Professional Documents

Culture Documents

Farewell To Fod

Uploaded by

César Gomez MartínezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Farewell To Fod

Uploaded by

César Gomez MartínezCopyright:

Available Formats

Farewell to Foreign Objects

Well-Planned Program Helps Eliminate

Sources of Debris from Your Aviation Facility

By Philip Terry, PE, SE

Commercial and military aviation have a funnysounding acronym, FOD, which stands for

foreign object damage or foreign object debris.

Anything and everything that is not secured can become debris.

Metal (wire, pieces, flakes/chips, drill

shavings)

Stones, rocks, twigs

Plastic, paper, cloth, rags

Plaster, concrete, pavement

Insulation

Construction debris

Paint (chips, excessive overspray)

Dirt and rust particles

Spider webs (they collect things and

clump together)

Debris in trenches, sumps and corners

Animal bodies, nests and droppings

Weld slag/spatter

Damage to an aircraft or engine attributed to

a foreign object is FOD.1 FOD can also be

the items (debris) that damage the aircraft, the

article or substance that is alien to the aircraft or

engine assembly.1 (See Figures 1 and 2.) For the

purposes of this article, FOD is the debris that

causes damage. (See Table 1.)

Most FOD can be attributed to poor

housekeeping, facilities deterioration, improper

maintenance or careless assembly, and inadequate

operational practices.2

Loose personal items jackets, paper,

pens

Tools

Weak, spalled, feathered edges, chipping

concrete and fins

Uncaptivated fasteners

Small screws without room temperature

vulcanization (RTV)

Rivets

Nuts or bolts not welded, not wired or

without locknuts

Clamps, brackets, clips, hooks, chains,

hasps

Cable ties and Velcro

Table 1: Examples of FOD.

The costs of foreign object damage to aircraft

and engines are high. According to a 1998

article from Boeing, FOD costs commercial and

military aviation worldwide around $4 billion per

year. Boeing reports that repairs to an engine

damaged by foreign objects can easily exceed

$1 million.3

The Defense Contract Management Agency

reports that in the past 5 years, (naval

aviation) alone experienced over $36 million

in reportable damage due to FOD.4 But its

not only the dollar value of the damage that

is of concern. There are also the possibilities

of injuries and deaths, compromised military

missions, schedule delays and damage to other

equipment or facilities.

FOD prevention programs are primarily oriented

toward manufacturing (assembling the aircraft)

and ramp operations. Those programs highlight

issues such as tool control, parts control,

rag control, jewelry and dress, housekeeping,

vehicle cleanliness, controlling packaging

and manufacturing debris, incentives, awards

and publicity.

TECHBriefs 2006 No. 4

Figure 1: Foreign object damage to engine fan.

Figure 2: Typical foreign object debris.

Engine Vibrations

In its 108-year history, Burns & McDonnell has

designed hundreds of aviation-related projects.

Some of these projects were for installed and

uninstalled engine testing (acoustic enclosures,

test cells and run stations, for example).

During engine testing, wind- and engine-induced

rocking or thrust will cause the structure to

move. Also, the intense sound from the engine

(in the 140 decibel or above range on an A scale)

causes the structure to vibrate. These acoustical

vibrations are powerful enough to dislodge

Burns &McDonnell

Acceptable techniques include:

Unacceptable techniques include:

Weld nuts tacked to bolt shank

Nuts/bolts wired per NASM 33540

(Safety Wiring)

Locknuts one piece, solid metal; hexhead; castellated; full-height; installed

and torqued to manufacturers written

instructions; meeting military or national

aerospace standards, matching adjacent

metal substrate

Cable ties (plastic or metal) and Velcro

Locknuts with plastic inserts

Improper wiring

Spot/undersized tack welds

Locknuts not installed to manufacturers

torque

Adhesives

Rivets

Tape, looped wires and other ad-hoc/

improvised methods

Note: RTV is not permitted where locknuts or welding can be achieved. There may be rare

instances where lock nuts or welding cannot be achieved. In those cases applying certain

types of RTV adhesive sealant may be acceptable.

Table 2: Captivation methods.

unsecured items, to completely unscrew bolts

and screws, and to cause cracks in seemingly

good welds and to fracture plates. Also, normal

exposure to the exterior atmosphere (moisture,

temperature) will cause facility components to

deteriorate. It is desirable that deterioration or

failed/broken items be identified at an early stage

so that they can be repaired before the structure

is weakened and before they become FOD.

The items that loosen can vibrate off ledges

and fall to the floor. If they are light, they may

be blown (by air movement from jet engines

or wind) directly into an engine. On the floor,

they may be blown along the floor until they

are ingested into an engine. If they fall behind

the engine, they may be blown into aircraft or

engines or toward personnel as projectiles.

Knowing the sources of FOD allows engineers to

eliminate or reduce those sources. All sources are

a real danger to aircraft, but it is not possible

to predict which potential source of FOD will

actually be the source that will lead to damage

or injury. The industry standard is to eliminate/

mitigate all potential sources and to regularly

inspect facilities for deterioration of components

and accumulation of debris.

Facility Inspection

Over time, vibration may cause equipment,

devices or components of the structure to loosen

or break. Inspections are required to determine

if any of the elements have moved, deteriorated,

cracked, broken, become damaged or weakened.

Inspections need to be thoroughly, patiently

and carefully performed by trained personnel.

Inspections should be organized, with progress

tracked so that no areas are missed.

Inspections are tedious because almost every

square foot of the structure and its components

are visually examined to ascertain if something

is damaged/degraded and if it has the potential

of becoming FOD. Inspectors make decisions

about the integrity of fasteners, components and

other items. They are looking for minute cracks

and missing items. Its a hands-on process

because they need to touch surfaces and probe

into crevices.

Engineers incorporate features into testing

structure designs to reduce the probability of

structural components becoming FOD. They also

eliminate surfaces where FOD can accumulate.

In critical areas, horizontal surfaces are reduced

and tight, hard-to-clean spaces are eliminated.

Concrete floor joints, edges of embedded items

and grout under equipment or columns should be

examined carefully. Any concrete edge has the

potential to crack, chip, splinter, separate

and dislodge. The edges of cracks may be

chipped, separated and subsequently dislodged.

Joint sealant may also become loose or separated.

Any suspect material, regardless of size,

tightness or location should be identified and

reported/removed.

Continuous welds replace spot welds, and

fasteners are captivated. The purpose of

captivation is to prevent the fastener (nut, bolt,

screw) from rotating off the end of the bolt or

out of the hole; to prevent the fastener from

becoming FOD and to prevent whatever the

fastener is holding (cover, plate, sheet metal)

from becoming FOD. (See Table 2.)

Any device, fixed or portable, subject to the high

energy levels created during engine testing is

prone to damage and may create a potential FOD

hazard. Inspectors are looking at items prone to

breakage or loosening, such as: electrical conduit

caps and breaker boxes; conduit and piping

supports; fire alarm and detection devices; hoses

and wires; access covers and associated handles,

Burns &McDonnell

TECHBriefs 2006 No. 4

hinges and hardware; bolts, nuts, washers and

welds; and captivation fasteners.

In addition to appropriate personal

protective equipment, inspectors/cleaners

will need:

Inspections should be documented with a report

stating:

Date and time of inspection

Name of inspector(s)

Written description of items and locations

found during inspection

A signature from an appropriate supervisor

stating that the inspection was made.

Lifts, ladders/scaffolds

Lights for examining poorly lit areas

Stiff brushes (large, medium and small), dental

pick type tools and scrapers for cleaning surfaces

and dislodging small items and testing concrete

surfaces for delamination/soundness

Non-water-soluble paint sticks (yellow, white or

red) for match-marking fasteners

Mirrors for looking behind equipment or structures

Shop vacuums with long extension cords and hoses

and nozzles with wide and narrow tips (it may be

necessary to fabricate small nozzles to vacuum in

narrow spaces)

Buckets or pouches for collecting debris

Items should be marked with indelible markers.

The report and markings provide a history for

facility maintenance decisions.

During the inspection, a thorough cleaning

of all horizontal surfaces could be performed,

but we typically recommend that the facility

be inspected separately from cleaning, and

that following the cleaning the facility be

inspected again.

Facility Cleaning

FOD is removed by manually picking up loose

items (screws, nuts, tools, paper) and placing

them in specially marked FOD containers or by

loosening items with brush, scraper or other tools

and vacuuming. (See Table 3.)

Table 3: Necessary equipment for facility cleaning.

Bottom Line

A well-planned FOD minimization, control and

identification program can substantially reduce

repair budgets and cut the risk of injury or

death, whether in an aviation facility or other

industry. In new construction, the key is to

implement FOD procedures from the beginning.

In an existing facility, a careful cleaning and

maintenance program can reduce FOD concerns.

We do not recommend high-pressure compressed

air or water to clean surfaces. They can force

debris into cracks and crevices rather than

remove it. Engine vibrations can then loosen the

debris from the cracks and allow it to move into

the air stream.

A limited and careful use of low-pressure

compressed air (such as from cans of compressed

air used for office dusting) can be helpful. In

areas that are difficult to reach with small tools

and fingers or by blowing with the mouth (such

as behind or underneath several parallel conduits)

low pressure compressed air from the container

can gently move items to a place where they can

be vacuumed or picked out by hand.

Water also has the potential for aiding corrosion

of the structure. Low pressure water may be

used to wash down concrete walls and floor

slab surfaces.

TECHBriefs 2006 No. 4

Philip Terry, PE, SE, is an

Footnotes

1. Definitions are adapted from FOD Prevention Guideline, 2000,

National Aerospace FOD Prevention Inc.

2. Aerospace Industries Association, National Aerospace Standard,

NAS 412, 1997.

3. Boeing Aeromagazine, Issue 01, January 1998.

4. DCMA Information Memorandum No. 06-163, May 16, 2006.

Burns &McDonnell

associate structural engineer

with the Aviation & Facilities

Group of Burns & McDonnell,

and has 25 years of experience

specializing in the design of

industrial, government and

aircraft facilities.

For more information, please e-mail:

pterry@burnsmcd.com

You might also like

- Confined Space Definition With ExpDocument7 pagesConfined Space Definition With Expehsan zahoorNo ratings yet

- Sheet Metal Damage, Repair and Types of Non Destructive TestingDocument11 pagesSheet Metal Damage, Repair and Types of Non Destructive TestingVasan VasanNo ratings yet

- Working at or Below Ground LevelDocument29 pagesWorking at or Below Ground LevelsingenaadamNo ratings yet

- UH InstallationGuideDocument4 pagesUH InstallationGuideAdmirador ClaheviNo ratings yet

- Amco TunnelDocument18 pagesAmco Tunnelengsam777No ratings yet

- Pressure Vessel InspectionDocument44 pagesPressure Vessel Inspectionأحمد صبحى100% (4)

- Safe Working EnvironmentDocument5 pagesSafe Working Environmentmohamed ibrahimNo ratings yet

- Hull Survey MethodsDocument21 pagesHull Survey MethodsSanta Clara100% (2)

- Onstruction Spects of UildingDocument27 pagesOnstruction Spects of UildingMalik ZainNo ratings yet

- Method Statement Lamps, Switches and Socket Outlets InstallationDocument2 pagesMethod Statement Lamps, Switches and Socket Outlets InstallationVõ Khắc GhiNo ratings yet

- A Subsea Housing Design Checklist PDFDocument8 pagesA Subsea Housing Design Checklist PDFmimi_chan_17100% (1)

- Chapter 4 Demolition WorksDocument25 pagesChapter 4 Demolition WorksAmir AlistyNo ratings yet

- 4-108 API Recommended Practice 571Document9 pages4-108 API Recommended Practice 571Alfonso Vallejo Aguilar100% (1)

- Step 1: Identify Equipment Prone To CuiDocument7 pagesStep 1: Identify Equipment Prone To CuiVajid Madathil100% (1)

- New Microsoft Word DocumentDocument20 pagesNew Microsoft Word DocumentSimon RajNo ratings yet

- Siwes Report GoogleDocument28 pagesSiwes Report GoogleelvisNo ratings yet

- Chapter 5. Nondestructive Inspection (Ndi) : Section 1. General 5-1. GENERAL. The Field of NDI Is Too VarDocument9 pagesChapter 5. Nondestructive Inspection (Ndi) : Section 1. General 5-1. GENERAL. The Field of NDI Is Too VarD Rider CasanovaNo ratings yet

- Lecture 11 - Defects in Casting and Inspection of CastingsDocument8 pagesLecture 11 - Defects in Casting and Inspection of CastingsManan GuptaNo ratings yet

- Q0155.1.22.04.20 - Awareness of FODDocument33 pagesQ0155.1.22.04.20 - Awareness of FODfranciscoNo ratings yet

- Const Tech & RulesDocument70 pagesConst Tech & Rulesariff.arifinNo ratings yet

- November New Letter 2012Document7 pagesNovember New Letter 2012Mohammed Jai Sujiya KhanNo ratings yet

- Nondestructive Testing Airplane TestDocument3 pagesNondestructive Testing Airplane TestAqil AmmarNo ratings yet

- FOD Prevention GuidelineDocument16 pagesFOD Prevention GuidelinejamilvoraNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Valmont Pole Owners ManualDocument6 pagesValmont Pole Owners ManualmdandersNo ratings yet

- Method Statement For Reinforced Concrete PoursDocument6 pagesMethod Statement For Reinforced Concrete Poursselva1965No ratings yet

- Repair and Rehabilitation of StructuresDocument81 pagesRepair and Rehabilitation of StructuresAngelinSavio0% (1)

- Heavy LandingDocument2 pagesHeavy LandinggamalazmiNo ratings yet

- Propeller MaintainanceDocument9 pagesPropeller Maintainancejacob ellyNo ratings yet

- Civil Engineering Maintenance: Assignment FourDocument6 pagesCivil Engineering Maintenance: Assignment FourNii BoyeNo ratings yet

- Failure Analysis Master Course V1Document21 pagesFailure Analysis Master Course V1manu6969aNo ratings yet

- Basic Processing Steps of A Liquid Penetrant InspectionDocument16 pagesBasic Processing Steps of A Liquid Penetrant Inspectionssrames7282No ratings yet

- Bulding Services Slide ShowDocument18 pagesBulding Services Slide ShowAre MalinaNo ratings yet

- Surface Preparation and Painting FinalDocument45 pagesSurface Preparation and Painting FinalthanghanvicoNo ratings yet

- Foreign Object Debris and Foreign Object Damage (FOD) Prevention For Aviation Maintenance & ManufacturingDocument53 pagesForeign Object Debris and Foreign Object Damage (FOD) Prevention For Aviation Maintenance & ManufacturingPappuRamaSubramaniamNo ratings yet

- UNIT-1 Non Destructive TestingDocument65 pagesUNIT-1 Non Destructive TestingPratap KumarNo ratings yet

- Mod 7 Book 11 N DT MethodsDocument53 pagesMod 7 Book 11 N DT Methodsranjit prasadNo ratings yet

- Ej Novo 1Document2 pagesEj Novo 1Filip NikolevskiNo ratings yet

- Sports and Fitness I&M Guide - ENDocument22 pagesSports and Fitness I&M Guide - ENMi doremiNo ratings yet

- Guide Inspection Plan For CUIDocument6 pagesGuide Inspection Plan For CUIMohamed SamyNo ratings yet

- CCPS Bulletin May 2009Document1 pageCCPS Bulletin May 2009Kim PullonNo ratings yet

- Guia de Prevencion FodDocument16 pagesGuia de Prevencion FodMibal Mibal MibalNo ratings yet

- Unit 4 (Demolishing Works)Document28 pagesUnit 4 (Demolishing Works)Zara Nabilah67% (3)

- NSC LECTURE Sept 2010 - Inspection of Pressure VesselsDocument21 pagesNSC LECTURE Sept 2010 - Inspection of Pressure VesselsMohammad Abubakar SiddiqNo ratings yet

- FormworkDocument33 pagesFormworkJICKNo ratings yet

- Bullet Catching MechanisamDocument97 pagesBullet Catching MechanisamswaparnikaNo ratings yet

- Demolition Feb 04Document107 pagesDemolition Feb 04ajaipurushothamanNo ratings yet

- Sample Inspection Report of ExchangerDocument22 pagesSample Inspection Report of Exchangerrtrajan_mech5408100% (4)

- Technical FodDocument52 pagesTechnical Fodprabs20069178No ratings yet

- Demolition Lecture 2Document70 pagesDemolition Lecture 2Afiq FuadNo ratings yet

- Pole Owner's Manual, Warranty & Maintenance Must Be Forwarded To The End User And/or CustomerDocument5 pagesPole Owner's Manual, Warranty & Maintenance Must Be Forwarded To The End User And/or CustomerkksdnjdaNo ratings yet

- Fall Protection in ConstructionDocument51 pagesFall Protection in ConstructionCảnh QuangNo ratings yet

- 2009 05 Mechanical IntegrityDocument1 page2009 05 Mechanical IntegrityHarshad SolankiNo ratings yet

- Technical Design Guide PDFDocument28 pagesTechnical Design Guide PDFPrabhu MohanNo ratings yet

- 42 Formwork: DefinitionsDocument13 pages42 Formwork: DefinitionsBJNo ratings yet

- Excavation & Trenching Safety PDFDocument51 pagesExcavation & Trenching Safety PDFPaul MaposaNo ratings yet

- Supervisory Development Programme-I (SDP-I) Topic: Non Destructive Testing (NDT) Faculty: Naveen SethDocument54 pagesSupervisory Development Programme-I (SDP-I) Topic: Non Destructive Testing (NDT) Faculty: Naveen SethvcpNo ratings yet

- DemolitionDocument2 pagesDemolitionGanga Daran100% (1)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- RT7736GGEDocument24 pagesRT7736GGEPedro AriasNo ratings yet

- Cadyce Catalog 2018Document34 pagesCadyce Catalog 2018Mayur MahajanNo ratings yet

- Tr110 Portable Roughness Tester Instruction ManualDocument12 pagesTr110 Portable Roughness Tester Instruction ManualandresNo ratings yet

- Signal Line 256 Gray Level 3 Channel Constant Current LED Driver ICDocument8 pagesSignal Line 256 Gray Level 3 Channel Constant Current LED Driver ICsteven MelgarejoNo ratings yet

- Ahu Room Size PDFDocument7 pagesAhu Room Size PDFMohammed AltafNo ratings yet

- Making of UmouseDocument18 pagesMaking of Umouseapi-26193001No ratings yet

- Attent PR 3005 TDocument4 pagesAttent PR 3005 TJuan CorreaNo ratings yet

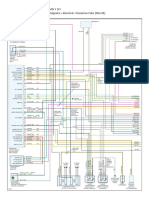

- Engine Controls (Powertrain Management) - NeonDocument3 pagesEngine Controls (Powertrain Management) - NeonRafael MejiaNo ratings yet

- Fig. 1 Type 3701-01 Solenoid ValveDocument4 pagesFig. 1 Type 3701-01 Solenoid Valveparthibanemails5779No ratings yet

- Secovac 12-24kvDocument21 pagesSecovac 12-24kvUrsula JohnsonNo ratings yet

- XS108B3NAL2: Product Data SheetDocument2 pagesXS108B3NAL2: Product Data SheetKenanNo ratings yet

- 1914 Milk Tea PlumbingDocument1 page1914 Milk Tea PlumbingPaul ChuaNo ratings yet

- Electrical / Electronic Equipment: From WM No. 5044 OnwardsDocument18 pagesElectrical / Electronic Equipment: From WM No. 5044 OnwardsMohammedasifNo ratings yet

- C-Lift® Chain Pulley BlocksDocument2 pagesC-Lift® Chain Pulley BlocksVarun ShahNo ratings yet

- 04 Maintenance PDFDocument60 pages04 Maintenance PDFFabo BarajasNo ratings yet

- DM4000 Accessories Fact SheetDocument4 pagesDM4000 Accessories Fact SheetSydney Sam S PhiriNo ratings yet

- Disco 3 FBH Workshop Manual Thermo Top VDocument46 pagesDisco 3 FBH Workshop Manual Thermo Top VDaniele GardellinNo ratings yet

- Summit X: With Expert PackageDocument2 pagesSummit X: With Expert PackagealexNo ratings yet

- Aircraft Wiring Harness DiagramsDocument22 pagesAircraft Wiring Harness DiagramsOscar MarinNo ratings yet

- B.Tech. Computer Science Engineering Effective For The Batches Admitted From Session 2022-23-38Document1 pageB.Tech. Computer Science Engineering Effective For The Batches Admitted From Session 2022-23-38rajat.20223200No ratings yet

- S C T 0 1 3 G - D: Ф16Mmaperture Split Core Current TransformerDocument5 pagesS C T 0 1 3 G - D: Ф16Mmaperture Split Core Current TransformerLa Juan RaulNo ratings yet

- Nlpkatalog GASDocument27 pagesNlpkatalog GASSvilen KirilovNo ratings yet

- Technical Specification: Minicas Ii, 24 V Ac/Dc and 120 V Ac Supervision RelayDocument4 pagesTechnical Specification: Minicas Ii, 24 V Ac/Dc and 120 V Ac Supervision RelaySEA ROCK TECHNICALNo ratings yet

- EIE Lecture Notes (6th Semester Electrical)Document84 pagesEIE Lecture Notes (6th Semester Electrical)asli almu0% (1)

- Manual PLC ZelioDocument16 pagesManual PLC ZelioAlexander FelizNo ratings yet

- Dwell Tach Test and CalDocument41 pagesDwell Tach Test and CalZé Pontes DetCordNo ratings yet

- Cooper Surge ArrestorDocument10 pagesCooper Surge ArrestoripraoNo ratings yet

- Report Adjustable Power Supply 2Document11 pagesReport Adjustable Power Supply 2Deeo DhadiwalNo ratings yet

- T11 Specifications 107D11811-1Document4 pagesT11 Specifications 107D11811-1Alexandra chata monsalve momsalveNo ratings yet

- Final demoLP-galingDocument7 pagesFinal demoLP-galingChabsNo ratings yet