fig. 10(a) indicates the summation of the maximum powers

346 IEEE TRANSACTIONS ON SUSTAINABLE ENERGY, VOL. 4, NO. 2, APRIL 2013

Fig. 9. (a) DCDC converters with control circuits; (b) experimental setup.

delivered by four solar modules. The efciency of the MPPT al-

gorithm has not been considered here, and the reason has been

explained in the later part of this section. Moreover, the simula-

tion results shown in Fig. 8 incorporate the MJ solar cell system

summarized in Table I, and the experimental results shown in

Fig. 10 incorporate the proof of concept modules built using

the commercially available crystalline solar cells. These results

have been summarized in Table IV. The measured efciency

of the converter with this loading was 84.6% at

steady-state.

The multiple input dc-to-dc converter shown in Fig. 6 consists

of four single input dc-to-dc boost converters, and the output

terminals of these single input boost converters are connected in

parallel. The efciency of the multiple input dc-to-dc converter

depends on the operating points of the individual single input

dc-to-dc converters. The overall efciency can be written as

(3)

where is the efciency of the multiple input dc-to-dc

converter, and is the efciency of the th single input dc-to-dc

boost converter. and are the input power of the th single

input dc-to-dc converter and summation of the input power of

the individual single input dc-to-dc converters, respectively.

is the output power of the multi-input dc-to-dc converter.

is the number of single input dc-to-dc converters with paral-

leled output.

It is possible to design a dc-to-dc boost converter so that it

operates near its peak efciency at the MPP of the connected

Fig. 10. Experimental results: (a) variation of output power versus time;

(b) variation of duty ratio of the dcdc converters versus time.

TABLE IV

MEASURED VOLTAGE AND CURRENT OF THE SOLAR MODULES

DURING THE EXPERIMENT

solar module. The efciency of the individual single input

dc-to-dc boost converters were measured at different load cur-

rents, although the output voltage was maintained at a steady

6.5-V level. The efciency versus load current of individual

single input dc-to-dc converters are shown in Fig. 11. The con-

duction loss in the series resistance of the inductor and the con-

duction losses of diodes and MOSFETs increase as the load

current increases. Therefore, the efciency of individual single

input dc-to-dc converter decreases with increased load current.

Converters 3 and 4 have two inductors in series resulting in

higher overall conduction loss. Therefore, the efciency of Con-

verters 3 and 4 decreases more rapidly compared to Converters

1 and 2 for the same variation in the load current. From the ob-

served results it is apparent that the overall efciency can be

improved by a better hardware implementation.

The experiment was performed outdoor with continuously

varying illumination. Therefore, it was not possible to measure

the steady-state efciency of the PSOalgorithmwhen it was im-

plemented with real solar cells. However, emulators were used

in a controlled environment to determine the efciency of the

algorithm. Each of the solar modules listed in Table IV was em-

ulated using a bench top power supply in series of a resistor,

ALAM et al.: OPTIMIZATION OF SUBCELL INTERCONNECTION FOR MULTIJUNCTION SOLAR CELLS 347

Fig. 11. Efciency versus load current curve of individual single input dc-to-dc

boost converters.

and the voltage and resistance of each emulator was selected

such that the MPP of this orientation matches the values shown

in Table IV. The efciency of the PSO algorithm thus measured

using emulators was found to be 96.7%. This efciency is highly

dependent on the value of the constants , , and , and this

MPP tracking efciency may vary by a fair amount for the orig-

inal MJ solar cell implementation. Therefore, the MPP tracking

efciency can be maximized by selecting proper values of these

constants.

Due to the unavailability of the commercially available MJ

solar cells, experiments were performed using commercially

available crystalline silicon (single junction) solar cells. There-

fore, the results obtained here may not match the dynamic be-

havior of the true MJ solar cell system. However, the method

presented in this paper explores the feasibility of the architec-

ture proposed in Fig. 6which represents a true MJ PV system.

An effective implementation of this system can be realized

using many commercially available microcontrollers [44]. The

cost of the microcontroller is considered as a xed cost and has

small contribution towards the total system cost. Moreover, a

high efciency (95% peak) multistring power converter with

built-in MPPT is already commercially available by SMA, and

it is named the Sunny Boy Multistring [29], [42] system. The

true implementation of subcell interconnection of different MJ

solar subcells and interfacing with the power converters can be

left as a future research. It is possible to observe the dynamic

performance of the MJ solar cells with the future implementa-

tion as well.

VIII. COMPARISON WITH CONVENTIONAL INTERCONNECTION

TECHNIQUES

In order to make a fare comparison with other possible inter-

connections, the components of the power converter in PSIM

have been simulated as ideal ones. The resulted output voltage

and current ratings by series connecting all the subcells of each

module listed in Table I are shown in Table V. In PSIM, these

four modules are connected in series in order to build a system

where all the subcells are connected in series, and the maximum

power output from the series interconnection of all the subcells

was found to be 11.88 W. In contrast, the power output from the

proposed interconnection using PSIM simulation was found to

be 17.47 W with PSO applied. Therefore, in the proposed in-

terconnection, it yielded 47.05% additional power compared to

the conventional nonoptimized solution. Considering 6 hours of

average insolation, it will result in approximately 681 kWh of

TABLE V

SUMMARY OF SERIES INTERCONNECTION OF ALL SUBCELLS

TABLE VI

SUMMARY OF OPEN CIRCUIT VOLTAGE MATCHED INTERCONNECTION

OF ALL SUBCELLS

energy gain per year for a 1-kW unit. In the second phase, the

subcells constructed from the same material were connected in

such a way that the open circuit voltages of four modules match

the best [15], [25]. The resulted voltage and current ratings of

these modules are shown in Table VI, and these modules were

connected in parallel. The maximumpower output of the system

from PSIM simulation was found to be 15.78 W, and therefore,

the proposed interconnection still provides 10.71% power gain.

This amount of efciency enhancement is really signicant in

solar power systems in critical applications such as in a battle-

eld of scientic expedition. The above comparisons are per-

formed using PSIM simulations considering ideal dc-to-dc con-

verters. In practice, the efciency of the converter will affect the

power gain magnitudes.

IX. EFFECT OF PARTIAL SHADING

The effect of partial shading in an MJ solar cell system

might be different from multistring solar systems constructed

from single junction solar cells. The subcells of a mechani-

cally stacked MJ solar cell or LMJ solar cell share the same

incident solar beam. Therefore, any partial shading will affect

all the subcells of the MJ cell under partial shading. As the

subcells are part of different modules, all the modules will be

affected. This phenomenon is illustrated in Fig. 12. Therefore,

partial shading will have more power degrading impact on the

MJ solar cell system discussed here compared to multistring

system of single-junction solar cells. However, most of the

concentrated PV (CPV) MJ solar cells system comes with a

concentrator system with homogenizer. The homogenizer is

used to improve ux uniformity, and it compensates for the

misalignment, reduces chromatic aberration, and compensates

for focusing errors [43]. The layout of a typical homogenizer

system has been shown in Fig. 13 which can potentially solve

the partial shading problem.

X. CONCLUSION

The efciency of crystalline multijunction solar cells is much

higher than the single junction solar cells, and the use of MJ

348 IEEE TRANSACTIONS ON SUSTAINABLE ENERGY, VOL. 4, NO. 2, APRIL 2013

Fig. 12. Effect of partial shading on proposed MJ solar cell system. Partial

shading will affect all the modules.

Fig. 13. MJ solar cell system with homogenizer in order to mitigate the effect

of partial shading.

solar cells is gradually increasing due to new material combina-

tions, advancement in concentrator materials and optical split-

ting techniques, and progress in fabrication processes at the cost

of reasonably increased price. In this paper, a subcell intercon-

nection technique for different crystalline MJ solar cells has

been presented. Due to higher $/watt, the application of these

MJ solar cells is limited to aerospace application and concen-

trated PV (CPV) systems [39], [40]. The ongoing research on

MJ solar cells is in place to enhance the efciency at the cell

level. To the knowledge of the authors, there is no signicant

work done on the optimal subcell interconnection of MJ solar

cells with efcient power electronic solution. The identication

of the optimum subcell interconnection for multijunction solar

cells using suitable power electronic circuit is the main consider-

ation of this work. It has been shown that the proposed intercon-

nection will result in achieving a completely matched subcell

interconnection system for different multijunction solar cells.

The possible partial shading scenarios have also been discussed

with tentative solutions.

ACKNOWLEDGMENT

The authors would like to acknowledge Prof. R. Menon of

University of Utah for his valuable suggestions regarding MJ

solar cells.

REFERENCES

[1] M. K. Alam, F. H. Khan, and A. M. Imtiaz, Interconnection and

optimization issues of multijunction solar cellsA new mitigation

approach using switching power converters, in Proc. IEEE Applied

Power Electronics Conf. (APEC), Feb. 2012, pp. 583589.

[2] M. K. Alam, F. H. Khan, and A. S. Imtiaz, An efcient power elec-

tronics solution for lateral multi-junction solar cell systems, in Proc.

IEEE IECON 2011, pp. 43734378.

[3] R. R. King, A. Boca, W. Hong, D. Law, G. Kinsey, C. Fetzer, M.

Haddad, K. Edmondson, H. Yoon, P. Pien, and N. Karem, High-ef-

ciency multijunction photovoltaics for low-cost solar electricity, in

Proc. Ann. Meeting IEEE Lasers and Electro-Optics Society, Nov.

2008, pp. 23.

[4] I. Bhattacharya and S. Y. Foo, Effects of gallium-phosphide and in-

dium-gallium-antimonide semiconductor materials on photon absorp-

tion of multijunction solar cells, in Proc. 1st Asia Symp. Quality Elec-

tronic Design, 2009 (ASQED 2009), pp. 237241.

[5] J. F. Wheeldon, C. E. Valdivia, A. Walker, G. Kolhatkar, T. J. Hall, and

K. Hinzer et al., AlGaAs tunnel junction for high efciency multi-

junction solar cells: Simulation and measurement of temperature-de-

pendent operation, in Proc. 34th IEEE Photovoltaic Specialists Conf.

(PVSC), 2009, pp. 106111.

[6] C. Z. Ning, A. L. Pan, and R. B. Liu, Spatially composition-graded

alloy semiconductor nanowires and wavelength specic lateral-multi-

junction full-spectrum solar cells, in Proc. 34th IEEE Photovoltaic

Specialists Conf. (PVSC), 2009, pp. 14921495.

[7] A. G. Imenes and D. R. Mills, Spectral beam splitting technology for

increased conversion efciency in solar concentrating systems: A re-

view, Solar Energy Mater. Solar Cells, vol. 84, no. 14, pp. 1969,

2004.

[8] T. Takamoto, T. Agui, and A. Yoshida et al., Worlds highest ef-

ciency triple-junction solar cells fabricated by inverted layers transfer

process, in Proc. Photovoltaic Specialists Conf. (PVSC), 2010, pp.

412417.

[9] R. K. Jones, P. Hebert, P. Pien, R. R. King, D. Bhusari, R. Brandt, O.

A. Taher, C. Fetzer, J. Ermer, A. Boca, D. Larrabee, X. Q. Liu, and

N. Karam, Status of 40% production efciency concentrator cells at

Spectrolab, in Proc. IEEE Photovoltaic Specialists Conf. (PVSC), Jun.

2010, pp. 189195.

[10] M. Yamaguchi, H. Suzuki, Y. Ohshita, N. Kojima, and T. Takamoto,

Recent R&Dtopics on concentrator multi-junction solar cells and ma-

terials under innovative solar cellss project, in Proc. 35th IEEE Pho-

tovoltaic Specialists Conf. (PVSC), 2010, pp. 237242.

[11] J. Boisvert, D. Law, R. King, D. Bhusari, X. Liu, A. Zakaria, W. Hong,

S. Mesropian, D. Larrabee, R. Woo, A. Boca, K. Edmondson, D. Krut,

D. Peterson, K. Rouhani, B. Benedikt, and N. H. Karam, Develop-

ment of advanced space solar cells at Spectrolab, in Proc. 35th IEEE

Photovoltaic Specialists Conf. (PVSC), 2010, pp. 123127.

[12] A. Barnett, C. Honsberg, D. Kirkpatrick, S. Kurtz, D. Moore, and D.

Salzman et al., 50% efcient solar cell architectures and designs, in

Proc. IEEE 4th World Conf. Photovoltaic Energy Conversion, 2006,

pp. 25602564.

[13] X. Wang, N. Waite, P. Murcia, K. Emery, M. Steiner, and F. Kiamilev

et al., Improved outdoor measurements for very high efciency solar

cell sub-modules, in Proc. 34th IEEE Photovoltaic Specialists Conf.

(PVSC), 2009, pp. 409414.

[14] W. Blocker, High-efciency solar energy conversion through ux

concentration and spectrum splitting, Proc. IEEE, vol. 66, no. 1, pp.

104105, Jan. 1978.

[15] C. R. Lewis, W. M. Phillips, V. B. Shields, and P. M. Stella,

Multi-bandgap high efciency converter (RAINBOW), in Proc.

IECEC 1997, pp. 401406.

[16] J. H. Karp and J. E. Ford, Multiband solar concentrator using trans-

missive dichroic beamsplitting, in Proc. SPIE, 2008, vol. 7043, pp.

70430F70430F-8.

[17] A. Barnett, D. Kirkpatrick, C. Honsberg, D. Moore, M. Wanlass, and

K. Emery et al., Very high efciency solar cell modules, Prog. Pho-

tovoltaics: Res. Applicat., vol. 17, pp. 7583, 2009.

ALAM et al.: OPTIMIZATION OF SUBCELL INTERCONNECTION FOR MULTIJUNCTION SOLAR CELLS 349

[18] M. A. Green and A. Ho-Baillie, Forty three per cent composite split-

spectrum concentrator solar cell efciency, Prog. Photovoltaics: Res.

Applicat., vol. 18, pp. 4247, 2010.

[19] L. Zhao, High Efciency Mechanically Stacked Multi-Junction

Solar Cells for Concentrator Photovoltaics, Ph. D. dissertation,

Katholieke Universiteit LeuvenFaculteit Ingenieurswetenschappen

Arenbergkasteel, Belgium, Mar. 2011.

[20] L. L. Kazmerski, Solar photovoltaics R&D at the tipping point: A

2005 technology overview, J. Electron Spectroscopy and Related Phe-

nomena, vol. 150, pp. 105135, 2006.

[21] National Renewable Energy Laboratory News Release NR-1907 [On-

line]. Available: http://www.nrel.gov/news/press/2007/524.html

[22] J. D. M. Cambridge, M. A. Steiner, B. L. Unger, K. A. Emery, E. L.

Christensen, and M. W. Wanlass et al., Compact spectrum splitting

photovoltaic module with high efciency, Prog. Photovoltaics: Res.

Applicat., vol. 19, no. 3, pp. 352360, May 2011.

[23] X. Wang and A. Barnett, One lateral spectrum splitting concentrator

photovoltaic architecture: Measurements of current assemblies and

analysis of pathways to 40% efcient modules, in Proc. 35th IEEE

Photovoltaic Specialists Conf. (PVSC), 2010, pp. 27452750.

[24] T. Esram and P. L. Chapman, Comparison of photovoltaic array max-

imumpower point tracking techniques, IEEE Trans. Energy Convers.,

vol. 22, no. 2, pp. 439449, Jun. 2007.

[25] A. L. Lentine, G. N. Nielson, M. Okandan, W. C. Sweatt, J. L. Cruz-

Campa, and V. Gupta, Optimal cell connections for improved shading,

reliability, and spectral performance of microsystem enabled photo-

voltaic (MEPV) modules, in Proc. 35th IEEE Photovoltaic Specialists

Conf. (PVSC), 2010, pp. 30483054.

[26] L. Gao, R. A. Dougal, S. Liu, and A. P. Iotova, Parallel-connected

solar PV system to address partial and rapidly uctuating shadow con-

ditions, IEEE Trans. Ind. Electron., vol. 56, no. 5, pp. 15481556,

May 2009.

[27] M. Calais, J. Myrzik, T. Spooner, and V. G. Agelidis, Inverters for

single-phase grid connected photovoltaic systemsAn overview, in

Proc. Power Electronics Specialists Conf., 2002, pp. 19952000.

[28] J. M. A. Myrzik and M. Calais, String and module integrated inverters

for single-phase grid connected photovoltaic systemsA review, in

Proc. Power Tech Conf., 2003, vol. 2, p. 8.

[29] M. Meinhardt, G. Cramer, B. Burger, and P. Zacharias, Multi-string-

converter with reduced specic costs and enhanced functionality,

Solar Energy, vol. 69 (Suppl.), no. 16, pp. 217227, 2000.

[30] S. A. Khajehoddin, A. Bakhshai, and P. Jain, A novel topology and

control strategy for maximum power point trackers and multi-string

grid-connected PV inverters, in Proc. APEC 2008, pp. 173178.

[31] M. Meinhardt and G. Cramer, Past, present and future of grid con-

nected photovoltaic- and hybrid-power-systems, in Proc. IEEE-PES

Summer Meeting, 2000, vol. 2, pp. 12831288.

[32] P. A. Lynn, Electricity From Sunlight an Introduction to Photovoltaics,

1st ed. Hoboken, NJ: Wiley, 2010.

[33] L. Gao, R. A. Dougal, S. Liu, and A. P. Iotova, Parallel-connected

solar PV system to address partial and rapidly uctuating shadow con-

ditions, IEEE Trans. Ind. Electron., vol. 56, no. 5, pp. 1548156, May

2009.

[34] L. Gao, R. A. Dougal, S. Liu, and A. Jotova, Portable solar systems

using a step-up power converter with a fast-speed MPPT and a parallel-

congured solar panel to address rapidly changing illumination, in

Proc. APEC 2007, pp. 520523.

[35] N. E. Ball, Parallel and Virtual Parallel Interconnection of Solar Cells

in Solar Panel, U.S. Patent 7521630, Apr. 21, 2009.

[36] M. Miyatake, M. Veerachary, F. Toriumi, N. Fujii, and H. Ko, Max-

imum power point tracking of multiple photovoltaic arrays: A PSO

approach, IEEE Trans. Aerosp. Electron. Syst., vol. 47, no. 1, pp.

367380, Jan. 2011.

[37] B. Mitchell, G. Peharz, G. Siefer, and M. Peters et al., Four-junc-

tion spectral beam-splitting photovoltaic receiver with high optical ef-

ciency, Prog. Photovoltaics: Res. Applicat., vol. 19, no. 1, pp. 6172,

2011.

[38] N. E. Ball, Parallel and Virtual Parallel Interconnection of Solar Cells

in Solar Panels, U.S. Patent 7,521,630 B2, Apr. 2009.

[39] D. Crisp, A. Pathareb, and R. C. Ewell, The performance of gallium

arsenide/germanium solar cells at the Martian surface, Acta Astronau-

tica, vol. 54, no. 2, pp. 83101, Jan. 2004.

[40] NREL, Concentrating Photovoltaic Technology [Online]. Available:

http://www.nrel.gov/csp/concentrating_pv.html

[41] C. Deline, Partially shaded operation of a grid-tied PV system, in

Proc. IEEE PVSC, Jun. 2009, pp. 001268001273.

[42] Sunny Boy 5000TL Multi-String [Online]. Available: http://www.ese-

dracoop.it/documenti/rete/sunny_5000.pdf

[43] D. C. Miller, M. D. Kempe, C. E. Kennedy, and S. R. Kurtz, Analysis

of transmitted optical spectrumenabling accelerated testing of CPVde-

signs, Proc. SPIE, pp. 74070G74070G-12, 2009, DOI: 10.1117/12.

826251.

[44] Texas Instruments [Online]. Available: http://www.ti.com/lit/sg/

sprb176l/sprb176l.pdf

Mohammed Khorshed Alam (S11) received the

B.S. degree in electrical and electronic engineering

from Bangladesh University of Engineering and

Technology, Dhaka, Bangladesh, in 2009. Since

2011, he is working toward the Ph.D. degree in

electrical engineering at the University of Utah, Salt

Lake City.

He was Lecturer at Ashanullah University of Sci-

ence and Technology, Dhaka, Bangladesh from 2009

to 2010. His research interest includes renewable en-

ergy harvesting, high power switched-capacitor con-

verters, fault detection, and reliability analysis of circuits.

Faisal Khan (S01M07) received the B.Sc., M.S.,

and Ph.D. degrees from Bangladesh University of

Engineering and Technology, Arizona State Uni-

versity, and University of Tennessee, Knoxville, in

1999, 2003, and 2007, respectively, all in electrical

engineering.

From 2007 to 2009, he has been with Electric

Power Research Institute (EPRI) as a senior power

electronics engineer. Since 2009, he is with the

Electrical and Computer Engineering Department,

University of Utah as an Assistant Professor. His

major area of interest is high-power capacitor-clamped converters. However,

since his appointment at the university, he has extended his research into the

eld of power converter reliability prediction and cell level power converter

design for photovoltaics, especially multijunction solar cells. In addition, he is

also involved with renewable energy research including wind energy harvesting

using split-phase induction generators and grid-tied energy storage.

Prof. Khan is a member of the IEEE Power Electronics Society, Industry Ap-

plications Society, and Industrial Electronics Society. He is the recipient of the

2007 IEEE IAS rst prize paper award for his contribution to high power mod-

ular multilevel dcdc converters. He is the award chair of IEEE ECCE 2012 and

the general chair of IEEE COMPEL 2013 in Salt Lake City.

Abusaleh M. Imtiaz (S11) received the B.S.

degree in electrical engineering from Bangladesh

University of Engineering and Technology (BUET),

Dhaka, Bangladesh, in 2009. He is currently working

toward the Ph.D. degree in electrical engineering at

University of Utah.

He is the author or a coauthor of more than

10 peer reviewed publications including journals

and conference proceedings. His research interests

include fabrication and characterization of the

state-of-the-art power semiconductor devices and

solar cells, energy management of plug in hybrid vehicles and design of power

converters for renewable energy sources.

You might also like

- Intesifikasi Pengembangan Pertanian Organik Dalam Meningkatkan Pendapatan PetaniDocument18 pagesIntesifikasi Pengembangan Pertanian Organik Dalam Meningkatkan Pendapatan PetaniStela TalawayNo ratings yet

- 2008rfh PDFDocument126 pages2008rfh PDFAhmad Diyanal Arifin100% (1)

- 1 s2.0 S1050464815301704 Main PDFDocument6 pages1 s2.0 S1050464815301704 Main PDFAhmad Diyanal ArifinNo ratings yet

- Featured Selection X4 PDFDocument10 pagesFeatured Selection X4 PDFAhmad Diyanal ArifinNo ratings yet

- (Biodiesel) PDFDocument9 pages(Biodiesel) PDFAhmad Diyanal ArifinNo ratings yet

- Jurnal Bagus THP PDFDocument7 pagesJurnal Bagus THP PDFAhmad Diyanal ArifinNo ratings yet

- Fibers 02 00075 v2 PDFDocument17 pagesFibers 02 00075 v2 PDFAhmad Diyanal ArifinNo ratings yet

- 1 s2.0 S2210784314000382 Main PDFDocument8 pages1 s2.0 S2210784314000382 Main PDFAhmad Diyanal ArifinNo ratings yet

- 1895 PDFDocument6 pages1895 PDFAhmad Diyanal ArifinNo ratings yet

- 1 s2.0 S096085240400080X Main PDFDocument4 pages1 s2.0 S096085240400080X Main PDFAhmad Diyanal ArifinNo ratings yet

- A New Mathematical Model For Effectiveness Factors in Biofilm Under Toxic ConditionsDocument12 pagesA New Mathematical Model For Effectiveness Factors in Biofilm Under Toxic ConditionsAhmad Diyanal ArifinNo ratings yet

- 3160Document8 pages3160Ahmad Diyanal ArifinNo ratings yet

- 1 s2.0 S096085240400080X Main PDFDocument4 pages1 s2.0 S096085240400080X Main PDFAhmad Diyanal ArifinNo ratings yet

- 262 750 1 PB PDFDocument10 pages262 750 1 PB PDFAhmad Diyanal ArifinNo ratings yet

- Transducers2013 SampleManuscriptDocument4 pagesTransducers2013 SampleManuscriptAhmad Diyanal ArifinNo ratings yet

- Fibers 02 00075 v2 PDFDocument17 pagesFibers 02 00075 v2 PDFAhmad Diyanal ArifinNo ratings yet

- JBNB 2014093015534207 PDFDocument10 pagesJBNB 2014093015534207 PDFAhmad Diyanal ArifinNo ratings yet

- JBNB 2013041716004779 PDFDocument14 pagesJBNB 2013041716004779 PDFAhmad Diyanal ArifinNo ratings yet

- Jurnal Penelitian NechiyanaDocument10 pagesJurnal Penelitian NechiyanaAhmad Diyanal ArifinNo ratings yet

- LM 324 NDocument14 pagesLM 324 NCarlos SoaresNo ratings yet

- Thermoelectric Generators For Automotive Waste Heat Recovery Systems Part I - Numerical Modeling and Baseline Model AnalysisDocument10 pagesThermoelectric Generators For Automotive Waste Heat Recovery Systems Part I - Numerical Modeling and Baseline Model AnalysismegustalazorraNo ratings yet

- SolarThermoelectricGenerator Sarah WatzmanDocument43 pagesSolarThermoelectricGenerator Sarah WatzmanAhmad Diyanal ArifinNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Example Pump Selection: Equipment Data SheetDocument4 pagesExample Pump Selection: Equipment Data SheetMohamed Yassine LahianiNo ratings yet

- Electrical SystemsDocument2 pagesElectrical SystemsMārcis RancānsNo ratings yet

- VIP396 ManualDocument8 pagesVIP396 ManualWONG HOW YANNo ratings yet

- DB224-E Product SpecificationsDocument2 pagesDB224-E Product SpecificationsTo VT3No ratings yet

- Course Assignment Submission Date: 30.09.2021: S.No Full Name ID - No QuestionsDocument2 pagesCourse Assignment Submission Date: 30.09.2021: S.No Full Name ID - No QuestionsEbisa RefisaNo ratings yet

- GroE Fiam ImoedanceDocument2 pagesGroE Fiam ImoedanceJawad AmjadNo ratings yet

- Marine GroundingDocument9 pagesMarine GroundingTara CollierNo ratings yet

- STM 32 F 207 VGDocument184 pagesSTM 32 F 207 VGCarlo ColloNo ratings yet

- Xitanium 20W LH 0.15-0.5A 48V 230VDocument7 pagesXitanium 20W LH 0.15-0.5A 48V 230VJane DoeNo ratings yet

- Comparison of Various PWM Techniques For Field Oriented Control Vsi Fed PMSM DriveDocument9 pagesComparison of Various PWM Techniques For Field Oriented Control Vsi Fed PMSM DrivechaitanyaNo ratings yet

- Using Keypad - MC17.1Document4 pagesUsing Keypad - MC17.1Farty PantsNo ratings yet

- Reference Letter TemplateDocument2 pagesReference Letter TemplateAnant Pratap Srivastava100% (3)

- Calculation and Measurement of Potential and Electric Field Distribution Along 1000 KV AC Transmission Line Composite InsulatorDocument6 pagesCalculation and Measurement of Potential and Electric Field Distribution Along 1000 KV AC Transmission Line Composite InsulatoralpcruzNo ratings yet

- Standard Tubular Fluorescent Lamps: Figure A6 Gives These Values For Different Arrangements of BallastDocument2 pagesStandard Tubular Fluorescent Lamps: Figure A6 Gives These Values For Different Arrangements of BallastNamik HadziibrahimovicNo ratings yet

- Cold Room Evaporator UnitDocument2 pagesCold Room Evaporator UnitAlex AndersNo ratings yet

- Thyssenkrupp Electrical Steel GMBHDocument32 pagesThyssenkrupp Electrical Steel GMBHRichard SyNo ratings yet

- No 1 26 33 Family 3Document8 pagesNo 1 26 33 Family 3naveenbabu19No ratings yet

- OIM GB 1190056002 Cnt0Document360 pagesOIM GB 1190056002 Cnt0Sandi Junior SihotangNo ratings yet

- What Are Computer NetworksDocument5 pagesWhat Are Computer NetworksJASMEET SinghNo ratings yet

- Mitsubishi TH-N Overload RelaysDocument7 pagesMitsubishi TH-N Overload RelaysGuillermo Hernandez0% (1)

- ProAc Studio 150 LeafletDocument2 pagesProAc Studio 150 Leafletxxlxxl59No ratings yet

- Synchronous Machines3Document103 pagesSynchronous Machines3Daniela CastroNo ratings yet

- Analysis and Implementation of Fuzzy Logic Controller Based MPPT To Enhance Power Quality in PV SystemDocument10 pagesAnalysis and Implementation of Fuzzy Logic Controller Based MPPT To Enhance Power Quality in PV SystemEditor IJTSRDNo ratings yet

- Week 2-Process and Instrumentation DiagramDocument31 pagesWeek 2-Process and Instrumentation DiagramMohd Yashfi Yunus100% (1)

- List of EquipmentDocument32 pagesList of EquipmentsutanuprojectsNo ratings yet

- PVMET-330 User's GuideDocument14 pagesPVMET-330 User's GuideM Fernanda Gerena DuarteNo ratings yet

- Process Control Concepts, Dynamics and Applications PDFDocument734 pagesProcess Control Concepts, Dynamics and Applications PDFAfzaalUmair71% (7)

- Application of Numerical Relays For HV Shunt Reactor ProtectionDocument5 pagesApplication of Numerical Relays For HV Shunt Reactor Protectionalex696No ratings yet

- DS - SG10KTL-MT Datasheet - V10 - EN PDFDocument1 pageDS - SG10KTL-MT Datasheet - V10 - EN PDFalbertusngNo ratings yet

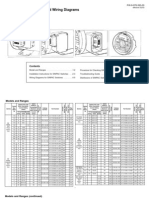

- Installation Instructions and Wiring Diagrams For All Models and RangesDocument8 pagesInstallation Instructions and Wiring Diagrams For All Models and RangesMaria MusyNo ratings yet