Professional Documents

Culture Documents

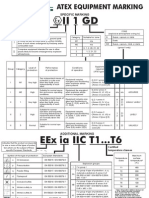

Atex Chart

Atex Chart

Uploaded by

ksamgeorgeCopyright:

Available Formats

You might also like

- Floodplain Modeling Using HEC-RASDocument772 pagesFloodplain Modeling Using HEC-RASboulafrag abdellatif100% (3)

- Conference IEC 60079-14Document79 pagesConference IEC 60079-14arturoncNo ratings yet

- Compex Ex01 To Ex04Document3 pagesCompex Ex01 To Ex04Muhammad Ali100% (1)

- AWWA M11 Steel Pipe - A Guide For Design and InstallationDocument301 pagesAWWA M11 Steel Pipe - A Guide For Design and InstallationLuis Daniel100% (1)

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocument1 pageiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNo ratings yet

- ATEXDocument90 pagesATEXRinjal Banerjee80% (5)

- EN ISO 14119: Safety of MachineryDocument16 pagesEN ISO 14119: Safety of MachineryHudson LegnarNo ratings yet

- Paper 62305-2Document6 pagesPaper 62305-2Jose Luis BarretoNo ratings yet

- HenkeDocument2 pagesHenkeDeepakSinghNo ratings yet

- Impact of SAP Implementation On RetailDocument37 pagesImpact of SAP Implementation On Retailsom21782100% (1)

- AtexDocument8 pagesAtexBao Quoc Mai100% (1)

- Po Ex en 170413 WebDocument1 pagePo Ex en 170413 Webswordleee swordNo ratings yet

- Explosive Atmospheres Brochure 3AUA0000037223 REVC en LowresDocument24 pagesExplosive Atmospheres Brochure 3AUA0000037223 REVC en Lowresckwei0910No ratings yet

- Atex ChartDocument1 pageAtex ChartShinoj B.c.100% (3)

- Equipment For Explosive AtmospheresDocument33 pagesEquipment For Explosive AtmospheresGreggBaeten0% (1)

- ATEX IECEx Seminar - PresentationDocument88 pagesATEX IECEx Seminar - PresentationHoang Anh TuNo ratings yet

- DS59 IEC 60079 0 2011 The Differences and The ConsequencesDocument3 pagesDS59 IEC 60079 0 2011 The Differences and The ConsequencesGlen AshwellNo ratings yet

- Cable Glands in Hazardous Areas CCG PresentationDocument59 pagesCable Glands in Hazardous Areas CCG PresentationAwotiku Abimbola100% (2)

- Hazardous Area ClassificationDocument63 pagesHazardous Area Classificationhtetwin100% (3)

- Atex GuideDocument44 pagesAtex Guideminah22100% (4)

- IECDocument1 pageIECJay Jay100% (2)

- En 60079 BSDocument2 pagesEn 60079 BSSivagurunathan Sp100% (1)

- ATEX DirectiveDocument11 pagesATEX Directiveasimozma100% (2)

- Is-IEC 60079-31 (2008) - Explosive Atmospheres, Part 31 - Equipment Dust Ignition Protection by Enclosure TDocument15 pagesIs-IEC 60079-31 (2008) - Explosive Atmospheres, Part 31 - Equipment Dust Ignition Protection by Enclosure TparathasiNo ratings yet

- ATEX Information English 2014.08.06Document12 pagesATEX Information English 2014.08.06Juli GreyNo ratings yet

- Atex GuideDocument6 pagesAtex GuideValiNo ratings yet

- Ex Basic - Electrical Installations in Hazardous AreaDocument288 pagesEx Basic - Electrical Installations in Hazardous Areaniteen123100% (6)

- Iec 60079-13Document21 pagesIec 60079-13alexsander_machado_5No ratings yet

- Hazardous Area Classification - Dust AtmospheresDocument23 pagesHazardous Area Classification - Dust AtmospheresMohd Lutfi MahaliNo ratings yet

- AtexDocument60 pagesAtexWendi Junaedi100% (1)

- Iec 60079-13Document11 pagesIec 60079-13nazaruddinmNo ratings yet

- ATEX Requirements Adn EU Certification System PDFDocument37 pagesATEX Requirements Adn EU Certification System PDFtintucinbNo ratings yet

- Basic Concepts For Explosion ProtectionDocument46 pagesBasic Concepts For Explosion Protectionkktay100% (1)

- Rockwell Machine Safety ISO 13849-1Document17 pagesRockwell Machine Safety ISO 13849-1Arun BabuNo ratings yet

- IEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Document104 pagesIEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Mohd Lutfi MahaliNo ratings yet

- ATEX ExplainedDocument1 pageATEX ExplainedDonal O'SullivanNo ratings yet

- Test Your Knowledge-DeepexDocument23 pagesTest Your Knowledge-DeepexvishnudasNo ratings yet

- (TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Document9 pages(TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Shirish100% (1)

- CMP IECEx ATEX 01Document10 pagesCMP IECEx ATEX 01rocket-vtNo ratings yet

- Iec 60079-6 - 2007Document19 pagesIec 60079-6 - 2007Victor Almeida BressianiNo ratings yet

- ATEX Explain 2 PDFDocument1 pageATEX Explain 2 PDFChâu Chúm ChímNo ratings yet

- For The World For Europe: Putting Iecex and Atex TogetherDocument1 pageFor The World For Europe: Putting Iecex and Atex Togetherhafnium99100% (1)

- ATEX Directive: ATEX Directive 94/9/EC (Also Known As ATEX 95 or ATEX 100A)Document6 pagesATEX Directive: ATEX Directive 94/9/EC (Also Known As ATEX 95 or ATEX 100A)SARAVANANo ratings yet

- 10-1 2018 3Document9 pages10-1 2018 3Efari BahcevanNo ratings yet

- ISA-61241 Electrical Aparatus To Use in Zone21y22Document26 pagesISA-61241 Electrical Aparatus To Use in Zone21y22nicolascsNo ratings yet

- Legal Compliance: Hazardous LocationsDocument53 pagesLegal Compliance: Hazardous LocationsCharles Mutetwa100% (1)

- Is Iec 60079 20 1 2010Document79 pagesIs Iec 60079 20 1 2010Nymphetamine AnhNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Explosion Hazards in the Process IndustriesFrom EverandExplosion Hazards in the Process IndustriesRating: 5 out of 5 stars5/5 (2)

- Atex MarkingDocument1 pageAtex Markinggangotri05No ratings yet

- Cable Sealing Solutions: For Hazardous AreasDocument12 pagesCable Sealing Solutions: For Hazardous AreasArun VaideeswaranNo ratings yet

- Proiector Si CIL Atmosfera Potential ExplozivaDocument14 pagesProiector Si CIL Atmosfera Potential ExplozivaMuzeul LampilorNo ratings yet

- IECEx Motors Check List - ED03 - 13aDocument9 pagesIECEx Motors Check List - ED03 - 13atopendwarriorNo ratings yet

- SirenaDocument6 pagesSirenaLuiza OcheanaNo ratings yet

- Fire ZoneDocument12 pagesFire ZoneMehman NasibovNo ratings yet

- Topic III Hazardous Area ClassificationDocument22 pagesTopic III Hazardous Area ClassificationJulius ChavezNo ratings yet

- HazLoc Guide To Zoned EquipmentDocument8 pagesHazLoc Guide To Zoned EquipmentDzeminSinNo ratings yet

- Atex ExplainedDocument3 pagesAtex ExplainedErica LindseyNo ratings yet

- EX AT: Equipment CategoriesDocument2 pagesEX AT: Equipment CategoriesAminNo ratings yet

- CMP E1fwDocument1 pageCMP E1fwHen Drix LevaNo ratings yet

- Hazardous Area Classification and Control of Ignition SourcesDocument9 pagesHazardous Area Classification and Control of Ignition SourcesKHALID HUBBAHNo ratings yet

- Washburn (An Introduction To The Principles of Physical Chemistry) (1915)Document484 pagesWashburn (An Introduction To The Principles of Physical Chemistry) (1915)Marcelo Silvano de CamargoNo ratings yet

- Rubber Behaviour Static and DynamicDocument13 pagesRubber Behaviour Static and DynamicTamaduianu IoanNo ratings yet

- Risk Management Plan Form - Greenlight GuruDocument5 pagesRisk Management Plan Form - Greenlight Gurupawanhv1454No ratings yet

- Implementation of Hand Gesture Recognition System To Aid Deaf-Dumb PeopleDocument15 pagesImplementation of Hand Gesture Recognition System To Aid Deaf-Dumb PeopleSanjay ShelarNo ratings yet

- NAT - 449 - Solutions 2018 PDFDocument4 pagesNAT - 449 - Solutions 2018 PDFPayal JainNo ratings yet

- Notification Spot Round Admission PG 08092023Document6 pagesNotification Spot Round Admission PG 08092023SOUMYA BHATTNo ratings yet

- BAKSHI - PDF Electronics and Microprocessor Basic Electrical and Electronics Engineering AnalogDocument1 pageBAKSHI - PDF Electronics and Microprocessor Basic Electrical and Electronics Engineering AnalogSushant ZingadeNo ratings yet

- FB5P 50 PDFDocument109 pagesFB5P 50 PDFДмитрийNo ratings yet

- Draught: (Chimney Design)Document5 pagesDraught: (Chimney Design)just randomNo ratings yet

- Fpgas: An Overview: Sanjiv MalikDocument24 pagesFpgas: An Overview: Sanjiv MalikSiva KrishnaNo ratings yet

- R01ds0272eu0100 Synergy SSP PDFDocument74 pagesR01ds0272eu0100 Synergy SSP PDFHarshil ShethNo ratings yet

- Ashrae Dammam 2017Document2 pagesAshrae Dammam 2017habeebNo ratings yet

- TherbligDocument3 pagesTherbligMarc Gabriel MediranNo ratings yet

- Radio Frequency Identification ReportDocument28 pagesRadio Frequency Identification Reportkhuzainey ismail100% (1)

- Jci Kodiak 300Document44 pagesJci Kodiak 300Francisco Agustín FernandezNo ratings yet

- Nupetiet Golgranzs DreadnoughtDocument7 pagesNupetiet Golgranzs DreadnoughtJesse WilliamsNo ratings yet

- SPECIFICATION-TOLL ROAD - 8 APRIL 2015-ENGLISH UPLOADDocument456 pagesSPECIFICATION-TOLL ROAD - 8 APRIL 2015-ENGLISH UPLOADTaufik GeodetikNo ratings yet

- Fireclass j408 2 4 8 424 8 Hagyomanyos Tuzjelzo Kozpontok Adatlap AngolDocument2 pagesFireclass j408 2 4 8 424 8 Hagyomanyos Tuzjelzo Kozpontok Adatlap AngolASIF IQBALNo ratings yet

- Build Your Home-Made 500Khz Frequency Meter!Document12 pagesBuild Your Home-Made 500Khz Frequency Meter!nagdeep58No ratings yet

- Orifice Plate Flow Meter OPTDocument12 pagesOrifice Plate Flow Meter OPTSteven TrigoNo ratings yet

- Apache Internals and Debugging: Ryan MattesonDocument41 pagesApache Internals and Debugging: Ryan MattesonGleb LegasovNo ratings yet

- NDIS Home Modifications Guidance For Builders and Designers: Version 2.0 - September 2022Document35 pagesNDIS Home Modifications Guidance For Builders and Designers: Version 2.0 - September 2022shane RossNo ratings yet

- MEE2Document24 pagesMEE2johnmarie DyMyNo ratings yet

- SIMS 8500214405 320GX SYW00968 PM 1000 - CV - PUTRI CAHYANI - Lubuk LinggauDocument1 pageSIMS 8500214405 320GX SYW00968 PM 1000 - CV - PUTRI CAHYANI - Lubuk LinggauTeguh Prabowo CenaNo ratings yet

- LX-402 802N CatDocument2 pagesLX-402 802N CatsegelecsrlNo ratings yet

Atex Chart

Atex Chart

Uploaded by

ksamgeorgeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atex Chart

Atex Chart

Uploaded by

ksamgeorgeCopyright:

Available Formats

Extronics

Products Explosion Proof & Pressurised Solutions

Engineered Solutions, Bespoke Certification and Development Training & Certification Services

ATEX Certification Definitions

Zoning Definitions

Categories

Zones

Gas

ATEX

Cat.

Definitions

Dust

Non-electrical Equipment

Typical Zone

Suitability

EN 60079-10 EN 61241-10

20

A place in which an explosive

atmosphere is continually present

1G

1D

Equip. suitable for zone 0

Equip. suitable for zone 20

21

A place in which an explosive

atmosphere is likely to occur in normal

operation occasionally

2G

2D

Equip. suitable for zone 1

Equip. suitable for zone 21

A place in which an explosive atmosphere

is not likely to occur in normal operation,

but if it does only occurs for short periods

3G

3D

22

IP Code

Dusts

1st Numerical

2nd Numerical

Protection against Solid Bodies

Protection against Liquid

0

1

2

3

4

5

6

0

1

2

3

4

5

6

7

8

No protection

Objects > 50mm

Objects > 12mm

Objects > 2.5mm

Objects > 1mm

Dust-protected

Dust-tight

US Enclosure Ratings

NEMA, UL

& CSA

type rating

Equip. suitable for zone 2

Equip. suitable for zone 22

Approximate

IEC/IP

classification

1

2

3

3R

4

IP20

IP22

IP55

IP24

IP66

4X

IP66

IP67

Zone

No protection

Vertically dripping water

Drops of liquid (75 to 90)

Sprayed water

Splashed water

Water jets

Heavy seas

Effects of immersion

Indefinite immersion

20

Requires 1D equipment

IP6X

21

Requires 1D or 2D equipment

IP6X

22

Requires 3D, 2D or 1D equipment

IP5X*

0.14

0.2

0.35

0.5

0.7

10

Cable Gland Selection

No

Is equipment

Ex d concept?

Yes

Yes

EN 13463-6

Control of ignition sources

EC-Type Examination

III

EN 13463-7

Pressurisation

Internal Control of Production

VIII

EN 13463-8

Liquid immersion

Unit Verification

IX

Production Quality Assurance

IV

Product Quality Assurance

VII

Product Verification

Conformity to Type

VI

Internal Control of Production

VIII

Unit Verification

IX

KEY

= mandatory unless Unit Verification is used

O = optional as an alternative to other modules

Y = one of two production phase modules for

the equipment category to be chosen by the

manufacturer

*refer to note 1

Ex e concept

Note 1: Non certified cable glands

may be used provided that they

maintain the minimum IP rating on

the certified equipment of IP54 for

outdoors and IP20 for indoor

equipment.

DUST

Type of Protection

EN 60079-0

General Requirements

ATEX

Code

Standard

EN 61241-0:2006

Ex ia & ib

EN 60079-11

Protection by Enclosures

tD

EN 61241-1:2004

Increased Safety

Ex e

EN 60079-7

Protection

pD

EN 61241-4:2006

Flameproof

Ex d

EN 60079-1

Intrinsic Safety

iD

EN 61241-11:2006

Pressurisation

Ex p

EN 60079-2

Powder Filling

Ex q

EN 60079-5

Encapsulation

Ex ma & mb EN 60079-18

Oil Immersion

Ex o

EN 60079-6

Type n

Ex n

EN 60079-15

Temperature

T-Class Max surface

temp in C

20

T1

450

T2

300

T3

200

T4

135

T5

100

T6

85

No

Encapsulation

mD

Type n EN60079-15

Enclosed break device

Non-incendive component

Hermetically sealed device

Sealed device

Encapsulated device

Energy limited apparatus & circuits

Restricted breathing enclosure

Non sparking

Does the

hazardous

gas require IIC

apparatus?

Yes

Ex e concept

Gland type

Use a barrier

gland

Yes

Is the

volume of

enclosure

greater than

2 dm3?

O O

*4

O

O O

O O

O O

O O

O O

II

Electrical equipment intended for use in places with an

explosive gas atmosphere other than mines susceptible to

firedamp

III

Electrical equipment intended for use in places with an

explosive dust atmosphere other than mines susceptible to

firedamp*

Gas Groups

EN 61241-18:2004

nC

nC

nC

nC

nC

nL

nR

nA

Brass

Does this

enclosure

contain an

internal source

of ignition?

Propane

IIIA

Combustible Flyings

IIB

Ethylene

IIIB

Non-conductive Dust

IIC

Hydrogen/Acetylene

IIIC

Conductive Dust

*Taken from the new IEC60079-0 2007

Simple Apparatus

Passive components

EN1127-1

Explosive atmospheres - Explosion prevention and protection.

Part 1, Basic concepts & methodology for surface industry

EN1127-2

Explosive atmospheres - Explosion prevention and protection.

Part 2, Basic concepts & methodology for mining

EN60079-10

Classification of hazardous areas

EN60079-14

Electrical installations in hazardous areas (other than mines)

EN60079-17

Electrical installations inspection and maintenance

EN60079-19

Equipment repair, overhaul and reclamation

EN60079-28

Protection of equipment and transmission systems using

optical radiation

Marking for

Dust or Flyings

and Fibres

Hazards

*refer to note 2

II 2 G Ex d IIC T4

XXXX

EC Mark

Gas

Type of

Protection

Explosion

Protection

Equipment

Category

Sources of generated energy not

more than *1.5V, 100mA & 25mW

NOT

piezoelectric crystal

protected components

voltage or current enhancement

Temperature

Gas Group*

Class

A, B or C

(T1-T6)

* Note: North America still

uses 1.2V and 20 microjoules

*If omitted suitable

for all gas groups

III 2 D Ex tD A21 IP66 T80C

XXXX

Complies with

European

Directive

Equipment

Group

EC Mark

Equipment

Group

Notified Body

Number

Dust

Equipment

Category

Type of

Protection

Ingress protection

and max. surface

temperature

Explosion

Protection

The threshold power of radio frequency (10 kHz to 300 GHz) for continuous transmissions and for pulsed

transmissions whose pulse durations exceed the thermal initiation time shall not exceed the values shown in Table 4.

Programmable or software control intended for setting by the user shall not be permitted.

For pulsed radar and other transmissions where the pulses are short compared with the thermal initiation time, the

threshold energy values Zth shall not exceed those given in Table 5.

Table 4 from IEC 60079-0

Radio Frequency Power Thresholds

No

No

Well defined sources of

stored energy considered

in safety analysis

Radio Frequency Sources

Use certified

cable glands

No

Is the area of

installation of

Zone 1?

Dust Groups*

IIA

Assessment of inadvertent ignition of flammable atmospheres

by radio frequency radiation (guide)

Notified Body

Number

*refer to note 3

No

*4

Electrical equipment intended for use in mines susceptible

to firedamp

BS6656

Ex n* or N

concept

Plastic

Yes

Other Useful Standards

Marking for

Gas Hazards

Use non-certified

cable glands

Yes

5V in

Zone 2

No

Note 2: Non certified cable glands

may be used provided they meet

the requirements of EN60079-0 and

EN60079-7 or EN60079-15.

Note 3: Internal sources of ignition

include sparks or equipment

temperatures occurring in normal

operation which can cause ignition.

An enclosure containing terminals

only or an indirect entry enclosure is

considered not to constitute an

internal source of ignition.

Yes

Refer to Ex d

cable selector

chart

Production Phase

* Notes:

1 Global Approach OJEC No.L220, 1993

2 ATEX Directive 94/9/EC

3 Suffix (E) refers to electrical equipment and

internal combustion engines

Suffix (N) refers to non-electrical equipment

4 Technical Files to be deposited with a notified

body

Complies with

European

Directive

Use non-certified

cable glands

Design Phase

Conformity Assessment Quality Modules Table

General Requirements

Is area zoned?

Zone 1?

No

Constructional safety

Standard

START

Yes

Is equipment

Ex i concept?

EN 13463-5

ATEX

Code

IK08 IK09 IK10

fr

Flame-proof enclosure

GAS

Type of Protection

Intrinsic Safety

Mechanical Impacts (UK) Code EN50102

Impact

Energy

(Joules)

Flow restricting enclosure

EN 13463-3

Types of Protection

Indoor, from contact with contents

Indoor, limited, falling dirt and water

Outdoor, from rain, sleet, windblown dust & ice damage

Outdoor, from rain, sleet & ice damage

Indoor & outdoor, from windblown dust, rain, splashing

& hose directed water & ice damage

Indoor & outdoor, from corrosion, windblown dust, rain,

splashing & hose directed water & ice damage

Indoor & outdoor, from hose directed water, water entry

during submersion & ice damage

IK06 IK07

EN 13463-2

Protective

System

Groups

Abbreviated Protection Description

IK01 IK02 IK03 IK04 IK05

Module Annex Equipment Category *3

*1

*2 M1 M2 M2 1 2 2 3

(E) (N)

(E) (N)

Basic methods & requirements

* Must be IP6X if dust is electrically conductive

NEMA 7 to 10 Hazardous Area Enclosures

IK Code IK00

IP

Rating

ATEX Category

Conformity Assessment Quality Modules

(concepts)

EN 13463-1

Use a suitable

flameproof cable

gland with a

sealing ring.

(Gland with

elastomeric

seals)

Table 5 from IEC 60079-0

Radio-frequency Energy Thresholds

Equipment

for

Threshold power

(W)

Thermal Initiation Time

(averaging period)

(s)

Equipment

for

Threshold Energy Zth

(J)

Group I

6.0

200

Group I

1500

Group IIA

6.0

100

Group IIA

950

Group IIB

3.5

80

Group IIB

250

Group IIC

2.0

20

Group IIC

50

Group III

6.0

200

Group III

1500

Extronics Ltd Meridian House Roe Street Congleton Cheshire CW12 1PG Tel: +44 (0)1260 292651 Fax: +44 (0)1260 297280 www.extronics.com info@extronics.com

The information in this wall chart is for guidance only. For detailed information see relevant Directives and Regulations.

Extronics Ltd 2008 07/08

You might also like

- Floodplain Modeling Using HEC-RASDocument772 pagesFloodplain Modeling Using HEC-RASboulafrag abdellatif100% (3)

- Conference IEC 60079-14Document79 pagesConference IEC 60079-14arturoncNo ratings yet

- Compex Ex01 To Ex04Document3 pagesCompex Ex01 To Ex04Muhammad Ali100% (1)

- AWWA M11 Steel Pipe - A Guide For Design and InstallationDocument301 pagesAWWA M11 Steel Pipe - A Guide For Design and InstallationLuis Daniel100% (1)

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocument1 pageiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNo ratings yet

- ATEXDocument90 pagesATEXRinjal Banerjee80% (5)

- EN ISO 14119: Safety of MachineryDocument16 pagesEN ISO 14119: Safety of MachineryHudson LegnarNo ratings yet

- Paper 62305-2Document6 pagesPaper 62305-2Jose Luis BarretoNo ratings yet

- HenkeDocument2 pagesHenkeDeepakSinghNo ratings yet

- Impact of SAP Implementation On RetailDocument37 pagesImpact of SAP Implementation On Retailsom21782100% (1)

- AtexDocument8 pagesAtexBao Quoc Mai100% (1)

- Po Ex en 170413 WebDocument1 pagePo Ex en 170413 Webswordleee swordNo ratings yet

- Explosive Atmospheres Brochure 3AUA0000037223 REVC en LowresDocument24 pagesExplosive Atmospheres Brochure 3AUA0000037223 REVC en Lowresckwei0910No ratings yet

- Atex ChartDocument1 pageAtex ChartShinoj B.c.100% (3)

- Equipment For Explosive AtmospheresDocument33 pagesEquipment For Explosive AtmospheresGreggBaeten0% (1)

- ATEX IECEx Seminar - PresentationDocument88 pagesATEX IECEx Seminar - PresentationHoang Anh TuNo ratings yet

- DS59 IEC 60079 0 2011 The Differences and The ConsequencesDocument3 pagesDS59 IEC 60079 0 2011 The Differences and The ConsequencesGlen AshwellNo ratings yet

- Cable Glands in Hazardous Areas CCG PresentationDocument59 pagesCable Glands in Hazardous Areas CCG PresentationAwotiku Abimbola100% (2)

- Hazardous Area ClassificationDocument63 pagesHazardous Area Classificationhtetwin100% (3)

- Atex GuideDocument44 pagesAtex Guideminah22100% (4)

- IECDocument1 pageIECJay Jay100% (2)

- En 60079 BSDocument2 pagesEn 60079 BSSivagurunathan Sp100% (1)

- ATEX DirectiveDocument11 pagesATEX Directiveasimozma100% (2)

- Is-IEC 60079-31 (2008) - Explosive Atmospheres, Part 31 - Equipment Dust Ignition Protection by Enclosure TDocument15 pagesIs-IEC 60079-31 (2008) - Explosive Atmospheres, Part 31 - Equipment Dust Ignition Protection by Enclosure TparathasiNo ratings yet

- ATEX Information English 2014.08.06Document12 pagesATEX Information English 2014.08.06Juli GreyNo ratings yet

- Atex GuideDocument6 pagesAtex GuideValiNo ratings yet

- Ex Basic - Electrical Installations in Hazardous AreaDocument288 pagesEx Basic - Electrical Installations in Hazardous Areaniteen123100% (6)

- Iec 60079-13Document21 pagesIec 60079-13alexsander_machado_5No ratings yet

- Hazardous Area Classification - Dust AtmospheresDocument23 pagesHazardous Area Classification - Dust AtmospheresMohd Lutfi MahaliNo ratings yet

- AtexDocument60 pagesAtexWendi Junaedi100% (1)

- Iec 60079-13Document11 pagesIec 60079-13nazaruddinmNo ratings yet

- ATEX Requirements Adn EU Certification System PDFDocument37 pagesATEX Requirements Adn EU Certification System PDFtintucinbNo ratings yet

- Basic Concepts For Explosion ProtectionDocument46 pagesBasic Concepts For Explosion Protectionkktay100% (1)

- Rockwell Machine Safety ISO 13849-1Document17 pagesRockwell Machine Safety ISO 13849-1Arun BabuNo ratings yet

- IEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Document104 pagesIEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Mohd Lutfi MahaliNo ratings yet

- ATEX ExplainedDocument1 pageATEX ExplainedDonal O'SullivanNo ratings yet

- Test Your Knowledge-DeepexDocument23 pagesTest Your Knowledge-DeepexvishnudasNo ratings yet

- (TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Document9 pages(TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Shirish100% (1)

- CMP IECEx ATEX 01Document10 pagesCMP IECEx ATEX 01rocket-vtNo ratings yet

- Iec 60079-6 - 2007Document19 pagesIec 60079-6 - 2007Victor Almeida BressianiNo ratings yet

- ATEX Explain 2 PDFDocument1 pageATEX Explain 2 PDFChâu Chúm ChímNo ratings yet

- For The World For Europe: Putting Iecex and Atex TogetherDocument1 pageFor The World For Europe: Putting Iecex and Atex Togetherhafnium99100% (1)

- ATEX Directive: ATEX Directive 94/9/EC (Also Known As ATEX 95 or ATEX 100A)Document6 pagesATEX Directive: ATEX Directive 94/9/EC (Also Known As ATEX 95 or ATEX 100A)SARAVANANo ratings yet

- 10-1 2018 3Document9 pages10-1 2018 3Efari BahcevanNo ratings yet

- ISA-61241 Electrical Aparatus To Use in Zone21y22Document26 pagesISA-61241 Electrical Aparatus To Use in Zone21y22nicolascsNo ratings yet

- Legal Compliance: Hazardous LocationsDocument53 pagesLegal Compliance: Hazardous LocationsCharles Mutetwa100% (1)

- Is Iec 60079 20 1 2010Document79 pagesIs Iec 60079 20 1 2010Nymphetamine AnhNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Explosion Hazards in the Process IndustriesFrom EverandExplosion Hazards in the Process IndustriesRating: 5 out of 5 stars5/5 (2)

- Atex MarkingDocument1 pageAtex Markinggangotri05No ratings yet

- Cable Sealing Solutions: For Hazardous AreasDocument12 pagesCable Sealing Solutions: For Hazardous AreasArun VaideeswaranNo ratings yet

- Proiector Si CIL Atmosfera Potential ExplozivaDocument14 pagesProiector Si CIL Atmosfera Potential ExplozivaMuzeul LampilorNo ratings yet

- IECEx Motors Check List - ED03 - 13aDocument9 pagesIECEx Motors Check List - ED03 - 13atopendwarriorNo ratings yet

- SirenaDocument6 pagesSirenaLuiza OcheanaNo ratings yet

- Fire ZoneDocument12 pagesFire ZoneMehman NasibovNo ratings yet

- Topic III Hazardous Area ClassificationDocument22 pagesTopic III Hazardous Area ClassificationJulius ChavezNo ratings yet

- HazLoc Guide To Zoned EquipmentDocument8 pagesHazLoc Guide To Zoned EquipmentDzeminSinNo ratings yet

- Atex ExplainedDocument3 pagesAtex ExplainedErica LindseyNo ratings yet

- EX AT: Equipment CategoriesDocument2 pagesEX AT: Equipment CategoriesAminNo ratings yet

- CMP E1fwDocument1 pageCMP E1fwHen Drix LevaNo ratings yet

- Hazardous Area Classification and Control of Ignition SourcesDocument9 pagesHazardous Area Classification and Control of Ignition SourcesKHALID HUBBAHNo ratings yet

- Washburn (An Introduction To The Principles of Physical Chemistry) (1915)Document484 pagesWashburn (An Introduction To The Principles of Physical Chemistry) (1915)Marcelo Silvano de CamargoNo ratings yet

- Rubber Behaviour Static and DynamicDocument13 pagesRubber Behaviour Static and DynamicTamaduianu IoanNo ratings yet

- Risk Management Plan Form - Greenlight GuruDocument5 pagesRisk Management Plan Form - Greenlight Gurupawanhv1454No ratings yet

- Implementation of Hand Gesture Recognition System To Aid Deaf-Dumb PeopleDocument15 pagesImplementation of Hand Gesture Recognition System To Aid Deaf-Dumb PeopleSanjay ShelarNo ratings yet

- NAT - 449 - Solutions 2018 PDFDocument4 pagesNAT - 449 - Solutions 2018 PDFPayal JainNo ratings yet

- Notification Spot Round Admission PG 08092023Document6 pagesNotification Spot Round Admission PG 08092023SOUMYA BHATTNo ratings yet

- BAKSHI - PDF Electronics and Microprocessor Basic Electrical and Electronics Engineering AnalogDocument1 pageBAKSHI - PDF Electronics and Microprocessor Basic Electrical and Electronics Engineering AnalogSushant ZingadeNo ratings yet

- FB5P 50 PDFDocument109 pagesFB5P 50 PDFДмитрийNo ratings yet

- Draught: (Chimney Design)Document5 pagesDraught: (Chimney Design)just randomNo ratings yet

- Fpgas: An Overview: Sanjiv MalikDocument24 pagesFpgas: An Overview: Sanjiv MalikSiva KrishnaNo ratings yet

- R01ds0272eu0100 Synergy SSP PDFDocument74 pagesR01ds0272eu0100 Synergy SSP PDFHarshil ShethNo ratings yet

- Ashrae Dammam 2017Document2 pagesAshrae Dammam 2017habeebNo ratings yet

- TherbligDocument3 pagesTherbligMarc Gabriel MediranNo ratings yet

- Radio Frequency Identification ReportDocument28 pagesRadio Frequency Identification Reportkhuzainey ismail100% (1)

- Jci Kodiak 300Document44 pagesJci Kodiak 300Francisco Agustín FernandezNo ratings yet

- Nupetiet Golgranzs DreadnoughtDocument7 pagesNupetiet Golgranzs DreadnoughtJesse WilliamsNo ratings yet

- SPECIFICATION-TOLL ROAD - 8 APRIL 2015-ENGLISH UPLOADDocument456 pagesSPECIFICATION-TOLL ROAD - 8 APRIL 2015-ENGLISH UPLOADTaufik GeodetikNo ratings yet

- Fireclass j408 2 4 8 424 8 Hagyomanyos Tuzjelzo Kozpontok Adatlap AngolDocument2 pagesFireclass j408 2 4 8 424 8 Hagyomanyos Tuzjelzo Kozpontok Adatlap AngolASIF IQBALNo ratings yet

- Build Your Home-Made 500Khz Frequency Meter!Document12 pagesBuild Your Home-Made 500Khz Frequency Meter!nagdeep58No ratings yet

- Orifice Plate Flow Meter OPTDocument12 pagesOrifice Plate Flow Meter OPTSteven TrigoNo ratings yet

- Apache Internals and Debugging: Ryan MattesonDocument41 pagesApache Internals and Debugging: Ryan MattesonGleb LegasovNo ratings yet

- NDIS Home Modifications Guidance For Builders and Designers: Version 2.0 - September 2022Document35 pagesNDIS Home Modifications Guidance For Builders and Designers: Version 2.0 - September 2022shane RossNo ratings yet

- MEE2Document24 pagesMEE2johnmarie DyMyNo ratings yet

- SIMS 8500214405 320GX SYW00968 PM 1000 - CV - PUTRI CAHYANI - Lubuk LinggauDocument1 pageSIMS 8500214405 320GX SYW00968 PM 1000 - CV - PUTRI CAHYANI - Lubuk LinggauTeguh Prabowo CenaNo ratings yet

- LX-402 802N CatDocument2 pagesLX-402 802N CatsegelecsrlNo ratings yet