Professional Documents

Culture Documents

Bosch Fuel Injection

Bosch Fuel Injection

Uploaded by

Yaser Akar100%(2)100% found this document useful (2 votes)

498 views204 pagesBosch Fuel Injection

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBosch Fuel Injection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(2)100% found this document useful (2 votes)

498 views204 pagesBosch Fuel Injection

Bosch Fuel Injection

Uploaded by

Yaser AkarBosch Fuel Injection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 204

BOSCH FUEL INJECTION— AN OVERVIEW 3

1. INTRODUCTION

Here's my plan for you to get the most out ofthis book: This

chapter Introduces the idea of fuel injection, and tells you why

virtually all cars being built today use fuel Injection. Ill give you

the broad picture of Bosch fuelinjection systems, and show

how the diferent systems are separated Into two basic types:

pulsed and continuous injection. You'll see that what bagan as

Control of the air-fuel ratio has expanded to include the precise

canteoL.of ignition timing and, often, idle rpm, loading to a new

term, engine management,

In chapter 2, to help you understand the principles behind

fuel injection, I'l look at the engine needs for each driving

condition and also discuss the Importance of fuel injection to

~eting. government standards for emission control and fuel

‘omy, Youll see how the precise control of fuel metering,

sometimes at a delivery rate of one drop of fuel in a few

rliseconds of time, meets those needs while stl providing

{good power.

In chapter 3, Il describe how each dierent Bosch pulsed

fuel injection systern works, including D-Jetronic, Luetronic,

LeWJetvonio, and Motronic. in chapter 5, Il describe how each

Bosch continuous fue! injection system works, including K-

Jetronig, Klambda, KE-Jetronic, and KE-Movonic. Inchapter 4,

Ii snow you now to service pulsed systems, and in chapter 6,

MI show you how to service continuous systems, In many

‘cases you can do this using enly simple tools, a voljohmmeter

(VOM) and a fuel-pressure gauge. Even if you don't want to do

much of the work yourself, you'll stil know enough about

troubleshooting and repairs to deal with the technician wao

may use spacial tools to service your car.

Most of these fuel injection systoms as installed by the

manufacturer are capable of delivering extra fuel for engine

"moditications thatincrease performance. In chapter 7. for those

want more power from their fusLnjection system, I'l show

you the diferent mocifcations for street-egal or offoad use,

{and giscuss which cnes work—and which ones dor't. For you

owners Wwho can tweak a carburetor by ear with a screwdriver

9 Saturday afternoon, this book will help you accept the

Performance of fuel injection as it takes away your need for

Carburetor skills. Even so, you can do a lot more to your

'velinyected car than most people realize.

2. FUEL INJECTION Is HERE

‘Today's cars are changing under the hood. The tangles of

Yacuum hoses—as well as emission-control miseries ~are be-

59 fePlaced by the ordery instalation of ueL.njection systems.

Delore we talk about spactic Bosch systems, you'l need to

understand some basics about fuel injection,

Fig, 2-1, Electonie conral ot ue! ection ana igritan (oe

for engine managarnent helps clean up ihe tangle

‘of urderhood hoses oatlo) which are necessary

‘when vacuum creuils are used

2.1 Air-Fuel Mixtures

Internal-combustion engines create power by burning fuel

‘mixed with ar. In gasoline-fueled engines, the proportions of air

‘and fuel—the airuel ratios or “mixtures” — are of crticalimpor-

tance to the quality of combustion and, therefore, to engine

ower output and running characteristics. Since the amount of

air required by the engine varies with rpm and lead, the re-

‘quited amount of fuel varies too.

The overall purpose of the systems covered by this manual

is to provide the engine with the best possible mixture—the

‘optimum air-fuel ratio—for the constantly changing engine op-

‘erating conditions.

Fuel Injection Is Here

4 BOSCH FUEL INJECTION— AN OVERVIEW

2.2. What is Fuel Injection?

The throttie of a gasoline ongine regulates only ar flow into

the engine. Since the proportions of air and fuel are crtica, tis

Lup to some other mechanism to meter the correct amount of

fuel into the moving air. 'l call this other mechanism the fuel

Gelivery system. The fuel delivery system—whatever type It

‘may be—responds to throtle changes and adjusts to contin:

ously supply the engine with a combustible mixture of alr and

fuel. Fuel injections an accurate and sophisticated type of tual

Gelivery system,

23 Fuel Delivery

For modem gasoline automobiles, there are two basictypes

of fuel detivery systems in use toclay, carburetors and fuel

injection. While these systems mix fuel and air, they achieve it

in very different ways,

Carburetors

Carburetors take advantage of the venturi principe. Briety,

this principle says that as air flow increases, pressure de-

‘creases. Airflow through the carburetor throat, as determined

bby the throttle opening, creates a low pressure condition, This

reduced pressure pulls fue! into the intake air Strearn where it

is vaporized to form a combustible alrfuel mixture, A wider

throttle opening causes more airflow which results in more fue!

flow, A smalier throtle opening Lkewise reduces fuel fow, By

this cause-and-etfect relationship, fuel is “metered” in propor

tion to air tlow.

Fig. 2.2. Modem Compiax feedback carburetors can be

-r@ expensive than tel injection systems to neta

‘and service. Drvoabaty cannot match mast fuel

‘njected cars. and emission contl is mere oicut

Fuel Injection Is Here

This olatvely simple and crude fuel delivery technology has

powered gasoline engines to acceptable levels of efficiency for

many decades. In recent times, however, closer scrutiny of

performance, fuel economy, and exhaust emissions has de-

manded even greater engine efficiency. This greater efficiency

requires more precise control of fuel metering, Carburetors,

although well developed after decades of use, are limited in

their abilty for precise fuel metering, especially under extreme

operating conditions, even with their complex set of fuel Cr-

cuits ets, ar bleeds, chokes and valves,

Fuel injection

Fuel injection systems deliver fuel by forcing it into the

incoming airsveam. Fuelinjection systems actually moasure

the incoming air and pressurize the fue! to deliver iin precise

amounts based directly on that measurement. Because fuel is

delivered to the manifold under pressure, the quaniiy of fuel

delivered can be more positively controlled. With this more

positive control, fuel deivery can be more easily manipulated to

‘meet the unique demands of extreme operating condtions, This

results in greater efficiency over a wider range of operation,

3. FUEL INJECTION TYPES

Bosch passenger-car fuel injection first appearedin 1927 as

a diesel design using engine-driven pumps developing high

pressure to deliver diesel fuel into the cylinders —direct injec:

tion. In 1997, thes# pumps were adapted to aircraft enginos,

with both diesel and gasoline fuel applications. In 1955, similar

engine: driven gasoline injection pumps were developed for the

Mercedes-Benz race cars and the 300SL production car, again

injecting fuel at high pressure direcly into the cylinders.

These mechanical systems used a precisely:timed, engine-

driven pump to dover measured quantities of fuel to each

cylinder in time withthe crankshatt and in proportion to throtie

‘opening. The complex and expensive systems were an ad.

‘vance over the carburetors of their time, mainly in terms of

performance, but production car applications were limited to

‘exotic makes and special models, They were very diffcult to

properly set up, and proper maintenance was an expensive

proposition.

The fuet.njection systems described in this book first ap-

peared about 1967. They are completely different from engine-

dhiven systems, delivering fuel at much lower pressures al the

intake ports, and are generally electronically controlled. The

early Bosch Iterature describes these systems. as “non

‘diven”. Bosch coined the term “Jetronic" to establish a com>

‘mon identity for their new designs in most of the 135 countries,

in which thay operate.

Fig. 3-1, Mercedes-Bere 200 Si. cars use dct fuel injec.

ton High-pressure engie-ckven pump, hanging

low under ttecblock injected gasaline rectly to

Cinco Adapted fem Bosch ciesel inaction sys

tome,

Owners of fuel.injected cars experience better starting and

driveability, especially when the engine is cold. Owners of the

first fuelinjected BMWs proudly showed off their cars: even on

a cold day, they would open the driver's window and, standing

outside, reach in to turn the key, then boast about the smooth

running engine at cold idle.

For the manutacturer, fuel injection means better emission

control and better fuel economy, both important in meeting

increasingly stingent government regulations. Fuel injection

offers the following advantages:

‘reduces air-fuel rato varlablity

‘S matches tue! delivery to specific operating requirements

* prevents staling caused by fust-bow! wash during corner:

ing

‘eliminates engine runon (dieseling) when the key is

turned off

Uni tow years go, because of looser emission

lis in Europe, many European cars were bulk with

{uel injection for delivery in the US, but had carbu-

‘eto for delivery in Europe. When | spoke with a

{Chief engineer of one ofthe largest European manu

tncturers he expressed reluctance to change his en-

{Sines fom carburetors to the more expensive fuel

injection, and suggested that we in the US. were a

litle paranoid about clean air. Now, Europeans rec-

CarIze the importance of clean ar, and tuo injection

Systems ave spreacing to more cars sold in Europ.

Infact, many late-model German car aro soldin both

the U.S. and Germany with the samo fuolinjocted

fngines using the samo lead: fuol catalyst emis-

son conto.

‘Multi-Point (or Port injection)

Allo the Bosch systems covered in tis book are multi-point

systoms. They deliver fuel at the engine intake ports near the

intake valves. This means that the intake manifold delivers only

air, in contrast to carburetors oF single-point fuel injection sys-

‘temsin which the intake manifold carries the ar-tuel mixture, AS

2 result, these systems offer the foliowing advantages:

‘greater power by avoiding venturi losses as in @ carbure-

tor, and by allowing the use of tuned intake runners for

better torque characteristics

‘improved driveability by reducing the throtle-change lag

which occurs while the fuel travels from the throttle body

to the intake ports

«increased fuel economy by avoiding condensation of fuel

fn interior walls ofthe intake manifold (manifold wetting)

‘© simplified turbocharger applications; the turbocharger

‘compressor need only handle air

Fon nor af >

lotake yw

‘Cynder head

Fig. 3.2, Pot injgolon delvors fuel tothe mario at the

ine va

Fig, 3.3, On fuotinjctod cars, tuned intake numers improve

performance by rsinioring ram elect to pack in

mae ai and increase torque

f

SEs SeRe ene See

6 BOSCH FUEL INJECTION— AN OVERVIEW

The simplicity ofa turbocharged Bosch systems evidentin

the Skio Barber Saab racing series cars which are powered by

nearly stock production Saab Turbo engines equipped with

Bosch LH+Jetronic fuel injection, as shown in Fig. 3-4

Fig. 8-4, Tubochargers and vlinjocton go weltogethe, in

both road cars and race cars,

3.1 Pulsed (Electronic) Systems

Tho pulsed systems are sometimes refered to as "Elec:

tronic Fuel injection” (EF I}, and these are the systems that most

people think of when you say “fuel injection.” There are several

Bosch variations of pulsed systems, but their basio functions

are the same,

Inall of the pulsed systems, incoming airs measured by a

Sensor which puts out an electronic signal proportional to air

flow. An electronic contol unit (ECU), responding tothe signals

‘rom the airflow sensor and other sensors, meters fuel to the

engine by way of electicaly-operated solenoid valve injectors.

Fuel is injected in a series of short pulses, always under

electronic control, In Bosch systems, the number cf pulses is

[proportional to engine rpm, The length of time of each pulse is

Controlled electronically, so the injectors deliver more or less

fuel per pulse depending on mixture requirements,

‘Since neatly all present day Bosch fuel injection systems

feature some kind of electronic contro, these systoms can no

longer be accurately identified by the EFI label. In this book, I

Use the term “pulsed to rater to all systems with solenoid:valve

injectors, opened in a series of pulses to meter the fuel, En-

ines equipped with pulsed systems can be quickly identified

by the electric injectors connected to @ common fuel supply

tall, as shown in Fig, 2.

Fuel Injection Types

Fig. 8:5, For pelted injection. {EF look tor elec

‘pated injoctors (1) connneteto the hal

a5 nts Porsche 944 Motion

3.2 Continuous Injection Systems

The continuous systems are sometimes raforred to as me-

chanical or hydra-mechanical, because fuel metering is doter

mined dy the mechanical relationship between an airflow

sensor and a fuel distibutor.

The tirst continuous systems were distinctly different from

EF systems, sinco thore was no electronic control of basic fuel

deivery. The continuous injection family has now grown and

spawned more highly developed versions, and electranic con-

trol has been a part of almost all CIS fuel injection since 1980.

Fig. 9-6. Forcontrucusinoctor (05) looklorthe puncte ct

fetes, usually brated io ths, leading to simple

Injectors without elecivcal connectors. a 8 tS

‘uct 5000 turbo,

BOSCH FUEL INJECTION— AN OVERVIEW 7

In continuous systems, Incoming ir is measured by an

airflow sensor plate which is mechanically linked to the fuel

distributor. Fuelis metered by this mechanical ink in proportion

to the incoming air flow, and delivered to the engine through

pressure-actuated injactors,

Fotis injected in continuous streams, all the time as longas

the engine is running. This continuous fuel delivery gives the

system its name, Continuous Injection System (CIS). The fuel

tistibutor manipulates {uel pressure to control the volume of

fuel detivered under various operating conditions,

4. ENGINE MANAGEMENT

Engine management is a term applied to systems that

‘control more than tue! injection; in particular, they control igni=

‘ion timing. Ignition timing has always been important to power

and economy, even when Henry Ford's Model A provided the

river with controls for timing and fuel. Later, a form of auto

‘matic contro! was provided by flywoights in the distributor that

advanced timing for inoreasing rpm, and by vacuurn dia:

phragms thet relarded timing for increasing engine foad.

Fig. 4-1. tn Forc Model A dtver contd Wining and fue

‘anualy, by storing colume levers, Meco ele:

tronis engine menagoment ystems automat

ont kl intion andigntion timing mary tines

teach second!

Beginning about 1982,

than the contol of fuel ee

1 njection” began to mean more

very. Igniton trning and fuel delivery

losely related. For examiple, careful adjustment of ignition

ING at icle can increase fuel economy and reduce emis-

Sons In Bosch “Motronic” engine-management systems, uel

Celery control and ignition timing contol are combined in one

Fanrol unit that processes all of the necessary engine infor-

eens, Besinning in 1984, Motronic engine-managemont sys-

' also controlled idle rpm,

4.1 Control of Ignition Timing

‘The correct timing of the sparkplug fling depends on many

Of the same variables that determine fuel metering, including

engine speed, engine temperature, altitude and, in some.

‘cases, whether the engine is knocking. In engine-management

systems, the ignition control uses these variables to compute

the ignition timing point. in most cases, as in Motronic systems,

the control unit refers toa timing map, a set of data points in the

ECU memory that give the best timing point for al conditions,

igston advance

Fig. 4-2. Motronic ignition teming depends on ignition ead-

‘only merry (RON) stored inthe elactonie coro!

uni. gnitontinirg can esa or bes peexmance

for any combination o load ard spr, based on

extensie teste,

4.2 Control of Idle Speed

Control of idle speed contibutes to fuel economy and

reduced emissions. Using many of the same variables already

‘nputto the ECU, the control unitadjustsiale rem by varying the

‘amount of air bypassing the throttle valve, as well as varying the

'gnition timing.

4.3 Other Electronic Controls

Other engine-management functions may be included in

the control unt functions. For example, some Motronic systems

control the opening and closing of the fuel-vapor charcoal

canister purge valve,

Engine Management

8 BOSCH FUEL INJECTION— AN OVERVIEW

5. THE BOSCH JETRONIC FAMILY TREE

Bosch builds two basic types of fuel injection —pulsed and

continuous —with several variations and improvements over

the years. You'l want to knovr these diferences in operation to

understand the function of each distinct system, and to service

‘each system. Fig. 5-1, a “family tree” diagram of all of the

Bosch systems covered by this book, shows the progression of

the two “branches.”

Contes

research &

evelopment

ae r[_twerens KeMovene

1008 Lrtvetronia KE etre

wea | owone

KJetonio

wah Lambda

sore | Leotonc

wh ert Kvatronio

974 | Lverone

1967 Duoterie

I

Continuous

Pulsed ection Feoscy roe

Fi

: cis)

Fig. 5-1. The Bosch Jeronic family tee branches can be

ded into ine pused systems, atten cated EF

‘ond the conteuous systems, offen cated CS oF

‘mechanisal. Some othe earer dettons ofthese

systems are leas use these days because all of

the systems inouding the "mechanic" ones use

elecvories.

The Bosch Jetronic Family Tree

5.1 Pulsed Fuel injection Systems

Daletronie. The frst Bosch Jetronio system, The D is short

{or Druck, the German word for pressure. Manifold pressure is,

‘measured to indicate engine load (how much ar the engine is,

using). This pressure is an input signal to the control unit ECU)

{or calculation of the correct amount of fuel defvery.

Laletronic. The Lis short for Lutt, the Getman word for air.

Ait flow into the engine is measured by an airflow sensor with

‘8 movable vane to indicate engine load. Later systems have

Laminda contro! (sometimes represented by the Greek letter \)

for more precise mixture control, For more on Lambda, see

chaptor 2. Letronic was often called Air-Flow Controlled

(AFC) injection, to further separate it trom the pressure-

controlled Dvietronic.

LH-Jetronie, LH-Jetronic measures air mass (weight of alr)

with @ hotwire sensor instead of measuring air flow with an ait

vane (volume of ait) as in Luletronic. Otherwise, L and LH

systems are very similar, The H is shor for Heiss, the German,

word for hot

Motronic: 6%

KEdotenie: 12%

Ubletonie: 9%

eter wan K:Lambca

Lame 11% Si

Letonio: 986

Oslotorie: 76

K Base: 15% |

sanomecr |

Fig, 52, Estimated Bocch bul tuetinjecton systems in the

US. through 1987. Out of about 6,000,000 cars.

‘bout 60% are continvous systems, and 40% are

pulsed systems About 7 out ef 10 systems have

lamba conta.

|

|

|

|

BOSCH FUEL INJECTION— AN OVERVIEW 9

5.2 Continuous Injection Systems

Koletronie, The first continuous system. Bosch called it K,

{or Kontinuertich, the German word for continuous. Air flow is

‘measured by a ciroular plate in the alr-flaw sensor, Until 1980,

fuel delivery Is sticly under mechanical control in direct rela

tion to air flow; there are no electronics. | call this K-basic

Volkswagen, Aual, and Mercedes cal it CIS.

KoJetronic with Lambda Control. This is an adaptation of

Kebasie mechanical control, The mixture is modulated with a

limited electronic control in a feedback system to maintain a

precise air-ue! ratio. As you'l see in chapter 2, Lambda (a)

refers to a certain air-fuel rato. | call this version Klambda.

KE-dJetronic, This combines K-Jetronic mechanical control

with total electronic modulation of the mixture. It uses many of

‘me same sensors used in LJetronic systems. Because it is

sed on K-Jetronic, itis stl capable of failsafe mechanical

‘operation ifthe electronics fail. I callt KE; Volkswagen, Auci,

and Mercedes call it CiS-

5.3 Engine-Management Systems.

Bosch engine-management systems are often grouped un-

derthe single term “Motronic.” This can be confusing, because

while the orginal Bosch engine-management system was

called Motronic to aitferentiate it from the Jetronic systems,

there are now many different Motronic-type engine-

management systems. So when you see 2 system called

"Motronic", make sure you know which type itis.

Motronic. The first “engine-management” system. It com-

bines LJetronic pulsed fue! injection with electronic ignition

timing control in one control unit. In most engines, it also has

electronic ate stabilization for a completa engine-management

system. For clarity, I may sometimes refer to this system as

Motronic. Beginning in about 1986, Motronic may alsa have

“ittonal functions:

‘* Knock regulation by ignition timing of individual eylinders.

‘* Adaptive circuitry —it adapts tuel delivery and ignition tim-

ing to actual conaitions. it does this so well that, beginning

'n 1968, idle rpm and mixture are no longer adjustable,

* Diagnostic circuitry—the control unit recognizes system

faults and stores faut information in its memory.

LH-Motronic. This is the same as Motronio, except that it

1US2S a hot-wire air-mass sensor, henca the LH, All LH-Motronic

Systems have electronic ide stabilization.

KE-Motronic. Igntion-trning control added to KE-Jetronic

21 njection. It has the same actional functions as Motronie

‘ystems,

ti Monotronic. | mention it nere, though it is not covered by

Ws book. This isa single-point, thratte-body Mottonic ower.

Ret ANS simpler than Motronie, not used In cars currenty

‘imported tthe US.

5.4 Bosch-Licensed Systems

Worldwide, almost all current fustinjection systems are

based on Bosch technology to.a greater o lesser degree. Most

Japanese fusl-njection systems are built under Bosch license,

land many US, cars use Bosch components, buit with Bosch

principles under licensed production. The following systems

are Bosch European-icensed systems installed in European

made cars sold in this country.

Volkswagen Digifant, This pulsed system was partly de-

signed by Volkswagen, but operates pretty much as Bosch

Motronic does. Its timing control map is less complicated than

the Bosch Motronic map. It daes not have a knock sensor.

Volkswagen Digifant Il refined version of Digifant. Along

with control improvements, it uses a knock sensor for more

precise ting control

Lucas. This system, used in Jaguar and Triumoh cars, is a

Bosch Lvetronic system licensed for production by Lucas.

6. Cars WITH BOSCH FUEL INJECTION AND

ENGINE-MANAGEMENT SYSTEMS.

Bosch Jetronic fuel injection arrived in America in 1967 in

the German-made Volkswagens. Emission-control legisiation

{forced their adoption on the VW air-cooled engines, because

their uneven cooling raises emissions. For more than ten years

since then, fuel injection has been virtually standard in Euro-

pean cars delivered in the U.S. The Japanese are catching up:

by 1969, over half their cars delivered in the US. are fuel-

Injected. The changeover to fue! injection is accelerating, Car-

buretors on new cars in the U.S. will soon be as rare as drum,

‘brakes on front wheels.

All cars delivered in the US.

Tegend

100%

__ Throtile body injection

{roan arian crs

80%: injection (restly

| Bosch or fiosen-tcensed)

mg Contewoous inaction

fall Bosch

o%

75 76 77 78 79 80 81 82 83 84 85 86 87.88

Model year move

Fig. 6-1, Tolalcar sales inthe US, chow he replacement of

carburetors by fuolinjection systems. The brat

Popularity of diesol fuel injecton in 1970-1981

‘caused a “chesel dip in gascsne injection procuc-

ten.

Cars with Bosch Fue! injection

and Engine-Management Systems

10 BOSCH FUEL INJECTION ~ AN OVERVIEW

How can you tell if your car has a Bosch fuehinjection

systom? None of the European cars sokt in the US. wear

Jotronic oF Motronic baciges, bul most have fuel jection clues

‘on the car badge, Lately, though, these clues are disappearing,

Apparent, considering that almost all of these European cars

sold in the US. injection, who needs to mcicate that

by badge? No longer Goes any car indioate cise brakes by

spelling it out on the brake pedal, as was once the vague,

Volkswagen, Audi. Early fuetinjected cars ware sold at the

same time as carbureted cars ~look for the words “Fuel Injeo

tion" on the roar deck, whether the VWis assambledin the US,

oF is imported, Since 1977, all Vis have been uel injected,

with fuel injacton badges. In GTI models, the | stands for

injection, Audi in the same farnily, also badged fuel injection,

sometimes you'l see turbo instead, but the car is stil fuel

Injected

1. Sometimes badges boast about numbor ol vals

Sorocoo, as most <-vee per cysnder engines

‘operates with fel njecton,

Fig. 6-2. VV vrs the fist user of Bosch Jotrns Emssion

-ntetlocstaion forced aietian is! cod

welt conrad

Fig, 6-5. Most Aucis spot it. Aus yes one ofthe

Users of Keron, a 1975,

Porsche, Saab, Volvo. These three began identifying fuel

Injection by adding € for Einsprite, the German word for injec

tion, The E-for-injection might be lostithe badge included T fot

turbo, or SC for super coupe. By 1976, fuel injection had

become normal, so we do not see Porsche SITE, 9246, oF

9286 even though all of these cars are fuel injected. Around

1980, the E on Volvo baxiges no longer indicates fue! injection,

but indicates a level of kucury equipment

Fig. 6-3. Viv15 the biggest user of Jtron

ear mpoctedt rom Germany and buitin US Most

iekat-cooled Ve are Rel welt

Cars with Bosch Fuel Injection

and Engine-Management Systems

BOSCH FUEL INJECTION— AN OVERVIEW 11

Saab 16 an eaty user, begnnang in 1970. Early

iuohinpeted cars were badiged E, for Esp 28

Furbo vas fis 0 drop & Fig, 6-8. Yohos and Sass have boon fuebinested for so

long that an inceaton of fukin

thas boon replaced ath a dank

‘equioment

Mercedes-Benz. They also began adding an E to identity

the fuel.injected cars from those with carburetors. Most gaso:

~ line Mercedes show E. An exception is the two-seater SL,

~ Which is fuel.injected but omits the E to distinguish itsel! from

Petes the coupes, SEC, and from the long sedans, SEL. All Mercedes:

|

i

}

Re AEE are fuel injected, the diesels are identified with D.

Fig. 6-7. Peracne has chopped the . Fersche began using

recon wih Pe 19709146

Fig. 610. Moroedes use KE-etronic. Swich fom 0:

KeJetionic wasn 1976, D badges are

FIG. 6-8, Volo 164€ hi tho marke! wy Oder 1972

Fst uso was o7 1800E w 1970,

Cars with Bosch Fue! injection

and Engine-Management Systems

12 BOSCH FUEL INJECTION— AN OVERVIEW

Fig. 6-19. BW i means (uo ijeotan. BMW began using

Lotonis in Soyinder engines in 1975. K-

Fig. 6:11. Omitting tho E hore helps cierentate this twor etre in A-cyknder engines in 1877

sealer SL-Sypor Loicht (he Geman word! for

ght) —ltom tho SEC coupes.

SSS SUR en

Fig. 6-14. On badge on fusl-jected BMW 3250, ¢ stands

for Eta, the Graok later for eFiciency

Fig. 6-12. € for Einsptzis mid vith S for Super and tor

Lang (he Garman word fr long} on tis Mer

‘ceces Sedan.

BMW. BMW usually adds i for injection, beginning with the:

Goylinder 530i. BMW 2002ti (a carbureted car), stands for

“touring international”; BMW 2002ti stands for “touring inter-

Rational, injection’. Since 1979, BMW has used E for ota, the

Greek letter for efficiency to indicate engines tuned for better

torque and economy at iow and mid-rpme; all BMWS are fuel

Injected but, in this ease, E does not stand for Einspritz, What's

8 in 528es? "Eta, Spon”.

Cars with Bosch Fuel Injection

ee eee

i

BOSCH FUEL INJECTION— AN OVERVIEW 13

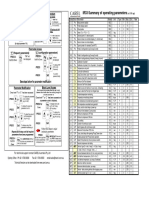

‘Table a will enable you to identily what type of Bosch fuel

injection systemis in your specific make and model. does not

include US. hybrid systems that mix Bosch components with

others, such as 1985+ Corvettes that use Bosch LHJetronic

airmass sensors and injectors. This lst concentrates on Euro-

pean cars, Including VWs mace in the US.

Table a. Bosch Fuel Injection Systems Sold in the

‘Spicer (1601-1985)

| Spear (1985-1989)

United States

‘Manufacturer Injection system ‘Number

Model Installed

(round

thousands)

‘ALFA

6 Luletronio wih Lambda | 1,000

Graduate (letronie wih Lambea | 11000

Graduate (1886.0) | Movoric .

Give vewonie with Lambda

Nino (1986) Motreric

iano (1987-1989) | LU-etonic

Lvetronic wth Lama

Motenie

ane |

‘lance (Catferia) | Lvetronie with Lambda. | 30,000,

‘aneetEncore | Leonie 15,000

(Calforia)

20D

ioots Kvetronc 27,000

Fon Ketone 8,000

2000 (1990) Keron 10,000

4000 [1981 on) | Ketronie wits Lambda. | 43,000

and +8

£000 Quatro KE Vetronc 13,000+

000 $ (1984-1997) | KEVetronis 44,0001

so0a 1978-1978) | kevatonio 38,900

eno (1920-1989) | Keeton with tama. | 72,000

© $ (1884-1685) | Keeton with Landa | 62000

00 § (805) Kedewrons “3.000

5000 8 (1807-1988) | KEdvetonic 121000+

3000 Turbo Ketone with Lambda. | 46,000

(1980-1985, 1985)

5000 Turbo (1884) | KE-Veronic

30008 Turbo | Kotani with Lambda

5000.68 Tuto | KESWotonto.

1980),

S60 C8 Guat cone

960 vate | Ketone with Lamba

5ac0 C3 Quatto | KEBotonie ‘

ate 988

War KE Motronic :

0790 wn, KE2Jetrone "

0190 Quatro

ouro0 Quateo | Keaton 7

wane duatwe | Kecioonie :

Soups (1981-1964) | KJatranic wth Lambda. | 11,000

Cave (385) KEveronie ‘4.000

Soup ST (986) | KE Vorom 3.000

eae KERetronie 2ocos

Ovateo Kuotronc wih Lambda | 2.000

‘eiertation

2 alate

Table a. Bosch Fue! Injection Systems Sold in the

United States (cont'd)

Manufacturer? Injection system Number

Model Installed

(in round

thousands)

BERTONE

x18 tL Jotronig with Lambda

BMW

3.03) Letronio

318i LWuetronic

8201 (1977-1979) | Kevotronie

3201 (1880-1963) | KJatronio with Lama

‘25/8256, Motronic

‘5286 (1971981) | LJetroni with Lambda

598E (1982 0n) | Motronic

520 Luawonie

S05/595iS Mtronic

e200 Lotronie

629CS) (1978-1979) | UJetronic

699CS% (1980-1981) } Cewonic win Lamoga

83808) (198209) | Moonie

S2ECSI Motronic

73 (1978-1978) | Letronic

7331 (1960-1981) | LJetronie with Lambda

7334 (1982 on) Motronic

135i Motronic

750 Li-Motronic

M3, 5, MB Mowonie

DeLOREAN

DeLorean Kevetronic wih Lamboa | 2.000

EAGLE

Medallion Luvetronic *

FERRARI

208 GTB Si ‘KJotronic with Lambda | 3,000

323678 KeJerronic wth Lambda | 2.0004

Mondial Mondiat | KJeronic with Lamoda | 2.0004

Testarossa KEvotorie 4000+

Har

Brava Lvetonicwith Lambda | 16,000

Spider LNetwonie wit Lambda | 43,000

Strada LJetonic wits Lambda | 21,000

xa Letione win Lambda | 15000

‘JAGUAR

Xasouspusvi2 | LJetonie wth Lambda | 95,000

(1980-1986) {

YUBUSHUSVI2 | Letonicwith Lameda | 23,000+

(1987-1989) Cavcast

LANCIA

Beta LWetwonie wits Lambda | 2,000

LoTus T ae

Esprit Turbo KeJotronio wih Lambda | 2000+

MASERATI

Maserati Motonic 1000+

‘continued on next page

Cars with Bosch Fuel Iniection

2

14 BOSCH FUEL INJECTION— AN OVERVIEW

‘Table a. Bosch Fuel injection Systems Sold in the Table a. Bosch Fuel Injection Systems Sold in the

United States (cont'd) United States (cont'd)

Wanaiocured | wiecton system | Wambor Manton Tajecden system | Naber

Move! Irate Move! toto

finroun roura

fhoveend) roveands)

MERCEDES-BENZ a RENAULT EEEH Hi

Toe (is0e98° | KevJorone 73000 Flegoruege Tuto | Lietoric wih tanta | 25000

too rae on” | Kedevone : (dee 8

one Kevverie 0004 loge tees) | LUvevonie 5.00

Boe (erttera | Buono zoco fica toSetonc 885

beac orriera) | Kvotons jo000 Rirmirooan | Coven ‘Seco

Zane iscoteet) | Rvotene wen tambo | ‘3208 Ria (see 660) | Caetone win tamodn | 2999

feo (07 Svatone Seco Fa (1365 totter 2000

Soon (096, Rectan aéiccos Soorvagen torent fe

on)

sane SEL 987) | neJevenc | 2x00 ROUS ROYCE

SE Tee ey moe | 260, RoleRoyefa)__|Kotonicwth tambas | 7.000%

SE (1908) relewencwan Lanbae. | i =a

‘ee resveone e00+ ee eet enc00

: 420 SEL (1987) KEvetronic 15,000 Le del zl

osoe Ovorone B09 99S (| Keeton 2000

(972178) Brubo” —| sonewin tanta | 4000

sor ere 079) | Ketone saono Ste ooo) | fistole win tba | 900

‘sce (in) feleronswin Lambda | Toe Secreta | Ronan as | 120%

500E (1983), Kedetonie with Lambda | 7,000 erat eee 7

Seo (reer toes) Keron win Lamba | 9000+ sto twee Ketone wih tanta | 50,000

$60 (1986, 1988 on) | KESJetronic 15,0004 a

Seo tse Revise 2n00 00 Tbe Levene 22.00

MERKUR + 3009, $, Turbo LH2Jetronic, 22,0004

Wein Siome, | Oumtone Foe) | snows ae =

: eas sass Maton eas 4000+

‘pe “

"iow

Manta 1e0ce___| tetanic 40,000 ter Lsernicwin Lambda | 25.000

peuGeST Tho Cerone wit Canbae_| +

08/5051 KeJotronic with Lambda | 60,000 Vouvo EEEEEE!

S05 Turbo, at sx | Nowe’ 000 vane Doron 25000

ee tearisrtso7 | Soeons a0

Fons je Bear tbe (1978 Reiceore ssc00

Couns, bret : ae cere es

9115 (1974187) | Ketone 15,000 San een,

98118C (1978-1979) | KuUetonic 4,000 pt ta) ee to

51130 (9601909) | Koverc win Lameda. | 18909 asoe (ere ore) | Karon 25,000

SMSC (8 ‘vane iano as0t (i879 Felevene wh tamoda | “3509

guitare | Kasten zaco Movoto — | Urevenene ‘p00

\ St tub ; Zea raat) | even min Lares | “ita

f 911 Turbo (1978) Keletronic 1,000 een ee eer

911 Turbo K-Jetronic with Lambda 3,000+ fae Urbietionic peeee

i (1986 or) (1984-1985)

912 LeJetronic | 1,000 fer! LHe vetronie 1

| S14E (1970-1973) | Detone 45,000 7figeson) A

| seeueccem) | Suara £3 $0 Lesa

928 (1976-1979) | KJetione 17.000 Dv (1980) Kedetronic 33.000

Sete | leone ose | 17983 DLae%0nq) | Keeronts win tamea | 92999

j 80 ‘ton 3000 Bciees ses) | Cuma 138.900

| 8245 (1987 0°) | Motionc : 11980) Keone 9.000

i S24 Tuto tierone wih embea | "5000. Sree Ketone win Lambda | $000

} 928 (1978-1979) | Kvetrone 7,000 1 (1962-1885) LHvetronio 68.000

98 (1680-1088) | Letronie wih Lamba | 7.000, ge ‘eetonic witn Lambda | 2,000

i 288 (1985-1986) | LitJetronie 61000 bisa ‘vetronic with Lambda | 38,000

L 9285 (1987) ‘Motronic 2,000 (1381-1994)

i wae oy | Merene 7 atta 289) | ustvoronc 2.000

ser Keron 1000

i: 948, S, Turbo Notions 50,000 + ‘continued on next page

Ettore nwo :

“oration

revavaioe

j

i Cars with Bosch Fuel Injection

‘ Taper Eehepiries Wintel ee

Table a. Bosch Fuel Injection Systems Sold in the

United States (cont'd)

BOSCH FUEL INJECTION— AN OVERVIEW 15

Manufacturer? Injection systern ‘Number

Model Installed

(inround

thousands)

VOLKSWAGEN

Types Duetronic

Type 4 (1971-1978) | Betton

Type 4 (1974) Lotionie

Boete eronic

Bus tronic

Cabriolet KE vetronie

Corrado Dagiant i

Dasher (1976-1980) | Kveronic

Dasher (1981) Ketone with Lambda

Fox Keronienveronie

wih Lambda

wot (1985-1987) | Kvetronic with Lambda

Got (1988 on) Digtantit

Goll GT! KE versie

(1998-1967)

Got Gr (5987) KE votonic *

Goll Gr (1388 or) | Digtant *

Goll GT 16 KEvevonic *

sata (1980) Kelotonic 9.000

seta (1981-1988) | KJevonic with Lambda | 102,000

seta (1986-1987) | KEVetrenic | 520004

“ota (1988 or) Digitera i +

eta GU KE votre *

(1985-1987)

ota GU Diotare *

(1308 ony

Quantum KeJotonie win Lambda | 43,000

(1362-1994)

usr KE veto 33,000+

(1985-1985)

Rabbit (187-1980) | Kvetonic 453,000

Rabot (1881 on) | KJetonio with Lambaa | 109,000 +

abot Gn KeJetronic with Lamba | "25,0004

(1983-1984)

Scirocco Kevetronie 77.900

"167 1900)

reco KoJetrone with Lambda | 94,000

1381-3987)

Scrocca 16 KE Jetronio .

Vanagon sronic with Lambda | 48,000

(6980-1999)

Vanagon Digiet WW version ot | 38,000

(1988-1985) LJtronic with Larrea)

Yenegon (1886 or) | Digitant! 24,0004

“information

ot avaiaols

Cars with Bosch Fuel injection

Caer eid ale aL eli h let ae

Chapter 2.

Engine Management

Fundamentals

Contents

1. Introduction

2. Basic Factors

24 AirFuel Ratios.

The Basic Combustible Mixture

Rich and Lean Mixtures.

‘Stoichiometric Ratio,

‘The Excess Air Factor—Lambda

22 Driveabilty and Emission Control

Fuel Economy - CAFE.

23 Air Flow, Fuel Delivery, and Engine Load

24 Fuel Prossure

25 Pressure Measurement

Gauge Pressure vs. Absolute Pressure vs,

Vacuum eee es

3. Operating Conditions and Driveability.

2.1 Normal (Warm) Cruise

32 Starting

Cold Start

Warm Start

Hot Start

lantion Timing and Starting

33. Post-Start and Warm-Up

10

10

10

1"

"

"

2

34 Idle

Cold and Warm-up lle

Warr Idle

8.8 Acosleration

8.6 Decoleration and Coasting

37 Attitude

3.8 Engine Shut-Off

3.9 RPM Limitation

3.10. ignition Timing,

jon Control

4.1 Combustion By-Products.

42 Effects of Air-Fue! Ratios on Polutants

49 Exhaust Gas Recirculation (EGR)

4.4 Exhaust Gas Aftertreatment,

AIR, Air Injection Reaction

Catalytic Converters

‘Three-way Catalytic Converters

- Control Systems

5.1 Closedtoop Control Systeme

Lambda Sensor.

Changing Engine Conditions,

2

12

18

13

13

4

4

4

14

18

18

16

7

7

7

7

7

18

18

18

19

ENGINE MANAGEMENT FUNDAMENTALS 3

1. INTRODUCTION

‘What sets fuelnjection and engine-management systems

apart from other fuel delivery systems is their abiliy to precisely

control fuel metering and adjust it in response to changing

‘operating conditions. The Key elements in the success of

Bosch fuelinjection and engine-management systems are (a)

‘a comprehensive understanding of the engine's varying fuel

elivery requirements over a broad range af operating condi-

tions, (b) extensive research into how the factors which influ-

‘ence the engine's fuel needs can be measured and interpreted

by control systems and, (¢) highly developed methods for

controling fuel metering to optimize overall performance.

In this chapter, review the basic factors governing air-fuel

‘mixture and fuel delivery, Il describe why various engine

crating conditions demand different airuel mixtures, and I'l

‘plain how the airuel ratio can be manipulated to improve

civeabilty and control exhaust emissions with litle sacrifice of

power. In chapter 3 and chapter 5, you'll see how Bosch

apoiies these principles to the design and operation of thelr

fuelinjection systems,

2. Basic Factors

First, the basics, We'l take a closer look at al-uel ratios and

the engine's basic demands for a combustible mixture. 1

describe adcitonal factors affecting fuet delivery which are

imposed by the demands of the car-buying public, and we'll

examine pressure and pressure measurement —a subject that

's fundamental to understanding how Bosch uel injection sys-

tems work,

2.1 Air-Fuel Ratios

‘An engine's throttle controls the amount of air the engine

«es in. The main function of any fuel delivery system isto mic

{uetwit that incoming arin the proper ratio. Small variations in

airfuel ratio can have dramatic effects on power output, fuel

Consumption, and exhaust emissions.

The Basic Combustible Mixture

Lawes of physics tellus that combustion of any substance

‘Sauires a suficient ratio of surface area to mass (eral enough

Bailes and the correct amount of oxygen (n proportion {0

the amount of tue. In internal combuston engines these

Epctions are met by atomizing the fel ino tiny droplets, anc

Mi meteting tel coreet proporton to the intake air In round

*, Approximately 14 pars of ar are required to support

Srl combustion of 1'part of fuel—in other words, an

Fat of about 14:1

Fuel

Fig. 2-1, By mass, lakes about 14 parts of air to support

Complete combustion of 1 part of fuel. Bator to-

‘ays canoes aver fue! ecascrry ang emissions,

an ar-ucrao somewhere case 0 14:1 was good

enough

Throughout this book, I follow generally accepted

practice and discuss air-fuel ratios primary in terms

‘of mass. This s the simplest and best way tohelp you

Understand the basic factors governing fuel delivery

land combustion. Many of the Bosch systems, how-

‘ever, measure alr tlow by volume. It is interesting 10,

see that, by volume, the proportion of air to fuel is

approximately 11,500:1

11.5001

Fig. 2:2. By volume it takes appronimatey 11,600 parts of

ito support comelete combustion of part ua,

Basic Factors

4 ENGINE MANAGEMENT FUNDAMENTALS

Notice that lam talking about combustion thatis complete —

‘combustion that makes the best, mast thorough use of fuel,

Alrfuel ratios which are higher or lower than approximately

14:4 wil stil burn, but such combustion produces unwanted

by-products and other side effects. As you read further into this

chapter, you'll see what those are, and why precise control of

the air-fuol ratio has become so important,

Rich and Lean Mixtures

The terms “tich” and “lean” are used to desctibe mixtures.

which deviate from the theoretically perfect airtuel ratio and

bum less efficiently

A tich miture is one with a lower air-fuel ratio: there is

insutticont air (oxygen) to support complate combustion of the

fuel, Rich moures increase fuel consumption and emissions of

hydrocarbons (HC) and carbon monoxide (CO) =the products

of incompletely burned gasoline, They tend to reduce power,

increase carbon deposits and, in the extreme case, foul spark

plugs and dilute the engine's lubricating of,

“Enrichment” is the process of metering more fuel for a

given amount of air to produce a richer mixture,

Fig. 2.3. Rich mixtures contain more fuel than can be com:

Pletely bumned in the given amex ofa

A lean mixture is one with a higher air-fuel ratio; there is

‘more air than necessary for complete combustion ofthe fuel,

‘The fue! will bum completely, but more slowly and at a higher

‘combustion temperature. Lean mixtures reduce power, elevate

engine temperature, and increase emissions of oxides ofritro-

{gen (NO,)—a product ef combustion at excessively high tem.

erature. They also tend to cause driveability problems. In the

‘extreme case, the high temperatures resuiting from lean com-

‘bustion wil cause pre-igniton ~ violent, untrmed combustion of

the mixture which has the potential to cause serious engine

damage.

Basic Factors

Fig. 24, Lean miures contain more at than is necessary

for combustion ofthe fue. Infor combustion ro

duces power and can cause engine damece

Stoichiometric Ratio

When "gas was cheap and the air was dirty,” carburetors

were usually set up to deliver matures richer than 14:1, per

haps with an airue! ratio as low as 12:1. As the car aged and

ailitle excess air leaked in around the gaskets ofthe carburetor

(r the intake manifold, the engine stil gat a good combustible

modure. Then, 100, the carburetor was farther from the end

cylinders than from the middle ones. A richer mixture was some

compensation for unequal fue! distribution,

‘There was another reason for soting up carbureted engines

to run a lite rich. Airuel mixture was less procise, and some

Variations were to be expected. As shown in Fig. 26, variations

in a rich mixture have only a small effect on power, while

Variations in a lean mixture affect power dramatically

ich ae fad vaion

‘Same varaion

lean site

Power:

Power

‘change!

Rich -— Alr-fuel ratio. —* Lean |

Fig. 2.5. Vaiaton in a ch aire

siference in power en the same variation in alea

ial rato,

rato makes much tess

ENGINE MANAGEMENT FUNDAMENTALS 5

For today's engines, with the increased emphasis on fuel

‘economy and reduced emissions, the ai-uel ratio has to be

‘controled much more carefully. The “idea!” air-uel ratio—the

‘ane which yields the most complete comoustion and the best

‘compromise between lean and nich mixtures —is 14.7:1. This is

called the "stoichiometric" ratio. The mixture is neither tich nor

lean

‘The Excess Air Factor—Lambda

The stoichiometric ratio can also be described in terms of

the air requirements of the engine. Bosch calls ths the “excess

air factor" and represents it using the Greek letter 4 (amibde),

{At the stoichiometric ratio—when the amount of air equals the

amount requited for complete combustion of the fuel and there

70 excess air—lambda (i

Fig. 2-6. The icoal oF “stoichiometric” aust rtio— hen

here is st enough ait to Bun al the Aul—is

14.75, The e alee deoetbod ae bs amis) = +

When there is excess air (air-fuel ratio leaner than stoichio-

‘metric), lambda is greater than one. When there is a shortage.

fair (air-fuel ratio richer than stoichiometric), lambda Is less

than one,

‘The concept of lambda (the excess air factor) was created

Specially to support thinking about fuel delivery in terms of

{he aie requirements of the engine. As you'll see later on, this

Concept plays a big part in controling exhaust emissions,

22 Driveability and Emission Control

unit Seseribed the engine's basic requirement for a com-

tole mixture of air and fuel, how variations in mixture influ

{eee Performances, anc how older carburetor systems tended

{in ficher than the ideal air-fuel ratio in the interest of

iwering smooth, reiable power.

While powor is ahvays a requirement, modern fuel delivery

systems face adcitional demands. increasing concern over the

cost and availabilty of gasoline has resulted in greater demend

for fuel economy. Environmental concerns and resuting legis-

lation demand rigid control of harmful exhaust emissions. And,

the car-buying public increasingly demands good

riveabilty—quickstarting and smooth, trouble-free perfor-

mance under any and all operating conditions. Each of these

factors places different dernands on the fuel delvery system,

and there are trade-cts,

Adjusting the system for maximum power also means in-

creasing fuel consumption. Minimizing fuel consumption

‘means sacrificing power and driveablity. Choosing either max-

imum power or minimum fuel consumption means increased

exhaust emissions. The modern fuel delivery system must be

‘ble to maintain strict control of air-fuel rato in order to achieve:

the best compromise and most these conficting demands in

the most acceptable way. In general, this means slight sacr-

fices of power and fuel economy in exchange for optimum

‘emissions control

Biosnioraiie

(teat

‘Atel rato 126:1

Lambda 1) =0.88

Fig. 27. Tho ai-tal rato which devers magenurn power I

‘sighty richer than stoiciometi; the one which

‘elves minimum fuel consumption i sight mere

lean han stoiciometic. The stoichiometric atin s

‘ compromise which sactloas very tte of ether.

Basic Factors

tt

6 ENGINE MANAGEMENT FUNDAMENTALS

Ho

Exhaust gag emissions

8

8

os 10 w

Excese-cir factor

Fig. 248, Stoichiometric sir-vel ratio (A = 1) yields the best

‘compromise for conto! of hydrocarbon (HO), car

‘bon moncxida (CO), and oxides of rragen (NO,)

emissions, belore Me catavic converter a) orator

1O,

Itis fuel injection’sabilty to maintain the air-uel ratio within

‘lose tolerances that makes it superior to carburetor systems.

For the manufacturer, fuebinjection means better emission

control and better fuel economy, both important in meeting

increasingly stringent goverment regulation, For the owner,

fuekinjection means achieving fuel economy and emission

contro! while preserving driveability and maximum power.

Fuel Economy - CAFE

‘Atong with the general demand for fuel economy, each

‘manufacturer must consider another factor: mandated federal

Standards for rated fuel economy ~the Corporate Average Fuel

Eoonomy (CAFE) standards. The industry trend in rated miles-

per-gallon (mpg) tuned upward beginning in 1975, as catalytic

‘converters replaced engine de-tuning as a means of emission

Basic Factors

Control. in addition, government legislation established an av-

erage mpg standard to apply to the total fleet of cars each

‘manufacturer delivers each year. Further, the target mpg stan:

dard rose each year, starting at 18 mpg in 1978, and rising to

27.5 mpg in 1965, but cut in 1986 to 26 mpg. By 1990 it was

‘back up to 27.5 mpg. Fuel injection’s precise control of fuot

You might also like

- Haynes Full Catalogue 2019Document177 pagesHaynes Full Catalogue 2019LlewellynNo ratings yet

- Vodou Auto Kits VR5 Variations From Book PlansDocument19 pagesVodou Auto Kits VR5 Variations From Book PlansTully MoreNo ratings yet

- Etymology: History of The AutomobileDocument5 pagesEtymology: History of The Automobilelatchanyanana100% (1)

- Allied 2008 CatalogDocument306 pagesAllied 2008 CatalogEvilJay20% (1)

- Vehicle Information: Vin: Engine Size/Type: Transmission Type: Drive Type: MileageDocument30 pagesVehicle Information: Vin: Engine Size/Type: Transmission Type: Drive Type: MileageJeffrey ValeoNo ratings yet

- CS Info Book Club Sports 3.2LDocument9 pagesCS Info Book Club Sports 3.2LGen ShibayamaNo ratings yet

- Brochure Donkervoort D8 GTO S 2017 ENGDocument68 pagesBrochure Donkervoort D8 GTO S 2017 ENGanderson3170No ratings yet

- Autohome Catalogue GBDocument100 pagesAutohome Catalogue GBpablogarciaclNo ratings yet

- Gt650 Parts Efi EditionDocument55 pagesGt650 Parts Efi EditionJuan Ruiz0% (1)

- 221 Remove - Install and Disassemble Rear ShelfDocument3 pages221 Remove - Install and Disassemble Rear ShelfChirag 4sAutoNo ratings yet

- Autoweek October 9, 1989Document4 pagesAutoweek October 9, 1989bzrongNo ratings yet

- Elise Alu ChassisDocument3 pagesElise Alu ChassisLee Chern FongNo ratings yet

- Spyder NEWDocument6 pagesSpyder NEWwchenowethNo ratings yet

- Huebsch LaundromatDocument4 pagesHuebsch LaundromatsossieNo ratings yet

- Cougar Full CatalogDocument268 pagesCougar Full CatalogJhonny FlodmanNo ratings yet

- Change or Die - DessyDocument43 pagesChange or Die - DessyZulkifli MansurNo ratings yet

- Catalogue BMW Individual m3 enDocument8 pagesCatalogue BMW Individual m3 enkalymistirlNo ratings yet

- Lotus Cars - Wikipedia, The Free EncyclopediaDocument18 pagesLotus Cars - Wikipedia, The Free EncyclopediabmxengineeringNo ratings yet

- Schemas Electriques Lancia Beta AnglaisDocument67 pagesSchemas Electriques Lancia Beta AnglaisÉlio SilvaNo ratings yet

- Torque Measuremen T: MQC SeminarDocument17 pagesTorque Measuremen T: MQC SeminarVaibhavNo ratings yet

- 1992 R129 Owners ManualDocument153 pages1992 R129 Owners ManualEduardo ReisNo ratings yet

- Thermal Stresses in The Cylinder HeadDocument3 pagesThermal Stresses in The Cylinder HeadArun KumarNo ratings yet

- Kincrome May June 2017Document24 pagesKincrome May June 2017Riverland Welding and Tool SuppliesNo ratings yet

- BMW Motorcycle Parts and Accessories - Capital CycleDocument5 pagesBMW Motorcycle Parts and Accessories - Capital CycleJavier Lopez0% (2)

- 92v Parts List ViperDocument194 pages92v Parts List Viperreltih18No ratings yet

- An Engineers Guide To Being BravoDocument262 pagesAn Engineers Guide To Being BravoBen Wanderer100% (1)

- BMW M3 M4 CatalogueDocument27 pagesBMW M3 M4 CatalogueDumitru Zaharia100% (1)

- Chapter 2B - Chassis ConstructionDocument54 pagesChapter 2B - Chassis Constructionfaris iqbal100% (1)

- HPMM Sample ChapterDocument8 pagesHPMM Sample Chapter4lexxNo ratings yet

- 2019 10 Tpms Oe Sensors Application ListDocument6 pages2019 10 Tpms Oe Sensors Application ListSOLID ENGENHARIA & PROJETOSNo ratings yet

- 2006-2007 Ssang Yong Rexton Y250 SMDocument1,009 pages2006-2007 Ssang Yong Rexton Y250 SMJohn Dooley100% (1)

- Bugatti Veyron ManualDocument200 pagesBugatti Veyron ManualChasity GuerreroNo ratings yet

- XR700 and XR3000: Ignition InspectionDocument20 pagesXR700 and XR3000: Ignition InspectionDevine LightNo ratings yet

- Brera PDFDocument270 pagesBrera PDFGiorgio VăleanNo ratings yet

- BMW M2 2016 PDFDocument23 pagesBMW M2 2016 PDFSculatorNo ratings yet

- AutoItalia - Issue 317 - July 2022Document102 pagesAutoItalia - Issue 317 - July 2022Joseph FazioNo ratings yet

- VNX5T ManualDocument59 pagesVNX5T ManualJoseph KapellasNo ratings yet

- Carel Ir33 Programming Guide PDFDocument2 pagesCarel Ir33 Programming Guide PDFIonutCiobanuNo ratings yet

- 2006 Cclass Clkclass Sclass Clclass SlclassDocument79 pages2006 Cclass Clkclass Sclass Clclass Slclassopenid_nHbxM2cxNo ratings yet

- 912 EngineDocument13 pages912 EnginescottseelyeNo ratings yet

- The Magazine LamboDocument34 pagesThe Magazine LamboDJDRANIXNo ratings yet

- Rizoma Catalog2012 en LowDocument137 pagesRizoma Catalog2012 en LowPeter BeharisNo ratings yet

- Jeep Renegade ManualDocument212 pagesJeep Renegade ManualMohamedNo ratings yet

- The SmartDocument29 pagesThe SmartChin Ting Xuan CrystalNo ratings yet

- BMW E21 Catalogues BrochuresDocument149 pagesBMW E21 Catalogues BrochuresTugrul TüfekciNo ratings yet

- VV8 PDFDocument1 pageVV8 PDFgabotoyoNo ratings yet

- Porsche Cars: Facts Everyone Should Know About Porsche 64, Porsche 914 and MoreFrom EverandPorsche Cars: Facts Everyone Should Know About Porsche 64, Porsche 914 and MoreNo ratings yet

- Weber 3236 DGV DrawingDocument1 pageWeber 3236 DGV DrawingFranco MaderaNo ratings yet

- Open Firmware - Technical Note TN1061Document13 pagesOpen Firmware - Technical Note TN1061muinteresante840No ratings yet

- MINI Cooper ClubmanDocument8 pagesMINI Cooper ClubmanJandy Aditya Pratisto0% (1)

- The Civilian HUMMERDocument4 pagesThe Civilian HUMMERankitshah01100% (1)

- Puma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsDocument4 pagesPuma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsRobert DennisNo ratings yet

- Kit Car Builder March 2014Document82 pagesKit Car Builder March 2014sanderribeiroNo ratings yet

- Koenigsegg Int-Range 2014 PDFDocument42 pagesKoenigsegg Int-Range 2014 PDFAekanshNo ratings yet

- Old Car Detective: Favourite Stories, 1925 to 1965From EverandOld Car Detective: Favourite Stories, 1925 to 1965Rating: 5 out of 5 stars5/5 (1)

- Building a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendFrom EverandBuilding a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendNo ratings yet