0% found this document useful (0 votes)

468 views4 pagesSS312 Type310

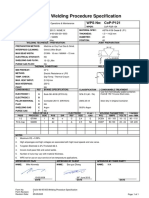

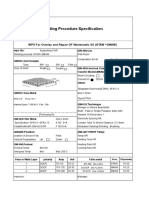

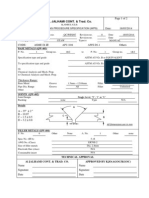

This document outlines the preliminary welding procedure specification for gas tungsten arc welding of SA-312 TP310/SA-182 GRADE F310/SA-403 WP310S steel. It specifies the joint details of a single V-butt joint with a 35 degree groove and no backing. ER310 filler metal in sizes 1.6mm and 2.4mm will be used in all positions with DCEN polarity. Preheating will be done to 10 degrees C and interpass temperature maintained below 175 degrees C. Root, hot, fill, and cap passes will be done with travel speeds between 80-175 mm/min and currents of 90-175 amps.

Uploaded by

Vimin PrakashCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

468 views4 pagesSS312 Type310

This document outlines the preliminary welding procedure specification for gas tungsten arc welding of SA-312 TP310/SA-182 GRADE F310/SA-403 WP310S steel. It specifies the joint details of a single V-butt joint with a 35 degree groove and no backing. ER310 filler metal in sizes 1.6mm and 2.4mm will be used in all positions with DCEN polarity. Preheating will be done to 10 degrees C and interpass temperature maintained below 175 degrees C. Root, hot, fill, and cap passes will be done with travel speeds between 80-175 mm/min and currents of 90-175 amps.

Uploaded by

Vimin PrakashCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd