Professional Documents

Culture Documents

PQR For Gmaw Saw 15.88

Uploaded by

Kumawat PrakashOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PQR For Gmaw Saw 15.88

Uploaded by

Kumawat PrakashCopyright:

Available Formats

Format No. WCL/SAWL/OPN/F/23 Rev.

02

WELSPUN Document No. PQR/SAWL/SOC/15.88/2015-38

Revision 0

Date / Shift 17.08.2015/G

Operation Page 01 of 02

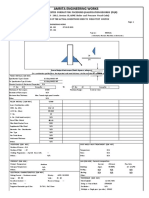

PROCEDURE QUALIFICATION RECORDS FOR GMAW & SAW (AS PER ASME SEC.IX 2015 QW-483 & CUSTOMER

Document SPECIFICATION )

Company Name & Location Welspun Corp Ltd. & Anjar, Gujarat, India

Plant/Department Name SAWL Plant/ Operation

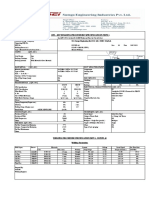

PQR No : PQR/SAWL/SOC/15.88/2015-38, Rev. 0 Welding Process(es) GMAW & SAW

Supporting WPS No : WPS/SAWL/SOC/15.88/2014-61, Rev. 0 Type GMAW (Auto & Semi Auto) & SAW (Auto)

Client Name : SOUTH OIL COMPANY (SOC), IRAQ JOINT (QW - 402)

Name of Welders : 90˚

GMAW (Auto) Mr. Dilip Parmar SAWL-081

GMAW (SemiAuto) Mr. Vijay Kumar SAWL-048

6.38 mm OD

SAW - Internal Mr. Suresh Dabhi SAWL-056 15.88 mm

5.50 mm RF

SAW - External Mr. Shamsher Singh SAWL-054 4.00 mm ID

Backing YES NO

Backing Material (Type) GMAW (Base Material) & SAW (Weld Metal) 90˚

BASE METAL (QW - 403) PRE - HEAT (QW - 406)

P No : 1

Pre-heat Temp. Ambient (36°C)

Group No : 2

Spec. Type & Grade API 5L X60M PSL 2 Inter pass Temp. NA

Pipe Thickness (mm) 15.88 POST WELD HEAT TREATMENT (QW - 407)

Pipe Diameter (mm) 1066.80 Temperature NA

Maximum Pass Thickness NA Time NA

FILLER MATERIAL (QW - 404) GAS (QW - 408)

Process GMAW(A) GMAW(SA) SAW ID SAW OD Gas Flow Rate

Shielding Gas for GMAW Gases

Spec. No - (SFA) 5.18 5.18 5.23 5.23 Mixture (%) (LPM)

AWS No - (Class) ER70S-6 ER70S-6 EA2, EM12K EA2, EM12K Auto CO2 100% 55

Filler Metal : F No. 6 6 6 6 Semi Auto CO2

100% 20

Weld Metal Analysis : A No. 1 1 1 1 ELECTRICAL CHARACTERISTICS (QW - 409)

Size of Filler Metal (mm) 4.0 1.6 4.0, 4.0, 4.0 4.0, 4.0, 4.0 Process SAW GMAW

F55TA0G-EA2-EM12K

Flux - Electrode - (Class) - - Current As per table As per table

Weld metal thickness (mm) 15.88 Heat Input As per table As per table

Type Manufacturer Brand/ Trade Name Polarity DCEP / AC DCEP

Flux (Agglomerated) LINCOLN 995N Mode of Metal Transfer (GMAW Auto) - Globular

SAW Wire PITTARC S2Mo, S2 Mode of Metal Transfer (GMAW Semi auto) - Globular

GMAW Wire PRECISION PWL MIG 2 TECHNIQUE (QW - 410)

Flux Preheat Temp = Heating at 270 ºC for 1 Hrs; String or Weave String

Holding at minimum 120 ºC in intermediate tank for ID and supply tank on OD.

Note :-Repair of tack welds perfomed by using Semi Auto GMAW grounded up to height of Oscillation NA

Automatic GMAW.

POSITION (QW - 405) Single Pass or Multi Pass Single Pass

Position of Weld Groove 1G Multiple for SAW

Single or Multiple Electrode

Weld Progression NA Single for GMAW

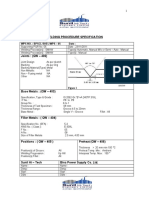

FILLER METAL CURRENT VOLTAGE SPEED HEAT I/P Wire distances & Angles

Sr. No.

NAME SIZE TYPE ( AMP ) (V) ( Mtr./min) (KJ/mm)

1 Auto Tack Welding

ER70S-6 4.0 DC 1250 22.5 4.35 0.39 5º

2 Semiauto Tack Repair 18

ER70S-6 1.6 DC 265 22.5 0.45 0.80

3 Internal SAW

T2 +15º T1-0º L -15º

EA2 4.0 DC 750 34.0

EM12K 4.0 AC 625 35.0 1.37 2.98

30 28 26

EM12K 4.0 AC 575 36.0 20 18

4 External SAW

T2 +15º T1-0º L -10º

EA2 4.0 DC 1025 34.0

EA2 4.0 AC 775 36.0 1.45 3.42

30 29 28

EM12K 4.0 AC 525 38.0 20 18

BATCH NO. of GMAW Wire ER70S6 (1.6 mm dia): RC5010216; GMAW Wire ER70S6 (4.0 mm dia) : DC5050840; SAW Wire EA2 (4.0 mm dia): 12010 2012,

REMARK

10249 2011; SAW Wire EM12K (4.0 mm dia): 981 2015; Flux 995N: F1FX150410

PREPARED BY REVIEWED BY APPROVED BY INSPECTION AGENCY

KHUSHAL ADWANI ASHIF SHEIKH SATYANARAYANA SAMAVEDAM

Engineer-Operation Section Head - Welding H.O.D - QA/QC

Format No. WCL/SAWL/OPN/F/23 Rev.02

WELSPUN Document No. PQR/SAWL/SOC/15.88/2015-38

Revision 0

Date / Shift 17.08.2015/G

Operation Page 02 of 02

Document PROCEDURE QUALIFICATION RECORDS FOR GMAW & SAW (AS PER ASME SEC.IX 2015 QW-483 & CUSTOMER SPECIFICATION )

Company Name & Location Welspun Corp Ltd. & Anjar, Gujarat, India

Plant/Department Name SAWL Plant/ Operation

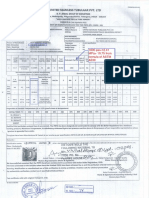

SPEC. API 5L 45th Edition, December 2012 WPS NO. WPS/SAWL/SOC/15.88/2014-61, Rev. 0

THICKNESS 15.88 MM PQR NO. PQR/SAWL/SOC/15.88/2015-38, Rev. 0

WELDING PROCESS (ES) GMAW & SAW MATERIAL GRADE API 5L X60M PSL 2

TYPE(S) GMAW (Auto & Semi Auto) & SAW (Auto) INSPECTION AUTHORITY SOC

Chemical Testing: Report No.:CTR/2015/02, Date of issue: 14.08.2015

Specified Requirements : For information only

PLATE/PIPE

ELEMENT C Si Mn P S Cr Ni Mo Cu Ti Nb V B

NO.

% 0.08 0.37 1.57 0.02 0.004 0.04 0.05 0.07 0.1 0.00 0.02 0.00 0.0009

J15031925

ELEMENT N Al Ca Nb+V+Ti CE(IIW) CE(PCM) -

(WELD)

% 0.004 0.021 0.001 0.02 0.37 0.18 -

PLATE/PIPE

ELEMENT C Si Mn P S Cr Ni Mo Cu Ti Nb V B

NO.

% 0.07 0.37 1.56 0.02 0.004 0.04 0.05 0.07 0.1 0.00 0.02 0.00 0.0009

J15031925

ELEMENT N Al Ca Nb+V+Ti CE(IIW) CE(PCM) -

(WELD)

% 0.005 0.021 0.001 0.02 0.37 0.18 -

Mechanical Testing: Report No.: UTM/2015/02, Date of issue: 14.08.2015

Specified Requirements - 520 MPa Min. - -

YIELD

FINAL LOAD ULTIMATE

AREA GAUGE Y.S. Rt0.5 U.T.S. Elongation REMARKS

PLATE/PIPE WIDTH / DIA THICK/ DIA GAUGE FRt0.5 LOAD

SR NO LENGTH YS/UTS

NO. (MM) (MM) (MM²) (MM)

LENGTH (kN )

(MM)

( kN ) (kN ) (MPa ) (MPa) %

1 19.03 16.09 306.19 ------ ------ ------ 184.33 ------ 602.00 ------ ------ TWT-1

J15031925

2 19.21 16.13 309.86 ------ ------ ------ 184.38 ------ 595.05 ------ ------ TWT-2

Mechanical Testing: Report No.: UTM/2015/07, Date of issue : 17.08.2015

Specified Requirements 415 MPa Min. 415 MPa Min. 520 MPa Min. 18% - -

FINAL YIELD YIELD

PLATE/PIPE WIDTH / DIA GAUGE ULTIMATE

SR NO AREA GAUGE LOAD LOAD Y.S. Rp0.2 Y.S. Rt0.5 U.T.S. Elongation

NO. (MM) LENGTH LOAD YS/UTS % Uniform Elongation

(MM²) (MM)

LENGTH FRp0.2 FRt0.5

(MM)

( kN ) (kN ) (kN ) (MPa ) (MPa ) (MPa) %

1 J15032195 6.19 30.09 25.00 31.21 16.37 16.14 19.53 543.99 536.49 648.90 24.84 0.83 10.12

GUIDED BEND TEST HARDNESS (VICKERS),

MACRO TEST

For Information Only

Specified Requirements: GBT - 180 ° Report No.: MACRO/2015/01, Date of issue: 14.08.2015

Base Metal: AT HV10 Max, Weld & HAZ : AT HV10 Max.

Required Jig Diameter = 172 mm Max.

Report No.: GBT/2015/02, Date of issue: 14.08.2015 Report No.: HTR/2015/01, Date of issue: 14.08.2015 Specified Requirements:

Misalignment : 3mm Maximum Observation at 10X Magnification

Used Jig Diameter Misalignment (mm)

PIPE NO. BASE HAZ WELD

SR NO A = 170 mm

ROOT FACE

1 J15031925 SAT SAT 178-192 201-229 215-229 0.20 Complete Penetration of Internal & External Weld observed & found satisfactory.

2 SAT SAT

IMPACT TESTING: Report No.: CIT/2015/01, Date of issue: 14.08.2015

ABSORBED ENERGY (JOULES) AT TEMPERATURE = 0°C

WELD (REQUIRED MIN 20J INDIVIDUAL,27 J

PIPE NO. BASE-T (REQUIRED MIN 30J INDIVIDUAL,40 J AVG) HAZ / FL (REQUIRED MIN 20J INDIVIDUAL, 27J AVG)

AVG) Remarks

1 2 3 AVG 1 2 3 AVG 1 2 3 AVG

J15031925 302 246 320 289.33 130 132 100 120.67 290 302 282 291.33 SATISFACTORY

RADIOGRAPHY TESTING PREVISUAL INSPECTION REPORT

REPORT NO: RTR/2015/2022, DATE/SHIFT: 10.08.2015/C REPORT NO: PVIR/2015/556, DATE/SHIFT: 10.08.2015/B

PIPE NO: J15031925 PIPE NO: J15031925

RESULT : SATISFACTORY RESULT : SATISFACTORY

Officer /Engineer (LAB) Officer /Engineer (NDT)

We certify that the statement in this record are correct and that the welds are prepared, welded and tested in accordance with the requirement in API 5L 45th Edition, December 2012 /ASME SEC IX 2015, ASME SEC II PART C 2015 &

Customer Requirements.

Remarks : Y.S.:- Yield Strength, U.T.S. :-Ultimate Tensile Strength, % E.L.:- Percentage Elongation, W.M.:- Weld Metal, F:- Flat, Rt0.5 : Yield strength (0.5% EUL)

LBT.:- Longitudenal Base tensile, TBT.:- Tansverse base tensile , TWT.:- Transverse Weld tensile, BOW.:- Broken Out of Weld

AWT.:-All Weld Tensile, FL : Fusion line, HAZ : Heat Affected Zone, SA : Shear Area, J : Joule, Ind. : Individual, Avg. : Average, Min. : Minimum, T-Transverse , L - Longidutinal

PREPARED BY REVIEWED BY APPROVED BY INSPECTION AGENCY

KHUSHAL ADWANI ASHIF SHEIKH SATYANARAYANA SAMAVEDAM

Engineer-Operation Section Head - Welding H.O.D - QA/QC

You might also like

- PQWDocument3 pagesPQWcorey jacobsNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Astm A36 Chapa Grossa Ate 19mm PDFDocument1 pageAstm A36 Chapa Grossa Ate 19mm PDFHugo RodriguezNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- Piping Inspection 22.01.2020Document72 pagesPiping Inspection 22.01.2020KarthikNo ratings yet

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- WPS - 021Document13 pagesWPS - 021MAT-LIONNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- DNV RU SHIP Pt2Ch4Document144 pagesDNV RU SHIP Pt2Ch4Rahul KamillaNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- AWS Weld Symbol BasicsDocument3 pagesAWS Weld Symbol Basicschairul anwarNo ratings yet

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- WPS and PQR of GMAWDocument8 pagesWPS and PQR of GMAW魏利强No ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- WPS RegisterDocument2 pagesWPS RegisterdaveswinburneNo ratings yet

- Steel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDDocument12 pagesSteel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDmalikasalNo ratings yet

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Acfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Document6 pagesAcfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Daniel CamposNo ratings yet

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Weld DefectsDocument78 pagesWeld DefectsKevin CheungNo ratings yet

- 11 - WELDING POSITIONS (1) .PPT (Compatibility Mode)Document20 pages11 - WELDING POSITIONS (1) .PPT (Compatibility Mode)Kumawat Prakash75% (4)

- Weld DefectsDocument78 pagesWeld DefectsKevin CheungNo ratings yet

- 6 Welding Procedure Qualification & Welder Qualification PDFDocument15 pages6 Welding Procedure Qualification & Welder Qualification PDFParminder Singh100% (2)

- Welding Consumable Selection: Flow ChartDocument4 pagesWelding Consumable Selection: Flow ChartKumawat PrakashNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- Arc 3 & Arc 4 Comparision of Heat InputDocument5 pagesArc 3 & Arc 4 Comparision of Heat InputKumawat PrakashNo ratings yet

- Astm E23Document28 pagesAstm E23Kumawat PrakashNo ratings yet

- Ie433 Cad/Cam Computer Aided Design and Computer Aided Manufacturing Part-4 Computer GraphicsDocument26 pagesIe433 Cad/Cam Computer Aided Design and Computer Aided Manufacturing Part-4 Computer GraphicsKumawat PrakashNo ratings yet

- Introduction To Nondestructive TestingDocument34 pagesIntroduction To Nondestructive TestingNanditha Mandava ChowdaryNo ratings yet

- Steam TurbinesDocument23 pagesSteam TurbinesNAYEEM100% (2)

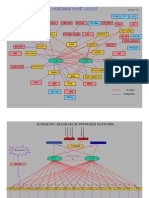

- Bhel Haridwar Plant Layout: CCX CAEDocument23 pagesBhel Haridwar Plant Layout: CCX CAEKumawat PrakashNo ratings yet

- GATE 2011 Answer Key, Solution, GATE 2011 SolutionsDocument4 pagesGATE 2011 Answer Key, Solution, GATE 2011 SolutionsRavi KantNo ratings yet

- AutobiographyDocument269 pagesAutobiographyBuziness MindNo ratings yet

- Multi-Wing Engineering GuideDocument7 pagesMulti-Wing Engineering Guidea_salehiNo ratings yet

- Experiment 1 Centrifugal Pump CharacteristicsDocument2 pagesExperiment 1 Centrifugal Pump CharacteristicsSyed Sufyan Ali Alvi100% (2)

- Offshore TechDocument351 pagesOffshore Techmarkengineer100% (2)

- Drying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesDocument4 pagesDrying Stages During The Heating of High-Alumina, Ultra-Low-Cement Refractory CastablesAnthony MarasiganNo ratings yet

- Science 10 4th Quarter ExamDocument4 pagesScience 10 4th Quarter Examzayd87% (38)

- Ground Improvement by Heating and Freezing MethodDocument7 pagesGround Improvement by Heating and Freezing MethodHamadNo ratings yet

- Data Sheet Jet Pulse Bag FilterDocument1 pageData Sheet Jet Pulse Bag FilterHassan SleemNo ratings yet

- 01 ElectrostaticsDocument14 pages01 ElectrostaticsAarav PatelNo ratings yet

- 2.3 Psychrometric Chart and Air ConditioDocument20 pages2.3 Psychrometric Chart and Air ConditioRey Niño GarciaNo ratings yet

- Science Paper 1. Question Paper. Stage 5. Cambridge Primary Progression Test - 45 MinutesDocument22 pagesScience Paper 1. Question Paper. Stage 5. Cambridge Primary Progression Test - 45 MinutesLayeb Fares75% (4)

- Assignment Questions For Unit 1 - 15EC409-Optical CommunicaitonDocument1 pageAssignment Questions For Unit 1 - 15EC409-Optical CommunicaitonSathiyanNo ratings yet

- Lab Report-Exp 1Document8 pagesLab Report-Exp 1abmarti1No ratings yet

- Cast Iron: History and Application: AbstractDocument12 pagesCast Iron: History and Application: Abstract13311A0341 S SHIVA SAI KIRANNo ratings yet

- Kwame Nkrumah University of Science and Technology (Knust)Document20 pagesKwame Nkrumah University of Science and Technology (Knust)BENNo ratings yet

- Performance Test On Double Stage Reciprocating Air CompressorDocument8 pagesPerformance Test On Double Stage Reciprocating Air Compressormohammed rashidNo ratings yet

- Chapter 15 Oscillations Version 2Document28 pagesChapter 15 Oscillations Version 2nabeelNo ratings yet

- Api 510 QuizletDocument6 pagesApi 510 QuizletMahmoud Alwasif100% (1)

- Hypersonic AerodynamicsDocument10 pagesHypersonic AerodynamicsBarbara SchlottNo ratings yet

- AIPMT 2016 Solution Code A PDFDocument74 pagesAIPMT 2016 Solution Code A PDFsubhakpatel patelNo ratings yet

- Floating Study PaperDocument6 pagesFloating Study Papervishalbhavar1100% (1)

- Dme Faires (Textbook)Document331 pagesDme Faires (Textbook)Cherry Ann CondinoNo ratings yet

- Heat Input in Welding: PT - Bakrie ConstructionDocument6 pagesHeat Input in Welding: PT - Bakrie ConstructionAlifNo ratings yet

- Fletcher, A. and J. Davis. How EOR Can Be Transformed by Nanotechnology. in SPE Improved Oil Recovery Symposium. 2010. Society of Petroleum Engineers.Document16 pagesFletcher, A. and J. Davis. How EOR Can Be Transformed by Nanotechnology. in SPE Improved Oil Recovery Symposium. 2010. Society of Petroleum Engineers.David MoedanoNo ratings yet

- NABERS Indoor Environment ReviewDocument20 pagesNABERS Indoor Environment ReviewSuthi Sae DanNo ratings yet

- Class XII Chemistry CH 5: Surface Chemistry Chapter Notes Top Concepts / Key LearningsDocument18 pagesClass XII Chemistry CH 5: Surface Chemistry Chapter Notes Top Concepts / Key Learningssanjit mukherjeeNo ratings yet

- UC 0300 0650 Chiller SPDocument1 pageUC 0300 0650 Chiller SPAjayNo ratings yet

- Interaction of RadiationDocument54 pagesInteraction of RadiationWayel AmanNo ratings yet

- BC Chapter 1Document37 pagesBC Chapter 1umarguyo38No ratings yet

- ACT01Document56 pagesACT01imtherr01No ratings yet

- 5.0 Ceramics, Graphite, and Diamond Structure, General Properties, and ApplicationsDocument3 pages5.0 Ceramics, Graphite, and Diamond Structure, General Properties, and ApplicationsAbdul RashidNo ratings yet