Professional Documents

Culture Documents

Guidelines On Energy Efficiency of LiftnEsc Installations 2007

Uploaded by

alvinhamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidelines On Energy Efficiency of LiftnEsc Installations 2007

Uploaded by

alvinhamCopyright:

Available Formats

page !

ol 27

"

"

#

#

$

$

%

%

&

&

'

'

$

$

(

(

&

&

)

)

*

*

(

(

+

+

(

(

&

&

,

,

-

-

.

.

+

+

/

/

/

/

$

$

0

0

$

$

&

&

(

(

0

0

.

.

*

*

/

/

1

1

$

$

/

/

2

2

3

3

+

+

)

)

0

0

4

4

'

'

4

4

2

2

*

*

,

,

5

5

(

(

)

)

2

2

4

4

'

'

'

'

4

4

2

2

$

$

*

*

(

(

)

)

2 20 00 07 7 L LD Dl lT Tl lO ON N

the

Supplement

to the

Code

document

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Prelace

The Code ol Praclice lor Lnergy Llliciency ol Lill & Lscalalor lnslallalions (Lill & Lscalalor Code)

developed by lhe Lleclrical & Mechanical Services Deparlmenl (LMSD) aims lo sel oul lhe minimum

design requiremenls on energy elliciency ol lill & escalalor inslallalions. ll lorms a parl ol a sel ol

comprehensive 8uilding Lnergy Codes (8LC) lhal addresses energy elliciency requiremenls in building

services inslallalions. The sel ol comprehensive 8LC covers lhe Lill & Lscalalor Code, lhe Codes ol

Praclice lor Lnergy Llliciency ol Lighling lnslallalions, Air Condilioning lnslallalions and Lleclrical

lnslallalions, and lhe Perlormance-based 8uilding Lnergy Code.

As a supplemenl lo lhe Lill & Lscalalor Code, lhe LMSD has developed lhis handbook ol Cuidelines

on Lnergy Llliciency ol Lill & Lscalalor lnslallalions (Cuidelines). The inlenlion ol lhe Cuidelines is lo

provide guidance noles lo compliance wilh lhe Lill & Lscalalor Code and draw allenlion ol lill &

escalalor designers & operalors lo general recommended praclices lor energy elliciency and

conservalion on lhe design, operalion & mainlenance ol lill & escalalor inslallalions. The Cuidelines

seek lo explain lhe requiremenls ol lhe Lill & Lscalalor Code in general lerms and should be read in

conjunclion wilh lhe Lill & Lscalalor Code. ll is hoped lhal designers will nol only design inslallalions

lhal would salisly lhe minimum requiremenls slaled in lhe Lill & Lscalalor Code, bul also pursue

above lhe minimum requiremenls.

The Cuidelines were lirsl published in 2000. Wilh lhe Lill & Lscalalor Code upgraded lo ils 2005

edilion, an addendum lor lhe Cuidelines was issued in 2005. The Cuidelines are amended in 2007 lo

suil lhe 2007 edilion ol lhe Lill & Lscalalor Code.

To promole lhe adoplion ol lhe 8LC, lhe Hong Kong Lnergy Llliciency Pegislralion Scheme lor

8uildings was also launched. The Pegislralion Scheme provides lhe cerlilicalion lo a building

complying wilh one or more ol lhe 8LC.

This book ol Cuidelines is copyrighled and all righls (including subsequenl amendmenls) are reserved.

Acknowledgemenl

ln lhe preparalion ol lhe Cuidelines, relerence has been made lo lhe lollowing publicalions.

a) Cl8SL Cuide D Transporlalion Syslems in 8uildings, Cl8SL

b) 8arney, C.C., and Dos Sanlos, S.M., Llevalor Trallic Analysis Design and Conlrol, Peler Peregrinus,

!995 Pelevanl conlenls quoled are. 2.8.2 (p57, 58), 3.! (p85), 3.3.3 (p95), Table 2.3 (p5!), and

Lxamples 2.!! & 2.!2 (p65 lo 67)

c) Slawinoga, Poland, "Designing lor Peduced Llevalor Lnergy Cosl", LLLVATOP WOPLD magazine,

Jan !994

d) Al-Sharil, Lulli, 8unching in Lills, LLLVATOP WOPLD magazine, Jan !996

e) Malinowski, John, Llevalor Drive Technologies, LLLVATOP WOPLD magazine, Mar !998

l) Cuide Noles on Llevalors (Lills) Planning, Seleclion and Design, !997, Deparlmenl ol Public Works

& Services, Auslralia Pelevanl conlenls quoled are. 7. Lleclrohydraulic Lills

The 8uilding Lnergy Codes, corresponding Cuidelines and Pegislralion Scheme documenls

are available lor download al hllp.//www.emsd.gov.hk/emsd/eng/pee/eersb.shlml

Lnquiry. hkeersb@emsd.gov.hk

C CH HL LC CK K W WL L8 8- -S Sl lT TL L l lO OP P L LA AT TL LS ST T l lN Nl lO OP PM MA AT Tl lO ON N

i

page ii ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

CONTLNTS

!. lNTPODUCTlON ........................... !

2. CODL COMPLlANCL......................... !

2.! Maximum Allowable Lleclrical Power ol Lills, Lscalalors and Passenger Conveyors !

2.2 Lnergy Managemenl ol Lills, Lscalalors & Passenger Conveyors ....... 2

2.3 Power Qualily Pequiremenls ...................... 2

3. CONSlDLPATlONS lN DLSlCN Ol LllTS & LSCALATOPS........... 3

3.! laclors Thal Allecl Lnergy Consumplion ol Lill and Lscalalor Syslem...... 3

3.2 Ceneral Principles lo Achieve Lnergy Llliciency ................. 3

4. LNLPCY LlllClLNCY lOP LllT AND LSCALATOP LQUlPMLNT....... 4

4.! Ceneral ............................... 4

4.2 Traclion Lill Lquipmenl ......................... 4

4.2.! Molor Drive Conlrol Syslem .................... 4

4.2.2 Molor Drive Cears ........................ 6

4.2.3 Molor ............................. 7

4.2.4 Olher Means lo Peduce Punning lriclion .............. 7

4.3 Hydraulic Lill Lquipmenl ........................ 8

4.3.! Main Componenls ........................ 8

4.3.2 8asic Arrangemenls ...................... 8

4.3.3 Valve Unil ........................... 9

4.3.4 Lnergy Llliciency lor Hydraulic Lill Lquipmenl .............. 9

4.4 Lscalalor and Passenger Conveyor Lquipmenl ............... !!

4.4.! Molor Drive Conlrol Syslem .................... !!

4.4.2 Molor Drive Cears and Power Transmission ............. !2

4.5 Power Qualily ol Lquipmenl ....................... !2

4.6 VVVl Molor Drive, Lnergy oplimizer, Service-on-demand Lscalalor !4

5. LNLPCY LlllClLNCY lOP DLSlCN Ol LllT AND LSCALATOP SYSTLM.... !4

5.! Appropriale Sizing ol Verlical Transporlalion Syslem ............. !4

5.2 Appropriale Zoning ol Lill lnslallalions .................. !6

5.3 Lnergy Managemenl ol Lill Syslem ..................... !7

5.3.! Provisions ol Melering Devices ................... !7

5.3.2 Conlrol Algorilhm ol Lill .................... !7

5.3.3 Slandby Mode ol Lill Lquipmenl .................. !8

5.4 Lnergy Managemenl ol Lscalalor and Conveyor Syslem ........... !9

5.4.! Provision ol Melering Devices .................. !9

5.4.2 Slandby Mode ol Lscalalors and Conveyors ............ !9

5.5 lnlernal Decoralion ol Lill Cars ...................... !9

5.6 Lill Trallic Design ........................... !9

5.7 Handling Capacily ol Lill Syslem ...................... 2!

6. HOUSLKLLPlNC MLASUPLS TO LNHANCL LNLPCY LlllClLNCY...... 22

7. MODLPNlSATlON Ol OLD LQUlPMLNT.................... 23

APPLNDlX l SAMPLL CALCULATlON lOP LllT TPAlllC ANALYSlS ....... 25

ii

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

!. lNTPODUCTlON

The primary objeclive ol lhe Code ol Praclice lor Lnergy Llliciency ol Lill & Lscalalor lnslallalions

(Lill & Lscalalor Code), published by lhe Lleclrical and Mechanical Services Deparlmenl (LMSD), is

lo sel oul lhe minimum energy-ellicienl design slandards lor lill & escalalor inslallalions wilhoul

imposing any adverse conslrainl on building lunclions, nor hindrance lo comlorl or produclivily

ol lhe building occupanls. The Cuidelines on Lnergy Llliciency ol Lill & Lscalalor lnslallalions

(Cuidelines) is a supplemenl lo lhe Lill & Lscalalor Code. The inlenlion ol lhe Cuidelines is lo

explain lhe principles behind relevanl requiremenls in lhe Lill & Lscalalor Code and provide

guidance on Code compliance. The Cuidelines also provide lhe recommended general praclices

lor energy elliciency and conservalion on lhe design, operalion & mainlenance ol lill & escalalor

inslallalions. Whilsl locusing on energy elliciency aspecls, lhe Cuidelines are nol lo provide a

comprehensive sel ol guidance noles in lill & escalalor design.

2. CODL COMPLlANCL

The Lill & Lscalalor Code mainly conlrols lhe lollowing areas.

The maximum allowable eleclrical power ol lills, escalalors & passenger conveyors.

Lnergy managemenl ol lills, escalalors & passenger conveyors

Tolal Harmonic Dislorlion and Tolal Power laclor lor molor drive syslem.

2.! Maximum Allowable Lleclrical Power ol Lills, Lscalalors & Passenger Conveyors

The requiremenl ol lhe maximum allowable eleclric power indicales ullimalely lhe energy

perlormance ol lhe equipmenl. The power lor lill equipmenl is lo be measured when lhe

lill is carrying ils raled load and moving upward al ils conlracl speed. lor escalalors and

passenger conveyors, since lhe raled load is usually delined as number ol person (nol in kg

weighl), lhere is no lheorelical raled load in kg lor lhe equipmenl. Thus lhe eleclric power is

lo be measured when lhe escalalor/conveyor is carrying no load and moving al ils raled

speed eilher in lhe upward or downward direclion. Conlrol ligures are given in lhe Lill &

Lscalalor Code.

lor lill equipmenl, lhe power is measured al lull load conlracl speed. A number ol laclors

will allecl lhis power consumplion. ln lhe case ol suspension lill, lhe weighl ol lhe lill car

will usually be balanced by lhe counlerweighl. Thus il power is measured al lhe conlracl

speed, lhe laclors lhal allecl lhe power consumplion will be primarily lhe proporlion ol lhe

lull load lhal is balanced by lhe counlerweighl. ln usual lill machine design, lhe

counlerweighl is usually sized lo balance lhe weighl ol lhe lill car plus 45'-50' ol lhe

conlracl load. ll lhe counlerweighl is designed lo balance 45' ol lhe conlracl load, lhe

power consumplion al lhe lull load conlracl speed up condilion will be higher. Olher laclor

lhal has signilicanl ellecls on lhis power consumplion is lhe elliciency ol lhe molor, lriclion,

lhe conlroller and lhe gear box. lor hydraulic lills, lhe dead weighl ol lhe lill car is lhe

predominaling laclor on lhis maximum running power as lhere is no counlerweighl lo

balance ils dead weighl.

ln escalalor and passenger conveyor equipmenl, lhe dominaling laclor is similar lo lhe

lraclion lill equipmenl. Thal is, lhe elliciency ol lhe molor, lriclion, lhe conlroller and lhe

driving gear box. The proporlion ol lriclional loss ol lhe machine can also become

signilicanl in lhe power consumplion in no load condilion, as il is lhe lix overhead lo keep

lhe equipmenl running.

lor lill and escalalor syslem designers, il is dillicull lo oblain lhis power ligure during lhe

design slage because mosl ol lhe lill manulaclurers can only provide lhe molor's power

raling ligure ol lheir equipmenl which is much larger lhan lhe running power. This running

power can only be measured during lhe lesling and commissioning process, lhus il is

page ! ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

dillicull lo lell exaclly during lhe design slage whelher a cerlain piece ol equipmenl comply

wilh lhe Code. ll is lherelore, advisable lo look al lesling and commissioning records ol

similar inslallalions when raled power is oblained lrom lill manulaclurers.

ln order lo meel lhe allowable eleclrical power, some good engineering praclices lor

lraclion lill are.

Lill machine lo locale direclly above lhe lill shall lo avoid losses lhrough addilional

pulley mechanism,

Maximum rise (m) lo limil lo 50 (s) x Speed (m/s) lo minimize lhe lravel dislance and

lhus lhe energy consumplion,

Maximum rise (m) lo limil lo 40m lor under slung lype roping arrangemenl wilh

basemenl/side lype lraclion, so as lo minimize lhe lravel dislance and lhus lhe energy

consumplion, and

Avoid blind hoisl way above lhe lop mosl landing lo minimize lhe dead weighl ol

ropes.

2.2 Lnergy Managemenl ol Lills, Lscalalors & Passenger Conveyors

lor lhe purpose ol energy managemenl, lhe Code requires lhal melering devices or

provision lor meler conneclion be provided lor laking readings concerning energy

perlormance. The readings laken can help lo compile a beller piclure ol building energy

consumplion during energy audil and lel building owners know lhe running cosls lhal lhey

are paying lor lheir verlical lransporlalion syslem.

The Code has allowed llexibilily lor equipmenl inslallalions. The provision ol only a

conneclion poinl wilh reasonable accessibilily and spacing is acceplable lo lhe Code while

lhe ideal provision is lo provide lhe melering equipmenl logelher wilh lhe lill/escalalor

equipmenl. ll should be noled lhal lhe word "provision" should reler lo permanenl

provisions. Melering devices or measuring provisions are nol required lor individual

equipmenl. lnslead only one sel ol melering device or provision is required lor each group

ol escalalors/conveyors or each bank ol lill. The readings lhal are required include vollage,

currenl (bolh line and neulral currenl), lolal power laclor, energy consumplion, power and

maximum demand. Mulli-lunclion meler lhal can measure mulliple ligures is acceplable

and recommended. ln lacl using mulli-lunclion meler can simplily lhe inslallalion work.

8esides lhe melering requiremenl, lhe Code requires lhal lor lill banks wilh lwo or more lill

cars, al leasl one lill car should be operaled under a "slandby" mode during oll-peak

period. ll is also required lhal during lhe slandby mode, lhe lill should nol response lo

passenger calls unlil il is relurned lo normal operalion mode. ll merely means lo shul down

one ol lhe lills in lhe lill bank during oll peak hours. Addilionally, il lhe lill car's molor

drive is DC-MC lype molor drive, il is required lhal lhe generalor driving molor ol lhe lill

car should be shul down during lhe slandby mode. As mosl ol newly inslalled lill

equipmenl in Hong Kong are VVVl equipmenl, lhis requiremenl is expecled lo have very

lillle impacl lo lhe lill induslry.

Anolher requiremenl is lo shul oll lhe venlilalion lan while a lill car has been idled lor more

lhan 2 minules. The reason lor nol shulling down also lhe lill car lighling is merely due lo

salely consideralions.

2.3 Power Qualily Pequiremenls

The power qualily requiremenls in lhe Code mainly sel oul in lorm ol Tolal Harmonic

Dislorlion requiremenl and Tolal Power laclor requiremenl. Pelevanl relerence malerials

concerning power qualily requiremenl can be oblained lrom lhe Cuidelines lor Lnergy

Llliciency ol Lleclrical lnslallalions published by lhe Lleclrical and Mechanical Services

page 2 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Deparlmenl. Designers should nole lhe measuring condilions and localions ol lhe power

qualily requiremenls. lor escalalors inslallalions, since lhe requiremenl ol Tolal Power

laclor is lo be measured under lhe molor brake load condilion, which is dillicull lo simulale

on sile, lhus, manulaclurer's calculalions or prool ol compliance will be considered

acceplable.

3. CONSlDLPATlONS lN DLSlCN Ol LllTS & LSCALATOPS

The lill and escalalor induslry is a very unique lrade among olher building services equipmenl

induslries. The equipmenl suppliers usually have lines ol basic producls. However, each

inslallalion is sile specilic. Thal is, lhe linal inslallalion is lailor-made lo suil individual sile's

conslrainls and requiremenls. This makes lhe eslablishmenl ol generic energy elliciency

slandard a dillicull lask, as lhere are large diversilies among dillerenl inslallalions.

3.! laclors Thal Allecl Lnergy Consumplion in Lill and Lscalalor Syslem

Lnergy is consumed by lill and escalalor equipmenl mainly on lhe lollowing calegories.

lriclion losses incurred while lravelling.

Dynamic losses while slarling and slopping.

Lilling (or lowering) work done, polenlial energy lransler.

Pegeneralion inlo lhe supply syslem.

The general approach lo energy elliciency in lill and escalalor equipmenl is merely lo

minimize lhe lriclion losses and lhe dynamic losses ol lhe syslem. There are many laclors

lhal will allecl lhese losses lor a lill and escalalor syslem.-

(A) Characlerislic ol lhe equipmenl

- The lype ol molor drive conlrol syslem ol lhe machine.

- The inlernal decoralion ol lhe lill car.

- Means lo reduce lriclion in moving parls (e.g. guide shoes).

- The lype ol lills and escalalors.

- The speed ol lhe lill/escalalor syslem.

- The pulley syslem ol lhe equipmenl.

(8) Characlerislic ol lhe premises

- The populalion dislribulion ol lhe premises.

- The lype ol lhe premises.

- The heighl ol lhe premises.

- The house keeping ol lhe premises.

(C) The conliguralion ol lhe lill/escalalor syslem

- The zoning ol lhe lill syslem.

- The combinalion ol lill and escalalor equipmenl.

- The slralegies lor verlical lransporlalion.

- The required grade ol service ol lhe syslem.

3.2 Ceneral Principles lo Achieve Lnergy Llliciency

ln general lhe principles lor achieving energy elliciency lor lill/escalalor inslallalions are.

Specily energy elliciency equipmenl lor lhe syslem.

Do nol over design lhe syslem.

Suilable zoning arrangemenl.

Suilable conlrol and energy managemenl ol lill equipmenl

Use lighl weighl malerials lor lill car decoralion.

Cood house keeping.

page 3 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

4. LNLPCY LlllClLNCY lOP LllT AND LSCALATOP LQUlPMLNT

4.! Ceneral

The mode ol verlical lransporl in buildings can be mainly classilied inlo lhree modes.

by slair lrallic

by lill lrallic

by escalalor lrallic

Lach ol lhese modes ol verlical lransporl has lheir own characlerislics and limilalions.

Despile lhe vasl diversilied usage ol lhe lill equipmenl, lhere are basically lwo main

calegories ol lill equipmenl, namely lraclion lill and hydraulic lill. lrom energy perlormance

poinl ol view, lraclion lill is more energy ellicienl lhan hydraulic lill syslem. ln hydraulic lill

inslallalion, a considerable amounl ol energy is wasled in healing up lhe hydraulic lluid

when building up lhe hydraulic pressure. Some inslallalions may even need separale coolers

lo cool down lhe lluid lo avoid overhealing. lurlhermore, hydraulic lills are usually nol

provided wilh a counlerweighl. Thus lhe lill molor has lo be large enough lo raise lhe raled

load plus lhe dead weighl ol lhe car cage. ln lraclion lill, lhe maximum weighl lo be raised

under normal operalion is only aboul hall ol ils raled load. Therelore, designers should

avoid using hydraulic lills il lhere is no conslrainl on lhe inslallalion ol lraclion lill

equipmenl.

4.2 Traclion Lill Lquipmenl

4.2.! Molor Drive Conlrol Syslem

Lleclricily is direclly consumed by lhe molor drive syslem ol lhe lill machine. Thus

how elleclive lhe molor drive can converl lhe eleclrical energy inlo lhe required

kinelic energy have a remarkable ellecl on lhe energy perlormance ol lhe

equipmenl. ln lhe hislory ol lill equipmenl developmenl, dillerenl lypes ol molor

drive syslem were developed. Some ol lhese molor drive syslems include.

- DC molor drive wilh generalor sel (DC M-C).

- DC molor drive wilh solid slale conlroller (DC SS).

- AC 2 speed molor drive.

- AC molor drive wilh variable vollage conlroller (ACVV).

- AC molor drive wilh variable vollage and variable lrequency

conlroller(ACVVVl).

Among lhe above drive syslems, DC M-C has lhe lowesl elliciency because ol large

energy loss in lhe molor and generalor arrangemenl, which converls eleclrical

energy inlo mechanical energy and linally back lo eleclrical energy again. Anolher

reason lor lhe low elliciency ol lhe DC M-C molor drive is lhal lhe molor has lo be

kepl running when lhe lill is idle.

Similarly, lhe AC 2 speed molor drive is also considered a less energy ellicienl drive

syslem. These lwo speed molors are usually slarled up wilh resislance in lhe high-

speed winding, whilsl smoolh deceleralion is oblained by inserling a buller

resislance, eilher in lhe low- or high-speed winding during lransilion lo low speed.

Somelimes, a choke is used inslead ol a buller resislance, which resulls in a

smoolher and less peaked curve ol braking lorque. The inserlion ol buller resislance

and choke wasles much energy during lhe slarl up and deceleralion. lurlhermore,

lwo-speed syslem is inslalled wilh a large llywheel lo smoolh lhe sudden change in

lorque. The llywheel slores energy, which is dissipaled laler, conlribuling lo lhe low

syslem elliciency.

page 4 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

A general guideline on lhe molor drive syslem lor lraclion lill equipmenl is shown in

lhe lollowing lable.

Conlracl Speed V

(m/s)

Suggesled Order ol Prelerence

Molor Drive Conlrol Syslems lor Passenger Traclion Lills

V s !.0 AC VVVl / AC VV / DC SS / AC 2-speed

!.0 < V s 3.0 AC VVVl / AC VV / DC SS

3.0 < V s 5.0 AC VVVl / AC VV

V > 5.0 AC VVVl

DC M-C sel is nol in lhe guideline lhroughoul lhe range as lhe energy perlormance

is exlremely poor. The AC-2 speed molor drive syslem is nol recommended lor lills

wilh conlracl speed higher lhan ! m/s due lo lheir inlerior energy perlormance. ll is

highly recommended lhal even lor lill wilh speed under ! m/s, building designers

should always consider lo use AC VVVl whenever leasible. As an illuslralion on lhe

energy saving polenlial lor ulilizing VVVl drive, lel's lake lhe energy ol a lill wilh a

pole-changing molor as !00'. Then lhe ACVV syslem requires approximalely 70'

ol lhis energy lor lhe same oulpul whereas ACVVVl will only require 50'. ll lhe

energy lo be led back inlo lhe mains supply is laken inlo accounl, a lurlher

reduclion ol 5' (i.e. 45') ol energy can be achieved lor lhe ACVVVl.

Speed

Currenl

AC 2 speed

VVVl

Currenl ol VVVl vs AC 2 speed

time

The ligure on lhe lell illuslrales lhe

operaling characlerislic ol some

molor drive syslems during an ideal

journey ol a lill car. The ideal

journey includes a linear

acceleralion, conlracl speed lravel

and a linear deceleralion. The

energy consumed lor lhe journey

should be proporlional lo lhe area

under lhe currenl line ol lhe

corresponding molor drive syslem,

lhal is.

energy l (l ) dl

}

0

T

Currenl

DC SS VVVl

Currenl ol VVVl vs DC SS

Currenl

ACVV VVVl

Currenl ol VVVl vs ACVV

This diagram is lor relerence only

page 5 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Thus il can be seen lhal a signilicanl proporlion ol energy has lo be consumed

during lhe acceleralion process as well as lhe deceleralion process. VVVl molor

drive consumes less energy during lhe slarl/slop cycle ol lhe lill car. The saving is

more remarkable when il is compared wilh an AC 2 speed molor drive syslem. ll

has also been slressed lhal in real lile applicalions a remarkable proporlion ol lill

journeys are non-ideal journey. Thal is, lhe conlracl speed ol lhe equipmenl is nol

achieved. ln lhis case, lhe lill equipmenl is always operaling in an

acceleralion/deceleralion cycle, which is lhe mosl energy-consuming mode.

8esides energy concern, ACVVVl also provides good riding comlorl due lo lhe

smoolhness ol speed conlrol.

4.2.2 Molor Drive Cears

The molor drive syslem is basically eilher geared or gearless lype. Cearless drive

usually is lor high speed lills wilh conlracl speed above 5 m/s. Lquipmenl

suppliers recenlly slarl lo exlend lhe usage range ol gearless drive lo lhe low

speed range. Allhough lhe original inlenlion is lo reduce lhe size ol lhe machine,

lhe eliminalion ol gear improves lhe energy elliciency ol lhe equipmenl. lor mosl

ol lhe low and medium speed lills, lhe sheave wheel is usually driven by gears. ln

lerms ol energy perlormance, gearless drive has no gear lransmission loss lhus

have a lransmission elliciency ol !00'. However, lhe disadvanlage lor gearless

molor drive lies wilh lhe lacl lhal mulliple-pole molor windings, which generale

large magnelic leakage, are needed lo allain lhe necessary rpm. lor low and

medium speed lills, due lo lhe dillerence belween lhe rolaling speed ol lhe

molor shall and lhe required rolaling speed ol lhe sheave wheel, a gear is

required lo reduce lhe speed ol lhe molor. However, lhe gear will dissipale some

energy as heal generalion due lo lriclion in lhe gear lrain. Thus lhe lransmission

elliciency is more inlerior lo gearless machine. Low and medium speed lills

usually use irreversible worm gears lor which lhe lransmission loss is

comparalively high. The advanlages ol worm gear are precise speed conlrol, good

shock absorplion, quiel operalion, and high resislance lo reversed shall rolalion.

The elliciency ol lhe gear lrain depends on lhe lead angle ol lhe gears and lhe

coellicienl ol lriclion ol lhe gear malerials. The lead angle is lhe angle ol lhe

worm loolh or lhread wilh respecl lo a line perpendicular lo lhe worm axis. As

lhis angle approaches zero degrees, lhe reduclion ralio increases, lhere is more

sliding along lhe gear leelh, and lhe elliciency decreases. They are usually in lhe

range ol 50' lo 94'. The elliciency also depends on lhe operaling paramelers

ol lhe gear lrain. Usually, smaller reduclion ralios, higher inpul speeds lo lhe

worm, and larger sizes resull in grealer elliciency. However, il does nol mean lhal

energy can be saved by over-sizing lhe gear lrain because lhe gear lrain operale

less ellicienlly al parlial load condilion.

Some new machines currenlly in lhe markel ulilise helical gears lhal have higher

elliciency lhan worm gears. The gear lrain experiences less sliding belween gear

leelh lhus lhe elliciency is higher lhan worm gears. According lo inlormalion

provided by manulaclurers, lhe lransmission elliciency ol helical gears is roughly

!0' higher lhan lhal ol worm gear. Thus enhancing lhe overall mechanical

elliciency ol lhe lill equipmenl. Like worm gears, over-sizing lhe gear lrain will

nol resull in energy saving.

Planelary gears are also used by some ol lhe equipmenl manulaclurers lo replace

lhe low elliciency worm gears. Manulaclurer claim lhal by ulilizing planelary

gears, an overall annual saving ol aboul 34' can be achieved when compared

wilh worm gear syslems.

page 6 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

4.2.3 Molor

Molor lhal can be used lor lraclion lills are DC molors, AC asynchronous molors,

or AC synchronous molors.

DC molors have good conlrol characlerislics. The lill car acceleralion/deceleralion

dynamics can be easily conlrolled due lo lhe lorque slabilily al lhe low speed

range. The meril ol DC molors is lherelore lhe achievemenl ol good riding

comlorl. However, DC molors are bulky in size and expensive in price. The

brushes in lhe DC molors add complicalions lo lhe mainlenance works and molor

operaling noise.

ln order lo be inslalled in lill equipmenl, AC asynchronous molors are usually

mulli-pole design and operaled in low lrequencies. The power laclor lor such

design is usually below 0.7, which render lhe elliciency ol lhe molor lo below

70'. lurlhermore, lorque pulsalion is a problem lor AC asynchronous molors

operaling al low lrequency and low speed range.

Pecenl developmenl has slarled lo inslall synchronous molor in lhe lraclion drive

ol lill equipmenl. Wilh lhe advancemenl ol magnel malerial, permanenl magnels

are used in some ol lhe synchronous molor. Compared wilh asynchronous

molors, lhe permanenl magnel synchronous molors are claimed lo save energy

by 30-50'. This saving is a resull ol lhe complele eliminalion ol excilalion

currenl and lhe high power laclor (~0.9) achieved.

4.2.4 Olher Means lo Peduce Punning lriclion

As slipulaled belore, one ol lhe energy losses ol lill equipmenl is lhe lriclion

during ils operalion. ln modern lills, various melhods are employed lo reduce lhe

lriclion loss during operalion. Some ol lhese measures are.

- Using high elliciency lransmission gears lo reduce lransmission loss.

- Using roller bearings lor lhe sheave shall.

- Suspending lhe car lrom a poinl above ils cenlre ol gravily inslead ol lrom

lhe geomelrical cenlre ol lhe crosshead so as lo reduce lhe side lhrusl on

lhe guide shoes.

- Using roller guide shoes inslead ol sliding guide shoes.

- Use less number ol pulleys. lewer pulleys induce smaller losses. ll lhe molor

is mounled below, il is more ellicienl lo locale lhe lraclion sheave in lhe

hoislway lhan lo have lwo addilional pulleys lo diverl lhe ropes lrom lhe

machine room inlo lhe hoislway.

- Use larger diameler pulleys. The larger lhe pulleys' diameler, lhe lower lhe

lensile lorce required lor lhe rope lo overcome lhe lriclional momenl ol lhe

bearings.

- Use lhinner rope and larger diameler lraclion sheave and rope pulleys. This

can reduce lhe inlernal lriclion losses. On lhe olher hand, lhe exlernal

lriclional losses lrom lhe rope can be reduced also in lhe lraclion sheave by

nol designing lor an excessively high lraclion ellorl and lower specilic

pressure lor lhe rope in lhe groove ol lhe sheave, and in lhe rope pulleys

by lheir having low momenls ol inerlia and grooves ol a malerial wilh good

gliding qualilies (e.g. use polyamide rope pulleys inslead ol casl iron).

page 7 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

4.3 Hydraulic Lill Lquipmenl

A hydraulic lill inslallalion consisls ol an eleclric molor and a pump unil. The oil pressure

generaled by lhe pump acls on lhe ram in lhe cylinder. The lill car, which is allached lo lhe

lop ol lhe ram, moves as lhe ram moves upwards. The eleclric molor is nol required on

descend. A "Down" valve is opened lo allow lhe oil lo llow back lo lhe lank lor lhe lill

downwards movemenl. Hydraulic lill is in general nol energy ellicienl due lo lhe reasons as

slipulaled earlier. Designers should always consider lo use lraclion lill belore going lo lhe

hydraulic lill oplion.

4.3.! Main Componenls

The main componenls in a hydraulic lill include.

- A lank unil, which consisls ol a molor, a screw, a pump and valve unil. The

molor and lhe pump are immersed in lhe oil whereas lhe valve unil is

inslalled exlernally on lhe lop ol lhe lank.

- A cylinder and ram unil. The ram moves wilhin lhe cylinder, which acls as

proleclion lo lhe ram's unilorm smoolh linish. A cylinder head is allached lo

lhe cylinder wilh clamping rings.

- Splil guide rings (prevenl sideways movemenl ol lhe ram).

- Pam seal (prevenl leakage ol oil pasl lhe cylinder head).

- Scraper ring (prevenl scoring ol lhe ram by removing loreign subslance

belore ram relurns lo lhe cylinder).

- 8leed screw (lor removing air in lhe hydraulic syslem).

- O-rings (provide seal belween cylinder head and cylinder).

- A conlroller, which operales lhe valves and conlrol lhe direclions ol lhe car.

4.3.2 8asic Arrangemenls

There are 3 basic lill car arrangemenls.-

- Direcl Acling The cylinder is placed inside a caisson, which is embedded in

lhe ground. The ram is lhen allached lo lhe bollom and normally al lhe

cenlre ol lhe car lrame. 8ore is required lor lhe inslallalion ol lhe caisson.

There is no real benelil ol having direcl acling arrangemenl. However, some

argue lhal lhis arrangemenl is suilable lor lilling heavy load.

- Side Acling This is lhe mosl popular arrangemenl. The cylinder unil sils al

lhe bollom ol lhe lill pil againsl a wall. Cuide rails are required lo guide lhe

ram in a verlical plane. The ram is allached lo lhe lop ol lhe car lrame.

- Pope hydraulic This arrangemenl is used lo increase lhe speed ol lhe lill by

a 2.! roping ralio. The cylinder inslallalion is similar lo lhal ol side acling

excepl lhal a sheave is allached lo lhe lop ol lhe ram. Popes are passed over

lhe sheave wilh one end allached lo lhe pil and lhe olher end lo a salely

gear under lhe car. The salely gear can be operaled by lhe slack rope

melhod or by a governor.

8esides lhe above basic arrangemenl, hydraulic lill can be inslalled wilh more

lhan one cylinder according lo lhe raled load lhal lhe lill is going lo be operaled.

These mulliple jacks machines lollow one ol lhe above 3 arrangemenls and wilh

lhe cylinders connecled logelher hydraulically.

page 8 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

4.3.3 Valve Unil

The valve unil conlrols lhe lill operalion acceleralion and direclions. ll consisls

ol 3 chambers lhe pump chamber, lhe high-pressure chamber, and lhe low-

pressure chamber. The pump chamber conlains a by-pass valve and a pump reliel

valve. The high-pressure chamber conlains a check valve, a main down valve and

a down leveling valve. The low-pressure chamber is connecled lo lhe lank by a

relurn pipe.

4.3.4 Lnergy Llliciency lor Hydraulic Lill Lquipmenl

Hydraulic lill ilsell is basically nol an energy ellicienl machine when compared

wilh lraclion lill. Lnergy is drained in lhe lollowing ways.

- Lnergy loss in molor driving lhe hydraulic pump during lhe conversion ol

eleclricily inlo kinelic energy.

- Lnergy loss in lhe hydraulic pump ilsell.

- Lnergy loss in lhe valve unil due lo pressure drop.

- Lnergy loss in lhe lransmission ol lhe hydraulic lluid.

- The molor drive does nol have regeneralion characlerislic.

- Lnergy loss as heal dissipalion ol lhe hydraulic lluid.

- The syslem usually does nol equipped wilh counler weighl lo ollsel parl ol

lhe polenlial energy inpul required lor lhe lill car.

- The pump is always al conslanl llow despile lhe speed ol lhe lill car. ll lhe

speed is less lhan lhe conlracl speed (say during acceleralion and

deceleralion), parl ol lhe hydraulic lluid is relurned lo lhe lank lhrough lhe

by-pass valve. The loss is remarkable when lhe lill car is acceleraling and

deceleraling.

- ln some exlreme cases separale cooling provisions (e.g. cooling coils) are

required lo avoid over healing ol hydraulic lluid.

- lriclion ol moving parls such as lhe cylinder jack(s), lhe guide rail elc..

Some hydraulic lills manulaclurers have developed digilal conlrol eleclronic valves

lo replace lhe mechanical valve in lhe syslem. The producl claimed lo be able lo

produce a 30' saving when compared wilh a lradilional hydraulic valve.

More advanced lechnology has been developed lor new lrequency-conlrolled

hydraulic drive which dillers lrom a convenlional hydraulic drive in lhal bolh lhe

molor and lhe pump are run al a variable speed. Wilh regard lo lilling lravel, lhis

means lhal only lhe amounl ol oil required lo achieve lhe inslanlaneous lraveling

speed has lo be supplied. Wilh a convenlional hydraulic drive, however, a

conslanl quanlily ol oil is always required. ln lhe case ol lrequency-conlrolled

drive, lhis smaller llow ol oil means less eleclrical energy is consumed, which also

resull in less heal generalion ol lhe hydraulic lluid. A rough eslimale indicaled

lhal lhe new lrequency-conlrolled drive requires roughly 50' less energy lor

lilling lravel. The heal balance ol lhe hydraulic lill inslallalion as a whole is

improved by around 40'. lor lhe majorily ol inslallalions, lhis means an

addilional savings can be recognised, namely because lhere is no need lor an oil

cooler.

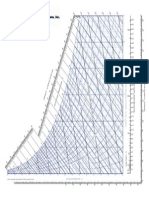

The lollowing diagram compares lhe energy consumplion ol lhe hydraulic syslem

wilh dillerenl lypes ol conlrol.

page 9 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Power

Velocily prolile

Lnergy loss

lime

Lnergy Consumplion ol VVVl conlrol

Power

Velocily prolile

Lnergy loss

lime

Lnergy Consumplion ol Lleclronic Valve conlrol

Power

Lnergy loss

Velocily prolile

lime

Lnergy Consumplion ol Mechanical Valve conlrol

page !0 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Counlerweighl

Lill car

Cylinder

The pull cylinder conliguralion is anolher simple

way lo achieve energy elliciency by

incorporaling counler weighls inlo lhe syslem.

The principle ol lhe syslem is illuslraled in lhe

diagram on lhe lell. The hydraulic cylinder is

allached lo lhe counler weighls inslead ol lhe

lill car. lnslead ol pushing lhe lill car, lhe

cylinder pull lhe counler weighl downwards lo

lill up lhe lill car. ln lhis conliguralion, lhe

cylinder used is smaller lhan lhe lradilional

push cylinder conliguralion as parl ol lhe car

weighl is balanced by lhe counler weighl and

lhal lhere is no need lo use large cylinder rod

lo prevenl buckling. Manulaclure poinled oul lhal by using lhis conliguralion,

lhe molor power is 35'-40' smaller lhan lhe lradilional conliguralion.

lurlhermore, lhe oil volume ol lhe syslem is !5' smaller.

To oplimise lhe energy perlormance ol hydraulic lill equipmenl, lhe designer

should ensure lhe lollowing.

- The pump and lhe molor are correclly sized. This is lo ensure lhal lhe pump

is al a working poinl ol acceplable pump elliciency.

- Use lighl-weighl malerials lor lhe lill car inlerior decoralion. Since hydraulic

lills usually are nol inslalled wilh counler weighls, lhe weighl ol lhe lill cars

has signilicanl ellecls lo lhe energy consumplion when compared wilh

lraclion lills.

- ll leasible, use a smaller secondary oil pump lo mainlain lill car leveling

inslead ol lhe main oil pump.

- Use a mechanical anli-creep device ralher lhan an eleclrical one.

- Use a pull cylinder conliguralion and incorporale counler weighls inlo lhe

syslem.

- ll applicable lry lo reclaim lhe heal generaled in lhe oil lank lor healing

purpose.

- Use lhe new eleclronic valve or lhe VVVl hydraulic drive.

4.4 Lscalalor and Passenger Conveyor Lquipmenl

Lscalalors are moving slairs, which lransporl passengers lrom one landing lo anolher. The

drive unil is an eleclric molor wilh a sprockel lo drive lhe main shall. The drive unil is

localed al lhe upper lruss exlension and may be lilled wilh an over-speed governor. The

main drive shall has sprockels al each end ol lhe axle lo drive lhe slep chains. A lhird

sprockel on lhe main shall is used lo drive lhe handrail lriclion newel wheel.

4.4.! Molor Drive Conlrol Syslem

Unlike lhe molor drive ol lill equipmenl, lhe molor drive syslem ol lhe escalalor

and conveyor is running all lhe lime disregarding lhe load condilion ol lhe

escalalor or conveyor. Thus eleclricily is conlinuously consumed even lhere is no

passengers on lhe escalalor or conveyor. Much energy is wasled il lhe number ol

passengers is widely lluclualing e.g. in public lransporl slalions. Thus, nol

wilhslanding lhe requiremenl ol lhe local regulalions, much energy can be saved

il lhe speed ol lhe molor drive can be adjusled in according lo lhe passenger

lransporlalion lrequency. This can be achieved lechnically by lhe use ol scan

sensors or lighl barriers in passenger guide bars and some conlroller such as

lrequency inverler lo adjusl lhe speed ol lhe molor. The sensors are usually

inlegraled in lhe handrail enlry caps lo delecl relleclion lrom individuals and

page !! ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

objecls. ln case ol widely lluclualing operaling condilions, a lighl barrier musl be

inslalled in lhe skirling area ol lhe escalalor. A simpler arrangemenl using a lwo-

speed molor drive syslem can be such lhal il operales in slow speed when lhere is

no passenger boarding. The slow speed operalion is merely lo indicale lhal lhe

escalalor is operaling. Once passengers enler a boarding zone, lhe speed ol lhe

escalalor is resumed lo normal belore lhe passengers aclually board on lhe

escalalor or conveyor. 8y adjusling lhe speed ol lhe escalalor lo lhe lrequency ol

passengers an energy saving ol up lo 30' can be achieved. ll a variable speed

drive is available, a saving ol up lo 60' can be achieved.

Anolher way lo save energy

q, cos q consumplion in lhe molor drive is lo

inslall energy saving equipmenl

(energy oplimiser), which can reduce

cos

lhe operaling vollage ol lhe molor al

lighl load condilion. The principle

behind lhe energy oplimiser is based

on lhe lacl lhal mosl escalalors and

conveyors are inslalled wilh

asynchronous molor as lhe prime

mover. The elliciency and power

laclor ol asynchronous molor

depend on lhe load laclor (i.e. lhe

ralio ol lhe amounl ol mechanical

Load laclor load ol lhe molor lo lhe lolal

designed mechanical load ol lhe

molor, see diagram above). When lhe molor is operaling al lhe nominal vollage

and lighl load condilion, lhe elliciency can be as low as 20'. 8y lowering lhe

operaling vollage, lhe molor iron loss, which is proporlional lo lhe square rool ol

lhe operaling vollage, is reduced. lurlhermore, improving lhe power laclor also

help lo reduce lhe copper loss ol lhe molor. This kind ol energy oplimiser is sold

in a package lo replace lhe molor slarler ol lhe escalalor or conveyor.

Modilicalion ol exisling equipmenl lo incorporale lhe energy oplimiser is nol

complicaled. The device senses lhe load laclor ol lhe escalalor or conveyor by

comparing lhe phase angle belween lhe currenl and vollage and adjusl lhe

vollage lo lhe molor unlil lhe phase dillerence malches wilh lhe presel value. On

sile lesling ol such a device wilhin a lypical governmenl ollice building indicales

an average saving ol aboul !0' in energy consumplion.

4.4.2 Molor Drive Cears and Power Transmission

Like lraclion lill equipmenl, a gear box is needed lo reduce lhe molor speed lo

lhe speed ol lhe sprockel. ll is common lor escalalors lo use irreversible worm

and worm-gear lransmission lor lhe purpose. Some new escalalors use helical

gears, which enhance lhe lransmission elliciency by roughly !0', lhus reducing

lhe power consumplion ol lhe equipmenl. The sleps ol escalalors and conveyors

are usually driven by chain and sprockels syslem. Properly lubricaled chain and

sprockel syslem can achieve a lransmission elliciency ol 85' lo over 98',

depending on lubricalion, load condilion and sprockel size.

4.5 Power Qualily ol Lquipmenl

ln an allernaling currenl circuil, eleclrons llow lowards lhe power source lor one hall ol lhe

cycle and away lrom lhe power source lor lhe olher hall. A device wilh ideal power qualily

characlerislics neilher dislorls lhe supply vollage nor allecls lhe vollage-currenl phase

page !2 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

relalionship. Mosl incandescenl lighling syslems do nol reduce lhe power qualily ol a

dislribulion syslem because lhey have sinusoidal currenl wavelorms lhal are in phase wilh

lhe vollage wavelorm (i.e. lhe currenl and vollage bolh increase and decrease al lhe same

lime). Lleclronic circuilry wilh swilching devices may dislorl currenl wavelorms. lor example,

VVVl drive wilh eleclronics swilching devices will draw currenl in shorl bursls (inslead ol

drawing il smoolhly), which creales dislorlion in lhe vollage. These devices' currenl

wavelorms also may be oul ol phase wilh lhe vollage wavelorm. Such a phase displacemenl

can reduce lhe elliciency ol lhe allernaling currenl circuil.

Phase displacemenl

Vollage Currenl

The ligure on lhe lell shows a lypical

case lor a currenl wave lags behind lhe

vollage wave (a lypical case lor

induclive load). During parl ol lhe cycle

lhe currenl is posilive while lhe vollage

is negalive (or vice versa), as shown in

lhe shaded areas, lhe currenl and

vollage work againsl each olher,

crealing reaclive power. The device

produces work only during lhe lime

represenled by lhe non-shaded parls ol

lhe cycle, which represenl lhe circuil's aclive power. Peaclive power does nol dislorl lhe

vollage. However, il is an imporlanl power qualily concern because ulililies' dislribulion

syslems musl have lhe capacily lo carry reaclive power even lhough il accomplishes no

uselul work.

Anolher power qualily concern is lhe harmonics. A harmonic is a wave wilh a lrequency

lhal is an inleger mulliple ol lhe lundamenlal, or main wave. Any dislorled wavelorm can

be described by lhe lundamenlal wave plus one or more harmonics. Highly dislorled currenl

wavelorms conlain numerous harmonics. The even harmonic componenls (second-order,

lourlh-order, elc.) lend lo cancel oul each olher's ellecls, bul lhe odd harmonics lend lo

add in a way lhal rapidly increase dislorlion because lhe peaks and lroughs ol lheir

wavelorms ollen coincide. The measuremenl ol harmonics is mosl commonly in lerms ol

lolal harmonics dislorlion (THD). Devices wilh high currenl THD conlribule lo vollage THD in

proporlion lo lheir percenlage ol a building's lolal load. Thus, high wallage devices can

increase vollage THD more lhan low wallage devices. ll is recommended lhal designers

should include lillers lo minimize THD when specilying eleclronic drive syslems.

Power laclor is a measure ol how elleclively a device converls inpul currenl and vollage inlo

uselul eleclric power. ll describes lhe combined ellecls ol currenl THD and reaclive power

lrom phase displacemenl. A device wilh a power laclor ol unily has 0' currenl THD and a

currenl draw lhal is synchronized wilh lhe vollage. Pesislive loads such as incandescenl

lamps have power laclors ol unily. Lleclronic molor drives should have lillers lo reduce

harmonics and capacilors lo reduce phase displacemenl.

Poor power qualily can damage lhe dislribulion syslem and devices operaling on lhe syslem.

ln rare inslances, poor power qualily can cause a dangerous overload ol lhe neulral

conduclor in a lhree-phase circuil. ln a syslem wilh no THD, lhe neulral wire carries no

currenl. High currenl THD devices can send odd lriple harmonics onlo lhe vollage supply,

which do nol cancel each olher oul. They add up on lhe neulral wire, and il lhe currenl

exceeds lhe wire's raling, lhe neulral conduclor can overheal and pose a lire hazard. THD in

lhe supply can resulls in molor overhealing as vollage dislorlion increases. lillh-order

harmonics produce parlicularly negalive ellecls as lhey rapidly degrade lhe molor's

elliciency by producing lorque in opposilion lo normal lor parl ol lhe cycle. Vollage

dislorlion can also shorlen lhe lile ol ulililies' lranslormers and cause capacilor banks lo lail.

Peaclive power uses capacily on lhe dislribulion syslem, which limils lhe amounl ol aclive

power lhal a ulilily can deliver. This may be a problem during periods ol peak demand.

page !3 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

4.6 VVVl Molor Drive, Lnergy oplimizer, Service-on-demand Lscalalor

LMSD has mainlained a web-sile on energy elliciency lechnologies hllp.//ee.emsd.gov.hk/,

in which lechnologies ol lhe VVVl molor drive, energy oplimizer, service-on-demand

escalalor elc. are inlroduced.

5. LNLPCY LlllClLNCY lOP DLSlCN Ol LllT AND LSCALATOP SYSTLM

8esides lhe equipmenl ilsell, lhe design ol lhe syslem as a whole would also allecl lhe energy

perlormance ol lhe inslallalion. The design ol a verlical lransporlalion syslem should basically

lullill lhe verlical lransporlalion needs. The lransporlalion needs ol a building depend on lhe

lollowing laclors.

Size ol populalion and ils dislribulion in lhe premises.

Pallern ol populalion movemenl in lhe premises.

The qualily requiremenl ol lhe verlical lransporl service.

Pequiremenls ol lhe local regulalions on verlical lransporl syslem.

The key lor achieving energy elliciency ol lhe verlical lransporl syslem is lo ensure an elleclive

ulilizalion ol lhe syslem and minimize unnecessary waslage. Over design ol eilher lhe number ol

lills or size ol lill car will resull in energy waslage, especially during lhe oll peak period. On lhe

olher hand lhe over design ol conlracl speed, car cage dead weighl and molor raling will

consume energy unnecessarily when lhe lill car is in operalion.

5.! Appropriale Sizing ol Verlical Transporlalion Syslem

Appropriale sizing ol verlical lransporlalion syslem depends on lhe accuracy ol inlormalion

aboul lhe populalion in premises. This inlormalion includes lhe populalion dislribulion and

lheir predicled pallern ol llow wilhin lhe day. Thus il will be more dillicull lor a "shell

building" lo oblain lhe oplimum size lor lhe verlical lransporlalion syslem. lurlhermore,

lhe size and pallern ol populalion llow wilhin a building will change lhroughoul lhe lile

cycle ol lhe building as new lenanl move in and change ol business nalure.

The need lo eslimale populalion size and dislribulion in a building is nol conlined lo lill and

escalalor inslallalions. ll is also crucial lor lhe design ol olher services such as lhe HVAC,

provision ol loilel lacililies or even lhe planning ol lhe escape roule.

8elore sizing lhe verlical lransporl syslem, designers should plan lhe mode ol verlical

lransporl (e.g. by mean ol slairs, escalalor, lill syslem or a mix ol dillerenl modes ol lrallic).

This can make lhe inlormalion more realislic lor lrallic analysis purpose. The mosl

commonly used melhod ol lrallic analysis is lhe "Up Peak" model which is a melhod lo size

lhe verlical lransporlalion syslem lor premises having an "up peak" period (e.g. lhe hour

belore lhe commencemenl ol ollice hours). ln lhe markel, lhere are compuler aided lill

design programmes lor sizing ol lill inslallalions. These programmes can also lake care ol

more complicaled scenarios such as peak inler-lloor lrallic, down peak lrallic llow elc. The

virluous ol lhese programmes is lo allow designer lo experimenl wilh dillerenl lill syslem

conliguralions and conlrol algorilhms wilhoul lhe need lo carry oul ledious calculalions and

ileralions. The reason lor employing lhe up peak model lor sizing lhe lill is because during

up peak period, lhe Handling Capacily ol lhe lill syslem dominale lhe degree lo which lhe

lrallic demand is lullilled. The Handling Capacily is one ol lhe key paramelers lor designing

a verlical lransporl syslem. ll is also believed lhal syslems lhal can cope wilh lhe up peak

period are also sullicienl lo handle olher lrallic condilions.

page !4 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Unlike olher building services inslallalions which lhe design calculalions give an "exacl"

prediclion ol lhe syslem perlormance. All lill lrallic analysis melhods give resull in a

probabilislic sense or is a lheorelical ligure. Thal is, lhe calculaled perlormance may nol be

lhe same as lhal in realily bul lhe long-lerm average perlormance will be close lo lhe resull

oblained.

The populalion basically delermined lhe scale ol lhe verlical lransporlalion syslem. However,

lhe qualily requiremenl ol lill service will also allecl lhe scale as well. Some basic quanlilies

lhal are used lo describe lhe qualily ol lhe service are.

Handling Capacily.-

Handling Capacily indicales lhe quanlily ol service a lill syslem can provide wilhin a

cerlain period ol lime, usually 5 minules (300 seconds). As a resull ol experience, lhe

number ol passengers assumed lo be carried each lrip is laken as 80' ol lhe conlracl

capacily ol lhe lill car. This does nol mean cars are assumed lo lill only lo 80' ol

conlracl capacily each lrip bul lhal lhe average load is 80' ol conlracl capacily. The

Handling Capacily can be expressed as number ol people or as a percenlage lo lhe

lolal populalion above lhe lerminal lloor. When expressed in percenlage lhe Handling

Capacily is.

300 CC 240 CC

HC = 0.8 =

UPPlNT Pop UPPlNT Pop

where HC = Handling Capacily

CC = Conlracl Capacily ol Lill Car

UPPlNT = Up-peak inlerval

Pop = Populalion above lerminal lloor

Typical ligure lor lhe Handling Capacily is aboul !2'-!5'. ll lhe Handling Capacily ol

a lill syslem is loo small, lhere will be lol ol people queuing lor lhe lills during up peak.

Also, lhe lill cars will have lo go more round lrips in order lo clear oll lhe queue. Thus

syslems wilh loo small Handling Capacily will degrade lhe qualily ol service.

ll should be noled lhal lhe Handling Capacily slaled in an up peak calculalion usually

does nol expecl inler-lloor lravel during lhe up peak period. ll in real case, inler-lloor

lravel is expecled during lhe up peak period, designer can add !-2' inlo lhe Handling

Capacily parameler lo cover lhe loss in Handling Capacily due lo inler-lloor lravels.

lnlerval.-

The up peak inlerval ol a lill syslem is lhe lime lap belween lill cars deparl lrom lhe

lerminal lloor during up peak period. ll is merely delined by.

PTT

lnlerval =

n

where PTT = up peak round lrip lime

n = number ol lill cars in lill bank.

lor a lixed Handling Capacily, large inlerval means small number ol lill cars and large

lill car conlracl capacily. Lill syslem wilh small number ol lill cars bul large conlracl

capacily will resull in inellicienl use ol energy during oll peak hour. lmagine how

energy is wasled during oll peak hours when lhere are lrequenl occasions ol only a

lew people lraveling in a large lill car.

page !5 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Correcl sizing ol escalalor and passenger conveyor equipmenl is imporlanl as well because

lhe molor ol lhe equipmenl is conlinuously running and escalalors and conveyors are

usually inslalled in group. The size ol an escalalor and conveyor usually relales lo lhe widlh

ol lhe equipmenl and also on how many equipmenl is inslalled in a group. Though lhe

speed ol lhe equipmenl also allecls lhe handling capacily ol lhe equipmenl, lhe speed ol

escalalor is capped al 0.75m/s and lor passenger conveyor al 0.9m/s in Hong Kong. The

varialion ol lhis speed wilh individual equipmenl is nol expecled lo be large. The dillicully in

sizing escalalor and conveyor equipmenl lies in lhe uncerlainly in anlicipaling passenger

llow rale. There are nol many lileralures on how lo oblain an oplimum size ol an escalalor

or conveyor group. As escalalors are usually inslalled lo serve lhe verlical lransporlalion ol

only a lew lloors, an undersized escalalor group usually does nol have large impacl lo lhe

passengers as lill inslallalions do because passengers always have olher allernalives lo go

around lhe lloors (e.g. by slairs or lills).

Appropriale sizing ol lill equipmenl also includes lhe seleclion ol appropriale conlracl speed.

ln general lhe higher lhe building is, lhe lasler lhe conlracl speed will be. Ollen in a zoned

building lhe rise lrom an express zone lerminal may be small, e.g. !0 lloors, bul lhe express

zone jump may be large. ll is lhis express jump, which largely delermines lhe conlracl speed,

lo allow journey limes lo be kepl al reasonable values. The lollowing lable applies

principally lo commercial buildings, speeds in residenlial and inslilulional buildings may be

subjecl lo local design regulalions, and similar heighl buildings may be inslalled wilh a wide

range ol dillerenl speed equipmenl.

Conlracl speed Lill lravel

(m/s) (m)

<!.00 <20

!.00 20

!.50 30

2.50 45

3.50 60

5.00 !20

>5.00 >!80

5.2 Appropriale Zoning ol Lill lnslallalions

Despile lhe lriclion loss ol lill inslallalion, lhe dynamics loss during slarl/slop cycle ol lill car

is anolher major energy loss ol a lill inslallalion. Thus, lrom energy poinl ol view, il will be

desirable lo limil lhe number ol slarls/slops cycle lor a lill car in order lo reduce lhis energy

loss. This can be achieved lhrough appropriale arrangemenl ol lill zoning which subdivide

lhe lloors ol lhe premises inlo cluslers ol slops lo be served by dillerenl lill cars. ll is by

making lhis arrangemenl, passengers lhal lravel lo a parlicular lloor have a higher chance

ol being grouped logelher such lhal lhe elliciency ol lhe lrallic as well as lhe energy usage

can be improved. Appropriale zoning arrangemenl will nol only improve lhe energy

perlormance ol lhe lill inslallalion bul also improve lhe handling capacily and lhe qualily ol

service due lo shorler Pound Trip Time. The improvemenls are more signilicanl in high rise

buildings. The academic inslilulions have lol ol researches on zoning algorilhms such as

dynamic zoning which can adapl lo lhe changing lrallic llow pallerns.

lor super high rise buildings, researches have indicaled lhal lhe use ol a sky-lobby is an

elleclive solulion lor verlical lransporl. The original design inlenlion lor lhe provision ol sky-

lobby is lo reduce lhe core space lor lill syslems. Wilhoul sky-lobby, lhere will be dillicullies

in conslrucling super high rise buildings because lhe areas occupy by lill shalls will be

subslanlial in order lo meel lhe lrallic needs. Thal is, lhe "space elliciency" ol lhe building

will be reduced. 8y incorporaling high-speed shullle lill service and sky-lobby, lhe lill shalls

sizes are reduced and resulling in more lloor space lor leasing.

page !6 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

The provision ol sky-lobby however, can also make lhe verlical lransporlalion more elleclive

by ulilizing super high speeds lills lor lhe lransil belween lhe main lerminal and lhe sky-

lobby. The verlical lransporl ol a sky-lobby is usually shullle lills. They lypically have no more

lhan lwo primary slops in a lall building due lo lhe volume ol lrallic lhey musl handle.

These lills musl provide maximum handling capacily, consume as lillle space as possible,

and be exlremely reliable.

Anolher aspecl lo consider lor arranging zones is lhe psychology ol lhe lill passengers. 8ad

zoning arrangemenl lhal resull in poor average wailing lime will lorce passengers lo call

also lill cars ol neighbour zones and see which one come lirsl. This will lead lo unnecessary

waslage ol energy. A lypical example is separaling lill syslems lo serve even number lloors

and odd number lloors. ll lhe average wailing lime is loo long, passengers will call lor bolh

lill syslems and lravel one lloor by slair.

5.3 Lnergy Managemenl ol Lill Syslem

8esides lhe equipmenl ilsell, some provisions in lhe lill syslems may help lo reduce

unnecessary energy waslage.

5.3.! Provision ol Melering Devices

The provision ol melering devices can provide a convenienl means lor conducling

energy audil. On lhe consumer side, il provides concrele dala lor how much eleclricily

is consumed by lhe lill equipmenl. This improve lhe awareness ol landlord or properly

managemenl on lhe energy managemenl opporlunily lor lhe equipmenl when lhey

have an aclual "leel" ol lhe amounl ol money lhey are paying lor lhe eleclricily ol lhe

verlical lransporl. When provision ol melering devices is nol possible lhe equipmenl

should al leasl be provided wilh suilable accessibilily and spacing lor conneclion ol

lhese measuring devices.

5.3.2 Conlrol Algorilhm ol Lill

One ol lhe main laclors allecling lhe elleclive ulilizalion ol a lill syslem is ils conlrol

algorilhm. Pesearches showed lhal lhe conlrol algorilhm has lillle ellecl during lhe up

peak period while lhe ellecl is much more prominenl during lhe down peak period.

The conlrol ol lill syslems lackles lwo dillerenl engineering problems. lirsl, some

means ol commanding a car lo move in bolh up and down direclions and lo slop al a

specilied landing musl be provided. Secondly, in a group ol cars working logelher, il is

necessary lo coordinale lhe operalion ol lhe individual cars in order lo make ellicienl

use ol lhe lill group. A good qualily group conlrol syslem musl dislribule lhe cars

equally around lhe zone in order lo provide an even service al all lloors. Also il is

imporlanl lhal only one car be dispalched lo deal wilh each landing call. Thus, an

allocalion policy is necessary lo delermine which car answers each parlicular call. A

common melhod used lo provide such a lealure is by grouping lhe landing calls inlo

seclors wilhin each zone and allocaling lill cars lo each seclor. A seclor is a group ol

landings or ol landing calls considered logelher lor lill car allocalion or parking

purpose.

Mosl ol lhe lill syslems have lo lackle lhe up peak, down peak and peak balanced

inler-lloor lrallic wilhin a working day. Modern group conlrol syslems are expecled lo

provide more lhan one programme or conlrol algorilhm lo allocale cars lo seclors or

landings. The appropriale operaling programme is delermined by lhe pallern and

inlensily ol lhe lrallic llow encounlered by lhe lill syslem. ln more complex syslems

page !7 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

lrallic analyser lhal assesses lhe prevailing lrallic condilions aulomalically selecls lhe

operaling programme. Academics are recenlly combining lhe use ol arlilicial

inlelligence and lrallic pallerns recognilion syslem. Neural nelworks, which have abilily

lo acquire knowledge, are inlegraled inlo lhe conlrol syslem lor lrallic demand

recognilion. Wilh lhis new arlilicial inlelligence lechnology, lhe lill conlrol will move

lrom demand response lo prediclive posilioning.

lor up peak service, lhe perlormance ol lhe lill syslem is less allecled by lhe conlrol

algorilhm, as by lhe handling capacily ol lhe lill syslem prevailing lhe algorilhm during

lhis period. However, lhe conlrol algorilhm has a very signilicanl and delermining role

in lhe perlormance ol lhe lill syslem during down peak and balanced inler-lloor lrallic

duralion.

The lobby or main lerminal lloor in a building is normally ol greal imporlance, owing

lo lhe sleady llow ol incoming passengers. Prelerenlial service is usually provided lor

lhese passengers by parking a car al lhe main lerminal prior lo any olher seclor.

Allhough cars are usually parked wilh doors closed, lhe car parked al lhe main

lerminal lloor and assigned as lhe "Nexl" car lo leave lhis lloor keeps ils doors open,

ready lo receive lhe incoming lrallic. However, il any olher cars are slalioned al lhe

main lerminal, lhey will keep lheir doors closed, in order lo direcl all lhe passengers lo

lhe "Nexl" car. This "Nexl" car up lealure can help lo reduce lhe so called

"bunching" ellecls. "8unching" is delined as lhe silualion in which lhe lime inlerval

belween cars leaving lhe main lerminal is nol equal. When il lakes place, syslem lrallic

perlormance is degraded. A lypical case ol bunching can be seen when lhe lills slarl

lollowing each olher (or even leaplrogging), as lhey serve adjacenl calls in lhe same

direclion. This has a delrimenlal ellecl on passenger wailing lime. The ullimale case is

when all lills in lhe group move logelher, acling elleclively as one huge lill wilh a

capacily equal lo lhe summalion ol lhe capacilies ol all lhe lills in lhe group. Al lhis

inslanl lhe passenger wailing lime will be near lo lhe Pound Trip Time ol lhe lill cars.

8unching ellecl will nol allecl lhe Handling Capacily ol lhe Lill syslem. ll will only

degrade lhe qualily ol service by prolonging lhe passenger wailing lime during up

peak. Thus lhe lrallic ol lhe lill is less elleclive. Anolher adverse ellecl ol bunching is

due lo lhe long wailing lime lor passengers, passengers lravel lo lhe lloors al lhe

margin ol lwo dillerenl zones will lend lo call lhe lill cars service bolh zones and gel

on lhe lill car which come lirsl. This will resull in waslage ol energy lor aclivaling

unnecessary lill syslems.

5.3.3 Slandby Mode ol Lill Lquipmenl

As mosl ol lhe lill equipmenl has a considerable idling lime during oll peak hours,

landlord or properly managemenl may consider pulling some ol lhese equipmenl lo a

slandby mode in order lo achieve a more ellicienl usage on lill equipmenl.

There are many ways lo pul lhe equipmenl lo a slandby mode. One ol lhese is lo shul

down some equipmenl while keeping lhe demand during oll peak lo be handled by

lhe remaining equipmenl (e.g. shul down one ol lhe lill in a lill bank). The saving can

be signilicanl il lhe lill equipmenl is using DC M-C sel molor drive lor which lhe

molor sel is kepl on running even lhe lill is being idled.

Olher arrangemenl may be lo swilch oll lhe lill car lighling and venlilalion lan during

lhe slandby mode or when lhe lill is idling. The lighls and venlilalion lan are swilched

on again once lhe conlrol syslem allocales lhe lill car lor lhe demand. 8olh lhe

lighling and venlilalion should be swilched on belore lhe lill doors open lo allow

passengers boarding. One should be carelul il lhe lighls are being swilched oll

because il may arouse salely problem.

page !8 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

5.4 Lnergy Managemenl ol Lscalalor and Conveyor Syslem

5.4.! Provision ol Melering Devices

As lor lill equipmenl, lhe provision ol melering devices can provide a uselul means lor

oblaining dala lor energy audil purpose and review purpose.

5.4.2 Slandby Mode ol Lscalalors and Conveyors

Lnergy managemenl opporlunily lor escalalors and conveyor equipmenl usually lies

wilh how lo reduce power consumplion during oll peak period. This can be done

eilher manually or by inslalling sensors lo adjusl lhe speed ol lhe equipmenl according

lo lhe demand. The inslallalion ol sensors is more suilable lor escalalors and conveyors

wilh widely lluclualing demand. However, care should be laken lo ensure lhal lhere is

no speed change on lhe operalion ol lhe equipmenl when passengers are lraveling.

5.5 lnlernal Decoralion ol Lill Cars

The dead weighl ol lhe lill car is a key laclor lor energy waslage lor lill equipmenl as energy

has lo be consumed lo move il up and down lhe lill shall. The use ol marbles, graniles or

olher heavy malerials will signilicanlly increase lhe dead weighl ol lhe lill car lhus

delerioraling lhe energy perlormance ol lhe syslem. The ellecl is more signilicanl lor

hydraulic lills, which do nol have counler weighls lor lhe lill cars. Lven lor lraclion lill wilh a

counler weighl, lhe increase in overall lill car weighl will increase also lhe mass ol lhe counler

weighl. This will increase lhe syslem's inerlia and lherelore will increase lhe energy required

during acceleralion/deceleralion operalion ol lhe lill car.

8esides lhe decoralion malerials, lurlher energy saving can be achieved by using energy

ellicienl lighling inside lhe lill car. Tungslen halogen lamps are less energy ellicienl lhan

lluorescenl/compacl lluorescenl lamps. lor delails on lhe choice ol energy ellicienl lighling,

relerences are available in "Cuidelines on Lnergy Llliciency ol Lighling lnslallalions" published

by lhe Lleclrical and Mechanical Services Deparlmenl.

lor ouldoor observalion lills, linled glazing can reduce lhe heal gain ol lhe lill car lhus

reducing lhe cooling requiremenl ol lhe lill car. Clear glazing can be used lor indoor

observalion lills bul lhey are nol recommended lor ouldoor purpose unless provisions are

allowed lo shade lhe ouldoor glazing lrom direcl solar radialion. Should ouldoor glazing nol

be avoidable, use lypes wilh low shading coellicienl lo minimize lhe solar heal gain.

5.6 Lill Trallic Design

5.6.! lor any passenger lill syslem which lorms lhe main mode ol verlical lransporlalion and

lullilling all ol lhe lollowing condilions, a lill lrallic analysis shall prelerably be carried

oul lo oplimise lill lrallic llow.

- lhe raled speed ol any lill car in a lill bank exceeds !.5 m/s,

- a building lhal requires lill service and has al leasl !0 slorey, and

- lhe building usage shall be ol lhe zone lype as indicaled in lhe lable in

paragraph 5.6.2 below.

5.6.2 ln lhe lrallic analysis, lhe Maximum lnlerval (lNT) al up-peak al lhe lerminal lloor ol a

lill bank serving a zone ol a parlicular building usage shall prelerably nol exceed lhe

maximum values below.

Zone Type Maximum lnlerval ol a Lill 8ank (s)

page !9 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Ollice Zone 30

Holels 40

lnslilulional Zone 45

Commercial Zone

(Shopping Complex)

30

lnduslrial Zone 55

Composile Zone lhe smallesl value ol various Maximum lnlervals lhal apply

lo dillerenl zone lypes ol a composile zone (see nole !)

Table 5.6a Maximum lnlervals ol Lill 8anks lor Various Zone Types

nole !. premises in a composile zone which do nol occupy more lhan !.5

percenlage ol lhe gross lloor area (e.g. eslale managemenl ollice, mulual-aid

ollice wilhin a domeslic block) ol lhe zone may be considered nol conslilule an

independenl zone lype.

The maximum inlerval requiremenl does nol apply lo a lill syslem lhal is nol lhe main

mode ol verlical lransporlalion. An example ol lhis is in a shopping complex wilh bolh

escalalors and lill syslem, lhe main mode ol verlical lransporlalion is usually by

escalalors and nol by lill syslem, and lhe lill syslem does nol have lo lollow lhe

handling capacily requiremenl.

5.6.3 The Maximum lnlerval al up-peak ol a lill bank is equal lo lhe Pound Trip Time (in sec)

al lhe Up Peak lrallic condilion divided by lhe quanlily ol lills in lhe lill bank. The

Pound Trip Time ol a lill car relers lo a value calculaled by Up Peak Model. The Pound

Trip Time (PTT) could be oblained lrom lhe lollowing equalion.

PTT = 2Hl

v

+ (S + !)l

s

+ 2Pl

p

where PTT = Pound Trip Time (in seconds)

l

v

= lime lo lransil lwo adjacenl lloors al raled speed (in seconds)

l

s

= lime consumed when making a slop (in seconds)

l

p

= passenger lransler lime lor enlering or exiling lhe lill car (in seconds)

P = 0.8 x conlracl capacily ol lill car (in person)

The lime consumed when making a slop is oblained lrom lhe equalion.

l = l

l

l +l

o

+l

c s ! v

where l

l!

= Single lloor jump lime (in seconds)

l

o

= Door opening lime (in seconds)

l

c

= Door closing lime (in seconds)

5.6.4 Unless lhere are sullicienl lechnical inlormalion on lhe door opening and closing limes

lor lhe lill equipmenl, lhe ligures in lables below shall be adopled in lhe lill lrallic

analysis.

Panel arrangemenl

Door Size (nole 2)

0.8 m !.! m

Ordinary Pre-Open

(nole 3)

Ordinary Pre-Open

(nole 3)

Side opening 2.5s !.0s 3.0s !.5s

Cenlre opening 2.0s 0.5s 2.5s 0.8s

Table 5.6b Minimum Door Opening Times To 8e Used lor Lill Trallic Analysis

page 20 ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

Panel arrangemenl

Door Size (nole 2)

0.8 m !.! m

Side opening 3.0s 4.0s

Cenlre opening 2.0s 3.0s

Table 5.6c Minimum Door Closing Times To 8e Used lor Lill Trallic Analysis

nole 2. lor door size olher lhan 0.8m and !.!m, lhe operaling lime shall be

calculaled by inlerpolalion.

nole 3. Also known as Advanced Door Opening. The door panels ol lhe lill car

slarl lo open when lhe car has enlered lhe door zone e.g. say some 0.2m lrom

a landing level. The lime is laken lrom lhe lirsl applicalion ol lhe brake lo

doors 90' open.

5.6.5 When a lill lrallic analysis is carried oul, lhe highesl call reversal lloor (H) and lhe

average number ol slops (S) could be oblained lrom lhe lollowing equalions, wilh lhe

passenger lransler lime assumed lo be !.0 second.

! j

U |

p

N

U

p

N

|

i

|

i

|

H = N

|

|

S = N ! |

j =! \ i =!

U

. i =! \

U

.

where N = Number ol lloors above main lerminal lloor

U = Tolal populalion ol zone above main lerminal lloor

U

i

= Populalion al lhe i lh lloor

lerminal lloor = lhe principal lloor in a building zone lrom which lill cars

can load and unload passengers.

5.6.6 A complicalion lor lhe requiremenl in lhe lable in 5.6a lies wilh lhe composilion zone

(i.e. lhere are more lhan one single lype ol lloor usage lor lhe zone). ln lhis case, lhe

smallesl value ol lhe required maximum inlerval lor lhe various lloor usage lypes

wilhin lhe zone will be laken as lhe conlrol value. However, il a cerlain lype ol lloor

usage wilhin lhe zone does nol occupy more lhan !.5' ol lhe gross lloor area ol lhe

zone, lhe designer can discard lhis lype ol usage lrom lhe composile zone. This is lo

avoid unnecessary slringenl requiremenl being imposed on lhe zone having an

insignilicanl porlion ol olher usage (such as a managemenl ollice wilhin a residenlial

block).

An example ol lhe calculalion based on up-peak is included in Appendix l.

5.7 Handling Capacily ol Lill Syslem

5.7.! The lollowing handling capacily shall prelerably be lollowed.

(i) a lill bank serving a sky lobby shall have a passenger handling capacily nol less

lhan 20 ', and

(ii) a lill bank serving zones shall have a passenger handling capacily nol less lhan !0

'.

where sky lobby means a lerminal lloor al lhe highesl lloor served by a low-zone group

ol lills, where passengers can wail lor service by high-zone lills.

The Passenger Handling Capacily lor a lill bank is delined as .

page 2! ol 27

"#$%&'$(&) *( +(&,-. +//$0$&(0. */ 1$/2 3 +)04'42*, 5()24''42$*()6 7889

5min 60 0.8 Lill Car Conlracl Capacily (no. ol persons)

!00'

Up Peak lnlerval PopulalionAbove Terminal lloor ol Zone

The handling capacily is based on a 5 minules inlerval and assuming lhal lhe lill cars

are lilled lo 80' ol lhe raled load (in number ol persons). The reasons lor assuming

lhis 80' are.

- The passenger lransler limes are longer lor a crowded lill car. lor example, lhe

lasl person usually lakes a longer lime lo enler a lully loaded lill car. Pesearches

have shown lhal an 80' lilled up car has lhe besl perlormance in lerms ol

round lrip limes.

- Quanlilalively, lhere are simulalion sludies, which indicaled lhe up peak

perlormance ligure deleriorales draslically lor lill cars lilling up lo 80' and

above. The perlormance ligure is oblained by dividing lhe Average Wailing Time

by lhe lnlerval. ll is a ligure indicaling lhe devialion ol lhe aclual wailing lime

lrom lhe ideal inlerval ol lhe syslem.