Professional Documents

Culture Documents

Hust WPS Gtaw - Smaw 6G

Uploaded by

truongtrungplhdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hust WPS Gtaw - Smaw 6G

Uploaded by

truongtrungplhdCopyright:

Available Formats

HANOI UNIVERSITY OF SCIENCE AND TECHNOLOGY

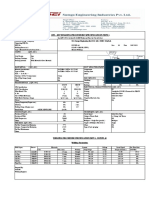

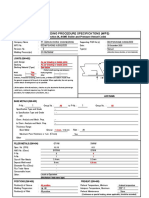

SCHOOL OF MECHANICAL ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS)

Department of Welding Engineering and Metals Technology (ASME IX:2007)

No. 1, Dai Co Viet Str., Hai Ba Trung Dist., Ha Noi, Vietnam

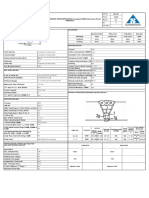

Welding Procedure Specification No.: HUST-WPS-GTAW.SMAW-6G JOINTS SKETCH

Date April 14, 2013 Joint design Groove and Fillet welds

Revision 0 Backing Yes (for SMAW)

Welding Process(es) GTAW+SMAW Backing Material (Type) Weld metal

Types (Manual/Automatic/Semi-automatic) Manual Other N/A

Procedure Qualification Record No. HUST-PQR-GTAW.SMAW-6G

BASE METALS POST WELD HEAT TREATMENT

Material Specification SA 355 Temperature 730 - 774 oC

Type or Grade P91 Time Min 2 hours. Cooling below 100 oC before PWHT

Group-No. to Group-No. 15E to 15E Other Heating & cooling rate: 100 - 150 oC/hour

Thickness (mm) 5 to 60

Size (mm) N/A ELECTRICAL CHARACTERISTICS

Other N/A Process GTAW SMAW

Current Polarity DC- DC+

FILLER METALS Amperes (Range) See the table below See the table below

Process GTAW SMAW Volts (Range) See the table below See the table below

F No. 6 4

A No. 5 5 GAS

SFA No. 5.28 A5.5 Process GTAW SMAW

AWS Class. ER 90S-B9 E9015-B9 Shielding Gas(es) Argon N/A

Elect/Filler Dia. Φ 2.0; 2.4 Φ 2.6; 3.2; 4.0 Percent Composition 99.999% N/A

9CrMoV-N (Lincoln) or Chromet 9MV-N (Lincoln) or

Elect/Filler Trade Name Flow Rat (l/ph) 8-25 N/A

Equivalent Equivalent

Electrode-Flux (Class) N/A N/A Gas Backing Argon N/A

Flux Trade Name N/A N/A Percent Composition 99.999% N/A

Non-Consumable Elect 2% Th N/A Flow Rat (l/ph) 4-15 N/A

Non-Consumable Elect Dia. 2.4 N/A Trailing Shielding N/A N/A

Deposited weld metal thick. - -

POSITION TECHNIQUE

Process GTAW SMAW Process GTAW SMAW

Position of Groove All All String or Weave Bead String or/and Weave String and/or Weave

Position of Fillet All All Orifice or Gas Cup Size No. 4, 5, 6 N/A

Weld Progression Uphill Uphill Interpass Cleaning Brushing and Grinding Brushing and Grinding

Other N/A N/A Method of Back Gouging N/A N/A

Oscillation N/A N/A

PREHEAT Contact Tube to Work Distance N/A N/A

Preheat Temperature Min 200 C o

Multiple or Single Pass (per Side) Multipass Multipass

Interpass Temperature Max 300 oC

Preheat maintenace Yes

Multiple or Single Electrodes Single Single

Method of Checking Temp. Crayon /Thermometer

Other N/A Travel speed (Range) See the table below See the table below

WELDING PARAMETER

Depth of Weld

Layer Elect/Filler Current Voltage T. Speed H. Input Deposit

Width of Weld Bead Backing gas flow Shielding gas flow

Pass No. Process rate (l/min) rate (l/min)

No

AWS Class Dia. Polarity A V mm/min kJ/mm mm mm

root 1.1 GTAW ER90S-B9 2.4 DC- 70 - 160 10 - 14 40 - 60 0.70 - 3.36 N/A N/A 4 - 15 8 - 25

2.1 ER90S-B9 2.4 DC- 70 - 160 10 - 14 40 - 70 0.60 - 3.36 N/A N/A 4 - 15 8 - 25

hot GTAW

2.2 ER90S-B9 2.4 DC- 70 - 160 10 - 14 40 - 70 0.60 - 3.36 N/A N/A 4 - 15 8 - 25

3.1 E9015-B9 2.6 DC+ 70 - 100 20 - 28 50 - 90 0.93 - 3.36 N/A 11.0 N/A N/A

Fill

and … SMAW E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 N/A 13.0 N/A N/A

Cap

n E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 N/A 16.0 N/A N/A

Prepared by: Reviewed by: Approved by:

Name: HAN LE DUY Name: Name:

Signature: Signature: Signature:

Date 14/4/2013 Date Date

HANOI UNIVERSITY OF SCIENCE AND TECHNOLOGY

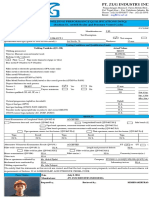

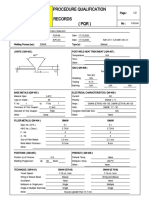

SCHOOL OF MECHANICAL ENGINEERING PROCEDURE QUALIFICATION RECORD (PQR)

Department of Welding Engineering and Metals Technology (ASME IX:2007)

No. 1, Dai Co Viet Str., Hai Ba Trung Dist., Ha Noi, Vietnam

Welder's Name & ID No. NGUYEN VAN THANG ID No.: 142512337

Procedure Qualification Record No.: HUST-PQR-GTAW.SMAW-6G JOINTS

Date April 14, 2013

Revision 0

Welding Process(es) GTAW+SMAW

Types (Manual/Automatic/Semi-automatic) Manual

Welding Procedure Specification No.: HUST-WPS-GTAW.SMAW-6G

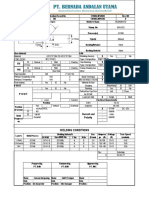

BASE METALS POST WELD HEAT TREATMENT

Material Specification SA 355 Temperature 730 oC

Type or Grade P91 Time Min 2 hours. Cooling below 100 oC before PWHT

Group-No. to Group-No. 15E to 15E Other Heating rate: 105 oC/hour; Cooling rate: 100 oC/hour

Thickness (mm) 30

Size (mm) N/A ELECTRICAL CHARACTERISTICS

Other N/A Process GTAW SMAW

Current Polarity DC- DC+

FILLER METALS Amperes (Range) See the table below See the table below

Process GTAW SMAW Volts (Range) See the table below See the table below

F No. 6 4

A No. 5 5 GAS

SFA No. 5.28 A5.5 Process GTAW SMAW

AWS Class. ER 90S-B9 E9015-B9 Shielding Gas(es) Argon N/A

Elect/Filler Dia. Φ 2.4 Φ 2.6; 3.2; 4.0 Percent Composition 99.999% N/A

Elect/Filler Trade Name 9CrMoV-N (Lincoln) Chromet 9MV-N Flow Rate (l/ph) 8-25 N/A

Electrode-Flux (Class) N/A N/A Gas Backing Argon N/A

Flux Trade Name N/A N/A Percent Composition 99.999% N/A

Non-Consumable Elect 2% Th N/A Flow Rate (l/ph) 4-15 N/A

Non-Consumable Elect Dia. (mm) 2.4 N/A Trailing Shielding N/A N/A

Deposited weld metal thick. (mm) 6 24

POSITION TECHNIQUE

Process GTAW SMAW Process GTAW SMAW

Position of Groove 6G 6G String or Weave Bead String or/and Weave String and/or Weave

Position of Fillet N/A N/A Orifice or Gas Cup Size No. 4, 5, 6 N/A

Weld Progression Uphill Uphill Interpass Cleaning Brushing and Grinding Brushing and Grinding

Other N/A N/A Method of Back Gouging N/A N/A

Oscillation N/A N/A

PREHEAT Contact Tube to Work Distance N/A N/A

Preheat Temperature 200 oC

Multiple or Single Pass (per Side) Multipass Multipass

Interpass Temperature Max 300 oC

Preheat maintenace Yes

Multiple or Single Electrodes Single Single

Method of Checking Thermometer

Other N/A Travel speed (Range) See the table below See the table below

WELDING PARAMETER

Depth of Weld

Pass Elect/Filler Current Voltage T. Speed H. Input Deposit

Width of Weld Bead Interpass Temp. Shielding gas flow

Layer No. Process rate (l/min)

No.

AWS Class Dia. Polarity A V mm/min kJ/mm mm mm 0

C

1 1.1 GTAW ER90S-B9 2.4 DC- 70 - 160 10 - 14 40 - 60 0.70 - 3.36 3.0 7.0 Max . 300 8 - 25

2 2.1 GTAW ER90S-B9 2.4 DC- 70 - 160 10 - 14 40 - 70 0.60 - 3.36 3.0 8.0 Max . 300 8 - 25

3.1 E9015-B9 2.6 DC+ 70 - 100 20 - 28 50 - 90 0.93 - 3.36 11.0 Max . 300 N/A

3 SMAW 2.5

3.2 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

4.1 E9015-B9 2.6 DC+ 70 - 100 20 - 28 50 - 90 0.93 - 3.36 11.0 Max . 300 N/A

4 SMAW 3.0

4.2 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

5.1 E9015-B9 2.6 DC+ 70 - 100 20 - 28 50 - 90 0.93 - 3.36 11.0 Max . 300 N/A

5 5.2 SMAW E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 3.5 13.0 Max . 300 N/A

5.3 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

6.1 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

6.2 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

6 SMAW 2.8

6.3 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

6.4 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

7.1 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

7.2 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

7 7.3 SMAW E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 3.0 16.0 Max . 300 N/A

7.4 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

7.5 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

8.1 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

8.2 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

8 8.3 SMAW E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 3.2 16.0 Max . 300 N/A

8.4 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

8.5 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

9.1 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 ### 13.0 Max . 300 N/A

9.2 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

9.3 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

9 SMAW

9.4 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

9.5 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

9.6 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

10.1 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

10.2 E9015-B9 3.2 DC+ 80 - 120 20 - 28 60 - 100 0.96 - 3.36 13.0 Max . 300 N/A

10.3 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

10 SMAW 3.0

10.4 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

10.5 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

10.6 E9015-B9 4.0 DC+ 100 - 150 20 - 28 60 - 110 1.09 - 4.20 16.0 Max . 300 N/A

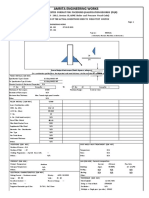

TENSILE TESTS

Ultimate

Width Ultimate

Specimen No. Thickness (mm) Area (mm2) Ultimate Total Load (N) Tensile strength Character of Failure and Location

(mm) (MPa)

Unit Stress (MPa)

TS1 19.02 29.60 562.99 295.00 - 524.0 BASE METAL

TS2 19.01 29.71 564.79 300.00 - 531.2 BASE METAL

GUIDE BEND TESTS

Type and Figure No. Thickness x Width (mm) Result

SB1 9.96 X 28.37 PASS

SB2 9.88 X 28.08 PASS

SB3 9.91 X 27.86 PASS

SB4 9.95 X 28.57 PASS

TOUGHNESS TESTS: N/A

Lateral Expansion Drop Weight

Specimen No. Notch Location Notch Type Test Temperature Impact Energy (J)

% Shear Measurement Break No Break

- - - - - - - -

- - - - - - - - -

- - - - - - - -

FILLET WELD TEST: N/A

Satisfactory Penetration into Parent Satisfactory

Judgment

Unsatisfactory Metal Unsatisfactory

Type and Character of Failure Macro-result:

NON DESTRUCTIVE EXAMINATION

Visual Examination No defects on all weld edsurface Result Acceptable

Radiographic Examination EMETC-NDT-06 Result Acceptable

OTHER TESTS

Hardness Test: 3h-position: (Parent metal: 160-181 HV10); (HAZ:176-193 HV10); (Weld metal: 193-199 HV10)

6h-position: (Paent metal: 160-181 HV10); (HAZ:165-199 HV10); (Weld metal: 193-206 HV10)

12h-position: (Parent metal: 186-193 HV10); (HAZ:193-206 HV10); (Weld metal: 193-209 HV10)

Other

CERTIFICATE OF COMPLIANCE

Test Conducted by: Nguyen Si Tin Laboratory Test No. Quatest 3

We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with requirements of ASME IX:2007

Prepared by: Reviewed by: Approved by:

Name: HAN LE DUY Name: Name:

Signature: Signature: Signature:

Date 4/14/2013 Date Date

(Detail of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the Code.)

You might also like

- AB60F Rebuild Manual PDFDocument652 pagesAB60F Rebuild Manual PDFFerry Darmawan67% (3)

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Grinding Wheel Safety POSTER-BondedDocument2 pagesGrinding Wheel Safety POSTER-Bondedcha100% (1)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix TerbarufebriNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Modulo Arranque Monicon GTR17Document6 pagesModulo Arranque Monicon GTR17Rommel Chang0% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- PT. VISTA BANGUN UTAMA Welder QualificationDocument1 pagePT. VISTA BANGUN UTAMA Welder QualificationHaryanto RNo ratings yet

- MEBS6006 Environmental Services I Psychrometric AnalysisDocument52 pagesMEBS6006 Environmental Services I Psychrometric Analysisahtin618100% (2)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- B00-MT-PRO-00045 - 0 RTR Validation ReportDocument16 pagesB00-MT-PRO-00045 - 0 RTR Validation ReportManik KNo ratings yet

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Gtaw WPQDocument3 pagesGtaw WPQMuhammadShabbirNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- WQT Record for Pipeline Welder QualificationDocument99 pagesWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- Science 8 Unit 4 Mechanical Systems Final Review BookletDocument45 pagesScience 8 Unit 4 Mechanical Systems Final Review BookletKostas KarageorgiouNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- REGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRDocument2 pagesREGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRAnonymous Xa5rkMZm9ZNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- PQR Procedure Qualification Records for GMAW and SAW WeldingDocument3 pagesPQR Procedure Qualification Records for GMAW and SAW WeldingKumawat PrakashNo ratings yet

- Comprehensive HVAC System Design and Maintenance TrainingDocument8 pagesComprehensive HVAC System Design and Maintenance TrainingSuresh Velu100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- 175 Smaw Zug Asme (Muhammad Wardi 3g) WPQDocument4 pages175 Smaw Zug Asme (Muhammad Wardi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Modular Fabrication Facility Welder Qualification RecordDocument7 pagesModular Fabrication Facility Welder Qualification RecordAvijit DebnathNo ratings yet

- Wps-01 C.S. GtawDocument2 pagesWps-01 C.S. GtawMohamed Tarek HamamNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- GTAW Welding Procedure for ASTM A53 PipeDocument2 pagesGTAW Welding Procedure for ASTM A53 PipeS. K. M. ShujonNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Procedure Qualification Record PQRDocument2 pagesProcedure Qualification Record PQRWalid BdeirNo ratings yet

- PQR PDFDocument8 pagesPQR PDFAnonymous OxKrLInOqNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Calificacion de Soldadores BARLUM PDFDocument6 pagesCalificacion de Soldadores BARLUM PDFAnonymous Rn3IlRsKVNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- Request welding procedure approvalDocument18 pagesRequest welding procedure approvalecsuperal100% (1)

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- ASME Boiler Pressure Vessel Welding Procedure SpecificationDocument2 pagesASME Boiler Pressure Vessel Welding Procedure SpecificationBalasahebNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Calificación Termotecnica CoindustrialDocument1 pageCalificación Termotecnica CoindustrialTato VargasNo ratings yet

- Suria Engineering: Procedure Qualification Record (PQR)Document2 pagesSuria Engineering: Procedure Qualification Record (PQR)suria qaqcNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- WPQRDocument1 pageWPQRangelito bernalNo ratings yet

- WPS-43 - Gtaw & Smaw Tig + SmawDocument19 pagesWPS-43 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WPS SS316Document4 pagesWPS SS316Budi Setia RahmanNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- Heating RoomDocument4 pagesHeating RoomMin ThaiNo ratings yet

- SuzukiDocument170 pagesSuzukiSebastian Ruiz PeraltaNo ratings yet

- CLG 836 Bsiii Wheel LoaderDocument2 pagesCLG 836 Bsiii Wheel Loaderအနာဂတ္ရဲ့ ဓူဝင္ျကယ္No ratings yet

- عزوزDocument3 pagesعزوزAhmad AbdNo ratings yet

- 04 0002 PDFDocument122 pages04 0002 PDFjbNo ratings yet

- ZienkiewiczDocument45 pagesZienkiewiczKTMONo ratings yet

- Bab II Wa600Document17 pagesBab II Wa600abrisal03No ratings yet

- Fluid Mech. Chapter6Document51 pagesFluid Mech. Chapter6Ekala XuhalxNo ratings yet

- Lab Manual TA211 (2023-2024 - SEM I)Document38 pagesLab Manual TA211 (2023-2024 - SEM I)Shrasti sahuNo ratings yet

- Dom - 2marks MinimumDocument4 pagesDom - 2marks MinimumRobinston Jeyasingh KNo ratings yet

- Megaflex BeltsDocument50 pagesMegaflex BeltsJosé Luiz NovelinoNo ratings yet

- U of A ANSYS Tutorials - Effect of Self WeightDocument5 pagesU of A ANSYS Tutorials - Effect of Self WeightJean David ChanNo ratings yet

- LPA In-Line Pumps Extension Series 50HzDocument4 pagesLPA In-Line Pumps Extension Series 50Hzmarpaung saberindoNo ratings yet

- Longjian Road & Bridge Co., Ltd. Paira Bridge (Lebukhali Bridge) Construction ProjectDocument4 pagesLongjian Road & Bridge Co., Ltd. Paira Bridge (Lebukhali Bridge) Construction Projectarif hossain labuNo ratings yet

- Wind Turbines Foundations1Document22 pagesWind Turbines Foundations1CristiNo ratings yet

- CE21M112 Gopalji L9Document2 pagesCE21M112 Gopalji L9Gopalji Sudamaji Kalojiya ce21m112No ratings yet

- Lecture-4 &5Document99 pagesLecture-4 &5Anusha DesaiNo ratings yet

- General Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)Document20 pagesGeneral Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)TuTuy AnNo ratings yet

- Chapter 13 Section 4 WebsiteDocument9 pagesChapter 13 Section 4 Websiteapi-260037870No ratings yet

- Extra Wide Flange Beams - HL and HLZ: Section Properties - Dimensions and PropertiesDocument2 pagesExtra Wide Flange Beams - HL and HLZ: Section Properties - Dimensions and PropertiesdependNo ratings yet

- Numerical Analysis of Ventilation For Ship E - R With CFD MethodDocument16 pagesNumerical Analysis of Ventilation For Ship E - R With CFD MethodTARIQUL EMONNo ratings yet

- Is It Possible To Model Double-Pipe and Multi-Tube Hairpin Exchangers in Aspen Shell & Tube ExchangerDocument4 pagesIs It Possible To Model Double-Pipe and Multi-Tube Hairpin Exchangers in Aspen Shell & Tube Exchanger王典No ratings yet

- SRV SRV-L Bronze Safety Relief ValveDocument2 pagesSRV SRV-L Bronze Safety Relief ValvePhong DuongNo ratings yet