Professional Documents

Culture Documents

RFP For Co-Gen at Palwal Sugar Mills LTD

Uploaded by

Arun GuptaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

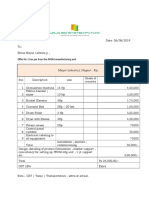

RFP For Co-Gen at Palwal Sugar Mills LTD

Uploaded by

Arun GuptaCopyright:

Available Formats

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

The Palwal Co-Operative Sugar Mills Limited

Palwal Haryana

(Telefax:-01275-263433)

Email:- palwalsugarmills@yahoo.com

Information about the The Palwal Coop. Sugar Mills

regarding installation, operation and maintenance of

a Co-gen. Plant more than 10 Megawatt.

1.

List of officers with Telephone Nos.

2.

I(1) Form.

3.

Technical flow of last 12 years.

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

1. List of officers of The Palwal Coop. Sugar Mills with Telephone

Nos.

DESIGNATION

NAME

TELEPHONE NO

MANAGING DIRECTOR

SH. V.S. HOODA

09466119494

CHIEF ENGINEER

SH. W.S. DHILLON

09466119496

CANE MANAGER

SH. K. S. DHAKA

09466119495

CHIEF CHEMIST

SH. S.K. SAXENA

09466119497

CHIEF ACCOUNT

OFFICER

SH. L.D. GOEL

09466119498

DY. CHIEF ENGINEER

SH. VIJAY PAL SINGH

08813866500

DY. CHIEF CHEMIST

SH. RAJENDER TYAGI

09034483177

DY. TECH. ADVISOR HARYANA SUGARFED PANCHKULA, SH. S.B.

AGNIHOTRI :- 09466112855

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

The Palwal Coop.Sugar Mills Ltd, Palwal Distt.Palwal (Haryana)

Form:I (1)

For central Sugar Factories Schedule of Machinery.

Name of the Factory

Mill

The Palwal Coop.Sugar

Ltd, Palwal Distt.Palwal

(Haryana)

Registration No.

CIL 99 (84) 26.3.1984

Capacity Registered

1250 TCD

Type of Plant

Steam Turbine Driven

Clarification Process used

Double Sulphitation

1. MILLING PLANT

1.Cane Carrier

a) Size, width and length between centers and Width: 1525 mm

length of horizontal part and feeding depth.

Horizontal length : 30 m

Inclined vertical : 26.04 m

Pitch of chain : 6

Feeding Depth

: 1.10 m

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

Pitch

: 150 mm

Type :Slat to slat conveyor,

two

Strand chain.

No.of slats:

840

Angle of inclination :18

degree

b) Drive ( H.P.if separate drive)

Electric motor :( Dyno drive)

Steam/Electric if electric state

50 H.P./1440 RPM

Type and Range of variable speed.

RPM

Variable speed : 120- 1200

Cane carrier speed :20

ft/min

c) One Auto-cane Feed Controller

chopper

Complete Automation of

Cane Cutter, leveler, Carrier

and Mills Turbines.

2. PREPARATION OF CANE

a)Cane knives: State No.of sets, No.

chopper,Leveler,Cutter

3.Nos sets of knives

and Pitch of the blades in each set and

particulars of drive specifying RPM, H.P No. of blades

for each sets, clearance between tips and

36

48

Motor Drive( Direct coupled)

48

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

carrier bed location of knives (if two sets) H.P.

250

150

250

+ chopper whether direct coupled

585

RPM

585

585

(center to center distance)

15mm

Clearance)

400 mm 55mm

Distance between three sets = 6 m

Swing dia

=1580

mm

b) Particulars of other preparatory

One No. kicker

equipment if any

No. of Blades

=18

H.P.

=25

Dia of out tips of blades - 1000

mm

Dia of central hollow pipe-400 mm

Shaft Dia

90 mm

RPM

70

Drive Motor RPM

1440,25

H.P

Reduction Gear Box Ratio: 30:1

Type HUB , Size : 8

Cane Un-loader( 3 Nos)

Three motions electrically operated

Over head unloading crane

2 Nos Hydraulic grab make:

Dupont,cap: 5

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

MT/lift, year 2007-08, year 2011-12

1 No. mechanical grab

Capacity 5 MT/lift

Make / Supplier : PHEW

Year of installation : 1984 -85

Span : 22 m, Gantry 30 m

3. MILLS

State Nos of mills and for each mill

Four mills tandem i.e. 12 Rollers,

3 roller each mill

The dia and length of roller in mm

Dia

820 mm

( also mentioned if mills have force

Length

1525 mm( 32x 60)

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

feeding arrangement, their type and No. All mills have TRPF Roller of 110

% with

given for each mills )

gear drive from top roller.

a)Type and No.of grooves and size

30 Nos

Type circumferential V- grooves

in mm (Surface and juice grooves)

Mill No.1

Pitch

Angle

Feed

50

40

Discharge

50

45

Top

50

50

Depth of

Groove(mm)

56

47

43

30 Nos grooves,masschert groove in

alternate groove with

width = 6mm,depth = 20 mm

Mill No.2

Feed

50

40

Discharge

50

45

Top

50

50

56

47

43

7

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

30 Nos grooves, masschert groove in

alternate groove with

width = 6 mm, depth = 20 mm

Mill No3

Feed

25

40

Discharge

25

45

Top

25

50

26.5

22.5

20.5

60 Nos grooves, masschert groove

after 2

No grooves with

width = 6 mm, depth = 20 mm

Mill No.4

Feed

25

35

Dis

25

50

Top

25

50

30

20.5

20.5

60 Nos grooves, masschert groove after 2 No

grooves with

width = 6mm,depth = 20 mm

8

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

b)Mill Setting in mm

iv mills

Tip to groove

ii

iii

Feed

34

27

20

Dis.

12

18

3

c)Type and setting of trash plate

C.S. trash

Tip to trash plate

plate in mm 45

41

35

30

d) Speed of Rollers in meter/

Speed 14 m/min at 6.0

RPM

minute and also RPM

e)Make and type of Hydraulic

accumulator

f) Total Hydraulic load in top

Roller in Tones & Hyd. Load

Edward Hydraulic accumulator

(Nitrogen and oil filled)

195 MT on each top Roller

128 MT on each top Roller per

per m length of Roller.

meter length

g)Length & Dia of Roller

Dia :375 mm

Journal in mm

length ; 475 mm

4. BAGASSE ELEVATOR, BAGASSE CARRIER,

RETURN BAGASSE CARRIER

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

Type, length and drive H.P

RBC

Rake type BE. BC&

if separate drive

66ft/minute

width 1.2 m ,speed

Length 58 M,95M,57M

Electrical motor

25H.P.40 H.P.,

15 H.P.,1440 RPM

5 DRIVE FOR MILLS.

Ist & 2nd mills are driven

a) State No. & type of engine,

by Ist

turbine.3rd & 4th mills

No.of crushers and mills driven

driven by

2nd turbine .

by each engines, dia of cylinders,

stroke ,RPM and normal H.P.

b)If steam turbines are used their

Two steam turbines

H.P. No.& exhaust pressure.

Make

Triveni

Size

290 mm

BHP

600 each

each

Inlet pr & Temp.= 18-21

kgf/cm2

10

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

= 320

15C

Ex. Pressure 0.95 kg/cm2

c) Type Reduction Ratio & Length

each

Enclosed gear box with

of teeth open red.gear train.

Turbine reduction ratio.

i) 8.7:1 ii)20:1 iii)7:1

gear teeth 204, pinion

teeth 29

RPM input (prime mover)

7000 RPM and reduction

Ratio RPM out put (mill)

5.7 (1224:1)

6. IMBIBITION

a)State whether water used

Hot water used

is hot/cold and arrangements

Automatic Bolounge type

provided for measuring & weighing.

per trip

weighing scale 1.2 M.T.

with recording counter.

b)State the imbibitions scheme followed.

11

compound Imbibitions.

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

II .CLARIFICATION PLANT

7. MEASUREMENT AND WEIGHMENT OF RAW JUICE

a) Weighing equipment

steam State No.& type and weighing capacity

Bolougne type

Automatic

juice per charge of each tank in qtls and

qtls

weighing scale of 30

arrangement capacity

recording

per trip with

counter.

8. JUICE HEATERS

State Nos, type & heating surface(m2)

Five Nos., H.S.170 m2

(each)

H.S of each whether working on vapour,

working with steam, Ist & II

steam purpose for which each is used.

4Nos

Body vapour of quad.

are inter-changeable and

are

used for R.J.& S .J and

1No. for clear juice

heating.

12

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

1No.VLJH of 240 m2

H.S. with

I.D./O.D = 42/45 mm, L

= 4 m,

At 4th evaporator body

but not

at 5th evaporator body

9. JUICE SULPHITATION STATION

State No.,type gross and

sulphitor

One No spurger type juice

working capacity in cubic meter

Gross capacity:20.97m3

of each together with circulation

working capacity 10.0 m3

arrangement

Dia. -2.378 m

10. SETTLERS

State No. & working capacity

clarifier)

One No.444(Rapidorr

In cubic meter of each in case of

dia.7.32 m, height 6.10 m i.e

13

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

continuous settlers, mention

cap.

24ft x20ft total juice holding

Dia, No. of compartments and.

2700 H.L four compartment.

Juice holding cap.in cubic m

11. SULPHUR DIOXIDE GAS PLANT

a) Sulphur furnace

State type and No. of furnaces

0.60

Two Nos. continuous type

m2 tray area.one for juice

and tray area in sq mtr for each.

and

one for syrup and also can

be

used each for juice and

syrup,

provision for sulpher

melting

steam jacket type melter.

.

One sulphur furnace is

having

waste heat recovery system

b)Air Compressors

14

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

State No. and type capacity in

m3/hr.Air

One No.1 kg/cm2 600

Cubic mtr displacement per inch and

sulphitor

displacement for juice

Delivery pressure.

1kg/cm2g

One No.200m3/hr &

For syrup sulphiter.

2 Nos.2.3 m3/min., 7kg/cm2

for

Instrumentation & C/F

station

12. FILTERATION EQUIPMENT

a) Rotary vacuum filer

filters

Two Nos .rotary vacuum

Make Nos.and dia. Length of

area

One of 10ft x 20ft. filtering

each and filtering area

F.A.

57.6 m2 and 2nd of 8ft x 16ft

37.4 m2

13,MILK OF LIME PLANT

Give details of lime slaker

One rotary type lime slaker

Type,size,RPM etc

length:4.5m, dia:0.92m.

15

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

14. EVAPORATORS

a) State No.and H.S.area for

Tube

H.S.

No. of

each evaporator

ID/OD

(m2 )

Tube

With Dimension of Tubes dia

(mm)

Height of body and size of vapours

42/45

Vapour Cell 1300

5050

Height of body and size of vapours

pipe of each body

42/45

Vapour Cell 1100

Body (1)

4200

750

2725

42/45

Body ( II)

560

2036

Body ( iii)

440

1650

Body (IV)

440

1650

42/45

42/45

.

42/45

42/45

Body (V)spare 440

1650

Tube length 2.0 M

Details of save all and juice catcher.

external

Standard entrainment with

Catcher umbrella type.

16

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

Arrangement for drawing condensate

collecting well

under ground condensate

From vessels

15. SYRUP TREATMENT PLANT

a) Sulphiting Tanks:

One No Syrup sulphitor

State No.and working capacity

and

type working capacity 2.15 m3

In cubic meter and gross capacity

gross capacity 6.386 m3

State continuous/ intermittent type.

b)Filters : State type No.and filling

Nil

area in centimeter.

16. SYRUP AND SUGAR MELT STORAGE TANK

State No.and tanks and capacity in

Four Nos.of 170 m3 for syrup

cubic meter of each.

melt

and two Nos.of 120 m3 for sugar

17.MOLASSES STORAGE TANK(PROCESS)

State No.and tanks of capacity in

H.L

Total 9 Nos. tanks rectangular 100

Cubic meter of each

capacity each.

17

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

18. VACUUM PANS.

State Type and Nos. of

One No. 60 M.T.-Low Head calandria 900

Pan, State the normal strike

mm tube length.

Capacity in H.L.and total

Five Nos.40 MT each 1200 mm.

Heating surface in sq.mtr

each

Tube length each heating surface 185 m2

(Mechanical circulator if any,

Tube I.D.96 mm, of 40 M.T Capacity pan

Mechanical circulator provided

on C vacuum pan

Vacuum Gauges

i) Recording vacuum

ii)Controlling pan boiling

Nil

iii)Save All and juice catcher

Standard entrainment separator.

Umbrella type in each pan.

iv) Boosters if any

Nil.

19.CONDENSATION PLANT

a)Condensers: State No.type dia

jet

Six Nos.single water entry multi-

and height in centimeters.Also give

condenser for pan.

particulars of pan and evaporator

Two for evaporators

connected to each evaporator.

Dia 0.9 m,height : 1.22 m

18

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

6 Nos.with automation of spray

Engg.

Panchkula Dia 0.9,height:0.96 m

each.

b) Condenser water pumps

State Nos .type, capacity in ltrs/hr

pumps.

6 Nos. Centrifugal type water

of each.

pans.

2 Nos. for evaporator and 4 Nos.for

Capacity:700 m3/hr (3 Nos,) 1000

m3/hr 2 Nos , 450 m3/hr,Head - 17

m each

delivery of all five pumps inter

Connected with the common

header.

c)Spray pumps: State No type and

capacity in cubic meters,

2000 m3/hr,100 H.P/1440 rpm,Head

10 m (1No)

1600 m3 /hr,75 H.P/1440 rpm 1No Head

10 m

d) Spray Pond: State No.and type

nozzles.

One spray pond volute type 300

19

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

of nozzles

20.CRYSTALLIZERS

State Nos.of crystallizers of such

One No.U.-shaped air cooled cry.of

Type(open or closed jacketed and

shaped

450 H.L capacity and three Nos. U-

For each cry.give the normal M/C

2Nos.

air cooled cry.of 320 H.Lfor AM/C,

Capacity type of M/C cooled and

Nos

U shaped air cooled cry.for B M/C, 5

Cooling surface in sq,m of coils

crys.for

U shaped water cooled moving coil

If any type of cooling coils.

320 H.L. cap.each for CM/C.Cooling

Surface in each cry.is 44 sq.m.

21. SEED CRYSTALLIZER

a) Seed Crystallizers

seed

One No open air cooled for dry

b)Nos. and capacity

Nil

c)Give detail of heating arrangement

No heating arrangement

in pug mil

d) Vacuum crystallizers

Three vacuum crystallizers of 275

20

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

H.L.capacity.

22. CENTRIFUGAL MACHINES

State, type and Nos of machine

2 Nos.Batch Type fully automatic

used as fore worker and after

1250kg/ charge WIL make

Worker separately for each of

Buckau

8.Nos. continuous machine (make

wolf

M/C and mention separately

their bascket dia and height in

2.No.NK-1100-CFW

mm,RPM and type of drive i.e

2 Nos.SC-1100 KT-CFW

belt

2 No.SC-1100 KT-CAW

Water or electrical whether

1 Nos.SC-1100 KT-BFW

annully

Operated semi automatically or

1 No.NK.1100 CAW

Fully automatic.

1 No. SC-1100 CAW & BFW

1 No. SC 1100 BFW

1 No NK-1100 BFW

21

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

23. SUGAR DRIER

State Nos.and type(e.g.granular

3 Nos.Grass hopper sugar drier No.2&3

Grass hopper)

& cold

provided with drying arrangement(hot

by blower)

1.

2.

Width

1.52m

1.52m

Length

12.92m

8.88m

Tray

tray

multi tray

1.52m

10.12m

multi tray

24 .SUGAR GRADER

State type, size and No. of decks

four

One No.vibrating type sugar grader of

Sugar melter

decks 15 tonnes capacity/hr,5width x

15length

25. BOILERS (STEAM & POWER

PLANT)

22

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

a) Boilers State No.type and

Make

2 Nos.bent tube water tube boilers

Make

Walchandnagar

For boiler its working Pressure (in

H.S.850

Working pressure: 21kg/cm2,

m 2 steam.

Kg/cm2.)

heating surface( Indian

Generating capacity 22 ton/hr super

Rating)steam

heated steam

Generating capacity in kg/hr grate

temp.315 deg.calcius.

Area for bagasse and coal in sq.m.

Super heater heating surface and

soot

heating surface,78 sqm, coil type

Details of soot blower

controlled

blower, steam operated hand

type.

b)Feed water treatment give

Delhi

One DM Plant of M/s Watcon, New

particulars of arrangement if any

water,feeding

for de-mineralizing the hard

for softening or otherwise heating

to boiler.

the feed water entering boilers.

c)Economisers and feed water heaters

23

Two Nos.coil type 400 M2 each

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

give particular stating type and heating

surface.

d)Air heater

Two Nos. HSA, 502 m2 each.

State accumulators No.type

Nil.

and capacity.

e) State if bricks or steel and give

One M.S.chimney self supported

diameter and height also type of

Height 30m, dia 3 m.

draught(forced,induced ,natural),

ft3/min

Induced Draught fan 100000

capacity of Induced and forced

H.P.=200, fan rpm 750

draught fans.

Temp. flue gas = 180 deg.C

Type : Radial curve blades

(Backward

Draught) = 100 mm

F.D Fan air displacement =35000

ft3/m

Motor H.P.=75 rpm 1440

25. Bailing press

Nil.

26. POWER PLANT

a) State No. of prime movers

set of Cummins

Two Nos.Diesel Generation

Cummins make

24

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

stating for each

1) The purpose for which it is used and

to

its make

320KVA,160 KVA 1No.each

generate power for the Plant

1) If any turbine is used state its type.

stage

One 1500 KW rating multi

No.of stages and steam condition

Turbine inlet pressure

of input and out put

18 -21kg/cm2 (32015C and

exhaust pressure

to 0.94 kg/cm2

b)State No.of electrical generators

stating for each

1) D.C. or AC

AC

11)Voltage and make

440 volts

111) Out put in KW

1500 KW

1V) Purpose for which is used

Lighting only or development of

Light and power both

power in factory.

V) If AC power factor No.of phase

50 HZ

0.95 power factor 3 phase

And frequency

VI) Maximum demand in KW

1450 KW in season

25

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

During season and off season.

212 KW (250KVA)

General

27.MAKE OF PLANT

State name and make or principal

M/s Prem Heavy Engg. Works

Pvt.Ltd,

Maker of machinery

Meerut.(U.P.)

28. FINALMOLASSES STROAGE TANK

State No.type and capacity

M.S.Tanks 2 Nos.

of each tank

each.

cylindrical 45000 qtls capacity

29.EFFLUENT DISPOSAL

Give particulars of arrangement

Treatment Plant

1.No. Mechanical Effluent

of 1200 M3/day

Provided for disposal of factory

effluent

process

capacity : Activated sludge type

2.Nos Wet scrubber tray type.

30.CONTROL INSTRUMENT AT BOILER

Number and specification

1. Single element control system

2.Temp.scanners.

26

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

3.Steam Flow Meter

4.Feed Water Flow Meters

31.DETAIL OF MACHINERY IN WORKSHOP

a)State Nos. of Lathes and their size

4 Nos

b) Nos. of shaping machine and size

18

6 Meter,3 m,2m,1-1/2 m one

stroke

c)No.of planner machine and their size

One

d) No.of coupola its capacity and size.

Nil.

e) Other machinery in work shop

hacksaw.pedastral

Drill,power

grinder.

32.SUGAR BAGS CLOSING MACHINE/ SUGAR HANDLING

SYSTEM

Sugar bags stiching machine

3 Nos.make Stichwell, 2 Nos

Sugar cillo

sugar with

100 ton for M and 80 ton for S

Automatic Sugar weighing scale

make

Power Built .

33. SUGAR GODOWN

Sugar Godown

4 Nos.equal capacity

Length : 87.55 m

Width : 21.55 m

Height : 10 m

Capacity : 70000 bags (100 kg/bag)

27

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

I hereby declare that all the details given in this return are true to the best of

my knowledge and belief.

Chief Chemist

Chief Engineer

Managing Director

The Palwal Cooperative Sugar Mills Ltd, Palwal (Haryana)

Details of Buildings

Sl No. Name of Building

Covered Year of

Value

2

Area in M Construction

in Rs

condition/

class of

construction

1. Main Factory Building

7194.00

1983-85

5644897/-

2.Tech.Office Building

187.25.

1983-85

246327/-

3.Canteen

160.60

1983-85

193819/-

136.60

1983-85

134440/-

5.General Toilets

59.00

1983-85

65633/-

6.Workshop

250.90 1983-85

232094/-

Building

4.Lime & sulpher Godown

7. General Store

320.60

1983-85

218714/-

8.Admin.Block

382.65

1983-85

744373/-

9.Time & Security Office

78.00

1983-85

68503/-

10.Electric Room

30.00

1983-85

28450/-

1991.00

1983-85

1445050/-

11.Sugar Godown No.1

28

Good

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

12.Sugar Godown No.2

1991.00

1987-88

2195756/-

13.Sugar Godown No.3

1991.00

1988-89

2950728/-

14.Sugar Godown No.4

1991.00

2001-02

5929033/-

15. Cane Office Buiding

406.70

2001-02

2188488/-

CHIEF ENGINEER

SDE(CIVIL)

Technical flow of last 12 years

29

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

30

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

THE PALWAL COOP. SUGAR MILLS LTD., PALWAL

CANE AREA PRODUCTION YIELD AND CANE AVAILIABILITY PER ACRE FOR

THE LAST 15 YEARS

YEAR

AREA

IN

ACRS

PRODUCTION

LAKH QTLS.

YIELD

PER

ACRE

IN

QTLS

CANE

CRUSHED

IN LAC

QTLS.

DRAWL/ACRS

IN QTLS.

1999-2000

20010

32.00

160

19.35

97

2000-2001

23806

43.00

180

29.76

125

2001-2002

28500

51.40

180

29.09

102

2002-2003

26986

36.00

134

22.89

85

2003-2004

18250

32.00

175

22.18

122

2004-2005

14101

25.40

180

16.57

118

2005-2006

15500

27.00

174

19.03

123

2006-07

19144

31.70

165

26.61

138

2007-08

18737

29.00

155

25.11

133

2008-09

10007

16.00

160

10.80

107

2009-10

5022

9.00

180

6.03

119

2010-11

8840

16.00

181

11.75

132

2011-12

14735

25.00

170

20.95

2012-13

17360

23.50

135

19.35

2013-14

13600

25.00

185

19.20

31

Installation, Operation and Maintenance of a Co-Gen Plant

at Palwal Co-operative Sugar Mills Ltd. on BOOT basis

Request for Proposal Document

Volume I: Instructions to Bidders

For any Query please contact Chief Engineer, Dy. Chief

Engineer Regarding the plant, Cane Manager regarding

the Cane area and cane availability, Chief Chemist, Dy.

Chief Chemist regarding the process, Chief Account

Officer regarding the Finance position and Dy. Tech.

Advisor Sh. S.B. Agnihotri for the whole project.

32

You might also like

- Batteries and InvertersDocument16 pagesBatteries and InvertersPratik VasagadekarNo ratings yet

- POWERLABS' High Voltage Solid State Flyback DriverDocument11 pagesPOWERLABS' High Voltage Solid State Flyback DriverArnab Acharya50% (2)

- Basic Weights Calc - ACHEDocument6 pagesBasic Weights Calc - ACHESiva ShankarNo ratings yet

- Boiler Erection 2Document51 pagesBoiler Erection 2Sam100% (7)

- Centrifugal Pump Selection and SizingDocument50 pagesCentrifugal Pump Selection and SizingmariasofiarossiNo ratings yet

- Land Rover DiscoveryDocument16 pagesLand Rover Discoveryrod3662100% (1)

- Weighing SystemDocument151 pagesWeighing SystemArun GuptaNo ratings yet

- Progressive Cavity Pump (PCP) : Mohamed ElbadriDocument46 pagesProgressive Cavity Pump (PCP) : Mohamed Elbadrimohanned salah100% (3)

- Double Skin Facades: Why, Where, What?Document23 pagesDouble Skin Facades: Why, Where, What?Ionut DiaconuNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Supply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDDocument9 pagesSupply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDgbaludbNo ratings yet

- Pumps and SystemsDocument5 pagesPumps and SystemsYashwant Kumar Saini100% (2)

- Introduction Letter: Subject: Company ProfileDocument21 pagesIntroduction Letter: Subject: Company ProfilePritam JadhavNo ratings yet

- Mud Pump Expendables Gardner DenverDocument8 pagesMud Pump Expendables Gardner Denverleo0% (1)

- Pump Layout & PipingDocument91 pagesPump Layout & Pipingrahult19100% (6)

- Mobile SubstationsDocument7 pagesMobile SubstationsAnonymous EVFw59No ratings yet

- Renold Chain CalculationsDocument23 pagesRenold Chain CalculationsKiran Kumar K T100% (1)

- 3.0-TDI Clean Diesel Engine PDFDocument111 pages3.0-TDI Clean Diesel Engine PDFCarlos Garcia GodoyNo ratings yet

- TDZ Hidraulic Vane PumpDocument26 pagesTDZ Hidraulic Vane PumpAndi IshakaNo ratings yet

- Sea WaterDocument39 pagesSea WaterArun GuptaNo ratings yet

- A Guide To Solar PV SystemsDocument24 pagesA Guide To Solar PV Systemserkamlakar2234100% (1)

- PAT Drilling Catalogue (ACF)Document22 pagesPAT Drilling Catalogue (ACF)sunilchoppala100% (3)

- JVK Filter Elements enDocument16 pagesJVK Filter Elements enArun GuptaNo ratings yet

- MMS Product GuideDocument40 pagesMMS Product GuideFelipe VargasNo ratings yet

- Project Profile On Mini Flour Mill: Prod U CTDocument11 pagesProject Profile On Mini Flour Mill: Prod U CTSunil ShawNo ratings yet

- US Energy Efficiency Full ReportDocument165 pagesUS Energy Efficiency Full Reportjosepmcdalena6542No ratings yet

- 22 ATC ARA DebottleneckingDocument15 pages22 ATC ARA DebottleneckingmkpqNo ratings yet

- Ship DesignDocument247 pagesShip DesignArun Gupta0% (1)

- Beretta Offer 22-244 t44 HondurasDocument4 pagesBeretta Offer 22-244 t44 HondurasMaynor PadillaNo ratings yet

- Danish Wind Turbine Industry Report - Sara GrobbelaarDocument23 pagesDanish Wind Turbine Industry Report - Sara GrobbelaarSara S Grobbelaar100% (1)

- Coal Feeding System (Coal Bunkers, RC Feeders & Coal Mills) : Dipti Ranjan Behera Manager (Elect)Document15 pagesCoal Feeding System (Coal Bunkers, RC Feeders & Coal Mills) : Dipti Ranjan Behera Manager (Elect)Sanjay GuptaNo ratings yet

- Company Profile & Products - Aswathi Industries Ltd. - 13.08.19Document35 pagesCompany Profile & Products - Aswathi Industries Ltd. - 13.08.19mOHITNo ratings yet

- 460 Mr. Abhijit GadekarDocument4 pages460 Mr. Abhijit GadekarAbhishekSengaokarNo ratings yet

- BhelDocument26 pagesBhelShankar SharmaNo ratings yet

- Rig 370 HPDocument15 pagesRig 370 HPAbdul Sani YatimNo ratings yet

- A Power Point Presentation of BHELDocument24 pagesA Power Point Presentation of BHELSiddharth SharmaNo ratings yet

- Bhel Block 3Document35 pagesBhel Block 3Aditya Aggarwal62% (13)

- 45 MM Monolayer 2 May 1450 NewDocument8 pages45 MM Monolayer 2 May 1450 Newmaddy7023No ratings yet

- Catalogo Bomba Gabbioneta Modelo VBN PDFDocument2 pagesCatalogo Bomba Gabbioneta Modelo VBN PDFPrabha KaranNo ratings yet

- Rolling Mill OrissaDocument19 pagesRolling Mill OrissakxenggNo ratings yet

- Details of MachinesDocument3 pagesDetails of Machinesprem skhNo ratings yet

- Transfer Pump BrochureDocument12 pagesTransfer Pump BrochureRafert RamNo ratings yet

- VOITHDocument14 pagesVOITHpraicevic74No ratings yet

- Welcome: Presentation ON Boilers & AuxiliariesDocument58 pagesWelcome: Presentation ON Boilers & Auxiliariestanuja singhNo ratings yet

- Catalogue: Lifting and Installation of MachineDocument24 pagesCatalogue: Lifting and Installation of MachineGocha KakhniashviliNo ratings yet

- Indian Oil Corporation Limited Mathura PPT - PPTX Ashu 11Document20 pagesIndian Oil Corporation Limited Mathura PPT - PPTX Ashu 11iampiyushsahuNo ratings yet

- Especificaciones Primeras MaquinasDocument12 pagesEspecificaciones Primeras MaquinasGeovanny SanchezNo ratings yet

- 1030 H000 A06010 0016 1615 0001 - R0Document69 pages1030 H000 A06010 0016 1615 0001 - R0Zahoor Ahmed100% (4)

- 120 BPM Bopp Labeling Machine & Shrink Wrapping MachineDocument6 pages120 BPM Bopp Labeling Machine & Shrink Wrapping MachineOMKAR JADHAVNo ratings yet

- 06 Instructions Manual Hagglunds Eximtec - CEI CollahuasiDocument261 pages06 Instructions Manual Hagglunds Eximtec - CEI CollahuasiJorge RiveraNo ratings yet

- FIN400 Production LineDocument5 pagesFIN400 Production LineMd Masudur RahmanNo ratings yet

- THQ Shahpur - Civil, Electrical and Plumbing Work: SR - No. DescriptionDocument8 pagesTHQ Shahpur - Civil, Electrical and Plumbing Work: SR - No. DescriptionAbid HussainNo ratings yet

- Frozen French Fries Processing Line For 300KGHDocument9 pagesFrozen French Fries Processing Line For 300KGHAnkit PatelNo ratings yet

- Duty Specification FOR Hot Oil System Package Unit: GeneraDocument5 pagesDuty Specification FOR Hot Oil System Package Unit: GeneraSuchart TarasapNo ratings yet

- Irc 090-1985Document68 pagesIrc 090-1985kruttika_apNo ratings yet

- Hot Mix Plant Model DM-45 Capacity 40-60 TPH UniversalDocument3 pagesHot Mix Plant Model DM-45 Capacity 40-60 TPH UniversalShreyansh TiwariNo ratings yet

- VFD Pump MultiChannelCaseIIDocument12 pagesVFD Pump MultiChannelCaseIISatender VermaNo ratings yet

- Pump JTN B1Document8 pagesPump JTN B1Patricia J ÁngelesNo ratings yet

- Oil-Fired Series: Operating Instructions and Parts ManualDocument34 pagesOil-Fired Series: Operating Instructions and Parts ManualJamal HabbasNo ratings yet

- Dal Mill ProjectDocument2 pagesDal Mill ProjectMahesh Raje BhosaleNo ratings yet

- 3599 Chana Dal Mil Plant 5 Ton Per Day (Rill Machine Machine) PDFDocument2 pages3599 Chana Dal Mil Plant 5 Ton Per Day (Rill Machine Machine) PDFMahesh Raje BhosaleNo ratings yet

- Flat Die Pellet MillDocument7 pagesFlat Die Pellet MillDan Felix100% (1)

- VTDocument12 pagesVTSlobodan AnticNo ratings yet

- 850TM 880TM 810TM: Marshall MultispreadDocument23 pages850TM 880TM 810TM: Marshall Multispreadal110No ratings yet

- Aulia Syafira Syaharani - 5008201069 - DPK (I) - SPESIFIKASI ALAT DAN CAPEX OPEXDocument34 pagesAulia Syafira Syaharani - 5008201069 - DPK (I) - SPESIFIKASI ALAT DAN CAPEX OPEXAulia syafiraNo ratings yet

- Internship Report of ISHAN EQUIPMENTS LTDDocument38 pagesInternship Report of ISHAN EQUIPMENTS LTDTapanNo ratings yet

- Power PDFDocument6 pagesPower PDFelrajilNo ratings yet

- Im 240 PEDocument62 pagesIm 240 PEHimanshu SharmaNo ratings yet

- 5 Offer For Vertical Pyrolysis Plant 10TDocument5 pages5 Offer For Vertical Pyrolysis Plant 10TGaurav BihaniNo ratings yet

- TB-119 Rev 0 Line Lengths and ElevationsDocument9 pagesTB-119 Rev 0 Line Lengths and ElevationsYosbanyNo ratings yet

- Pump Unit 1890775-9, 1890776-0 1890778-4, 1890779-6Document29 pagesPump Unit 1890775-9, 1890776-0 1890778-4, 1890779-6Jose Ortiz100% (1)

- P39 462 464 80 501Document2 pagesP39 462 464 80 501PabloDavidTMNo ratings yet

- Agitator DesignDocument6 pagesAgitator DesignGLENDA CASINONo ratings yet

- 34 ST 25 35Document112 pages34 ST 25 35Arun GuptaNo ratings yet

- Sugar Storage in SilosDocument5 pagesSugar Storage in SilosArun GuptaNo ratings yet

- S. N Description QTY Mtrs Unit Price Rs Total Amount RsDocument1 pageS. N Description QTY Mtrs Unit Price Rs Total Amount RsArun GuptaNo ratings yet

- Digital Online TDS MeterDocument6 pagesDigital Online TDS MeterArun GuptaNo ratings yet

- Dehumid Prod ListDocument9 pagesDehumid Prod ListArun GuptaNo ratings yet

- Static Mixer DataDocument6 pagesStatic Mixer DataArun GuptaNo ratings yet

- Traffic Rules & Regulations For Two-Wheeler Riders: We Can Avoid Accidents by Following GuidelinesDocument1 pageTraffic Rules & Regulations For Two-Wheeler Riders: We Can Avoid Accidents by Following GuidelinesArun GuptaNo ratings yet

- RPM IndicatorDocument2 pagesRPM IndicatorArun GuptaNo ratings yet

- Rpm/Rate Indicator With Alarms: SpecificationsDocument2 pagesRpm/Rate Indicator With Alarms: SpecificationsArun GuptaNo ratings yet

- Blackouts in The US/Canada and Continental Europe in 2003: Is Liberalisation To Blame?Document7 pagesBlackouts in The US/Canada and Continental Europe in 2003: Is Liberalisation To Blame?Evans EjegiNo ratings yet

- Identifikasi Kegiatan Konservasi Di Sektor IndustriDocument98 pagesIdentifikasi Kegiatan Konservasi Di Sektor IndustriHera WahyuniNo ratings yet

- Effect of Dust Humidity and Air Velocity On Efficiency of Photovoltaic CellsDocument4 pagesEffect of Dust Humidity and Air Velocity On Efficiency of Photovoltaic CellsLomer AntoniaNo ratings yet

- STIRPAT ModelDocument29 pagesSTIRPAT ModelMohammadHas'sanNo ratings yet

- 1000V SG IEC Certificate 202401Document37 pages1000V SG IEC Certificate 202401thangbv.dnpcNo ratings yet

- ALTAIR05T-800: Off-Line All-Primary-Sensing Switching RegulatorDocument28 pagesALTAIR05T-800: Off-Line All-Primary-Sensing Switching RegulatorJosé M. Do PradoNo ratings yet

- 90-1074-03 (Pir9400)Document2 pages90-1074-03 (Pir9400)Donny FitradiNo ratings yet

- Distribution Transformers: Single-Phase OverheadDocument4 pagesDistribution Transformers: Single-Phase OverheadIttaq Qullaha ShabaraNo ratings yet

- Autonomous Communication ØrnulfDocument26 pagesAutonomous Communication ØrnulfZhiyong ShanNo ratings yet

- 01 Variable LoadDocument11 pages01 Variable LoadPaul CamuNo ratings yet

- Cisco CSR ReviewDocument4 pagesCisco CSR ReviewVikram JeetNo ratings yet

- Bladeless WindmillDocument22 pagesBladeless WindmillSudarsan reddyNo ratings yet

- Portable Gensets Honda ProductsDocument20 pagesPortable Gensets Honda ProductsRajan KumarNo ratings yet

- Research English 1Document8 pagesResearch English 1api-316930036No ratings yet

- Engine PDFDocument8 pagesEngine PDFEsam PhlipeNo ratings yet

- Green Engine 2 PDFDocument7 pagesGreen Engine 2 PDFharivardhanNo ratings yet

- V112-3.0 MW - VestasDocument20 pagesV112-3.0 MW - Vestasjamesr277272No ratings yet

- CIBSE LETI FAQ Rev1Document60 pagesCIBSE LETI FAQ Rev1zaidiamna9No ratings yet

- PPT - England PDFDocument48 pagesPPT - England PDF7esabat7033No ratings yet