Professional Documents

Culture Documents

Welding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3

Uploaded by

Erick HoganOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3

Uploaded by

Erick HoganCopyright:

Available Formats

COMBINED GROUP CONTRACTING COMPANY (K.S.C.

C)

WPS No : WPS / CGC / 014

WELDING PROCEDURE SPECIFICATION (W.P.S)

Rev. 00

According to ASME IX &ASME B31.3

PROCESS: GTAW + SMAW

SHEET : 1 OF 2

PQR No.: PQR/CGC/014

TYPE: MANUAL

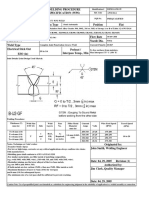

JOINT (QW-402)

Joint Design:

Backing (y/n):

Backing/Retainer Material:

BASE METAL (QW-403)

P-No 1 Gr. No : 1

Type & grade: ASTM A333 Gr6&A106

to type & grade: ASTM A333 Gr6&A106

JOINT DETAILS

See Joint Details

None

Base metal

to

P-No 1 Gr. No : 1

&A420WPL6&A694F52&A234WPB &A105

&A420WPL6&A694F52&A234WPB &A105

Thickness range : 13 mm TO

32 mm for Groove & Unlimited for Fillet (QW-451.4)

Diameter Range : 1 inch To Unlimited

Test Coupon : PIPE ASTM A333Gr6

10 " DIA. &THICKNESS 25.4 mm

(ROOT&HOOT)

GTAW

5.18

ER 70S-3

F6

A1

5 mm

2.4 mm

FILLER METAL (QW-404)

Spec. No (SFA)

AWS No (Class)

F-No

A-No

Deposited weld metal (MAX) :12.7 mm

Filler metal electrode size

Electrode flux type

Tungsten electrode size

Tungsten electrode type

2.4 mm

EW Th 2%

Trade Name

LINCOLN

POSITION (QW-405)

Position(s) of groove :

6G

Welding direction (up/down)

Uphill

Position(s) of fillet :

All

POST WELD HEAT TREATMENT (QW-407)

Heating Rate (C/h):

150 C/HR MAX.

STARTED FROM AMBIENT TEMP

Temperature range (C): 593 C 620 C

Holding time (h): 1.5 HR

Cooling Rate (C/h): 150 C/HR MAX. AIR TO 300 C THEN COOL IN STILL

DOWN TO AMBIENT TEMP.

(TWO CYCLES)

(FILLING) SMAW

(CAP) SMAW

5.1

E7018-1 H4R

F4

A1

3.25 &4 mm

Low hydrogen iron powder

5.1

E7018-1 H4R

F4

A1

3.25 mm

Low hydrogen iron powder

-

LINCOLN

PREHEAT (QW-406)

Preheat temperature (min):

LINCOLN

79 oC

Interpass temperature (max.) : 250 C

Other : preheating is done by heating

torch

GAS (QW-408)

Shielding:

Trailing:

Backing:

Gas(es)

Argon

N.A.

None

% Composition

99.99%

N.A.

N.A.

ELECTRICAL CHARACTERISTICS (QW-409)

Type of current : DC

Polarity :Straight (DCEN) for ROOT and HOOT pass& Reverse (DCEP)-OTHER

Amps/Volts range: see table shown below

TECHNIQUE (QW-410)

String or weave beads:

Orifice or gas cup size:

Initial & interpass cleaning:

Multiple or single electrodes:

Oscillation:

String for ROOT &Weave for Others

N/A

Grinding and/or brushing

Single

N.A.

CGC

QA/QC ENGINEER

DATE

16/11/2011

NAME

AMR ABD EL-AZIZ MOHAMED

SIGNATURE

Multiple or single pass (for side):

Method of back gouging

Peening :

Contact tube to work distance:

Other:

Multipass

N.A.

None

N.A.

N.A.

KOC (CLINT)

APPROVAL

Flow rate (Lliter/min)

15- 25

N.A.

N.A.

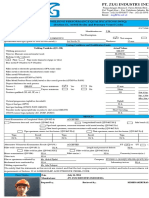

COMBINED GROUP CONTRACTING COMPANY (K.S.C.C)

WPS No : WPS / CGC / 014

WELDING PROCEDURE SPECIFICATION (W.P.S)

Rev. 00

According to ASME IX &ASME B31.3

PROCESS: GTAW + SMAW

Sheet : 2 OF 2

PQR No.: PQR/CGC/014

TYPE: MANUAL

ELECTRICAL CHARACTERISTICS

LAYER No. /

Weld Pass No.

Deposited

Weld Metal

FILLER METAL

PROCESS

CURRENT

CLASSIFICATION

SIZE

(mm)

TYPE

AMPERES

VOLTS

TRAVEL

SPEED

MAX. HEAT INPUT

(cm/min)

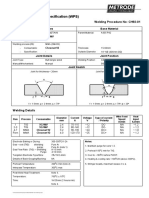

1st/1st

ROOT

GMAW

ER 70S-3

2.4

DCEN

138 -140

9 - 10

7.0

1.2 KJ/mm

2 /2

nd

HOOT

GMAW

ER 70S-3

3 /3

10.5

1.14 KJ/mm

4 /4

E7018-1 H4R

E7018-1 H4R

9 - 10

22 -25

th

SMAW

SMAW

141 -142

79 - 80

th

FILLING

FILLING

DCEN

DCEP

0.852 KJ/mm

rd

2.4

2.5

10.0

rd

3.2

DCEP

118 - 120

22 -26

10.0

1.8 KJ/mm

th

4 /5

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

124 - 126

22 -26

10.7

1.8 KJ/mm

th

5 /6

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

124 -126

22 -26

10.7

1.9 KJ/mm

th

5 /7

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

128 - 130

22 -26

10.9

1.86 KJ/mm

th

5 /8

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

127 - 129

22 -27

10.8

1.9 KJ/mm

6 /9

th

E7018-1 H4R

3.2

DCEP

128 - 130

20 -26

15.6

1.3 KJ/mm

6 /10

FILLING

FILLING

SMAW

th

SMAW

E7018-1 H4R

3.2

DCEP

126 - 128

20 -26

15.5

1.3 KJ/mm

6 /11

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

126 - 128

20 -26

15.5

1.28 KJ/mm

6 /12

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

128 - 130

20 -26

15.5

1.3 KJ/mm

th

nd

th

th

th

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

128 - 130

20 -26

15.3

1.3 KJ/mm

7 /14

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

128 - 130

20 -26

15.4

1.3 KJ/mm

7 /15

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

128 - 130

20 -26

15.0

1.4 KJ/mm

7 /16

th

FILLING

SMAW

E7018-1 H4R

3.2

DCEP

128 - 130

20 -26

15.2

1.4 KJ/mm

8 /17

th

CAP

SMAW

E7018-1 H4R

2.5

DCEP

79 - 80

19-24

13.5

0.85 KJ/mm

8 /18

th

CAP

SMAW

E7018-1 H4R

2.5

DCEP

79 - 80

19-24

14.0

0.82 KJ/mm

8 /19

th

CAP

SMAW

E7018-1 H4R

2.5

DCEP

79 - 80

19-24

14.5

0.80 KJ/mm

8 /20

th

CAP

SMAW

E7018-1 H4R

2.5

DCEP

79 - 80

19-24

14.7

0.78 KJ/mm

8 /21

th

CAP

SMAW

E7018-1 H4R

2.5

DCEP

79 - 80

19-24

14.0

0.85 KJ/mm

7 /13

th

th

th

th

th

th

th

th

th

CGC

QA/QC ENGINEER

DATE

16/11/2011

NAME

AMR ABD EL-AZIZ MOHAMED

SIGNATURE

KOC (CLINT)

APPROVAL

You might also like

- Job Hazard Analysis Changing A Tire ExampleDocument4 pagesJob Hazard Analysis Changing A Tire ExampleNur Hidayah Ishak Hizam94% (33)

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- MFC 12M e 2006Document22 pagesMFC 12M e 2006Ramil100% (1)

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- Cajon-001 WPSDocument2 pagesCajon-001 WPSDanem HalasNo ratings yet

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 pagesWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshNo ratings yet

- CME 3303 HW 6 Solution PDFDocument4 pagesCME 3303 HW 6 Solution PDFrum kaunNo ratings yet

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Astm A500 A500m-21Document6 pagesAstm A500 A500m-21alvin duey100% (1)

- Annex Form J1 D1.1 D1.1M 2020 PDFDocument4 pagesAnnex Form J1 D1.1 D1.1M 2020 PDFDarioNo ratings yet

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Catalogo AWSDocument46 pagesCatalogo AWScesarNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument7 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCTrường Tùng LýNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Welding Protocol For Extrusion 1Document1 pageWelding Protocol For Extrusion 1Mark Kevin BechaydaNo ratings yet

- ASME IX (2023) - Essential Variable For WPS & WeldersDocument37 pagesASME IX (2023) - Essential Variable For WPS & WeldersMohammed Khalid HussainNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- A53a53m 16142 PDFDocument23 pagesA53a53m 16142 PDFabdulkadir aliNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301No ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Evaluating The Performance of Radiographic Digitization SystemsDocument4 pagesEvaluating The Performance of Radiographic Digitization SystemsERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- Mechanical Testing 01B: Part 2 Charpy Impact TestingDocument25 pagesMechanical Testing 01B: Part 2 Charpy Impact Testingsamurai7_77100% (1)

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Manual CalidadDocument23 pagesManual CalidadGabriel GaraventaNo ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pages177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNo ratings yet

- D17.1 D17.1M 2017 Sample PQTR FormDocument1 pageD17.1 D17.1M 2017 Sample PQTR FormPabloLamelaNo ratings yet

- Filler Metal Data Handbook - CompleteDocument330 pagesFiller Metal Data Handbook - Completeessnelson100% (2)

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Wps Guides 2006Document25 pagesWps Guides 2006BE GNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- SSPC QP 3Document6 pagesSSPC QP 3anoopkumarNo ratings yet

- Pipe Clamps For Welding Alignment (DWT Babcock) 3Document2 pagesPipe Clamps For Welding Alignment (DWT Babcock) 3Daniel AriefinNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Welding Procedure Specification: Wps NoDocument1 pageWelding Procedure Specification: Wps NoLipika Gayen100% (1)

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- M 4 D1.1 2015 Form PDFDocument1 pageM 4 D1.1 2015 Form PDFDabbar TaherNo ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- GB 1591 Q420 Steel PropertiesDocument6 pagesGB 1591 Q420 Steel Propertiespbp2956No ratings yet

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- Welding Procedure Specification Structural-3GDocument3 pagesWelding Procedure Specification Structural-3Gdndudc78% (9)

- 1015 To Hastelloy VickoDocument14 pages1015 To Hastelloy Vickovgestantyo100% (1)

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- Cambridge English Vocabulary PDFDocument269 pagesCambridge English Vocabulary PDFErick HoganNo ratings yet

- Week13 Iron Carbon Phase DiagramDocument49 pagesWeek13 Iron Carbon Phase DiagramvishalNo ratings yet

- Iron Carbon Part1 PDFDocument33 pagesIron Carbon Part1 PDFErick HoganNo ratings yet

- English DialogueDocument5 pagesEnglish DialogueErick HoganNo ratings yet

- (Class 16) Bulk ModulusDocument18 pages(Class 16) Bulk ModulusJavier UribeNo ratings yet

- Soilds, Liquids & Gases Revision BookletDocument4 pagesSoilds, Liquids & Gases Revision BookletAnonymous pYNNFWNo ratings yet

- Atoll 1100Document2 pagesAtoll 1100Cesar Ventura100% (1)

- KR SCAC (R410A 50,60Hz) Saudi CO MFL67986317 0CSL0-05A (April.2021)Document140 pagesKR SCAC (R410A 50,60Hz) Saudi CO MFL67986317 0CSL0-05A (April.2021)ahmed ragabNo ratings yet

- Toku AirtoolenDocument9 pagesToku AirtoolenJhun AquinoNo ratings yet

- Ntorq Cat 21 3 18Document39 pagesNtorq Cat 21 3 18David ManjgaladzeNo ratings yet

- Technical Boiler Inside Cleaning Unit 02 PW Plant (Rev.00)Document17 pagesTechnical Boiler Inside Cleaning Unit 02 PW Plant (Rev.00)Iqbal Safirul BarqiNo ratings yet

- DMBD BMR Topb 21-JuniDocument2 pagesDMBD BMR Topb 21-JuniFeri PadandiNo ratings yet

- Hilti HSA Expansion Anchor: Technical DatasheetDocument11 pagesHilti HSA Expansion Anchor: Technical Datasheetmohammad alsayyidNo ratings yet

- Bench BlastingDocument2 pagesBench BlastingAgha Shafi Jawaid KhanNo ratings yet

- Pump Room SystemsDocument8 pagesPump Room SystemsArdyas Wisnu Baskoro100% (1)

- Parts Catalogue: CD DeluxeDocument52 pagesParts Catalogue: CD DeluxeJonathan FiquitivaNo ratings yet

- 05 Erection ChecklistDocument8 pages05 Erection ChecklistAnonymous cG5MyHMNo ratings yet

- Direct Shift Gearbox 02E, Four-Wheel DriveDocument157 pagesDirect Shift Gearbox 02E, Four-Wheel Driveits4u20102744100% (2)

- Bray Product ProfileDocument24 pagesBray Product ProfilehassanNo ratings yet

- Further Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionDocument7 pagesFurther Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionMark SternNo ratings yet

- 03a Direct Stiffness Method Spring and BarDocument23 pages03a Direct Stiffness Method Spring and BarAnamolNo ratings yet

- TRZ 03 TRZ 03: Turbine Meter Turbine MeterDocument6 pagesTRZ 03 TRZ 03: Turbine Meter Turbine MeterLuigi PortugalNo ratings yet

- Cantilever Retaining Walls - An Overview of The Design ProcessDocument4 pagesCantilever Retaining Walls - An Overview of The Design ProcessSergiu GraurNo ratings yet

- Samsung Multi Zone System ComponentsDocument8 pagesSamsung Multi Zone System Componentse-ComfortUSANo ratings yet

- TLE TVL SHIELDED METAL ARC WELDING NCI ACTIVITY SHEET NO. 2 2nd QuarterDocument6 pagesTLE TVL SHIELDED METAL ARC WELDING NCI ACTIVITY SHEET NO. 2 2nd QuarterMaricar CarandangNo ratings yet

- Anna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Document5 pagesAnna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Sai KrishnaNo ratings yet

- Welding ProcessDocument6 pagesWelding ProcessRENGANATHAN PNo ratings yet

- NAK Catalogue-Product OverviewDocument24 pagesNAK Catalogue-Product OverviewichsanNo ratings yet

- Natural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsDocument11 pagesNatural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsResearcherzNo ratings yet

- Design of Mechanical ComponentsDocument40 pagesDesign of Mechanical Componentsharish1989No ratings yet

- Crouse HindsDocument1 pageCrouse Hindsedi hendrikusNo ratings yet