Professional Documents

Culture Documents

WPS P1 Group Any To P1 Group Any GTAW-FCAW (Manual-Machine)

Uploaded by

Prasad ChakkrapaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS P1 Group Any To P1 Group Any GTAW-FCAW (Manual-Machine)

Uploaded by

Prasad ChakkrapaniCopyright:

Available Formats

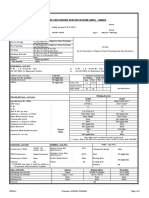

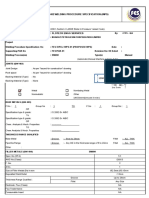

WELDING PROCEDURE SPECIFICATIONS (WPS) - QW482

Welding Procedure Specification No. : Dated :

Qualification Standards : ASME Section IX (E.D 2017)

Supporting PQR No. (s) : Dated :

Welding Process(es) : GTAW+ FCAW Type : Manual + Machine

Client Name :

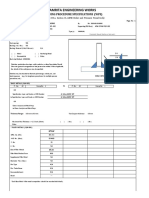

JOINTS - (QW 402)

Groove Design : As Per Annexure-1 /Drawings/Specifications

Root Spacing : As Per Annexure-1/ Drawings/Specifications

Details

No For Root Run & yes for Hot Pass &

Backing :

Subsequent passes As Per Annexure-1/ Drawings/Specifications

No For Root Run & Weld metal For

Backing Material :

Hot Pass & Subsequent Passes.

Retainers : None

□ Metal □ Nonfusing Metal

□ Non metallic □ Other

BASE METAL - (QW 403)

P. No. : 1 & Group No. : Any To P. No. : 1 & Group No. : Any

t Pass>1/2 in. (13 mm) : 5mm Max. Thickness Qualified in mm

Diameter Range

Change in P No. Qualified : Not Applicable As Welded With PWHT Qualified (in NPS)

Other(s) : Not Applicable Min. Max. Min. Max.

As With

Welded PWHT

Comp. Pen. 5 38.00 -- --

Impact Tested --- --- -- -- Min. Max. Min. Max.

No

Fillet Welds All All -- -- No -- --

Min.

Welding Process

FILLER METALS - (QW 404)

GTAW FCAW

Specification No. (SFA) : 5.18 SFA 5.20/5.36***

AWS Class : ER70S-2 E71T1-12MJ*

F. No. : 6 6

A. No. : 1 1

Size & Dia. (in mm) : 1.6, 2.0 & 2.4 1.2

Addition or Deletion of Filler : With Filler Only Not Applicable

Filler Metal Product Form : Bare (Solid) Flux Cored

Consumable Insert : None Not Applicable

Addition or Deletion of Flux : None Not Applicable

Supplemental filler matal : Not Applicable None

Alloy Elements : Not Applicable None

Groove 22 Max. 28.8 max.

Deposite Weld thickness (mm) :

Fillet All All

t Limits (S. cir. arc) : Not Applicable None

*Max Hydrogen content (ml/100 g) shll be 8

Other(s) :

*** As per SFA 5.36 AWS classification shall be E71T1-M21-AP5-CS2-DH4

POSITIONS - (QW 405) PREHEAT - (QW 406) PWHT - (QW 407)

GTAW : All Preheat Temp. Min. For T≤19 mm 45 °C

Position(s) of Weld : : Temperature Range : Not Applicable

FCAW :1G(Rotating)** (Both Process) & For T>19mm 120°C

GTAW : Uphill Interpass Temp. Max.

Weld Progression : : 300ºC Time : Not Applicable

FCAW : Flat (Both Process)

Position(s) of Fillet : All Preheat Maintenance : YES T> 19 MM Heating Rate : Not Applicable

Other(s) : Nil Others : Cooling Rate : Not Applicable

** For NPS less than 4" minimum 2 passes Other(s) : Nil

CE shall be Less than equal to 0.45

shall be welded

GAS - (QW 408) Gas(es) Mixture Ratio Flow Rate

Shielding Gas (GTAW) Argon 99.995 % (Single) 10-15 LPM

Shielding Gas (FCAW) Argon + Co2 80% + 20% 15-22 LPM

Trailing Gas None None None

Backing Gas None None None

Other(s) Nil

WPS No. : Processes : GTAW-M + FCAW-M/C Page 1 of 2

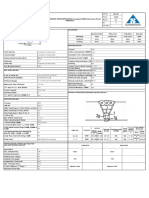

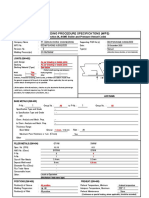

ELECTRICAL CHARACTERISTICS - (QW 409)

Filler Metal Current

Others

Voltage Travel Speed

(Remarks, Hot Wire

Weld Pass(es) Welding Process Range (mm/min.)

Dia Type & Amp. Range Addition, Technique,

Class (Volts) (Min.)

(mm) Polarity (A) Torch Angle Etc.)

1.6 90-110 9-10

1st Pass GTAW ER70S-2 2 DCEN 100-120 10-11 60-65

2.4 100-120 10-12

1.6 90-120 10-11

2nd& Susequent

GTAW ER70S-2 2 DCEN 100-130 10-13 70-80 Nil

Passes

2.4 100-143 10-15

1,2,3rd & Subsequent

FCAW E71T-1M 1.2 DCEP 190-220 24-26 115-130

Passes

4th &

FCAW E71T-1M 1.2 DCEP 210-240 24-27 130-145

Subsequent Passes

Pulsing Current : Not Used Heat Input Max. : NA

Tungsten Electrode Size & Type (GTAW) : Dia. 2.4 mm & SFA 5.12 EWTh -2 (2 % Thoriaed)

Metal Transfer Mode : GTAW : Not Applicable , FCAW : Globular

Wire feed Speed Range : 7-10 meter/minute

Other(s) : Nil

Welding Process

TECHNIQUE - (QW 410)

GTAW FCAW

String or Weave : String or Weave String /Weave

Orifice or Gas Cup Size (mm) : 6.25-10 upto 19

Method of cleaning : Wire Brushing & Grinding Wire Brushing & Grinding

Method of Back Gauge : Grinding if required Grinding if required

Width None 15-19 mm

Oscillation : Frequency None 0.15 to 0.33 cycle /sec

Dwell Time None 0.01 to 0.02 sec

Tube to Work Distance : Not Applicable 15-25 mm

Mutiple to Single Pass per Side : Multiple Multiple

Closed to Out Chamber : None Not Applicable

Single to Mutiple Electrodes Single Single

Electrode Spacing : None None

Manual or Automatic : Manual Machine

Peening : Not Allowed Not Allowed

Use of Thermal Process(es) : Not Allowed Not Allowed

1) This WPS shall be used for tacking, welding, weld repair & temporary attachments.

Other(s) : 2) The joint area shall be clean on either side of groove atleast 25 mm to remove

impurities like rust, dirt , oil & grease etc.

Name Signature/Seal Name Signature/Seal Name Signature/Seal

Witnessed/Reviewed By TPIA/Client ( If

Prepared By Approved By

required)

WPS No. : Processes : GTAW-M + FCAW-M/C Page 2 of 2

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding Procedure Specifications (WPS) - Qw482Document23 pagesWelding Procedure Specifications (WPS) - Qw482vichu_villamarNo ratings yet

- WPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticDocument2 pagesWPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticAlex MendozaNo ratings yet

- P1 Group Any To P1 Group Any GTAW-GMAW (Manual-Machine)Document2 pagesP1 Group Any To P1 Group Any GTAW-GMAW (Manual-Machine)Reda ElsayedNo ratings yet

- WPS P1 Group Any To P1 Group Any GTAW FCAW Manual MachineDocument2 pagesWPS P1 Group Any To P1 Group Any GTAW FCAW Manual MachinePrasad ChakkrapaniNo ratings yet

- Welding Procedure Specification for GTAW and FCAWDocument2 pagesWelding Procedure Specification for GTAW and FCAWTC Chick WilliamNo ratings yet

- C-Spec: Welding Procedure Specification - Page 1Document3 pagesC-Spec: Welding Procedure Specification - Page 1fatihkisaNo ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Wps-01 C.S. GtawDocument2 pagesWps-01 C.S. GtawMohamed Tarek HamamNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps Train 01 (AIDIL)Document2 pagesWps Train 01 (AIDIL)aidil30No ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Form WPS for MIG Welding ProcedureDocument10 pagesForm WPS for MIG Welding ProcedurePrakash PatelNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- WQT Record for Pipeline Welder QualificationDocument99 pagesWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pages(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023No ratings yet

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWDocument1 pageSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcNo ratings yet

- WPS-Shell To Shell Joint (CS-CS) .Document1 pageWPS-Shell To Shell Joint (CS-CS) .suria qaqcNo ratings yet

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Document2 pagesWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiNo ratings yet

- Plantilla WPS (SMAW) Junta TDocument1 pagePlantilla WPS (SMAW) Junta Tjhojan garciaNo ratings yet

- Plantilla WPS (SMAW) Junta TDocument1 pagePlantilla WPS (SMAW) Junta Tjhojan garciaNo ratings yet

- QW 482Document2 pagesQW 482Ramu NallathambiNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- WPS & PQR of Ravindra KumarDocument4 pagesWPS & PQR of Ravindra Kumartripatipankaj023No ratings yet

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocument2 pagesNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- WPS-Nozzle Without Reinforcement Pad (CS-CS) .Document1 pageWPS-Nozzle Without Reinforcement Pad (CS-CS) .suria qaqcNo ratings yet

- Ex Wps Train 01Document2 pagesEx Wps Train 01aidil30No ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- AWS WPS for welding steel with SMAWDocument2 pagesAWS WPS for welding steel with SMAWSleyda MunozNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Report on Welding Procedure Specifications for Single V-Groove JointsDocument15 pagesReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- WPS SS316Document4 pagesWPS SS316Budi Setia RahmanNo ratings yet

- Weld Procedure Specification (WPS)Document2 pagesWeld Procedure Specification (WPS)Senthil Kumaran0% (1)

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Pt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Document1 pagePt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Ilham PaneNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- Welding Procedure Specification: JOINTS (QW-402)Document3 pagesWelding Procedure Specification: JOINTS (QW-402)Nitin KurupNo ratings yet

- KSL BL 22-04-2022 Chennai EPaper Stocks 01Document1 pageKSL BL 22-04-2022 Chennai EPaper Stocks 01Prasad ChakkrapaniNo ratings yet

- PQNDT 2019 Salary Survey Results Reveal Strong Growth for NDT ProfessionalsDocument27 pagesPQNDT 2019 Salary Survey Results Reveal Strong Growth for NDT ProfessionalsPrasad ChakkrapaniNo ratings yet

- Gas Chromatography Terms and Relationships: Standard Practice ForDocument6 pagesGas Chromatography Terms and Relationships: Standard Practice ForPrasad ChakkrapaniNo ratings yet

- Commodity Technical Report Sept 27Document7 pagesCommodity Technical Report Sept 27Prasad ChakkrapaniNo ratings yet

- Posters Transducers en 201608 WebDocument1 pagePosters Transducers en 201608 WebGonzalo TelleríaNo ratings yet

- Magnaflux NDT Glossary: Alternating Current (AC) : Best Before End (BBE) Date: BleedoutDocument5 pagesMagnaflux NDT Glossary: Alternating Current (AC) : Best Before End (BBE) Date: BleedoutPrasad ChakkrapaniNo ratings yet

- Section - Rock Shield Pipeline Protection Mesh Part 1 - GeneralDocument1 pageSection - Rock Shield Pipeline Protection Mesh Part 1 - GeneralPrasad ChakkrapaniNo ratings yet

- How To Prepare ElectrodesDocument11 pagesHow To Prepare ElectrodesAlfred AryadiNo ratings yet

- Water Treatment of BoilersDocument2 pagesWater Treatment of BoilersPrasad ChakkrapaniNo ratings yet

- Shutdown ListDocument5 pagesShutdown ListAnoop A.kNo ratings yet

- Derivatives Daily: Wednesday, March 23, 2022Document5 pagesDerivatives Daily: Wednesday, March 23, 2022Prasad ChakkrapaniNo ratings yet

- Effect of Elemental Sulfur On Pitting Corrosion of SteelsDocument8 pagesEffect of Elemental Sulfur On Pitting Corrosion of SteelsGovindan KrishnamoorthybashyamNo ratings yet

- April 2022 1st Regulatory Update For SheelOnline Com SubscribersDocument2 pagesApril 2022 1st Regulatory Update For SheelOnline Com SubscribersPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Vertical LinesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Vertical LinesPrasad ChakkrapaniNo ratings yet

- نقشه استاندارد چرخدندهDocument7 pagesنقشه استاندارد چرخدندهPrasad ChakkrapaniNo ratings yet

- Bob's Weekly ScheduleDocument2 pagesBob's Weekly Schedulecikgujohn2No ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Top Counterclockwise 1 - 4 and 1 - 2 CirclesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Top Counterclockwise 1 - 4 and 1 - 2 CirclesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Top Clockwise 1 - 4 and 1 - 2 CirclesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Top Clockwise 1 - 4 and 1 - 2 CirclesPrasad ChakkrapaniNo ratings yet

- Norms Overview.: Pipeline ConstructionDocument3 pagesNorms Overview.: Pipeline ConstructionRjeb mohamedNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Slash LinesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Slash LinesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Top Clockwise 1 - 4 and 1 - 2 CirclesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Top Clockwise 1 - 4 and 1 - 2 CirclesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Slash LinesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Slash LinesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Top Counterclockwise 1 - 4 and 1 - 2 CirclesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Top Counterclockwise 1 - 4 and 1 - 2 CirclesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Right Counterclockwise 1 - 4 and 1 - 2 CirclesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Right Counterclockwise 1 - 4 and 1 - 2 CirclesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Vertical LinesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Vertical LinesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Pre Writing Exercises - Practice Right Counterclockwise 1 - 4 and 1 - 2 CirclesDocument1 pageBasic Handwriting - Pre Writing Exercises - Practice Right Counterclockwise 1 - 4 and 1 - 2 CirclesPrasad ChakkrapaniNo ratings yet

- Basic Handwriting - Practice 48Document1 pageBasic Handwriting - Practice 48Prasad ChakkrapaniNo ratings yet

- Basic Handwriting - Practice 36Document1 pageBasic Handwriting - Practice 36Prasad ChakkrapaniNo ratings yet

- HEC HMS - User's - Manual v4.11 20231018Document1,039 pagesHEC HMS - User's - Manual v4.11 20231018carmona.eitNo ratings yet

- Cryptography - Lucee DocumentationDocument2 pagesCryptography - Lucee Documentationrangel.sardinhaNo ratings yet

- Civil/Structural Calculation SheetDocument19 pagesCivil/Structural Calculation Sheetfbaxter22No ratings yet

- Unit 1Document112 pagesUnit 1gemerb505No ratings yet

- 056-123 Simulation Injection TestingDocument6 pages056-123 Simulation Injection TestingRoxanneNo ratings yet

- Ai-Ml in 5G Challenge ReportDocument11 pagesAi-Ml in 5G Challenge ReportUsha ChandrakalaNo ratings yet

- BS en 12953-12-2003Document22 pagesBS en 12953-12-2003Tuấn ChuNo ratings yet

- Specification For 11/0.433 KV Distribution Transformers, Dry Type (Cast Resin), Ground Mounted For Indoor ApplicationsDocument10 pagesSpecification For 11/0.433 KV Distribution Transformers, Dry Type (Cast Resin), Ground Mounted For Indoor ApplicationsIhab Shawkiه8No ratings yet

- Devanshi Shipping Agency PVT LTD: Infinity International Infinity InternationalDocument5 pagesDevanshi Shipping Agency PVT LTD: Infinity International Infinity InternationalTARUN SUTHARNo ratings yet

- EagleBurgmann - PDGS Dry Gas Seal Upgrade For Australian LNG ProjectDocument2 pagesEagleBurgmann - PDGS Dry Gas Seal Upgrade For Australian LNG Projectsudhindra_tiwariNo ratings yet

- DC Motoren LSK Technical Catalogue en Iss201712 e 3805 PDFDocument164 pagesDC Motoren LSK Technical Catalogue en Iss201712 e 3805 PDFJEDPNo ratings yet

- Fault Codes HyundaiDocument12 pagesFault Codes HyundaiAnonymous j7LBFXO50% (2)

- Maritime StandardsDocument102 pagesMaritime StandardsMgZin0% (1)

- 2. CHUYÊN ĐỀ 2 (LỖI SAI + VIẾT CÂU)Document4 pages2. CHUYÊN ĐỀ 2 (LỖI SAI + VIẾT CÂU)farm 3 chi di0% (1)

- Writing A Concept Paper-1Document29 pagesWriting A Concept Paper-1Yhazmin Iris IlustrisimoNo ratings yet

- ConocoPhilips Addendum To Norsok Z-010Document11 pagesConocoPhilips Addendum To Norsok Z-010XamiPatiNo ratings yet

- M5A78L-M PLUS-USB3 Devices ReportDocument21 pagesM5A78L-M PLUS-USB3 Devices ReportDante MoretaNo ratings yet

- Hybrid Pile Foundations IPWE SeminarDocument22 pagesHybrid Pile Foundations IPWE Seminarrohit100% (1)

- Technical Specifications 500 - 11 - 0.415 Dyn11 CuAl Imp 6Document1 pageTechnical Specifications 500 - 11 - 0.415 Dyn11 CuAl Imp 6Dilesh SwitchgearNo ratings yet

- M I M Nafrees QSDocument2 pagesM I M Nafrees QSnafreesmimNo ratings yet

- Quantifying The Seasonal Cooling Capacity of Green Infrastr 2020 LandscapeDocument21 pagesQuantifying The Seasonal Cooling Capacity of Green Infrastr 2020 Landscape熙槃No ratings yet

- Ip Half Yearly Exam 1 - 2022Document7 pagesIp Half Yearly Exam 1 - 2022Ayushmaan MaithaniNo ratings yet

- Kalibrr Brochure 2020 PDFDocument12 pagesKalibrr Brochure 2020 PDFSuryadi YadiNo ratings yet

- Array in C++Document19 pagesArray in C++Shweta ShahNo ratings yet

- WCFX-E Guide SpecificationDocument3 pagesWCFX-E Guide SpecificationaftabNo ratings yet

- Data Domain Command Reference Guide 6.0Document464 pagesData Domain Command Reference Guide 6.0markus_egli100% (1)

- B. Tech-in-Computer-Science-and-Engineering-Data-Science-Thir-Year-2023-24Document73 pagesB. Tech-in-Computer-Science-and-Engineering-Data-Science-Thir-Year-2023-24Sushant5inghrajputNo ratings yet

- Study On Electricity Distribution Substation Operation Amp Maintenance of DescoDocument46 pagesStudy On Electricity Distribution Substation Operation Amp Maintenance of DescoJayant KoshtiNo ratings yet

- + - OSDI2020-FIRM - An Intelligent Fine-Grained Resource Management Framework For SLO-Oriented MicroservicesDocument22 pages+ - OSDI2020-FIRM - An Intelligent Fine-Grained Resource Management Framework For SLO-Oriented MicroservicesBENKEMCHI OussamaNo ratings yet

- Test Procedure Offer 019-14V 3015Document5 pagesTest Procedure Offer 019-14V 3015sohaibNo ratings yet