Professional Documents

Culture Documents

Kralik Kralik Aspekty2010clanok

Uploaded by

sugyanibalaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kralik Kralik Aspekty2010clanok

Uploaded by

sugyanibalaCopyright:

Available Formats

Structural and Physical Aspects of Civil Engineering, 2010

Probabilistic assessment of the soil-foundation-machine dynamic

interaction

Juraj Krlik and Juraj Krlik, jr.

Slovak University of Technology Bratislava,

Faculty of Civil Engineering, Department of Structural Mechanics

Faculty of Architecture, Institute of Constructions in Architecture and Engineering Structures

e-mail: juraj.kralik@stuba.sk, juraj_kralik@stuba.sk

Abstract

This paper deals with the possibility of the probabilistic analysis of the reliability of the machine foundation

considering the soil-foundation-machine interaction. The requirements to design of the foundation under rotating

machines increased due to development of calculation method and computer tools. The advantages and

disadvantages of the deterministic and probabilistic analysis of the machine foundation resistance are discussed.

The sensitivity of the machine foundation to the uncertainties of the soil properties due to long-time rotating

movement of machine is not negligible for design engineers. The Response Surface Method (RSM) for the

analysis of the compressor foundation reliability was used on program ANSYS. The probabilistic analysis gives

us more complex information about the soil-foundation-machine interaction as the deterministic analysis.

Key words: soil-foundation-machine interaction, probability, sensitivity, ANSYS, FEM, RSM

Introduction

The vibration of the machines in the industrial enterprises impacts to the building structures

and technology as well as to the human comfort [2, 3, 5, 7, 9, 10 and 11]. The requirements to

design of the foundation under rotating machines increased in the last years. The Eurocodes

and national standard define much of these requirements [4, 7, 9 and 11]. The soil-foundation

and foundation-machine interaction are the principal problems what determine the effect of

the industry performance to the environs. The designers have to consider these effects in the

point of view of the safety, reliability and durability of the structures.

Behaviour of soil and structures depends on character and intensity of dynamic load. The

velocity of strain and stress intensity in the subsoil has important influences to the material

characteristics of the soil. Randomness in the loading and the environmental effects, the

variability of the material and geometric characteristics of structures and many other

-1-

Juraj Krlik and Juraj Krlik,jr.

"uncertainties" affecting errors in the computing model lead to a situation where the actual

behaviour of a structure is different from the modelled one [1, 6, 7 and 8].

During the structural design process, an engineer has to consider problems of the safety,

reliability and durability of machine foundations from the point of view of its planned life

cycle. Much attention should be paid to using the probabilistic approach in an analysis of the

reliability of structures [8]. Most problems concerning the reliability of building structures are

defined today as a comparison of two stochastic values, loading effects E and the resistance R,

depending on the variable material and geometric characteristics of the structural element.

The variability of those parameters is characterized by the corresponding functions of the

probability density fR(r) and fE(e). In the case of a deterministic approach to a design, the

deterministic (nominal) attributes of those parameters Rd and Ed are compared.

The deterministic definition of the reliability condition has the form

Rd Ed

(1)

and in the case of the probabilistic approach, it has the form

RF = R E 0

(2)

where RF is the reliability function, which can be expressed generally as a function of the

stochastic parameters X1, X2 to Xn, used in the calculation of R and E.

RF = g ( X 1 , X 2 ,..., X n )

(3)

The failure function g(X) represents the condition (reserve) of the reliability, which can either

be an explicit or implicit function of the stochastic parameters and can be single (defined on

one cross-section) or complex (defined on several cross-sections, e.g., on a complex finite

element model).

The most general form of the probabilistic reliability condition is given as follows:

(4)

p f = P ( R E < 0) P ( RF < 0) < pd

where pd is the so-called design (allowed or acceptable) value of the probability of

failure.

The reliability criteria are defined in the Eurocode in dependency on reliability index, what

is adequate to target level of failure probability (Table 1).

Table 1: Target reliability index and probability of failure by Eurocode 1990

Limit state

Target reliability index d

50 years

1 year

Ultimate

3,8 (pf 10-4)

4,7 (pf 10-6)

Fatigue

1,5-3,8*) (pf 10-110-4)

Serviceability

1,5 (pf 10-1)

3,0 (pf 10-3)

In the case of the stochastic approach, various forms of analyses (statistical analysis,

sensitivity analysis, probabilistic analysis) can be performed.

The reliability assessment criteria according to the reliability index were mentioned below.

Most well-known is the modified Monte Carlo method and Latin Hypercube Sampling (LHS)

simulations. The simulation methods on the base of Monte Carlo method are more

advantageous for the estimation of the failure probability. The probability of failure is

calculated as best estimation of the statistical parameters and theoretical model of the

probability distribution of the reliability function Z = g(X).

The probability of failure is defined as best estimation of the numerical simulations in the

form

-2-

Structural and Physical Aspects of Civil Engineering, 2010

1 N

(5)

I g ( X i ) 0

N i =1

where N is the simulation number, g(.) is the failure function, I[.] is the function with value

1, if the condition in the square bracket is fulfilled, otherwise is equal to 0.

The variation of this failure estimation can be described by Melcher in the form

2

1 N

1 1 N 2

2

s pf =

I g ( X i 0 ) I g ( X i 0 )

(6)

( N 1) N

i =1

N i =1

The various forms of analyses (statistical analysis, sensitivity analysis, probabilistic analysis)

can be performed. Most of these methods are based on the integration of Monte Carlo (MC)

simulations [8]. Three categories of methods have been presently realized:

Direct methods

(Importance Sampling - IS, Adaptive Sampling - AS,

Direct Sampling - DS)

Modified methods

(Conditional, Latin Hypercube Sampling - LHS)

Approximation methods (Response Surface Method - RSM)

pf =

A) The direct Monte Carlo Simulation (MCS) method is based on generation of sets of

realizations of the random variables in the limit state function (with the assumed known

probability distributions) and to record the number of times the resulting limit state function is

less than zero (i.e., failure). The estimate of the probability of failure (Pf) then is simply the

number of failures divided by the total number of simulations (N). Clearly, the accuracy of

this estimate increases as N increases, and a larger number of simulations are required to

reliably estimate smaller failure probabilities. The generation of random variables is a

relatively simple task (provided the random variables may be assumed independent) and

requires only (1) that the relevant CDF is invertible (or in the case of normal and lognormal

variants, numerical approximations exist for the inverse CDF), and (2) that a uniform random

number generator is available. The generation of correlated varieties is not described here, but

information may be found in the literature [8].

The accuracy of this method is depended on the number of the simulations and it is defined by

the variation coefficient

1

(7)

pf =

Np f

where N is the number of simulations. When the target probability of failure is pf = 10-4, thus

the variation factor is equal to 10% for the number of simulations N=106, what is acceptable.

Advantages of the method:

the final values of the reliability reserves can be continuously displayed in the form of

a histogram or cumulative function; the simulations are independent,

the method is easily understandable and transparent,

the method enables the estimation of the statistical discrepancy of the estimation on a

particular relevance level.

Drawbacks of the method:

large number of simulations for small probability values,

slow calculations of complex problems (for Finite Element Method models, the

calculations are expensive and ineffective).

-3-

Juraj Krlik and Juraj Krlik,jr.

B) The Modified LHS method is based on the simulations of the function g(X) so thus MC

method, but the definition domain of the distribution function (Xj) is divided to N intervals

with the identical probability 1/N. Characteristic values of the simulations as calculated

randomly on the base of the permutation integer number 1,2,...N. The reliability function g(X)

must be determined from the N simulation. The interval of the random simple is used one

time only. This method gives us the best estimation of the statistical parameters of the

structure in the comparison with MC method. The result of the LHS analysis is the parameter

of the failure function mean value Z , standard deviation z, skew coefficient z, kurtosis

coefficient ez, versus empirical cumulative distribution function.

C) Approximation methods - Response Surface Methods are based on the assumption that it

is possible to define the dependency between the variable input and the output data through

the approximation functions in the following form:

N

N 1 N

i =1

i =1

i =1 j >i

Y = co + ci X i + cii X i2 + cij X i X j

(8)

where co is the index of the constant member; ci are the indices of the linear member and cij

the indices of the quadratic member, which are given for predetermined schemes for the

optimal distribution of the variables or for using regression analysis after calculating the

response [8].

Approximate polynomial coefficients are given from the condition of the error minimum,

usually by the "Central Composite Design Sampling" (CCD) method or the "Box-Behnken

Matrix Sampling" (BBM) method.

Advantages of the method:

considerably less number of simulations than with the straight Monte Carlo method,

it is possible to define dependencies using the "design experiments" method or

regression analysis from the defined points in the case of improper approximation

functions,

particular simulations are independent from each other parallel calculations can be

used here.

Drawbacks of the method:

the number of simulations depends on the number of variable input parameters; in the

case of a large number of input parameters, the method is ineffective,

the method is unsuitable in the case of discontinuous changes in the dependencies

between the input and output values (e.g., the method is not suitable for resolving the

stability of ideal elasto-plastic materials beyond the failure limit...).

The ANSYS Program belongs among the complex programs for solving potential problems

[8]. It contains a postprocessor, which enables the execution of the probabilistic analysis of

structures. In Figure 3, the procedural diagram sequence is presented from the structure of the

model through the calculations, up to an evaluation of the probability of structural failure. The

postprocessor for the probabilistic design of structures enables the definition of random

variables using standard distribution functions (normal, lognormal, exponential, beta, gamma,

weibull, etc.), or externally (user-defined sampling) using other statistical programs. like

AntHILL or FReET. The probabilistic calculation procedures are based on Monte Carlo

simulations (DS, LHS, user-defined sampling) and "Response Surface Analysis Methods

(RSM)" (CCD, BBM, user-defined sampling). The statistical postprocessor compiles the

results numerically and graphically in the form of histograms and CDF.

-4-

Structural and Physical Aspects of Civil Engineering, 2010

Damping and stiffness soil characteristics

Dynamic soil characteristics can be determined from the refraction and reflex investigation of

the locality. The material characteristics of the soil are dependent on the shear and longitude

wave velocity. The wave velocities are measured between two bores for various levels under

free field. The shear velocity of the wave is calculated from the strain in the soil due to

experimental results or comparison with the similar type of soil.

The fundamental material parameter characteristic for the dynamic of soil [3] is dynamic

shear modulus Gdyn (versus Young elastic modulus Edyn)

v 2p 2v 2s

2

2

Gdyn = vs .,

(9)

Edyn = vs . .2 (1 + dyn ) ,

dyn =

2 ( v 2p v 2s )

where is density, vs shear velocity of the soil, vp is longitude velocity, vdyn dynamic

Poisson constant. The stiffness and damping characteristics of the soil depends on the ground

peak acceleration by Eurocode 8.

Dynamic soil modulus measured in situ is adequate for the small dynamic action. These

values are correct for the calculation of SSI in the case of machine foundation and small

seismic loads. The dynamic stiffness of the calculation model of the subsoil depends not only

on physical and mechanical properties of the soil but on the shape and depth of the foundation

[8 and 10] also.

Table 2: Ratio of the dynamic and static modulus [10]

Ground type

Incohesive ground

Cohesive ground

Rock

Edyn/Estat

2,54,0

4,010,0

6,060,0

Estat [MPa]

30-120

6-30

60-700

The dynamic response is other in the case of stiff and soft soil [2, 3, 5, 6, 9 and 10] due to

soil-foundation interaction effects. There are following aspects:

Soil move can affect the rotation of foundation about its horizontal axis,

First period of foundation under soft soil will be longer as in the case of stiff soil,

Eigenvalues and a participation factors will be different in the case of soft and stiff

soil,

No proportional damping is depend on the radial and reflex damping of soil under

foundation and different damping of foundation structure

The consideration of SSI effects is very important. The influence of stiffness and damping

characteristic of the soil to the structure are not negligible.

Optimal design of the machine foundation

From the point of view of Eurocode [4] the engineer-designer has take into account following

influences

Impact of machine vibration to structures

Impact of machine vibration to the people and operation (mechanic, acoustic, optic)

Impact of machine vibration to the technology (requirements of manufacturer)

On the base of the evaluation of all influences it is necessary to check following assessment:

-5-

Juraj Krlik and Juraj Krlik,jr.

Criterion of limit state design of structures,

Physiological criterion,

Functionality criterion,

The design forces and displacements are calculated using the harmonic response analysis of

the structures for normal and extreme operation. The maximum displacements and velocities

must be checked to the criterion of the standards STN 730032 and DIN 4024 (Table 3 and 4).

Table 3: Limit values of the machine vibration and the production facilities by STN 730032

Limit value for the frequency f

Sensitivity class

of the machine or

Characteristics

amax[mm.s-2]

vmax[mm.s-1]

equipment

f < 10Hz

f > 10Hz

I

High

6,3

0,1

II

Middle

63,0

1,0

II

Low

250,0

4,0

IV

None

>250.0

>4.0

Table 4: Limit values of the machine vibration and the production facilities by DIN4024

Limit value for the frequency f

Machine

vmax[mm.s-1]

umax[m]

performance

f > 10Hz

f < 10Hz

Normal

63

2,8

Initial

23

1,0

Design values of the displacements, velocities, accelerations and forces have be obtained from

the combination of the static and dynamic load for the normal and extreme machine

performance. The practical experiences prove the fact that the disregard of the soil machine

interaction effects can to cause the malfunction of the machine. The foundation shape

machine design has to respect the designing principles as follow:

The foundation masses must be higher than the machine device or equipment,

The eccentricity between the machine mass centre and the foundation contact area

centre have be less than 5% of the foundation dimension,

In the case of the vertical excitation forces the horizontal foundation dimension has be

lower than the vertical distance between the machine centre and contact area otherwise

in the case of the horizontal excitation forces the horizontal foundation dimension has

be higher,

The foundation dimensions ensure against its collapse, the stability of the foundation in

the rotation has be guarantee,

The optimal design of the machine foundation pursues the minimization of the dynamic

effects of the machine to the structure. This task can be achieved to respect following

requirements:

To change the frequency tuning of the structure (to change the ratio between the impact

and structure frequencies) by changing the stiffness, masses of the system, etc.

To change the localisation of the structure and equipment or the dynamical effect of this

system,

To reduce the effect of the excitation forces,

To improve the stiffness and damping characteristics of the subsoil,

To design the efficiency damping system between the machine and foundation,

-6-

Structural and Physical Aspects of Civil Engineering, 2010

Table 5: Recommended natural frequency of the machine foundation

important

less important

low-frequency

Machine

Natural

frequency

f p / f n < 0.5 or 2 < f p / f n

f p / f n < 0 .6 or 1 .5 < f p / f n

3 < f p / fn

The efficiency of the dynamic characteristics of the machine foundation can be improved by

avoid the resonance effects. The recommended ratio of the natural frequency of the structure

fn and the frequency of the machine fp are presented in Table 5.

Model of compressor foundation

The analysis of the soil-foundation-machine interaction was realized on the case of

compressor foundation type 13K401 fy. DEMAG DELAVAL using in the building

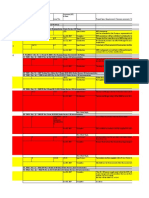

RAYTHEON Slovnaft Bratislava (Figure 1).

Figure 1: Scheme of compressor 13K401 and foundation FEM model

Compressor 13K401 (with total masses 5,8t) and turbine GK 22/28 fy. SIEMENS AG (with

total masses 7,5t and pipe system 22t) is put on the reinforced concrete foundation in the form

of invert table on the level +6,52m. This structure consists the foundation plate (with

dimension 5000x8250x1000mm) on level -1,45m, four columns

(with dimension

400x400x5875mm) and horizontal reinforced concrete frame, resp. plate (with dimension

3050x7250x800mm) on level +6,52m. The mass of foundation frame is 192,44t. The subsoil

consist the gravel. The material properties were taken from the geophysical test in this

locality. We considered three FEM models Z4L, Z4M and Z4H (with various soil models low, medium and high). FEM model consist 888 elements (shell, solid, beam) and 1001

nodes.

Table 6: Comparison of foundation principal frequencies

Model

Foundation

Soil

13K401L

13K401M

13K401H

Low

Medium

High

Direction X

Direction Y

Direction Z

Frequency Prop. ratio Frequency Prop. ratio Frequency Prop. ratio

[Hz]

[Hz]

[Hz]

[%]

[%]

[%]

15,02

48,9

12,06

53,9

14,66

65,8

18,18

51,7

14,69

55,1

16,47

54,8

22,04

52,5

17,91

55,4

17,78

41,8

-7-

Juraj Krlik and Juraj Krlik,jr.

On the base of measured data three soil models low, medium and high were incorporated in

the FEM model (Table 6). The stiffness of soil has the considerable influence to the modal

characteristic and the eigenvalues of entire structure (Figure 2).

Figure 2: Dominant horizontal and vertical modes of compressor foundation 13K401

The dynamic loads were defined by intensity of forces in the point of anchor and rotation

velocity. In the case of normal operation the velocity of turbine (resp. compressor) rotor is

equal to 12500 r.p.m (resp. 10998 r.p.m) and for extreme condition the velocity of turbine

(resp. compressor) rotor were defined by manufacturer as 4700 r.p.m (resp. 17200 r.p.m).

Uncertainties of input variables

The effect of soil-structure interaction can be investigated in the case of probabilistic

assessment by sensitivity analysis of the influence of variable properties of soil [8]. Soil

stiffness variability in the vertical direction is defined by the characteristic stiffness value kz

from the geological measurement [1] and the variable factor kz.var. The random distribution of

the soil stiffness under foundation plate is approximated with bilinear function on the slab

plane in dependency on three parameters kz.var, kxx.var, kyy.var

( x xo ) k

( y yo ) k

k ( x, y ) = k z.var + 2

(10)

yy.var + 2

xx.var k z ,k

Lx

Ly

where kz.k is a characteristic value of soil stiffness xo, yo are coordinates of foundation

structure gravity centre, Lx and Ly are the plane dimensions of the slabs in directions x and y.

The variability of geometric characteristics is defined with h.var (column dimension), d1.var

(foundation plate thickness), d2.var (compressor plate thickness). The stiffness of the structure

is determined with the characteristic value of Youngs modulus Ek and variable factor evar.

A load is taken with characteristic values Gk, Fk, Fr.k and variable factors gvar, fvar and fr.var

(Table 7). The uncertainties of the calculation model are considered by variable model factor

R and variable load factor E for Gausss normal distribution. The results of the probability

analysis of the foundation model present that the principal frequencies are variable in the

direction X (from 4,32HZ to 6,37Hz), Y (from 13,05HZ to 17,61Hz) and Z (from 16,84HZ to

21,68Hz). These frequency intervals have the important influence to response from the

harmonic compressor excitation.

-8-

Structural and Physical Aspects of Civil Engineering, 2010

Name

Soil

Material

Load

Geometric

Model

Table 7: Probabilistic model of input parameters

Quantity

Charact. Variable Histogram Mean Standard

value

paramet.

deviation

Stiffness

kz,k

kz_var

Uniform

1,085

0,240

kxx,k

kxx var

Uniform

0

0,580

kyy,k

kyy var

Uniform

0

0,580

Youngs modulus

Ek

e_var

Lognormal

1

0,050

Dead

Gk

g_var

Normal

1

0,100

Live amplitude

Fk

f_var

Lognormal

1

0,100

- frequency

Frk

fr_var

Normal

1

0,100

Height

hk

h_var

Normal

1

0,050

Thickness

d1k

d1_var

Normal

1

0,010

d2k

d2_var

Normal

1

0,010

Model uncertainties

Te_var

Normal

1

0,100

E

Resistance uncert.

Tr_var

Normal

1

0,100

R

Min.

value

0,67

-1

-1

0,868

0,719

0,752

0,719

0,860

0,972

0,972

0,719

0,719

Max.

value

1,5

1

1

1,149

1,281

1,317

1,281

1,140

1,028

1,028

1,281

1,281

Reliability criteria for seismic resistance of structure

Reliability of the foundation structures is analyzed in accordance of national and Eurocode

standard requirements [3 and 8] for ultimate and serviceability limit state. Horizontal

reinforced plane structures are designed on the bending and shear loads for ultimate limit state

function (3) in the next form

g ( M ) = 1 M E M R 0 , g (V ) = 1 VE VR 0 , g ( N ) = 1 N E N R 0

(11)

where ME, VE, NE are the design bending moment, shear and normal forces of the action and

MR, VR, NR are the resistance bending moment, resistance shear and normal forces of the

structure element. The failure function of the amplitude of horizontal displacement u and

velocity v is defined in the form

g (u ) = 1 uE uR 0 ,

g ( v ) = 1 vE vR 0

(12)

where uE, vE are maximum amplitude of displacement and velocity from action and uR, vR are

limit displacement and velocity (Figure 3).

Figure 3: Reliability density function of horizontal and vertical velocity

-9-

Juraj Krlik and Juraj Krlik,jr.

Sensitivity analysis

Sensitivity analysis of the influence of the variable input parameters to the reliability of the

structures depends on the statistical independency between input and output parameters.

Matrix of correlation coefficients of the input and output parameters is defined by Spearman

in the form [8]

n

rs =

( Ri R ) ( Si S )

i =1

( Ri R ) ( Si S )

2

i =1

(13)

2

i =1

where Ri is rank of input parameters within the set of observations [xi]T, Si is rank of output

parameters within the set of observations [yi]T, R, S are average ranks of the parameters Ri

and Si respectively.

Figure 4: Sensitivity analysis of the horizontal and vertical displacement of foundation

The results of the sensitivity analysis of the vertical displacement of the compressor

foundation are presented in the Figure 4.

Figure 5: Sensitivity analysis of the vertical displacement for normal and extreme

performance

- 10 -

Structural and Physical Aspects of Civil Engineering, 2010

Variability of three input quantities (velocity of the turbine rotor, load amplitudes, foundation

mass and stiffness) is important to the displacement of compressor foundation (Figure 4) due

to normal performance of rotor. The frequency of rotor movement is lower in the case of

extreme performance than the normal performance. It is the reason of the higher sensitivity of

foundation to the variability of the model input parameters. The sensitivity of the vertical

displacement over the compressor operation frequencies is demonstrated in the Figure 5a for

normal performance and in the Figure 5b for the extreme performance. The horizontal

displacements of the compressor foundation are higher for the lower frequency as 5Hz. In the

case of vertical displacements their peaks are about the frequency 15Hz for both performances

normal and extreme (Figure 5).

Comparison of deterministic and probabilistic analyses

The comparison of deterministic and probabilistic solution of the safety and reliability of the

compressor foundation is documented in the table 8.

Table 8: Comparison of deterministic and probabilistic analyses

Method

Deterministic

Probabilistic

Deterministic

Probabilistic

Deterministic

Probabilistic

Deterministic

Probabilistic

Deterministic

Probabilistic

Deterministic

Probabilistic

Model

Z4L

Z4M

Z4H

Z4L

Z4M

Z4H

Maximum displacement amplitude [mm] Maximum velocity amplit.[mm/s]

St.dev

St.dev

P0.05

P0.95

P0.50

P0.05

P0.95

P0.50

Normal operation of turbine and compressor

0.09220

1.08290

0.06113 0.18119 0.12110 0.03651 0.56067 1.69163 1.12545 0.34365

0.07874

1.68280

0.05685 0.11783 0.08719 0.01855 0.67532 2.59868 1.63442 0.58289

0.07357

1.49000

0.05425 0.10153 0.07767 0.01439 1.32758 1.90912 1.60778 0.17649

Extreme operation of turbine and compressor

Maximum normal force [kN]

Maximum bending moment[kNm]

215.18

258.50

180.30

256.90

218.47

23.27

216.50 308.85 262.62

28.05

213.72

256.67

179.30

250.42

214.77

21.62

215.54 300.49 257.95

25.79

213.16

255.94

178.74

248.77

213.69

21.26

215.00 298.28 256.58

24.27

The differences between deterministic and probabilistic results are equal about to 5-33% (or

50-100%) for mean (or maximum) displacement amplitude values. In the case of normal

forces and bending moment these differences are lower.

Conclusion

This paper deals with the possibility of the sensitivity and probabilistic analysis of the

reliability of the compressor foundation depending on variability of the soil stiffness, structure

geometry and machine operation. The sensitivity of the machine foundation to the

uncertainties of the soil properties due to long-time rotating movement of machine is not

negligible for design engineers. On the example of compressor foundation 13K401 and

- 11 -

Juraj Krlik and Juraj Krlik,jr.

turbine GK22/28 fy. SIEMENS AG the affectivity of the probabilistic design methodology

was presented. The simulation method RSM for the analysis of the compressor foundation

reliability was used on program ANSYS. The 151 simulations for five load cases were

calculated in the real time on PC (CPU=626sec). The probabilistic analysis gives us more

complex information about the soil-foundation-machine interaction than the deterministic

analysis.

Acknowledgements

This project was realized with the financial support of the Grant Agency of the Slovak

Republic (VEGA 1/0849/08).

References

[1]

Baecher,G.B. and Ingra,T.S. , Stochastic FEM in Settlement Prediction, J. of the

Geotechnical Engineering Division, ASCE, Vol. 107, No. GT4, pp. 451-463, 1981.

[2]

Braka,M. Kala,J. Salajka,V. Studie vlivu modelovn podzklad na provozn

dynamiku kompresoru, lnek v Sbornk vdeckch prac Vysok koly bsk TU

Ostrava, ISSN 1213-1962, TU Ostrava, 2008.

[3]

Gazetas,G., Foundation vibrations, Foundation Engineering Handbook, (H.Y. Fang,

editor), Van Nostrand Reinhold, New York, 1991.

[4]

Handbook 2, Implementation of Eurocodes Reliability Backgrounds. Guide of the basis

of structural reliability and risk engineering related to Eurocodes. Development of

Skills Facilitating Implementatio of Eurocodes. Leonardo Da Vinci Pilot Project

CZ/02/B/F/PP-134007. Prague, CR, 2005.

[5]

Kotrasov,K. Kormankov,E. The Ground Plate on the Winkler Foundation. In:

Modelovn v mechanice, VB TU Ostrava, 19-20.mj 2009, pp. 65-67, ISBN 978-80248-1705-7. Full Text in CD, Ostrava, 2009.

[6]

Krlik,J. Krlik,J.,jr. Probability and Sensitivity Analysis of Soil-Structure Interaction

of High-Rise Buildings, Slovak Journal of Civil Engineering, Slovak University of

Technology Bratislava, vol. 2006/3, pp.18-32, Bratislava, 2006.

[7]

Krlik,J. Krlik,J.,jr., Probability and Sensitivity Analysis of Machine Foundation and

Soil Interaction. Applied and Computational Mechanics. ZCU Plzen. ISSN 1802-680X,

2009, Vol.3, No.1.

[8]

Krlik,J., Reliability Analysis of Structures Using Stochastic Finite Element Method,

Published by STU Bratislava, 2009, 143pp. ISBN 978-80-227-3130-0.

[9]

Makovika,D., Vpoet stavebnch konstrukc zatench dynamickmi inky stroj.

Koment k SN 730032. NM Praha, 1980.

[10] Richart,F.E.,Jr., Hall,S.R. and Woods,R.D. Vibrations of Soils and Foundations,

Prentice-Hall, Inc., 1970.

[11] STN 73 0032, Vpoet stavebnch konstrukc zatench dynamickmi inky stroj.

NM Praha 1977.

- 12 -

You might also like

- Stochastic Analysis of Historical Masonry StructuresDocument8 pagesStochastic Analysis of Historical Masonry StructuresAlexis LopezNo ratings yet

- Probability and Sensitivity Analysis of Machine Foundation and Soil InteractionDocument14 pagesProbability and Sensitivity Analysis of Machine Foundation and Soil InteractionsugyanibalaNo ratings yet

- Structural Reliability Analysis Using Doproc Method: SciencedirectDocument8 pagesStructural Reliability Analysis Using Doproc Method: SciencedirectChinmayi MohanNo ratings yet

- Reliability Analysis of Structures Under Seismic LoadingDocument10 pagesReliability Analysis of Structures Under Seismic LoadingRega SaputraNo ratings yet

- Reliability Analysis of A Finite Slope Considering The Effects of Soil UncertaintyDocument11 pagesReliability Analysis of A Finite Slope Considering The Effects of Soil UncertaintysauravkarNo ratings yet

- Reliability Analysis of Large Structural SystemsDocument5 pagesReliability Analysis of Large Structural Systemsuamiranda3518No ratings yet

- Retaining WallDocument15 pagesRetaining WallMarija DojcinovskaNo ratings yet

- Probabilistic Safety Analysis under Random and Fuzzy ParametersDocument54 pagesProbabilistic Safety Analysis under Random and Fuzzy ParametersSEULI SAMNo ratings yet

- C 20 Daffas Zevgolis 2017 RomeDocument2 pagesC 20 Daffas Zevgolis 2017 RomeyzevgolisNo ratings yet

- ACTA Mechanica-2012Document18 pagesACTA Mechanica-2012wzhang8No ratings yet

- Inherent Variability of An Experimental Crack Growth Curve: F. Casciati, P. Colombi, L. FaravelliDocument11 pagesInherent Variability of An Experimental Crack Growth Curve: F. Casciati, P. Colombi, L. FaravelliOmar AbdelAzizNo ratings yet

- 14 - 09 01 0141 PDFDocument6 pages14 - 09 01 0141 PDFJuan Carlos Tasilla VillanuevaNo ratings yet

- Levels of Reliability MethodsDocument27 pagesLevels of Reliability MethodsManuel CampidelliNo ratings yet

- Comparison of Probability Based Design and Eurocode 7 in Slope Stability AnalysisDocument8 pagesComparison of Probability Based Design and Eurocode 7 in Slope Stability AnalysisLaidon ZekajNo ratings yet

- Fuzzy Randomness - Towards A New Modeling of Uncertainty: Bernd Möller, Wolfgang Graf, Michael Beer and Jan-Uwe SickertDocument10 pagesFuzzy Randomness - Towards A New Modeling of Uncertainty: Bernd Möller, Wolfgang Graf, Michael Beer and Jan-Uwe SickertRajib BeheraNo ratings yet

- Chok 2016Document14 pagesChok 2016Nipa BiswasNo ratings yet

- 3D Petrophysical Modeling Using Complex Seismic Attributes and Limited Well Log DataDocument5 pages3D Petrophysical Modeling Using Complex Seismic Attributes and Limited Well Log DataMehdl EftekharlNo ratings yet

- Risk and Reliability Analysis of Slope Stability-Deterministic and Probabilistic MethodDocument4 pagesRisk and Reliability Analysis of Slope Stability-Deterministic and Probabilistic MethodZola1stNo ratings yet

- Olma 2021Document56 pagesOlma 2021KarimaNo ratings yet

- Wind Turbines, EurocodeDocument9 pagesWind Turbines, EurocodeIvan JovanovicNo ratings yet

- Response Surface Augmented Moment Method For EfficientDocument12 pagesResponse Surface Augmented Moment Method For EfficientJa VaNo ratings yet

- Effects of Missing Observations On Predictive Capability of Central Composite DesignsDocument18 pagesEffects of Missing Observations On Predictive Capability of Central Composite DesignsAnonymous lVQ83F8mCNo ratings yet

- VS LA GeocongressDocument9 pagesVS LA GeocongressHari Dwi WahyudiNo ratings yet

- Structural Damage Identification from Static Test Data Using Sensitivity AnalysisDocument12 pagesStructural Damage Identification from Static Test Data Using Sensitivity Analysisdban1965No ratings yet

- 2015-Effect of 2-D Random Field Discretization On Failure Probability and Failure Mechanism in Probabilistic Slope Stability (Model For Sentence)Document11 pages2015-Effect of 2-D Random Field Discretization On Failure Probability and Failure Mechanism in Probabilistic Slope Stability (Model For Sentence)Ibnu RiswanNo ratings yet

- A Practical Reliability-Based Method For Assessing Soil Liquefaction PotentialDocument31 pagesA Practical Reliability-Based Method For Assessing Soil Liquefaction PotentialPendamping Kecamatan Wakorumba UtaraNo ratings yet

- Automotive CAE Durability Analysis Using Random Vibration ApproachDocument16 pagesAutomotive CAE Durability Analysis Using Random Vibration ApproachThiago PalmieriNo ratings yet

- Materials: Fatigue Reliability Analysis of A Compressor Disk Based On Probability Cumulative Damage CriterionDocument15 pagesMaterials: Fatigue Reliability Analysis of A Compressor Disk Based On Probability Cumulative Damage CriterionHarshitNo ratings yet

- Finite Element and Probabilistic Analysis For Simple Truss BridgeDocument13 pagesFinite Element and Probabilistic Analysis For Simple Truss BridgeMoza Make UPNo ratings yet

- Keywords Ključne Reči: Radetomic@ppt - Co.rsDocument6 pagesKeywords Ključne Reči: Radetomic@ppt - Co.rsmedica101No ratings yet

- Polidoro, Ghosh, TanDocument10 pagesPolidoro, Ghosh, TanLuisGarciaNo ratings yet

- OMAE2012-83586: Safety Factors For Fatigue Analysis of Flexible Pipes Based On Structural ReliabilityDocument6 pagesOMAE2012-83586: Safety Factors For Fatigue Analysis of Flexible Pipes Based On Structural ReliabilityBruno ChagasNo ratings yet

- Probabilistic Stochastic Graphical Models With Improved TechniquesDocument14 pagesProbabilistic Stochastic Graphical Models With Improved TechniquesAJER JOURNALNo ratings yet

- An Investigation of The Effect of Shot Peening On The Properties of Lm25 Aluminium Alloy and Statistical ModellingDocument11 pagesAn Investigation of The Effect of Shot Peening On The Properties of Lm25 Aluminium Alloy and Statistical ModellingInternational Journal of computational Engineering research (IJCER)No ratings yet

- Catovic-Paper NTREM2009Document18 pagesCatovic-Paper NTREM2009Daniel RiosNo ratings yet

- Shinozuka (1983) Basic Analysis of Structural SafetyDocument20 pagesShinozuka (1983) Basic Analysis of Structural SafetyFlavia GelattiNo ratings yet

- Road Accidents Forecasting Model Using Multi-Level Recursive MethodDocument7 pagesRoad Accidents Forecasting Model Using Multi-Level Recursive MethodAbhishek JainNo ratings yet

- A New Sensitivity and Reliability Analysis Framework For Structural and Geotechnical SystemsDocument8 pagesA New Sensitivity and Reliability Analysis Framework For Structural and Geotechnical SystemsaminNo ratings yet

- Working Papers in Economics and Statistics: University of InnsbruckDocument21 pagesWorking Papers in Economics and Statistics: University of InnsbruckdeforlfNo ratings yet

- Ijeet: International Journal of Electrical Engineering & Technology (Ijeet)Document7 pagesIjeet: International Journal of Electrical Engineering & Technology (Ijeet)IAEME PublicationNo ratings yet

- Methods of ReliabilityDocument26 pagesMethods of ReliabilityNISHANT ROYNo ratings yet

- Reliability Based Structural Design: Ton VrouwenvelderDocument9 pagesReliability Based Structural Design: Ton VrouwenvelderFlávio LasmarNo ratings yet

- Wen-Jing ZHANG, Li-Mao ZHANG, Xian-Guo WU and Yang LIUDocument6 pagesWen-Jing ZHANG, Li-Mao ZHANG, Xian-Guo WU and Yang LIUShafie ZubierNo ratings yet

- 1978 - Jelínek-Kropáček1978 Article StatisticalProcessingOfAnisotrDocument13 pages1978 - Jelínek-Kropáček1978 Article StatisticalProcessingOfAnisotrluis velderrain RojasNo ratings yet

- Efficient Ontology Meta-Matching Using Alignment Prescreening Approach and Gaussian Random Field Model Assisted NSGA-IIDocument7 pagesEfficient Ontology Meta-Matching Using Alignment Prescreening Approach and Gaussian Random Field Model Assisted NSGA-IIAnonymous zSAmVM9WdNo ratings yet

- Journal of Statistical SoftwareDocument25 pagesJournal of Statistical Softwarecarles1972mmNo ratings yet

- 06 Chapter 7Document46 pages06 Chapter 7anderson marcosNo ratings yet

- TH13 25 (Rev)Document15 pagesTH13 25 (Rev)Pratishtha MishraNo ratings yet

- The Basics of Probabilistic Internal Stability Analysis and Design of Reinforced Soil Walls ExplainedDocument8 pagesThe Basics of Probabilistic Internal Stability Analysis and Design of Reinforced Soil Walls ExplainedxfvgNo ratings yet

- Fuzzy Finite Element MethodDocument14 pagesFuzzy Finite Element Methodamitu2bmineNo ratings yet

- Sensitivity Based Damage Detection Algorithm For Structures Using Vibration DataDocument15 pagesSensitivity Based Damage Detection Algorithm For Structures Using Vibration DataJH YNo ratings yet

- Robust Nonlinear Model Predictive Control With Reduction of Uncertainty Via Robust Optimal Experiment DesignDocument6 pagesRobust Nonlinear Model Predictive Control With Reduction of Uncertainty Via Robust Optimal Experiment DesignMarcelo LucasNo ratings yet

- Mass Volume CurveDocument29 pagesMass Volume CurveDeepakGujraniyaNo ratings yet

- Reliability Engineering and System Safety: SciencedirectDocument15 pagesReliability Engineering and System Safety: SciencedirectErik GunawanNo ratings yet

- (2018) Four Types of Dependencies For The Fuzzy AnalysisDocument12 pages(2018) Four Types of Dependencies For The Fuzzy AnalysisSyahiir KamilNo ratings yet

- Modified Moment Estimation For A Two Parameter Gamma DistributionDocument9 pagesModified Moment Estimation For A Two Parameter Gamma DistributionInternational Organization of Scientific Research (IOSR)No ratings yet

- Geostatistical Simulations of Geothermal Reservoirs: Two-And Multiple-Point Statistic ModelsDocument13 pagesGeostatistical Simulations of Geothermal Reservoirs: Two-And Multiple-Point Statistic ModelsIoannis KapageridisNo ratings yet

- BVM Lecure at VV Nagar On 26-5-2016Document407 pagesBVM Lecure at VV Nagar On 26-5-2016sugyanibalaNo ratings yet

- TheDocument1 pageThesugyanibalaNo ratings yet

- Trivia On SpiritualityDocument39 pagesTrivia On SpiritualitysugyanibalaNo ratings yet

- Comment (N°) & Date - Project Spec. Requirement / Siemens Comment / Client ReplyDocument33 pagesComment (N°) & Date - Project Spec. Requirement / Siemens Comment / Client ReplysugyanibalaNo ratings yet

- Research 1Document81 pagesResearch 1sugyanibalaNo ratings yet

- Selection of Research Topic: Dr. Atul K. DesaiDocument81 pagesSelection of Research Topic: Dr. Atul K. DesaisugyanibalaNo ratings yet

- Microsoft PowerPoint - GEP2013 - Offshore - 02Document28 pagesMicrosoft PowerPoint - GEP2013 - Offshore - 02sugyanibalaNo ratings yet

- Performance of Precast Driven Piles in Marine ClayDocument21 pagesPerformance of Precast Driven Piles in Marine ClaysugyanibalaNo ratings yet

- Guidelines For SpreadsheetsDocument1 pageGuidelines For SpreadsheetsHans Hans SadzNo ratings yet

- Performance of Test Embankment Constructed To Failure On Soft Marine ClayDocument22 pagesPerformance of Test Embankment Constructed To Failure On Soft Marine ClaysugyanibalaNo ratings yet

- Marine 2Document8 pagesMarine 2sugyanibalaNo ratings yet

- Das, Braja M. - Geotechnical Engineering Handbook-J. Ross Publishing, Inc. (2011) PDFDocument508 pagesDas, Braja M. - Geotechnical Engineering Handbook-J. Ross Publishing, Inc. (2011) PDFsugyanibalaNo ratings yet

- Ocean Engineering: M.M. Stickle, P. de La Fuente, C. Oteo, M. Pastor, P. DuttoDocument13 pagesOcean Engineering: M.M. Stickle, P. de La Fuente, C. Oteo, M. Pastor, P. DuttosugyanibalaNo ratings yet

- Marine DataDocument8 pagesMarine DatasugyanibalaNo ratings yet

- Accelerated Testing of Cement Treated Singapore Marine Clay Cured Under Elevated TemperatureDocument10 pagesAccelerated Testing of Cement Treated Singapore Marine Clay Cured Under Elevated TemperaturesugyanibalaNo ratings yet

- Ocean Engineering: M.M. Stickle, P. de La Fuente, C. Oteo, M. Pastor, P. DuttoDocument13 pagesOcean Engineering: M.M. Stickle, P. de La Fuente, C. Oteo, M. Pastor, P. DuttosugyanibalaNo ratings yet

- Beginner's Guide to Programming FISH in FLAC 3DDocument14 pagesBeginner's Guide to Programming FISH in FLAC 3DsugyanibalaNo ratings yet

- Alkali-Activated Ground-Granulated Blast Furnace Slag For Stabilization of Marine Soft Clay PDFDocument7 pagesAlkali-Activated Ground-Granulated Blast Furnace Slag For Stabilization of Marine Soft Clay PDFsugyanibalaNo ratings yet

- A PDFDocument1 pageA PDFsugyanibalaNo ratings yet

- Device That Is Used To Control The Speed of An AC Motor by Varying The Frequency of The Voltage Supplied To It. These Are Also Known As AdjustablDocument1 pageDevice That Is Used To Control The Speed of An AC Motor by Varying The Frequency of The Voltage Supplied To It. These Are Also Known As AdjustablsugyanibalaNo ratings yet

- Computers and Geotechnics: H. Elsafti, H. OumeraciDocument25 pagesComputers and Geotechnics: H. Elsafti, H. OumeracisugyanibalaNo ratings yet

- Flac 3D 2Document2 pagesFlac 3D 2Robert AguedoNo ratings yet

- Lec 13Document24 pagesLec 13sugyanibalaNo ratings yet

- HTTPS://WWW Google Com/search?q Suction+pile+foundation+ppt&tbm Isch&source Univ&sa X&ved 2ahUKEwil1dufouLjAhUWinAKHZoMBUsQsAR6BAgHEAE#Document118 pagesHTTPS://WWW Google Com/search?q Suction+pile+foundation+ppt&tbm Isch&source Univ&sa X&ved 2ahUKEwil1dufouLjAhUWinAKHZoMBUsQsAR6BAgHEAE#sugyanibalaNo ratings yet

- FLAC 3D IntroductionDocument18 pagesFLAC 3D IntroductionsugyanibalaNo ratings yet

- Energy Piles: Current State of Knowledge and Design ChallengesDocument17 pagesEnergy Piles: Current State of Knowledge and Design ChallengessugyanibalaNo ratings yet

- CE 632 Bearing Capacity PDFDocument48 pagesCE 632 Bearing Capacity PDFNoel Malinao CablindaNo ratings yet

- Flac 3D 2Document2 pagesFlac 3D 2Robert AguedoNo ratings yet

- FLAC 3D IntroductionDocument18 pagesFLAC 3D IntroductionsugyanibalaNo ratings yet

- ContenidosDocument5 pagesContenidosWALKER DANILONo ratings yet

- Material Safety Data Sheet: Chemtherm 550Document6 pagesMaterial Safety Data Sheet: Chemtherm 550Javier vaca villalbaNo ratings yet

- A Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiDocument7 pagesA Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiShabir AhmadNo ratings yet

- 88 Dean StreetDocument36 pages88 Dean StreetPatrick BatyNo ratings yet

- Shangqiu Jinpeng Industrial Co., LTD.: Widely Used Waste Rubber Pyrolysis Equipment (XY-7)Document2 pagesShangqiu Jinpeng Industrial Co., LTD.: Widely Used Waste Rubber Pyrolysis Equipment (XY-7)Salma FarooqNo ratings yet

- SilverDocument16 pagesSilversharma_shruti0% (1)

- PAForge D20 Weapons CompendiumDocument29 pagesPAForge D20 Weapons Compendiumdjbonefish100% (1)

- How To Attract Love and Powerful Soul ConnectionsDocument5 pagesHow To Attract Love and Powerful Soul Connectionskinzaali71916No ratings yet

- Iodine Summaryupdate 2016Document26 pagesIodine Summaryupdate 2016FrankNo ratings yet

- FV10 Excel Flux Tutorial en 2Document36 pagesFV10 Excel Flux Tutorial en 2Ahcene BouzidaNo ratings yet

- Entry-Exit Arrangement With Service RoadDocument1 pageEntry-Exit Arrangement With Service RoadRamBhuvan SonkarNo ratings yet

- Air Sentry - Energy Statement App 3 Dessicant and Filters PDFDocument20 pagesAir Sentry - Energy Statement App 3 Dessicant and Filters PDFEsteban Fernando Meza IbacetaNo ratings yet

- TCB E-F 015cukDocument2 pagesTCB E-F 015cukTempcoNo ratings yet

- of The Blessedness of God.Document3 pagesof The Blessedness of God.itisme_angelaNo ratings yet

- Line Pack Presentation - Dec 2018Document7 pagesLine Pack Presentation - Dec 2018Goran JakupovićNo ratings yet

- Fundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisDocument14 pagesFundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisPYDNo ratings yet

- Regulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixDocument10 pagesRegulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixAnonymous 7gJ9alpNo ratings yet

- High Pressure Processing For Preservation of FoodsDocument36 pagesHigh Pressure Processing For Preservation of FoodsPravin Zine PatilNo ratings yet

- SaponificationDocument2 pagesSaponificationK.SaravananNo ratings yet

- Determining The Thickness of Glass in Airport Traffic Control Tower CabsDocument17 pagesDetermining The Thickness of Glass in Airport Traffic Control Tower CabsAdán Cogley CantoNo ratings yet

- Engineering Statics FundamentalsDocument28 pagesEngineering Statics FundamentalsurwaNo ratings yet

- Maximizing Area and Minimizing Costs with CalculusDocument18 pagesMaximizing Area and Minimizing Costs with Calculusanon_218576188No ratings yet

- Rainas, Lamjung: Office of Rainas MunicipalityDocument5 pagesRainas, Lamjung: Office of Rainas MunicipalityLakshman KhanalNo ratings yet

- CFD Answer KeyDocument12 pagesCFD Answer KeyRaahini IzanaNo ratings yet

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Whirlpool - Service Information Frontloader Washing Machine AWO/D 43115Document53 pagesWhirlpool - Service Information Frontloader Washing Machine AWO/D 43115amandialopes50% (2)

- Rotating Sharp Shooting Multi Target Mechanism Improves Military AimDocument13 pagesRotating Sharp Shooting Multi Target Mechanism Improves Military AimVishal GNo ratings yet

- Al-Imam Al-Kadhum College For Islamic Science Department: Computer Eng. 1 Stage Electrical M.SC. Worod Adris ShutnanDocument38 pagesAl-Imam Al-Kadhum College For Islamic Science Department: Computer Eng. 1 Stage Electrical M.SC. Worod Adris ShutnanMêly CrêâzyGîrlNo ratings yet

- Fundamental aim training routines and benchmarksDocument8 pagesFundamental aim training routines and benchmarksAchilles SeventySevenNo ratings yet

- Singaporean Notices To Mariners: Section ContentDocument35 pagesSingaporean Notices To Mariners: Section ContentGaurav SoodNo ratings yet

- Ic M802 UDocument79 pagesIc M802 Uharis_fikriNo ratings yet