0% found this document useful (0 votes)

645 views3 pagesQCDC Safety Operation Guidelines

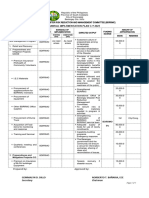

This document provides guidelines for operating safety features on an offloading system. It describes the key equipment in the offloading protection system, including a quick connect disconnect coupler (QCDC), marine breakaway coupling (MBC), and 200T SWL quick release hook. The document outlines emergency response procedures to release the export floating hose and unmoor a shuttle tanker if unsafe weather or tanker emergency conditions arise. It details activating audible alarms and valves to close off cargo transfer and release the hose and mooring equipment. An oil spill response would be initiated if any spilled oil resulted.

Uploaded by

barrysmith77Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

645 views3 pagesQCDC Safety Operation Guidelines

This document provides guidelines for operating safety features on an offloading system. It describes the key equipment in the offloading protection system, including a quick connect disconnect coupler (QCDC), marine breakaway coupling (MBC), and 200T SWL quick release hook. The document outlines emergency response procedures to release the export floating hose and unmoor a shuttle tanker if unsafe weather or tanker emergency conditions arise. It details activating audible alarms and valves to close off cargo transfer and release the hose and mooring equipment. An oil spill response would be initiated if any spilled oil resulted.

Uploaded by

barrysmith77Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- FSO Operations Guideline: Guides the operation and safety protocols for an FSO, including equipment testing, installation, and maintenance.

- Emergency Procedures: Outlines specific procedures to be followed during emergencies involving the FSO, including system activation.