0% found this document useful (0 votes)

39 views2 pagesDSP 006a

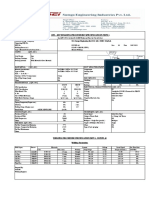

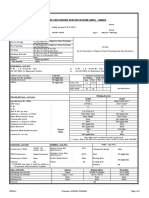

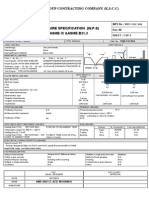

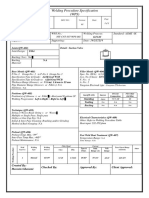

This document is a Welding Procedure Specification (WPS) for Larsen & Toubro Limited related to the CPCL Ref. III Expansion Project, detailing the welding processes, materials, and parameters. It specifies the use of GTAW for butt joints with various base materials and filler metals, including ER-309L. The document includes information on preheat, electrical characteristics, and welding techniques necessary for the project.

Uploaded by

Ebrahim Abdelhady ElmekaweyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

39 views2 pagesDSP 006a

This document is a Welding Procedure Specification (WPS) for Larsen & Toubro Limited related to the CPCL Ref. III Expansion Project, detailing the welding processes, materials, and parameters. It specifies the use of GTAW for butt joints with various base materials and filler metals, including ER-309L. The document includes information on preheat, electrical characteristics, and welding techniques necessary for the project.

Uploaded by

Ebrahim Abdelhady ElmekaweyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd