Professional Documents

Culture Documents

WPS No.: 1.203 Rev.: 4

Uploaded by

beyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS No.: 1.203 Rev.: 4

Uploaded by

beyCopyright:

Available Formats

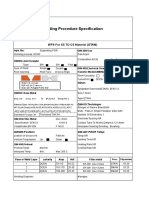

Approved: WPS No.: 1.203 Rev.

: 4

Date: March 7, 1994 Revision Date: September 30, 1998

Supporting PQR No. (s): w/o PWHT L4169 (PRN031) & L4189 (PRN032)

With PWHT L6126 (PRN038)

Welding Process: GTAW Type(s): Manual

JOINTS (QW-402)

Refer to WPS No. GEN for typical joint designs. This WPS may be used with or without backing.

This WPS is qualified for minus (-) 50 degrees F. Impact tested fabrication per ASME B31.3.

BASE METALS (QW-403)

P-No.: 1 Group No.: 1 or 2 to P-No.: 1 Group No.: 1 or 2

Thickness Range:

0.120 thru 0.750 w/o PWHT

Base Metal: Groove 0.625 thru 1.438 with PWHT Fillet Any

Other The deposition of any pass shall not exceed .

FILLER METALS (QW-404)

Spec No. (SFA): 5.28

AWS No. (Class): ER80S-Nil

F-No.: 6

A-No.: 10

Size of Filler Metals: 1/16, 3/32, 1/8

Weld Metal:

Thickness Range:

0.750 Maximum w/o PWHT

Groove: 0.500 Maximum with PWHT

Fillet: All

Electrode-Flux (Class) Not Applicable

Flux Trade Name Not Applicable

Consumable Insert None Allowed

Other

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove: All Temperature Range: Condition (1): As-Welded

Welding Progression: Up XX -or-

Down ____ Condition (2): Stress Relieved

Position(s) of Fillets: All

Time Range: 2.5 Hour Maximum

PREHEAT (QW-406) GAS (QW-408) Percent

Composition CFH

Preheat Temperature Minimum: 50oF Gas(es) (Mixture) Flow Rate

Interpass Temperature Maximum: 350oF Shielding Argon 100 15 Min

Preheat Maintenance: None Required Trailing None None None

Backing None None None

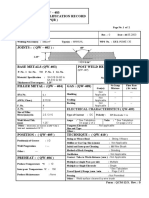

WPS No.: 1.203 Rev.: 4

ELECTRICAL CHARACTERISTICS (QW-409)

Current: AC or DC: DC Polarity: EN

Tungsten Electrode Size and Type: 3/32 or 1/8 2% Thoriated (SFA 5.12, AWS EWTh-2)

Electrode Wire Feed Speed Range: Neither required nor prohibited

Travel

Filler Metal Speed

Weld Amp. Volt Range Other

Layer(s) Process Class Dia. Range Range (IPM)

Root Pass GTAW ER80S-Nil 1/16 60-180 10-17 Note 3

and/or GTAW ER80S-Nil 3/32 60-180 10-17 Note 3

Fill & Cap GTAW ER80S-Nil 1/8 60-180 10-17 Note 3

TECHNIQUE (QW-410)

String or Weave Bead String or Weave

Orifice or Gas Cup Size Diameter Minimum

Initial and Interpass Cleaning As per WPS No. GEN.

Method of Back Gouging As per WPS No. GEN.

Oscillation Manual

Contact Tube to Work Distance Not Applicable

Multiple or Single Pass (per side) Multiple

Multiple or Single Electrodes Single

Peening None Allowed

Other

NOTES:

Note 1: This WPS must be used in conjunction with WPS No. Gen.

Note 2: All passes shall be made with the addition of filler metal.

Note 3: For impact tested fabrication, minimum travel speed shall be determined by the following

formulas where S stands for Minimum Allowable Travel Speed:

PWHTd Fabrication: S = Volts X Amps

640

As-Welded Fabrication: S = Volts X Amps

1155

You might also like

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 pagesWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Basic Operation Electrical - Total - Eng - Prot PDFDocument439 pagesBasic Operation Electrical - Total - Eng - Prot PDFdidik setiawan100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Piping DesignDocument89 pagesPiping Designbey100% (2)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Introduction To Drilling: School of Hassi MessaoudDocument210 pagesIntroduction To Drilling: School of Hassi MessaoudbeyNo ratings yet

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- Toaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRDocument17 pagesToaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRBhumika SahuNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- RestraintsDocument48 pagesRestraintsLeena Pravil100% (1)

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Wps Model 2 PDFDocument17 pagesWps Model 2 PDFbeyNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- Flare Ignition ProcedureDocument4 pagesFlare Ignition ProcedurebeyNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Benefits of Silicone Coated Glass InsulatorsDocument10 pagesBenefits of Silicone Coated Glass InsulatorsMuhammad Waseem AhmadNo ratings yet

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- A I R P O R T S Construction Program Management 56Document56 pagesA I R P O R T S Construction Program Management 56Carl WilliamsNo ratings yet

- Bakery Ind HygieneDocument104 pagesBakery Ind Hygienelabie100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Engineering Data Book: Gas Processors Suppliers AssociationDocument30 pagesEngineering Data Book: Gas Processors Suppliers Associationbey0% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- 403 Rev 2Document2 pages403 Rev 2beyNo ratings yet

- 5 B503 Rev 5Document2 pages5 B503 Rev 5beyNo ratings yet

- 104 Rev 2Document2 pages104 Rev 2beyNo ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 pagesAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1No ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- STD WPSDocument1 pageSTD WPSWaqas WaqasNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- WPS-PQR Gr. CF8MDocument9 pagesWPS-PQR Gr. CF8Mansarmulla711No ratings yet

- WPS-PQR Gr. WCBDocument9 pagesWPS-PQR Gr. WCBansarmulla711No ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Welding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic MachineDocument1 pageWelding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic Machinesoroushsadeghi60No ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Pipeline & Piping ScheduleDocument12 pagesPipeline & Piping SchedulebeyNo ratings yet

- 4 Wti Wellsite ValidationDocument6 pages4 Wti Wellsite ValidationbeyNo ratings yet

- Bilad 2018 01 21Document25 pagesBilad 2018 01 21beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Well Test Interpreta TionDocument6 pagesWell Test Interpreta TionbeyNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- Sonahess: Bechtel Spécification Du Procédé de Soudage Welding Procedure SpecificationDocument2 pagesSonahess: Bechtel Spécification Du Procédé de Soudage Welding Procedure SpecificationbeyNo ratings yet

- PRN List For Volume 1-113001Document1 pagePRN List For Volume 1-113001beyNo ratings yet

- Table of Contents-Rev. 07Document4 pagesTable of Contents-Rev. 07beyNo ratings yet

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Document1 pagePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNo ratings yet

- PRC-0008 CurrentDocument50 pagesPRC-0008 CurrentbeyNo ratings yet

- GENREV11Document14 pagesGENREV11beyNo ratings yet

- Wa0016Document3 pagesWa0016Vinay DahiyaNo ratings yet

- Cooling SistemadeRefrigeracion RefroidissementDocument124 pagesCooling SistemadeRefrigeracion RefroidissementPacoNo ratings yet

- Sudheer Kumar CVDocument3 pagesSudheer Kumar CVGujjar Dhayki valeNo ratings yet

- Manual Gavita Pro 600e SE EU V15-51 HRDocument8 pagesManual Gavita Pro 600e SE EU V15-51 HRwhazzup6367No ratings yet

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaNo ratings yet

- Wes Jackson PM PMP OhioDocument10 pagesWes Jackson PM PMP Ohioraj jdsNo ratings yet

- CRM McDonalds ScribdDocument9 pagesCRM McDonalds ScribdArun SanalNo ratings yet

- PD 984Document38 pagesPD 984mav3riick100% (2)

- Distribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoDocument15 pagesDistribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoaldiNo ratings yet

- Aliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterDocument2 pagesAliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterConstantin UdreaNo ratings yet

- Qi Gong & Meditation - Shaolin Temple UKDocument5 pagesQi Gong & Meditation - Shaolin Temple UKBhuvnesh TenguriaNo ratings yet

- TDS Shell Spirax s6 Gxme 75w-80Document2 pagesTDS Shell Spirax s6 Gxme 75w-80rstec pyNo ratings yet

- Pentacam Four Maps RefractiveDocument4 pagesPentacam Four Maps RefractiveSoma AlshokriNo ratings yet

- MAIZEDocument27 pagesMAIZEDr Annie SheronNo ratings yet

- UK FreshTECH Jammer RecipeBook 0Document24 pagesUK FreshTECH Jammer RecipeBook 0Temet NoscheNo ratings yet

- Traditional vs. Enterprise Risk Management - How Do They DifferDocument4 pagesTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanNo ratings yet

- Umur Ekonomis Mesin RevDocument3 pagesUmur Ekonomis Mesin Revrazali akhmadNo ratings yet

- Narrative ReporDocument3 pagesNarrative ReporMARK LUKE ULITNo ratings yet

- Group 7 Worksheet No. 1 2Document24 pagesGroup 7 Worksheet No. 1 2calliemozartNo ratings yet

- Full Bridge Phase Shift ConverterDocument21 pagesFull Bridge Phase Shift ConverterMukul ChoudhuryNo ratings yet

- Presentation - Factors Affecting ClimateDocument16 pagesPresentation - Factors Affecting ClimateAltoverosDihsarlaNo ratings yet

- Richard Teerlink and Paul Trane - Part 1Document14 pagesRichard Teerlink and Paul Trane - Part 1Scratch HunterNo ratings yet

- Virtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonDocument1 pageVirtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonPlay Dos ChipeadaNo ratings yet

- W2 - Fundementals of SepDocument36 pagesW2 - Fundementals of Sephairen jegerNo ratings yet