Professional Documents

Culture Documents

F 070 Mue F

Uploaded by

Fari PratomosiwiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F 070 Mue F

Uploaded by

Fari PratomosiwiCopyright:

Available Formats

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

ASSESSMENT OF OIL ANALYSIS DATA FOR MEDIUM VOLTAGE

DISTRIBUTION TRANSFORMERS

A. Mller1*, M. Jovalekic1, S. Tenbohlen1

Institute of Power Transmission and High Voltage Technology, University of Stuttgart, Germany

*Email: andreas.mueller@ieh.uni-stuttgart.de

Abstract: To ensure a safe and secure operation of transformers various diagnosis

techniques are known. A lot of them are only applied to large power transformers regarding the costs. But distribution transformers can also benefit from the knowledge. In this

contribution the results from 37 oil analyses of medium voltage distribution transformers

with different load history and age are presented. The considered transformers are 10 to

55 years old. The rated power varies between 160 kVA and 1250 kVA. All transformers

are oil immersed. The objects of investigation are the physio-chemical properties of the

observed oils. In addition to routine tests for distribution transformers like breakdown

voltage, water content and acid number some extra tests were also performed: for example the loss factor respectively the oil conductivity and the dissolved gases in oil. Also the

transformers main data e.g. rated power and ages are considered. Aim of the investigation is to improve the evaluation of the results and to show their physical or statistical correlation. The analysis of the results also considers effects of parameters e.g. oil temperature at sampling time. Finally, in the conclusion a suggestion of diagnostic techniques and

sampling intervals is proposed.

INTRODUCTION

In this contribution the results from many oil

analyses of medium voltage distribution transformers with different load history and age are

presented. The oil samples were taken during a

routine test of University of Stuttgarts distribution

transformers. These transformers are sampled

once a decade which was the reason to analyse

the physio-chemical properties of the used oils.

Aim of the investigation is to improve the evaluation of the results and to show their physical and

statistical correlation. Thus several routine oil tests

are performed, including colour number, breakdown voltage, water content and total acid number.

In addition loss factor respectively oil conductivity

and dissolved gases in oil were measured.

In this contribution also a short survey of the used

measuring apparatuses with their advantages and

disadvantages as well as accuracies and possible

error sources are given.

2

MEASUREMENT EQUIPMENT

In the following sections the measurement

methods and equipment are presented.

2.1

Breakdown voltage measurement

This measurement is an integral oil examination. It

shows effects on oil quality caused by several

sources. Obviously, an increase of the water content will decrease the breakdown voltage. Particles

and other aging products have an influence too.

With this quick measurement method it is possible

to get a rough overview of the oil condition and

decide further tests.

The presented tests follow IEC 60156. The setup

uses a 2.5 mm gap distance between two calotte

electrodes (VDE). The test cell is filled with

approximately 400 ml oil. It is important to follow at

least the waiting times recommended by the standards (5 min) because of air bubbles resulting from

the filling process. Six breakdowns are produced

(pause and stirring of 2 min). The result is the

mean breakdown voltage with a standard deviation. Typically, the relative standard deviation for

mineral oil is between 10 % and 20 %. A steady

increase in breakdown voltage during the test indicates that the waiting times could have been too

short. This is often the cause when a dielectric fluid

has a higher viscosity than usual (e.g. natural

esters). Depending on the transformer's rated voltage the measured value has to satisfy 30 kV,

40 kV or 50 kV for the highest voltages [1, 2].

2.2

Determining total acid number

The total acid number (TAN) of the oil gives some

information about the aging of the oil-paper insulation system. It is determined by titration and is

defined by how many milligrams of KOH solution

are needed to neutralize the acid in 1 gram of oil.

New oils can have a TAN of 0.01 whereas for aged

oil 0.25 is already an alarming value and 0.50 is

critical. The typical absolute measurement accuracy is +/- 0.01 for titration of about 10 g oil. As the

name total acid number implies, this parameter

shows a super-imposition of several aging products from oil aging and paper aging. Normally, it

cannot distinguish between them, for example low

and heavy molecular weight acids. Still an elevated

TAN indicates aging. Especially for overloading

and high operating temperatures over longer

periods of time a rise in TAN should appear [3].

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

2.3

Determination of water content with

coulometric Karl-Fischer titration

The water content in oil is used for two diagnostic

methods. Firstly, it is directly connected to the

breakdown voltage and thus is important for the

safe operation of a transformer. Secondly, it is

used for estimating ageing progress and remaining

lifetime of the transformer. In this case the interesting part is the moisture content of the solid insulation which is estimated indirectly with moisture

equilibrium diagrams from water in oil or dielectric

spectroscopy of the whole insulating system.

The absolute moisture content in oil is measured

with coulometric Karl-Fischer titration. In mineral oil

the water content is very low, so it is common to

use ppm values, which are defined by g of water

per gram oil. Obviously, the determination of very

small amounts of water is difficult. Satisfying

results can be achieved with direct injection of oil in

the Karl-Fischer reagent. It is also necessary to

take into account the sensitivity limits of the titrator.

An acceptable repeatability has been obtained with

water amounts greater than 10 g, which can be

achieved by injecting larger volumes of oil into the

titrator. Additionally a display of double exponential

titration curves helps defining titration stop criteria

and simplifies quality control [4].

2.4

Loss factor measurement of the oil

The dielectric loss factor can be measured with a

Schering bridge or more recently with the vector

impedance method. It is convenient to use test

cells defined for conductivity measurement. As the

measurement frequencies and polarisability of the

oil are very low, the loss factor is proportional to

the conductivity. A combination of ageing products

and water can have an influence on the conductivity and thus on the loss factor. Also the

measurement temperature has to be considered as

conductivity is exponentially temperature dependent [5].

2.5

headspace sampling and stripping. Each method

has advantages and disadvantages. For this

contribution headspace method is used. In a small

vial (volume 20 ml) 10 ml of oil is in contact with

headspace filled with argon. After 30 min of shacking at 70 C equilibrium is reached. Afterwards a

gas sample is automatically injected in the GC.

After the analysis it is possible to calculate the fault

gas concentration in oil using the Ostwaldcoefficients.

In the GCs columns the injected gas mix is separated to its components. The individual gas components are measured by two detectors: a flame

ionization detector (FID) and a thermal conductivity

detector (TCD). The FID only measures combustible gases with high accuracy. The TCD can measure all gases with a different thermal conductivity

than the carrier gas. A methanizer is used to convert CO and CO2 to methane and thus these gases

can be detected more precisely in the FID.

The detection limit of the whole analysing system

should be 5 l/l for hydrogen and 1 l/l for the

hydrocarbons according IEC 60567 with good

reproducibility.

For the analysis in this contribution a Siemens

Sichromat 2/8 GC (2 columns in independent ovens, FID, TCD, methanizer, argon as carrier gas)

with a Hewlett Packard HP 7694 headspace sampler is used.

3

3.1

TRANSFORMERS UNDER SURVEY

Technical specifications

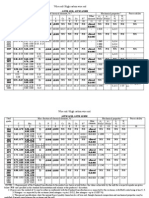

The results from 37 oil analyses of medium voltage

distribution transformers with different load history

and age are determined. The oil samples are taken

during a routine test of University of Stuttgarts distribution transformers. The considered transformers are 10 to 55 years old, see Figure 1.

Dissolved gas analysis

The Dissolved gas analysis (DGA) is a well known

and accepted diagnostic method for oil immersed

electrical equipment. Especially for power transformers it is a common routine test. This

measurement is based on the fact that electrical or

thermal failures in transformers generate various

gases which then dissolve in the surrounding oil.

After taking an oil sample and analysing it in the

laboratory, it is possible to ascertain the transformers internal error. Typically 11 fault gases are

measured: H2, CH4, C2H2, C2H4, C2H6, C3H6, C3H8,

CO, CO2, O2 and N2.

The measurement is done according IEC 60567 [6]

using a gas chromatograph (GC) linked with a degassing system. To degas oil samples several

techniques are available: vacuum degassing,

Figure 1: Transformer fleet age distribution

The rated power varies between 160 kVA and

1250 kVA, see Table 1.

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

Table 1: Transformers power ratings

Power

rating

quantity

400 kVA

11

> 400 and

800 kVA

14

> 800 kVA

12

The rated voltage is 10 kV / 400 V for all transformers. All transformers are oil immersed; 34 of

them are equipped with a free breathing oil conservator, 3 are hermetically sealed transformers.

3.2

service years. As the paper insulation ages the

water content should be increasing. A tendency

can be recognized, but the value depends on

many factors like oil temperature or equilibration

time. Therefore the next section discusses the

temperature dependence of the measured values.

Oil Sampling

Correct sampling is very important for an accurate

measurement of all oil diagnosis values. For

sampling a sealed aluminium bottle is recommended. Normally two bottles are needed: one for

oil characteristics determination (min. 500 ml) and

one for DGA (100 1000 ml according degassing

technique). Because of the small oil volume of distribution transformers only one sample bottle

(625 ml) is used.

Figure 2: Transformer oil breakdown voltages

Before sampling it is important to be sure that the

transformer is offline or that it is possible to take

samples safely. It is very important to fill the

sample bottle carefully. The bottle should be absolute full without headspace or any air bubbles. It

should be quickly sealed to avoid contamination

(e.g. water or gases from ambient air) [6]. After

sampling it is necessary to write down the top-oil

temperature of the transformer. The sample bottles

should be stored dry and protected from sunlight

and analysed as fast as possible.

In the laboratory it is recommended to measure the

water content and the dissolved gases first

because of cross contamination with ambient air.

4

4.1

Figure 3: Total acid number depending on age

RESULTS

Oil characteristics

Figure 2 shows the average breakdown voltage

over all investigated transformer oils. It is evident

that they are generally in a good condition for

medium power voltage transformers regardless the

age, which can be up to 55 years.

As mentioned the total acid number is one indicator for ageing. In Figure 3 the acid number is plotted over the age of the respective transformer. A

significant variation of the total acid number

exists, but it does not depend on the service years.

One could speculate that the influence of the transformers load is dominating. TAN does not change

much over time, but at elevated temperatures its

trend could give useful information about the accelerated thermal degradation and thus the structural condition.

A more difficult interpretation is the assessment of

water content in oil and its implications. Figure 4

shows the absolute water content plotted against

Figure 4: Water content in oil depending on age

4.2

Sampling temperature dependence

It is well known that water migrates between solid

and liquid insulation. This process is governed by

the oil temperature as the water saturation limit of

oil changes drastically with temperature. For cold

transformers water migrates into the paper. For hot

operating temperatures the water content of the oil

rises. Therefore ppm values of the hot oil seem to

be higher. Figure 5 illustrates the effect, even if the

transformers have unknown and possibly different

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

moisture contents in the solid insulation. The consequence is that the oil from the warmer transformer, which therefore has to be more wet, will

have a worse breakdown voltage, which normally

is measured at ambient temperature. Three solutions can overcome this problem:

Sampling the oil only at a well-defined oil

temperature, e.g. 20C top oil.

Heat the breakdown voltage test cell up to the

sampling temperature for measurement.

Use a temperature correcting formula for the

breakdown voltage and water value, which is already suggested in some standards.

As oil and paper age, not only water is produced,

but also organic acids, which is reflected in the

total acid number. Here also an investigation is

made to see if acids migrate between solid insulation and oil like water does. Figure 6 shows TAN

against sampling temperature. A dependency can

not be observed. It seems that the acids do not

behave as dynamically as water. Additionally their

composition of weak or strong polar molecules is

unclear.

4.3

Dissolved gas analysis

In Figure 7 the concentration of total dissolved

combustible gases (TDCG, here: H2, CH4, C2H2,

C2H4, C2H6 and CO) are plotted over transformers

age. The TDCG concentration is normally a hint for

an ongoing fault in the transformer. However, the

transformers fault gas concentrations are in a typical range [7]. In this case the observed transformers only accumulated fault gases over the years.

The CO2/CO ratio is known as an indicator of the

decomposition of cellulose [8]. In Figure 8 the ratio

is printed over transformers age. In the diagram

transformers between 10 and 30 years have a variable ratio between 5 and 48. This distribution may

result from various load situations of the considered transformers. In comparison the older ones

ratio (> 35 years) is smaller. The older transformers have a smaller CO2/CO ratio by trend then

younger ones. As a conclusion a fix CO2/CO ratio

as diagnostic indicator is problematical because

the ratio changes over the years.

The temperature dependent loss factor, respectively the oil's conductivity is measured at room

temperature. An exact relationship between high

TAN and water content to high loss factors could

not be found. In some cases the conductivity was

very high in some cases still low.

In Figure 9 the concentrations of CO2 and CO are

plotted over transformers age. In the diagram CO2

concentrations vary over their age. But a concentration maximum can be seen at an age of around

20 years. Older and younger ones have a lower

CO2 concentration. It is unclear if a correlation can

be found without the knowledge of the loading. In

comparison the CO concentration is slightly

increasing over the years.

Figure 5: Water content vs. sampling temperature

Figure 7: Combustible gases produced over years

Figure 6: TAN vs. sampling temperature

Figure 8: CO2/CO ratio over transformer age

XVII International Symposium on High Voltage Engineering, Hannover, Germany, August 22-26, 2011

importance of the electric equipment. Useful data

can be gained from total acid number, water content and CO2/CO ratio as ageing indicators.

A quick overview of the insulating system condition

can already be obtained by measuring breakdown

voltage. Hereby, it is possible to get information

about safety of operation, but is highly dependent

on oil sampling temperature.

6

Figure 9: CO2 and CO development over age

REFERENCES

[1] IEC Standard 60422, "Mineral insulating oils in

electrical equipment - Supervision and maintenance guidance", 3. Edition, International Electrotechnical Commission, Geneva, Switzerland,

2005

[2] IEC Standard 60156:1995 "Insulating liquids

Determination of the breakdown voltage at

power frequency Test method", International

Electrotechnical Commission, Geneva, Switzerland, 1995

[3] IEC Standard 62021-1:2003 "Insulating liquids

Determination of acidity Part 1: Automatic potentiometric titration", International Electrotechnical Commission, Geneva, Switzerland, 2003

Figure 10: CO2/CO ratio over total acid number

In Figure 10 the CO2/CO ratio is displayed over the

total acid number. As mentioned the total acid

number is one indicator for ageing. However, in the

diagram no correlation between the ratio and total

acid number can be seen. So maybe CO2/CO ratio

could be time and load dependent. The ratio interpretation could be improved by considering the

origins of the gases like oil ageing and cellulose

ageing.

5

CONCLUSION

In this contribution the results from 37 oil analyses

of medium voltage distribution transformers of different age were presented. Also a short survey of

the used measuring apparatuses considering

advantages and disadvantages as well as accuracies and possible error sources were discussed.

As the analysed transformers are mainly operated

at lower partial load the measured values can be

seen as a reference for regular ageing. For water

content assessment the oil sampling temperature

is of crucial importance. Neglecting this fact could

lead to an erroneous diagnosis. For ageing assessment it seems that load history has a higher

influence than normal natural ageing.

In case of higher loading or even overloading a

transformer, the interval for oil sampling should be

reduced in order to get better trend information.

Eventually, the chosen interval depends on the

[4] IEC Standard 60814: "Insulating Liquids - OilImpregnated Paper and Pressboard - Determination of Water by Automatic Coulometric Karl

Fischer Titration", 1997

[5] IEC Standard 60247: "Insulating liquids measurement of relative permittivity, dielectric dissipation factor (tan) and d.c. resistivity", International Electrotechnical Commission, Geneva,

Switzerland, 2004

[6] IEC Standard 60567, "Oil-filled electrical

equipment - Sampling of gases and of oil for

analysis of free and dissolved gases - Guidance", 3. Edition, International Electrotechnical

Commission, Geneva, Switzerland, 2005

[7] IEC Standard 60599, "Mineral-oil impregnated

electrical equipment in service - Guide of the

interpretation of dissolved and free gases analysis", 2.1 Edition, International Electrotechnical

Commission, Geneva, Switzerland, 2007

[8] R. Mller, H. Schliesing, K. Soldner: "Die Beurteilung des Betriebszustandes von Transformatoren durch Gasanalyse", Elektrizittswirtschaft, Jg. 76, Heft 11, pp. 345-349, 1977

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Device Code ListDocument383 pagesDevice Code ListBach BuiNo ratings yet

- Topic 1.2 Analytical ProcessDocument52 pagesTopic 1.2 Analytical ProcessEyzah75% (8)

- Method Validation ProtocolDocument17 pagesMethod Validation ProtocolDilawar Bakht100% (2)

- 04591226Document7 pages04591226Fari PratomosiwiNo ratings yet

- Dynamic Properties of Dielectrics E F (T) : P + P (T) 0 P (T) (P P)Document24 pagesDynamic Properties of Dielectrics E F (T) : P + P (T) 0 P (T) (P P)Fari PratomosiwiNo ratings yet

- Materials in High Voltage TechnologyDocument27 pagesMaterials in High Voltage TechnologyFari PratomosiwiNo ratings yet

- Mineral Oil TransformersDocument9 pagesMineral Oil TransformersAnonymous 9VcxlFErfNo ratings yet

- The Invisible Supply of Reliable Power Power Cables MV, HV & EhvDocument44 pagesThe Invisible Supply of Reliable Power Power Cables MV, HV & EhvFari Pratomosiwi100% (1)

- ManualDocument221 pagesManualFari PratomosiwiNo ratings yet

- Indonesia Solar Power Mapping Study Using Secondary Data Paulus Agus Winarso Supriadi LeginoDocument7 pagesIndonesia Solar Power Mapping Study Using Secondary Data Paulus Agus Winarso Supriadi LeginoFari PratomosiwiNo ratings yet

- Mineral Oil TransformersDocument9 pagesMineral Oil TransformersAnonymous 9VcxlFErfNo ratings yet

- Introduction To Power SystemsDocument21 pagesIntroduction To Power SystemsPhil KerrNo ratings yet

- Electric Breakdown in Gases: Department of Electric Power EngineeringDocument30 pagesElectric Breakdown in Gases: Department of Electric Power EngineeringFari PratomosiwiNo ratings yet

- Surface DischargesDocument18 pagesSurface DischargesFari PratomosiwiNo ratings yet

- HVT 7 Pedrow Insulation CoordinationDocument4 pagesHVT 7 Pedrow Insulation CoordinationFari PratomosiwiNo ratings yet

- Electric Fields: - Exact Methods - Approximate Solutions - Computer SimulationsDocument17 pagesElectric Fields: - Exact Methods - Approximate Solutions - Computer SimulationsFari PratomosiwiNo ratings yet

- HVT 6 Pedrow OvervoltagesDocument26 pagesHVT 6 Pedrow OvervoltagesFari PratomosiwiNo ratings yet

- HVT 7 Measurement of HVDocument20 pagesHVT 7 Measurement of HVFari PratomosiwiNo ratings yet

- HVT 6 Generation of HV Part2 PDFDocument19 pagesHVT 6 Generation of HV Part2 PDFFari PratomosiwiNo ratings yet

- HVT 7 Pedrow Measurement o High Voltages and CurrentsDocument5 pagesHVT 7 Pedrow Measurement o High Voltages and CurrentsFari PratomosiwiNo ratings yet

- HVT 6 Generation of HV Part1Document7 pagesHVT 6 Generation of HV Part1Fari PratomosiwiNo ratings yet

- HVT 5 Applications of Insulating Materials, 3Document6 pagesHVT 5 Applications of Insulating Materials, 3sahiiiiNo ratings yet

- HVT 2 Electrical Breakdown in Gases - Part1Document11 pagesHVT 2 Electrical Breakdown in Gases - Part1Fari PratomosiwiNo ratings yet

- HVT 4 Breakdown in Liquids ChalmersDocument16 pagesHVT 4 Breakdown in Liquids ChalmersFari PratomosiwiNo ratings yet

- HV BushingsDocument5 pagesHV BushingssabrahimaNo ratings yet

- HVT 3 Conduction N Breakdown in Solids PedrowDocument12 pagesHVT 3 Conduction N Breakdown in Solids PedrowFari PratomosiwiNo ratings yet

- 1304 5516Document22 pages1304 5516Fari PratomosiwiNo ratings yet

- B 049 Wie F PDFDocument4 pagesB 049 Wie F PDFFari PratomosiwiNo ratings yet

- HVT 2 Electrical Breakdown in Gases - Part2 From Pedrow Washington StateDocument16 pagesHVT 2 Electrical Breakdown in Gases - Part2 From Pedrow Washington StateFari PratomosiwiNo ratings yet

- Maintain High-Voltage BushingsDocument10 pagesMaintain High-Voltage BushingsNoé Rafael Colorado SósolNo ratings yet

- Use of The BRESSER MikroCam AdaptersDocument2 pagesUse of The BRESSER MikroCam AdaptersFari PratomosiwiNo ratings yet

- F 048 CHM F PDFDocument5 pagesF 048 CHM F PDFFari PratomosiwiNo ratings yet

- Steerable AntennaDocument44 pagesSteerable AntennaKenNediaNo ratings yet

- The Laws of Thermodynamics and Your Air Conditioner (less than 40 charsDocument13 pagesThe Laws of Thermodynamics and Your Air Conditioner (less than 40 charsluizcristianofsNo ratings yet

- Operation and Maintenance ManualDocument39 pagesOperation and Maintenance Manualhdf17No ratings yet

- Chapter 1-Bipolar Junction Transistor (BJT)Document78 pagesChapter 1-Bipolar Junction Transistor (BJT)Manish Kumar VermaNo ratings yet

- Fuel Oil AnalysisDocument6 pagesFuel Oil AnalysisPawan BeniwalNo ratings yet

- High Carbon Wire RodDocument9 pagesHigh Carbon Wire Rodninganray6316100% (1)

- Scotch Tape Method: Producing Graphene FlakesDocument3 pagesScotch Tape Method: Producing Graphene Flakestaniya balochNo ratings yet

- Hardtop XP (Azad)Document5 pagesHardtop XP (Azad)Anonymous f1NlMPnNo ratings yet

- Ats 2 (Csir Net) PDFDocument17 pagesAts 2 (Csir Net) PDFAayushi VermaNo ratings yet

- Aerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionDocument16 pagesAerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionAlberto De La CruzNo ratings yet

- Crude Oil Tank Mixer Data SheetDocument3 pagesCrude Oil Tank Mixer Data Sheetsiska bedegul100% (1)

- Redox 2Document366 pagesRedox 2Ana Emily Prentiss100% (1)

- GLA0039 Final Report.926cd0f7Document146 pagesGLA0039 Final Report.926cd0f7Ntombi Langa-RoydsNo ratings yet

- 13NO03 GN 60 001 Deliverable ListDocument4 pages13NO03 GN 60 001 Deliverable Listbagus handokoNo ratings yet

- The High-Latitudude IonospehereDocument639 pagesThe High-Latitudude IonospehereSainath Bharadwaj100% (2)

- Dowtherm Vent CondenserDocument1 pageDowtherm Vent Condensersushant_jhawerNo ratings yet

- Normas GTX Rock TestingDocument2 pagesNormas GTX Rock TestingOWEMNo ratings yet

- Non-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementDocument7 pagesNon-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementstevensurandomNo ratings yet

- Mahatma Jyotirao Govindrao PhuleDocument12 pagesMahatma Jyotirao Govindrao PhuleSagar V. ThakkarNo ratings yet

- Chemistry 9 Chap 1 Long QADocument17 pagesChemistry 9 Chap 1 Long QAAkbar Ali AhmedNo ratings yet

- 5018.optical Networking Best Practices HandbookDocument3 pages5018.optical Networking Best Practices HandbookashithaprNo ratings yet

- 2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)Document4 pages2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)AnnafiNo ratings yet

- Geology Geophysics in Oil ExplorationDocument70 pagesGeology Geophysics in Oil Explorationberbere68100% (1)

- Barett PDFDocument20 pagesBarett PDFlnadolskiNo ratings yet

- Test II. Multiple Choice. Encircle The Letter of The Correct AnswerDocument1 pageTest II. Multiple Choice. Encircle The Letter of The Correct AnswerjoylynNo ratings yet

- Tool Makers MicroscopeDocument13 pagesTool Makers MicroscopeLokesh LokiNo ratings yet