Professional Documents

Culture Documents

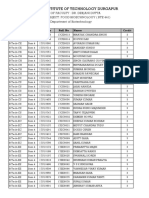

!"#"$%&' $&" III - %"+$&,"-. (/ - (0 ($$1 Cementing III - Protecting Strrings of Ø177,8 MM (7'')

Uploaded by

cindydianita0%(1)0% found this document useful (1 vote)

25 views3 pagescement

Original Title

Cement

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcement

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

25 views3 pages!"#"$%&' $&" III - %"+$&,"-. (/ - (0 ($$1 Cementing III - Protecting Strrings of Ø177,8 MM (7'')

Uploaded by

cindydianitacement

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

!

"#$%&'()*+,"*)

!"#"$%&'()*$&" III - %"+$&,"-.(/ .(0($$1

-+.+/$%)

177,8## (7)

Cementing III Protecting Strrings of 177,8

mm (7'')

!"#"$ %"&"'()#*+,')"& -."$)(/01 + +23*4'"'))

04"$-56)7 3*$8*(*+)("4/'27 #,.*(:

- 0-3"#+,9:"# 3* .-#*+2& #,.*(,& ) 03"%),4)0( 3*

%"&"'()#*+,')5 $*4;'2 '":,+)0)&* $#-8 *( $#-8,

+23*4')(/ 3*$(+"#;$,56)" #,0<"(2 3* *.="&,&

%"&"'('*8* #,0(+*#,;

- 3#*)'>*#&)#*+,(/ 8,:*?,#*(,;')?*+ ) )';"'"#, 3*

.-#*+2& #,0(+*#,& * 3#"$3*4,8,"&27 ?

)03*4/:*+,')5 +*$2 $41 :,(+*#"')1, %"&"'('*8*

#,0(+*#, ) *.="&,7 +2("0'"')1; -?,:,(/ ): ?,?)7

&"#')?*+ .-$"( +23*4'1(/01 :,.*# +*$2 $41

:,(+*#"')1. @#*&" (*8*, -?,:,(/ 3#*8'*:)#-"&*"

-+"4)<"')" *.="&, + ,?()+'27 "&?*0(17 *( 7+*0(*+*9

) 8*4*+'*9 3*#%)9 (#,0(+*#,);

- 3#*&2(/ +0" 4)')) ', -0(/". A,&"#)(/ ) :,3)0,(/

*.="& 4)')) *( %"&"'()#*+*<'*8* ,8#"8,(, $* #*(*#,

(3*4, .-#*+*9 +2B?));

- 3#*+"#)(/ ', *(0-(0(+)" -("<"? + 4)')) 3*$,<) +*$2

$41 :,(+*#"')1 #,0(+*#,. C0" *(7*$16)" *( $,''*9

4)')) :,$+);?) $*4;'2 .2(/ 3"#"?#2(2 )

:,.4*?)#*+,'2;

- '"3*0#"$0(+"''* 3"#"$ ',<,4*& %"&"'()#*+,')1

.-#)4/6)? ) 8,:*?,#*(,;')?) (3* #,0(+*#,&) $*4;'2

:,3)0,(/ -#*+') +* +0"7 &"#')?,7.

D"&"'()#*+,')" *.0,$'*9 ?*4*''2 177,8&& (7)

.-$"( *0-6"0(+41(/01 3* $+-70(-3"'<,(*9 07"&", 0

3*$="&*& %"&"'(, $* -0(/1:

1.

E."03"<)(/, <(*.2 +0" :,$"90(+*+,''2"

0(*#*'2 .24) 3#*)'>*#&)#*+,'2 * +#"&"') ',<,4,

3#*+"$"')1 #,.*(, *.="&,7 023-<)7 &,("#),4*+,

;)$?*0() :,(+*#"')1 ) 3#. C#"&1, :,(#,<"''*" ',

$*+"$"')" +0"7 *0'*+'27 3*4*;"')9 $* 3"#0*',4,

3*&*;"( 8,#,'()#*+,(/ -03"B'*" 3#*+"$"')" #,.*(

3* %"&"'()#*+,')5.

2.

F-3"#+,9:"# 3* .-#*+2& #,.*(,& )

03"%),4)0( 3* %"&"'()#*+,')5 $* ',<,4, 3#*+"$"')1

#,.*(, $*4;'2 '":,+)0)&* +23*4')(/

3*$(+"#;$,56)" #,0<"(2 3* *.="&,& %"&"'('*8*

#,0(+*#,. !"#"$ %"&"'()#*+,')"& ?*4*''2 3#*+*$)(/

$-.4)#-56)9 ,',4): (,&3*',;'*8* #,0(+*#, +

.,#*&"(#)<"0?)7 -04*+)17, , (,?;" ,',4): ',

8,:*3#*')%,"&*0(/.

3.

!#*)'>*#&)#*+,(/ 8,:*?,#*(,;')?*+ )

)';"'"#, 3* .-#*+2& #,0(+*#,& * 3#"$3*4,8,"&27 ?

)03*4/:*+,')5 +*$2 $41 :,(+*#"')1, %"&"'('*8*

#,0(+*#, ) *.="&,7 +2("0'"')1; -?,:,(/ ): ?,?)7

&"#')?*+ .-$"( +23*4'1(/01 :,.*# +*$2 $41

:,(+*#"')1. @#*&" (*8*, -?,:,(/ 3#*8'*:)#-"&*"

-+"4)<"')" *.="&, + #,.*<)7 "&?*0(17.

4.

E."03"<)(/, <(*.2 ', +0"& 3#*(1;"')) #,.*(

Before cementing ensure in fulfillment of the

following preparation works:

- the drilling operation supervisor and cementing

specialist are to make calculations of cement

grouping volumes independently;

- to inform gas loggers and drilling mud engineer

about the expected water for tempering, cement

grouping and displaced volumes; mention from

which gauging tanks water will be taken for

tempering. Moreover, mention the forecasted

increase of volume in active tanks of head and tail

portions (of mud);

- wash out all lines at the wellhead. Measure and

write down the volume of lines from the cementing

installation to the rotor (derrick floor);

- check the absence of leaks in the water inlet line

for setting-up of the grouting. All valves on the

spurs from the line are to be closed and blocked;

- just before the beginning of cementing the driller

and gas logger are to register levels in all gauge

reservoirs (for each grouting).

Cementing of a boring casing of 177,8&& (7)

will be performed according to the double-stage

schedule with lifting of cement up to the wellhead:

1.

Provide all participating parties to be

informed about the time of work performance

beginning, volume of loose materials, tempering

liquid and other parameters. The time spent for

informing of the personnel about the main

provisions ensure the successful fulfillment of

cementing works.

2.

The drilling operation supervisor and

cementing specialties are to fulfill approving

calculations before the beginning of work

performance independently in relation to the

cement grouting volumes. Before cementing of the

casing a back-up analysis is to be executed

regarding the grouting mortar at barometric

conditions as well as gas penetration.

3.

To inform gas loggers and drilling mud

engineer about the expected water for tempering,

cement grouping and displaced volumes; mention

from which gauging tanks water will be taken for

tempering. Moreover, mention the forecasted

increase of volume in working tanks.

4.

To ensure that there is enough time

3* %"&"'()#*+,')5 )&"401 $*0(,(*<'29 :,3,0

+#"&"').

5.

!#*&2(/ +0" 4)')) ', #*(*#". A,&"#)(/ )

:,3)0,(/ *.="& 4)')) *( %"&"'()#*+*<'*8* .4*?, $*

#*(*#, (3*4, .-#*+*9 +2B?)).

6.

!#*+"#)(/ ', *(0-(0(+)" -("<"? + 4)'))

3*$,<) +*$2 $41 :,(+*#"')1 #,0(+*#,. C0" *(7*$16)"

*( $,''*9 4)')) :,$+);?) $*4;'2 .2(/ 3"#"?#2(2 )

:,.4*?)#*+,'2.

7.

G"3*0#"$0(+"''* 3"#"$ ',<,4*&

%"&"'()#*+,')1 .-#)4/6)? ) 8,:*?,#*(,;')?) (3*

#,0(+*#,&) $*4;'2 :,3)0,(/ -#*+') +* +0"7 &"#')?,7.

8.

G,+"#'-(/ %"&"'()#*+*<'-5 8*4*+?-,

0&*'()#*+,(/ %"&"'()#*+*<'2" 4)')) ) *3#"00*+,(/

)7 ', $,+4"')" + 1,5 #,:, 3#"+2B,56"" &,?0)&,4/'*

*;)$,"&*" $,+4"')" 3#) %"&"'()#*+,')).

9.

!#*&2(/ 0?+,;)'- $* +2#,+')+,')1

3,#,&"(#*+ #,0(+*#, $* :',<"')9, :,$,''27

?*'%"3%)"9 )/)4) 3#*"?(*&, ) 3*$8*(*+)(/ 0?+,;)'? %"&"'()#*+,')5 ?*4*''2.

10.

A,?,<,(/ .->"#'-5 ;)$?*0(/, %"&"'('29

#,0(+*#, 3#*$,+*<'-5 ;)$?*0(/ + ?*4)<"0(+,7,

0**(+"(0(+-56)7 #,0<"('2& 3,#,&"(#,&,

3#*+"$"''2& 3* >,?()<"0?)& $,''2& $41

%"&"'()#*+,')1 3"#+*9 0(-3"').

11.

F3-0()(/ +"#7'55 3#*$,+*<'-5 3#*.?-.

H."$)(/01, <(* 3#*.?, +2B4, ): %"&"'()#*+*<'*9

8*4*+?), 3*04" <"8* *0-6"0(+)(/ 3#*$,+?%"&"'('*8* #,0(+*#, .-#*+2& #,0(+*#*&.

12.

C ?*'%" 3#*$,+?) 0'):)(/ )'("'0)+'*0(/

3*$,<), *(&"()(/ 3*0,$?- 3#*.?) 3#) -+"4)<"'))

$,+4"')1 ', 3-5I!, +2B" $,+4"')1 :,?,<?). !#)

*(0-(0(+)) 3#):',?*+ 3*0,$?) 3#*.?) ', *.#,('29

?4,3,', 3#*?,<,(/ ',0*0*& &,?0)&-& 50 % *.="&,

%"&"'('*8* 0(,?,', $41 3*32(?) 3*0,$)(/ 3#*.?-.

F(#,+)(/ $,+4"')" ): *.0,$'*9 ?*4*''2 $41

3#*+"#?) 3"#"(*?,.

13.

J,03,?"#*+,(/01 ) #,0?#2(/ 3*#(2 &->(2

0(-3"'<,(*8* %"&"'()#*+,')1.

14.

!#*&2(/ 0?+,;)'-. E0(,+)(/ 0?+,;)'- ',

EAD ', 3"#)*$ '" &"'"" 48 <,0.

15.

!#*+"0() 3#*&2+?- 0?+,;)'2 .-#*+2&

#,0(+*#*& ) :,%"&"'()#*+,(/ :,(#-.'*" 3#*0(#,'0(+*

+2B" IFD $* -0(/1.

16.

A,?,<,(/ .->"#'-5 ;)$?*0(/ ) %"&"'('29

#,0(+*#. D"&"'()#*+,')" 3"#+*9 0(-3"') III ("7')<"0?*9 ?*4*''2 $),&"(#*& 177,8&& (7) .-$"(

*0-6"0(+41(/01 %"&"'('2& #,0(+*#*& 34*('*0(/5

1900 ?8/&3 (1,90 sg). D"&"'()#*+,')" +(*#*9 0(-3"')

III - ("7')<"0?*9 ?*4*''2 $),&"(#*& 177,8&& (7)

.-$"( *0-6"0(+41(/01 %"&"'('2& #,0(+*#*&

34*('*0(/5 1650 ?8/&3 (1,65 sg).

F %"4/5 3#"$-3#";$"')1 +*:')?'*+"')1 -<,0(?*+

0+*.*$'*8* 3,$"')1 (,&3*',;'*8* #,0(+*#, +

3#*%"00" %"&"'()#*+,')1 '"*.7*$)&* *."03"<)(/

allowance throughout the work on cementing.

5.

Wash out all lines at the rotor. Measure and

write down the volume of lines from the cementing

installation to the rotor (derrick floor).

6.

Check the absence of leaks in the water inlet

line for setting-up of the grouting. All valves on the

spurs from the line are to be closed and blocked.

7.

Just before the beginning of cementing the

driller and gas logger are to register levels in all

gauge reservoirs (for each grouting).

8.

Screw on the circulating head, mount

cementing lines and press them to reach the

pressure at 1.5 times higher than the maximum

anticipated pressure during cementing.

9.

Rinse well to the alignment parameters of

the solution to the values defined by the concept

and / or project, and prepare well for cementing the

string.

10.

Load the fluid injection, cement mortar,

overflush fluid in amounts corresponding to the

calculated parameters, carried out on actual data for

cementing the prime.

11.

Run the top cementing plug in the hole.

Make sure that the plug came out of the circulating

head, and then displace cementing mortar with the

drilling mud.

12.

At the end of displacement reduce the flow

rate, measure the fit of the plug as the pressure

increases on the 3-5Mpa (I!,) higher than

pressure injection. In the absence of identifiers of

the fit the plug to the float coupling, to pump a

maximum of 50% of the volume of cement

coloumn to "fit" plug. Vent the pressure from he

production string to check the cross flow.

13.

To packer off and open sockets of the stage

cementing collar.

14.

Rinse the well. Leave the well in the WOC

for a period of not less than 48 hours.

15.

To rinse the well with drilling mud and

cement the casing annulus from the cement stage

collar to the wellhead.

16.

Load the fluid injection and cement mortar.

Cementing the prime of the III - protecting string

177,8 mm diameter (7) is to fulfill with the

cementing mortar with a density of 1900 kg/m3

(1,90 sg). Cementing the second stage of the III protecting string 177,8 mm diameter (7) is to

fulfill with the cementing mortar with a density of

1650 kg/m3 (1,65 sg).

17.

Reset the top cementing plug; pump the

B(-%)#*+,')" :,?*4*''*8* 3#*0(#,'0(+,.

C:1(/ 3#*.2 #,0(+*#, (+ ',<,4" ) + ?*'%"

3#)8*(*+4"')1), $41 *3#"$"4"')1 0#*?*+ 07+,(2+,')1,

:,8-0("+,')1, 3#*<'*0() %"&"'('*8* ?,&'1.

17.

F.#*0)(/ +"#7'55 %"&"'()#*+*<'-5 3#*.?-,

:,?,<,(/ 3#*$,+*<'-5 ;)$?*0(/ (.-#*+*9 #,0(+*#) )

:,?#2(/ %"&"'()#*+*<'2" *?',.

18.

!#*+"0() EAD, *#)"'()#-10/ ', 07+,(2+,')"

*(*.#,''27 %"&"'('27 3#*. '* '" &"'"" 48 <.

19.

K"&*'()#*+,(/ *.*#-$*+,')".

20.

F*0(,+)(/ *(<"( 3* %"&"'()#*+,')5, ?*(*#29

$*4;"' 7#,')(/01 ', .-#*+*9.

!*04" 03-0?, ) ?#"34"')1 177,8&& (7) *.0,$'*9

?*4*''2 -0(/" 0?+,;)'2 *.*#-$-"(01 0*84,0'*

3#*%"$-#,& ) 07"&,& *.+1:?) !CE, #,:#,.*(,''*9 )

-(+"#;$!''*9 + -0(,'*+4"''*& 3*#1$?" .-#*+2&

!*$#1$<)?*& ) 0*84,0*+,''*9 0 A,?,:<)?*&,

3#*()+*>*'(,''*9 04-;.*9, *#8,',&)

F,'*,(?*'("7',:*#,(,.

overflush fluid (drilling mud) and close cementing

slots.

18.

To do the WOC, concerning the thickening

time of the cementing test but no less then 48 hours.

19.

Dismantle equipment.

20.

Draw up a report on the cementing, which

must be kept on "drilling".

After descending and mounting 177, 8 mm (7 ")

casing wellhead is equipped according to the

procedures and schemes trim defense, developed

and of approved drilling in the prescribed manner

by the Contractor and agreed with the customer,

blow out elimination service, departments of

Sanoatkontekhnazorat.

Operations, fulfilling after cementing:

Align the production string in the rotor after

cementing;

Check, if there are some cement pollutions

2*3(%1, 4'()(5" 4(-0" 6"#"$%&'()*$&7:

of the blow out preventer and take measures to

*(%"'(#)#*+,(/ *.0,$'-5 ?*4*''- + #*(*#" 3*04" clean it;

Not to run the instrument in to the string

*?*'<,')1 %"&"'()#*+,')1;

3#*+"#)(/, '" :,8#1:'"'2 4) %"&"'(*& !CE )

until resistance power of the cement stone rich the

3#)'1(/ &"#2 3* "8* *<)0(?";

state no less then 1.5 MPa;

'" 03-0?,(/ )'0(#-&"'( + ?*4*''-, 3*?, '" .-$"( Accessories of the production string footage

$*0()8'-(, 3#*<'*0(/ %"&"'('*8* ?,&'1 '" &"'"" 1,5

is to drill with the tri-cone bit, and in the absence of

I!,;

the PDC with the fan bottom bit to prevent

*0',0(?- '):, *.0,$'*9 ?*4*''2 04"$-"(

connection the impact stress to the string.

#,:.-#)+,(/ (#"7B,#*B"<'2& $*4*(*&, + 04-<,"

*(0-(0(+)1 PDC $*4*(*& 0* 0');"''*9 ',8#-:?*9 +*

):.";,')" 0**.6"')1 ?*4*''" -$,#'*9 ',8#-:?).

!

!

You might also like

- Earthwork and excavation analysisDocument128 pagesEarthwork and excavation analysisniroshnirosh100% (18)

- Mother Teresa JerseyDocument2 pagesMother Teresa JerseyTanya van Zyl100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Engineering, Procurement, Construction and Commissioning or MEO Project Water Pipe Re-Routing Tie-In Work Method StatementDocument3 pagesEngineering, Procurement, Construction and Commissioning or MEO Project Water Pipe Re-Routing Tie-In Work Method StatementNorisham Mohamed Ali0% (2)

- Manual & Spare Parts Ardo A800Document20 pagesManual & Spare Parts Ardo A800zavaidoc70No ratings yet

- D6M Test Hydraulic SystemDocument21 pagesD6M Test Hydraulic SystemTeresa Marina Peralta100% (3)

- BOQ 2 BedroomDocument83 pagesBOQ 2 BedroomOgunfolaji Rasheed100% (1)

- Piping Isometric TutorialDocument45 pagesPiping Isometric Tutorialcepong89100% (1)

- Factory made uPVC windows installationDocument2 pagesFactory made uPVC windows installationAmit Singh100% (2)

- Checklist - SWM Jpif DBKLDocument4 pagesChecklist - SWM Jpif DBKLPhang S. SunNo ratings yet

- MANUFACTURER'S DATADocument4 pagesMANUFACTURER'S DATAfaharaNo ratings yet

- Illinois VOC and LEED 2009 LimitsDocument5 pagesIllinois VOC and LEED 2009 LimitsspecmasterNo ratings yet

- Shipbuilding Technology 4th Semester SyllabusDocument30 pagesShipbuilding Technology 4th Semester SyllabusDiploma in Engineering Shipbuilding TechnologyNo ratings yet

- Ek2001nov 95 Me Kg4 Sr. No10Document3 pagesEk2001nov 95 Me Kg4 Sr. No10Bhupender RamchandaniNo ratings yet

- Boring Bar ManualDocument41 pagesBoring Bar ManualPranjal Chakraborty100% (1)

- Distillation Column Design MulticomponentDocument23 pagesDistillation Column Design Multicomponentsuleman205100% (1)

- MSB P15 Screw Press Manual (2022) PDFDocument25 pagesMSB P15 Screw Press Manual (2022) PDFajialiidris97No ratings yet

- Engineering Info CompleteDocument14 pagesEngineering Info CompleteIvanNo ratings yet

- Mono WorksDocument9 pagesMono WorksTarun ChopraNo ratings yet

- Bechtel France S.A.S. Quality Control and Inspection Specification for Painting, Coating, Insulation, Fireproofing and Refractory LiningDocument22 pagesBechtel France S.A.S. Quality Control and Inspection Specification for Painting, Coating, Insulation, Fireproofing and Refractory Liningravi00098No ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDocument6 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusNo ratings yet

- The Deputy Manager 220kv GIS G/S Ravi LahoreDocument9 pagesThe Deputy Manager 220kv GIS G/S Ravi LahoreJavaid IqbalNo ratings yet

- Coconut Wood-Fiber Cement BoardsDocument9 pagesCoconut Wood-Fiber Cement BoardsFrank DagohoyNo ratings yet

- Marine Engineer Exam QuestionsDocument3 pagesMarine Engineer Exam QuestionsBhupender RamchandaniNo ratings yet

- Lab Experiment #3B: Hydrometer AnalysisDocument5 pagesLab Experiment #3B: Hydrometer AnalysishamiddinkomaNo ratings yet

- Drill Exam ComboDocument79 pagesDrill Exam ComboMakiber100% (2)

- Shipbulding Technology 5th Semester SyllabusDocument33 pagesShipbulding Technology 5th Semester SyllabusDiploma in Engineering Shipbuilding Technology100% (1)

- Drilling PPDocument26 pagesDrilling PPAnonymous T32l1R100% (1)

- Timing Belt Manual: From Professionals For ProfessionalsDocument164 pagesTiming Belt Manual: From Professionals For ProfessionalsPetrus Van SchalkwykNo ratings yet

- Steps in Facility DesignDocument20 pagesSteps in Facility DesignVarun MehrotraNo ratings yet

- SIStec Major Project Report On GSM Based Pump Control SystemDocument81 pagesSIStec Major Project Report On GSM Based Pump Control Systemukpandey25No ratings yet

- Curriculum Vitae: Subas SinghDocument4 pagesCurriculum Vitae: Subas SinghpatelshishirNo ratings yet

- Section 1: GC Wastewater BS TS PS AT SSDocument6 pagesSection 1: GC Wastewater BS TS PS AT SSSreedhar Reddy SajjalaNo ratings yet

- Yathali Commercial CentreDocument5 pagesYathali Commercial Centreaqeel_al_triniNo ratings yet

- TPO WWT-Cal SheetDocument26 pagesTPO WWT-Cal SheetAob AprilNo ratings yet

- 11c - Pile Cap Details - StructuralDocument2 pages11c - Pile Cap Details - StructuralAnthony FedericoNo ratings yet

- Rehabilitation of Street Lights Along Saraki RoadDocument47 pagesRehabilitation of Street Lights Along Saraki RoadAbdulyekini AhmaduNo ratings yet

- Prolect Report of Material Management of Renusager Power Divison Hindalco Industries LTDDocument122 pagesProlect Report of Material Management of Renusager Power Divison Hindalco Industries LTDRahul RoyNo ratings yet

- P & ID Theory 7Document2 pagesP & ID Theory 7atifme022No ratings yet

- SOR Road Works 2013Document98 pagesSOR Road Works 2013vineetvceb100% (4)

- Process Filter EvalDocument10 pagesProcess Filter EvalKenny RuizNo ratings yet

- Interlocking Concrete Paver SpecsDocument6 pagesInterlocking Concrete Paver Specscarolinetrippin100% (1)

- Capital Costs: Total Price (Ex Vat) Installation of Pipe From Mine To SiteDocument3 pagesCapital Costs: Total Price (Ex Vat) Installation of Pipe From Mine To SiteMichael LomaxNo ratings yet

- Voco 2011Document42 pagesVoco 2011pgrvillavicencioNo ratings yet

- Innovative Mechanical Final Projects List 2013 SooxmaDocument6 pagesInnovative Mechanical Final Projects List 2013 SooxmaRajKumawatNo ratings yet

- Urgent works before monsoon at power plantDocument2 pagesUrgent works before monsoon at power plantGajanan JagtapNo ratings yet

- Wind Code Change Proposal SEAOC 1609 6 (07-08 Submittal) - EditedDocument7 pagesWind Code Change Proposal SEAOC 1609 6 (07-08 Submittal) - EditedtheshadowknightNo ratings yet

- Qdoc - Tips Electrical Panel Board Project ReportDocument18 pagesQdoc - Tips Electrical Panel Board Project Reportsampath rajannaNo ratings yet

- جدول نسب خلط الخرسانة حسب القوة التصميميةDocument2 pagesجدول نسب خلط الخرسانة حسب القوة التصميميةHany Seif-Aldien Nasser0% (1)

- Detailed Specification: Name of WorkDocument3 pagesDetailed Specification: Name of WorkHilary WatsonNo ratings yet

- CH 2 - Estimate I & DDocument23 pagesCH 2 - Estimate I & DHarish Kumar MahavarNo ratings yet

- Master-Vol-I (B) - YTCDocument275 pagesMaster-Vol-I (B) - YTCAbu BiduNo ratings yet

- DPWH MATERIALS ENGINEERING EXAM REVIEWER FOR ITEM 300 WITH NOTES FROM A MATERIALS ENGINEER LLDocument76 pagesDPWH MATERIALS ENGINEERING EXAM REVIEWER FOR ITEM 300 WITH NOTES FROM A MATERIALS ENGINEER LLWillard Apeng97% (38)

- Detail-Reqd (1) .By Erda (Ccppi) Tech. DetailDocument3 pagesDetail-Reqd (1) .By Erda (Ccppi) Tech. Detailabdulyunus_amirNo ratings yet

- Transpo AuditDocument3 pagesTranspo AuditRemar ElumbaringNo ratings yet

- Technical BidDocument50 pagesTechnical BidPerkresht PawarNo ratings yet

- EWS Design Guidelines For PCB Manufacture May 2012Document5 pagesEWS Design Guidelines For PCB Manufacture May 2012wandai_81No ratings yet

- Short Span Trail Bridge Standard Suspended Type Volume II Form No. 2Document11 pagesShort Span Trail Bridge Standard Suspended Type Volume II Form No. 2koklenderNo ratings yet

- Government of Andhra Pradesh Irrigation & CAD Department Pula Subbaiah Veligonda Project WorksDocument347 pagesGovernment of Andhra Pradesh Irrigation & CAD Department Pula Subbaiah Veligonda Project WorksThirukandiyur Sudarsana Sri RamanNo ratings yet

- PSPICEDocument5 pagesPSPICERobertDumitruNo ratings yet

- Excess (+) %: Validate Print HelpDocument2 pagesExcess (+) %: Validate Print HelpPerkresht PawarNo ratings yet

- Final PPT Analysis and Design of T-Beam Girder and Box Girder SuperstructureDocument34 pagesFinal PPT Analysis and Design of T-Beam Girder and Box Girder Superstructureamit_saxena_1075% (4)

- Divided States: Strategic Divisions in EU-Russia RelationsFrom EverandDivided States: Strategic Divisions in EU-Russia RelationsNo ratings yet

- Estimating Greenhouse Gas Emissions Level of A Natural Gas Pipeline - Case Study From A To B Point in West Java-IndonesiaDocument1 pageEstimating Greenhouse Gas Emissions Level of A Natural Gas Pipeline - Case Study From A To B Point in West Java-IndonesiacindydianitaNo ratings yet

- Standard StatesDocument1 pageStandard StatescindydianitaNo ratings yet

- Gases and VapoursDocument5 pagesGases and VapoursbvkvijaiNo ratings yet

- THE Title: First Author, Second Author, Third AuthorDocument7 pagesTHE Title: First Author, Second Author, Third AuthorcindydianitaNo ratings yet

- THE Title: First Author, Second Author, Third AuthorDocument7 pagesTHE Title: First Author, Second Author, Third AuthorcindydianitaNo ratings yet

- The 8 Forms of Corrosion: A Guide to Identifying TypesDocument21 pagesThe 8 Forms of Corrosion: A Guide to Identifying TypesJunaldi75% (4)

- Perrone MW LabDocument8 pagesPerrone MW LabcindydianitaNo ratings yet

- Properties of Gases Lecture NotesDocument24 pagesProperties of Gases Lecture NotesVivek AgrawalNo ratings yet

- Pipeline Tech JournalDocument72 pagesPipeline Tech JournalcindydianitaNo ratings yet

- Offshore pipeline allowable stress calculationsDocument5 pagesOffshore pipeline allowable stress calculationscindydianitaNo ratings yet

- 4-6 Inverse Trigonometric FunctionsDocument32 pages4-6 Inverse Trigonometric FunctionscindydianitaNo ratings yet

- VolatileLiquid PDFDocument7 pagesVolatileLiquid PDFHandugan Quinlog NoelNo ratings yet

- Jas Gas Kinetic TransportDocument15 pagesJas Gas Kinetic TransportcindydianitaNo ratings yet

- Combining Thermo and Fluid Modelling For CO2 Flow AssuranceDocument10 pagesCombining Thermo and Fluid Modelling For CO2 Flow Assurancetiarnanc89No ratings yet

- Emission Calculation SheetDocument5 pagesEmission Calculation SheetcindydianitaNo ratings yet

- Test Questions and Answers-Russian LawDocument7 pagesTest Questions and Answers-Russian LawcindydianitaNo ratings yet

- 10 MeteringDocument48 pages10 MeteringchkzaNo ratings yet

- 2013 18 PDFDocument147 pages2013 18 PDFDurgaRaoVutlaNo ratings yet

- Cindy Dianita - Bisstech 2015Document17 pagesCindy Dianita - Bisstech 2015cindydianitaNo ratings yet

- Gas Flaring Reduction in IndonesiaDocument141 pagesGas Flaring Reduction in IndonesiacindydianitaNo ratings yet

- Transport of CO2Document16 pagesTransport of CO2Archie SmileyNo ratings yet

- Co2 Pipeline Infrastructure Lessons LearntDocument12 pagesCo2 Pipeline Infrastructure Lessons LearntcindydianitaNo ratings yet

- Standards For Calculating Pipe Wall ThicknessDocument17 pagesStandards For Calculating Pipe Wall ThicknesscindydianitaNo ratings yet

- Distillation Project Report VanHoogstraten Dunn UCT 1998Document28 pagesDistillation Project Report VanHoogstraten Dunn UCT 1998Dtf6969100% (1)

- Transport of CO2Document16 pagesTransport of CO2Archie SmileyNo ratings yet

- Transport of CO2Document8 pagesTransport of CO2cindydianitaNo ratings yet

- 13th Century: History of Russia List of Leaders of Russia Bolshevik Gregorian Calendar Old StyleDocument5 pages13th Century: History of Russia List of Leaders of Russia Bolshevik Gregorian Calendar Old StylecindydianitaNo ratings yet

- Lifting and RiggingDocument2 pagesLifting and RiggingcindydianitaNo ratings yet

- Learn More: National Weather ServiceDocument2 pagesLearn More: National Weather Servicedamien boyerNo ratings yet

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- Eutelsat 12 West A Satellite FootprintDocument2 pagesEutelsat 12 West A Satellite FootprintSkybrokersNo ratings yet

- Differences in Left Ventricular and Left Atrial FuDocument10 pagesDifferences in Left Ventricular and Left Atrial FueugeniaNo ratings yet

- A Grammar of Anong Language Death Under Intense ContactDocument409 pagesA Grammar of Anong Language Death Under Intense ContacthaoyichuanNo ratings yet

- Genética, Modificaciones y MutacionesDocument12 pagesGenética, Modificaciones y MutacionespokemaniacoplancheNo ratings yet

- Kyocera Fs-6900 Parts ManualDocument28 pagesKyocera Fs-6900 Parts ManualNic CowpeNo ratings yet

- Science 8-02.02 - Sensitivity in Living OrganismsDocument9 pagesScience 8-02.02 - Sensitivity in Living OrganismsAnoushia AhmerNo ratings yet

- Let Us Be HappyDocument2 pagesLet Us Be HappyMarjule DechavezNo ratings yet

- Welcome Students!: Week 8 (3 Quarter)Document28 pagesWelcome Students!: Week 8 (3 Quarter)Erika Lloren Luyun-GaliaNo ratings yet

- Sampling and Field Testing at Wastewater Treatment FacilitiesDocument11 pagesSampling and Field Testing at Wastewater Treatment FacilitiesSundarapandiyan SundaramoorthyNo ratings yet

- Animal cell organelle and plant cell structure quizDocument20 pagesAnimal cell organelle and plant cell structure quizSITI ZAHILA ARYANIE BINTI ABD RAHIM KPM-GuruNo ratings yet

- Category D Fluid ServiceDocument2 pagesCategory D Fluid Serviceaslam.ambNo ratings yet

- Interpuls Novinki 2014Document64 pagesInterpuls Novinki 2014BaklanovaSVNo ratings yet

- Tooth Development, Eruption & Applied Aspects: Saurabh Roy 09.03.2016Document95 pagesTooth Development, Eruption & Applied Aspects: Saurabh Roy 09.03.2016reema aslamNo ratings yet

- BAlochistanDocument14 pagesBAlochistanzee100% (1)

- Walet - Further Mathematical Methods PDFDocument79 pagesWalet - Further Mathematical Methods PDFPeter BraamsNo ratings yet

- EE 102 Cabric Final Spring08 o Id15Document10 pagesEE 102 Cabric Final Spring08 o Id15Anonymous TbHpFLKNo ratings yet

- AABB Accredited DNA Testing FacilitiesDocument2 pagesAABB Accredited DNA Testing Facilitiesjosueduran75No ratings yet

- General ALT Model For Step Stress TestDocument12 pagesGeneral ALT Model For Step Stress TestAnshul NautiyalNo ratings yet

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet

- Fair Directory 02-2016Document44 pagesFair Directory 02-2016Ravichandran SNo ratings yet

- Lista de Precios Tones y Staleks 01.04Document3 pagesLista de Precios Tones y Staleks 01.04Maria T. OliverosNo ratings yet

- Astm A 182-2021Document17 pagesAstm A 182-2021Mohammed AliNo ratings yet

- List of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFDocument26 pagesList of Students Allotted in Open Elective Subjects (B. Tech and M. Tech (Dual Degree) Integrated MSc. - 4th Semester - Regular - 2018 - 19) - 2 PDFArpan JaiswalNo ratings yet

- Dsa 5300Document8 pagesDsa 5300Nguyen Van ToanNo ratings yet

- Deks Olje ArticleDocument5 pagesDeks Olje ArticleTomMacNaughtonNo ratings yet

- MD R2 Nastran Release GuideDocument276 pagesMD R2 Nastran Release GuideMSC Nastran BeginnerNo ratings yet