Professional Documents

Culture Documents

Asme Wps

Uploaded by

Asaad MohamedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Wps

Uploaded by

Asaad MohamedCopyright:

Available Formats

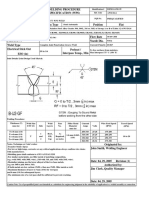

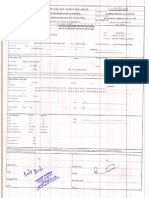

Welding Procedure Specification (WPS)

Sheet 1 of 3

ASME Boiler and Pressure Vessel Code , Section IX

Company Name: www.WPSAmerica.com

Company Address: info@WPSAmerica.com, 1 (877) WPS-WELD

Welding Procedure Specification WPS No.: DEMO-WPS

Revision No.: (0)

Date: 12,12, 2005

Supporting PQR No. (s): DEMO-PQR

Date: 11,12, 2005

BASE METALS (QW-403)

P-No.: 4

Group No.: 1

Material Specification: SA-335

Type or Grade: P11

Group No.: 1

Material Specification: SA-234

Type or Grade: WP11, Class 1

Welded to

P-No.: 4

OR

Chem. Analysis and Mech. Prop.

N/A

Welded to Chem. Analysis and Mech. Prop.

N/A

Qualified Thickness Range mm (in)

Groove: 5 mm (3/16 in.) to 60 mm (2.36 in.)

Fillet: Unlimited

Qualified Diameter Range mm (in)

Groove: All Sizes

Fillet: Unlimited

Other information: This is a DEMO WPS from www.WPSAmerica.com

Welding Process (es):

Type (s):

FIRST PROCESS

SECOND PROCESS

Gas Tungsten Arc Welding (GTAW)

Shielded Metal Arc Welding (SMAW)

Manual

Manual

FILLER METALS (QW-404)

AWS Classification

Electrode-Flux Class (SAW)

ER80S-G (see sheet 3)

E8016-B2 (see sheet 3)

SFA Specification

SFA 5.28

SFA 5.5

Filler Metal F-No.

Weld Metal Analysis A-No.

Size of Filler Metals mm (in)

2.0 mm (see sheet 3)

3.25 mm (see sheet 3)

Solid copper coated wire

Iron powder low hydrogen

Filler Metal Product Form

Max. Weld Pass Thickness mm (in)

Qualified Weld Metal Range: Groove mm (in)

Qualified Weld Metal Range: Fillet mm (in)

Weld Deposit Chemistry

1/8 in.

3/16 in.

10 mm (3/8 in.)

60 mm (2.36 in.)

Unlimited

Unlimited

N/A

N/A

Position (s) of Groove

ALL Position

ALL Position

Welding Progression

Up

Up

ALL Position

ALL Position

Preheat Temp. C (F)

150 C

150 C

Interpass Temp. Max. C (F)

280 C

280 C

Preheat Maintenance C (F)

New Joint

New Joint

100% Ar

N/A

Flux Trade Name and Flux Type (SAW)

Consumable Insert, Class and Size

Other information: This is a DEMO WPS from www.WPSAmerica.com

POSITIONS (QW-405)

Position (s) of Fillet

PREHEAT (QW-406)

GAS (QW-408)

Shielding Gas Type (Mixture)

Flow Rate

lt/min. (CFH)

Trailing Gas Type (Mixture)

Flow Rate

lt/min. (CFH)

Gas Backing (Mixture)

Flow Rate

lt/min. (CFH)

7 to 9 lt/min.

N/A

N/A

N/A

N/A

POSTWELD HEAT TREATMENT (QW-407)

Holding Temperature Range C (F): 680 C + or - 10 C

Holding Time Range: 1 hr/ in. (15 minutes Min.)

Heating Rate C/hr (F/hr): 120 C/hr

Method: Furnace

Cooling Rate C/hr (F/hr): 120 C/hr

Method: Open Air

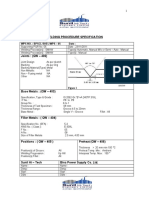

WPS No. DEMO-WPS

Rev. (0)

Sheet 2 of 3

ELECTRICAL CHARACTERISTICS (QW-409)

FIRST PROCESS

Following data may also shown on Table below in this sheet

Current/ Polarity

SECOND PROCESS

DCEN

DCEP

Amps (Range)

90 to120

100 to 130

Volts (Range)

18 to 25

20 to 28

Wire Feed Speed (Range) mm/min (in/min)

Travel Speed (Range) mm/min (in/min)

Mode of Metal Transfer for GMAW (FCAW)

Tungsten Electrode Size mm (in)

Tungsten Type

Manual control

Manual control

N/A

N/A

2.5 mm

SFA 5.12 EWTh-2

TECHNIQUE (QW-410)

String or Weave Bead

String Bead

Multiple or Single Electrodes

Multiple or Single Pass (per side)

Orifice or Gas Cup Size

Contact Tube to Work Distance mm (in)

Initial and Interpass Cleaning

Method of Back Gouging

Oscillation

Peening

String and Weave Bead

Single

Single

Multiple

Multiple

5/8 in. Nozzle Size

Brushing

Brushing and Grinding

n/a

n/a

Not Required

Not Required

Other information: Clean each layer before start welding new passes/layers

JOINTS (QW-402)

Joint Design: Groove Design Used

Joint Details/ Sketch:

Backing Type: Metal

Backing Material (Refer to both backing and retainers.): Same as base metals

Groove Details (or as per production drawing): Root Opening G: _

Root Face RF: _

Groove Angle: _

Radius (J-U): _

Table for recorded welding parameters; Refer to QW-409

Pass

No. (s)

Process

Filler Metal

Classification

Filler

Size

Diameter

mm (in)

Current

Amps

Range

Current

Type &

Polarity

Wire Feed

Speed Range

mm/min

(in/min)

Volts

Range

Travel

Speed Range

mm/min

(in/min)

Max. Heat Input

kJ/mm (kJ/in)

Or

Remarks

GTAW

ER80S-G

2.0 mm

90-120

DCEN

N/A

18-25

Root Pass

2 to 3

GTAW

ER80S-G

2.0 mm

90-120

DCEN

N/A

18-25

3 to n

4 to n

SMAW

E8016-B2

3.25 mm

100-130

DCEP

N/A

20-28

Weld

Layer(s)

Additional Notes: This is a DEMO-WPS prepared by online welding software of www.WPSAmerica.com

Manufacturer or Contractors Welding Engineer:

Authorized by:

Name: Jim Clark

Name: John Smith

Signature: J.C.

Signature: J.S.

Title: Welding Engineer

Title: QA Manager

Date: 12, 12, 2005

Date: 12,12, 2005

Fill and Cap Passes

WPS No. DEMO-WPS

Rev. (0)

Sheet 3 of 3

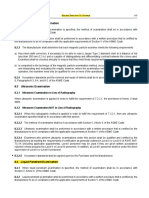

Heat Treatment (ASME Codes Guideline):

PREHEAT TABLE:

ASME Section I: Preheating from Appendix A (A-100)

(a) 250 F (120 C) for material which has either a specified minimum tensile strength in

excess of 60,000 psi (410 MPa) or a thickness at the joint in excess of 1/2 in. (13 mm):

(b) 50 F (10 C) for all other materials of P-No. 4 group.

POSTWELD HEAT TREATMENT TABLE:

ASME Section I: Mandatory Requirements for PWHT of Table PW-39

Min. Holding Temperature: 1,200 F (650 C)

Min. Holding Time for Weld Thickness (Nominal):

Up to 2 in. (50 mm): 1 hr/in. (2 min/mm), 15 min Min.

Over 2 in. (50 mm) to 5 in. (125 mm): 1 hr/in. (2 min/mm)

Over 5 in. (125 mm): 5 hr plus 15 min for each additional inch over 5 in. (125 mm)

Heating rate: The weldment shall be heated slowly to the holding temperature, Min. 100 F (55 C)/hr

Cooling rate: Cool slowly in a still atmosphere to a temperature not exceeding 800 F (425 C)

For Non-Mandatory conditions of PWHT, See Notes (1), (2) of Table PW-39

WPS Qualified Range (ASME IX Guideline):

Qualified Positions (Groove, Fillet): All Positions for Plate or Pipe. Unless specifically required otherwise by the welding variables (QW-250), a

qualification in any position qualifies the procedure for all positions. The welding process and electrodes must be suitable for all positions

permitted by the WPS (ASME Section IX, QW-203). (For impact test application, there are some restrictions for welding in vertical-uphill

progression position; See ASME Section IX, QW-405.2)

Qualified Thicknesses (Groove, Fillet): 3/16 in. (5 mm) Min., 2T Max. (Plate or Pipe)

[For GMAW-Short Circuit Arc, when T is less than 1/2 in. (13 mm): 1.1T Max. ASME IX, QW-403.10]

[For impact test application, except ESW process: Min. Qualified Thickness is either T or 5/8 in. (16 mm), whichever is less; This variable does

not apply when a WPS is qualified with a PWHT above the upper transformation temperature or when an austenitic material is solution annealed

after welding. ASME IX, QW-403.6]

[For ferrous base metals other than P-No. 7, 8 and 45 (when test coupon receives a PWHT above the upper transformation temperature): 1.1T

Max. ASME IX, QW-407.4]

[For any weld pass greater than 1/2 in. (13 mm) thick: 1.1T Max. (Except GTAW process). ASME IX, QW-403.9]

T: Thickness of Test Plate or Pipe Wall in PQR (ASME Section IX, Table QW-451.1)

Qualified Diameters (Groove, Fillet): All Nominal Pipe (Tube) Sizes, within Qualified Thicknesses in PQR

WPS Base Metal P-Numbers Allowed by PQR: Any metals of the same P-No. 4, plus combination between any metal from P-No. 4 to any metal

from P-No. 3 or P-No. 1 (ASME Section IX, QW-424)

Qualified WPS Filler Metal Allowed by PQR: Only Filler Metal categories with the same F-number and same A-number tested in PQR. Any

electrode diameter sizes can be used in WPS, as it is not an essential variable for the most process and conditions. For Non-impacted test

applications only, filler metal classification within an SFA specification, with the same F-number and the same A-number and the same minimum

tensile strength and the same nominal chemical composition can be used in WPS. (ASME Section IX, QW-250)

You might also like

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Colour Coding As Per BHELDocument7 pagesColour Coding As Per BHELKedar Choksi0% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroNo ratings yet

- PWHT, HT, Igc, MawpDocument40 pagesPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Is 7310 RequirementsDocument4 pagesIs 7310 RequirementsRavichandran Tirupattur SubramaniamNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala Qatari100% (1)

- AWS D1.1 GuidesDocument7 pagesAWS D1.1 GuidesMuhammad FakhriNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- 188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQDocument1 page188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Pwps 06Document1 pagePwps 06eldobie3No ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Mild Steel Welding ElectrodeDocument12 pagesMild Steel Welding ElectrodeVĩnh NguyễnNo ratings yet

- Hot Tap Welding ParametersDocument7 pagesHot Tap Welding ParametersSiva RamNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- ST 60-2Document1 pageST 60-2AmiNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- Critére D'acceptation PT API 650 ASME VIIIDocument4 pagesCritére D'acceptation PT API 650 ASME VIIITahar DabbarNo ratings yet

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad Rizki100% (1)

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- WPS PQR-08Document8 pagesWPS PQR-08Ranjan KumarNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps DemoArupendranarayan ThakurNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariablesAnonymous rYZyQQot55No ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocument2 pagesFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- PWPS - GTSM-73 Rev-ADocument5 pagesPWPS - GTSM-73 Rev-AVimin PrakashNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Recapitulation Quiz 1Document2 pagesRecapitulation Quiz 1Umer AhsanNo ratings yet

- New - Quality Manual - Triple G (Case Study)Document12 pagesNew - Quality Manual - Triple G (Case Study)Umer AhsanNo ratings yet

- ENMS Pre-Course Reading Material & QuizDocument8 pagesENMS Pre-Course Reading Material & QuizUmer AhsanNo ratings yet

- Pre-Course Reading Material & QuizDocument8 pagesPre-Course Reading Material & QuizUmer Ahsan100% (1)

- Course Summary ISO 17025Document7 pagesCourse Summary ISO 17025Umer AhsanNo ratings yet

- The Metallurgy of Carbon SteelDocument103 pagesThe Metallurgy of Carbon SteelUmer AhsanNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- FLUKe 726 Model Manual For UsersDocument2 pagesFLUKe 726 Model Manual For UsersUmer AhsanNo ratings yet

- SSPC Vis 1Document2 pagesSSPC Vis 1cesar100% (3)

- 2009 Special Inspection ManualDocument15 pages2009 Special Inspection ManualUmer AhsanNo ratings yet

- Fourier Series Applications 1: - Harmonic AnalysisDocument9 pagesFourier Series Applications 1: - Harmonic AnalysisUmer AhsanNo ratings yet

- Compliance Certificate# 67Document1 pageCompliance Certificate# 67Umer AhsanNo ratings yet