Professional Documents

Culture Documents

157 408 1 SM

Uploaded by

Minh Le VuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

157 408 1 SM

Uploaded by

Minh Le VuCopyright:

Available Formats

ISSN 2321 9149

Research Article

IJAEES (2013) Vol.1, No.2, 25-37

International Journal of Advancement in Earth and Environmental Sciences

A STATISTICAL STUDY OF THE EVOLUTION OF

THE MANAGEMENT OF OLIVE MILL

WASTEWATER (OMWW) IN SFAX REGION,

TUNISIA, USING PRINCIPAL COMPONENT

ANALYSIS

Houda SahnounI*, Mohamed Moncef SerbajiII, Boubaker KarrayIII , Khaled MedhioubIV

I*

Faculty of sciences, Sfax, Tunisia (Unit of scientific research: Study and management of urban and coastal environments). Off ice de la topographie

et de la cartographie. Rue du Commandant Bjaoui, 3000 Sfax, Tunisie Tel : 00 216 25 217 555 (houdaenis@yahoo.fr)

II

National Engineering School, Sfax, Tunisia (Unit of scientific research: Study and management of urban and coastal environme nts).

III

Institution of Agricultural Research and Higher Education, Tunisia.

IV

Preparatory Engineering Institute, Sfax, Tunisia (Unit of scientific research: Study and management of urban and coastal environments).

---------------------------------------------------------------------------------------------------------------------------------------------ABSTRACT: Two investigations were carried out with oleifactors of Sfax region during the seasons 2003 - 04 and 2005 06. Their objectives were the exhaustive geo-referencing of the oil mills and the OMWW tanks and the creation of a

database by using Geographical Information Systems (GIS). To have an idea about the different mechanisms of OMWW

management in Sfax and their evolution between the two study campaigns, the Principal Component Analysis (PCA) and

the Hierarchical Classification (HC) were carried out with oleifactors who were surveyed in the two campaigns. The

preserved variables were 14 and they were related to the localization of the oil mills, the triturating system and the

evacuation place of OMWW. Of these 14 variables, 11 were regarded as active continuous variables and 3 as illustrative

continuous variables. Thus, five homogeneous axis and five classes were retained for the two campaigns. The results

showed that, the OMWW management was largely changed, between these two campaigns. This change can be related to

the type of the season. Indeed, olive-growing production in 2003 - 04 was about 464.000T tons but it was only about

235.000 tons during 2005 - 06.

KEY WORDS: Olive mill waste water (OMWW), management, Principal Component Analysis (PCA), Hierarchical

Classification (HC)

---------------------------------------------------------------------------------------------------------------------------------------------1.

INTRODUCTION: - Principal components analysis (PCA) is an exploratory, multivariate, statistical

technique that can be used to examine data variability. It is frequently applied to environmental data, where datasets

may be large and difficult to interpret, and where complex inter-relationships between variables are difficult to

identify and visualise (1). Multivariate techniques can consider a number of factors which control data variability

simultaneously (2) and therefore offer significant advantages over univariate techniques, where errors associated with

repeated statistical testing can occur (3).

PCA can be used in several application fields, such as environmental domain. It has been applied, for

example, to surface and groundwaters [(4), (5)], soils [(2), (6)], sediments [(7), (8)] and biota (9).

In this paper, we applied PCA in OMWW management. In fact, OMWW is generated after triturating olives.

It presents different characteristics depending on the variety of olive, its ripeness, the fruit maturity, the climate, soil

conditions and the oil extraction method [(10), (11)]. The main characteristics of OMWW are high values of COD and

BOD, a low pH, a high organic electrical conductivity, a high concentration of free polyphenol and a high organic

content (11).

This can causes serious environmental problems in the Mediterranean countries (12), and can have a major

impact on land and water environments (13).

Many processes have been tested in order to treat or dispose these effluents based on evaporation ponds,

thermal concentration, physico-chemical (14) and biological treatments, as well as its direct application to agricultural

soils as an organic fertilizer [(15), (16), (17)]. However, the most frequently used methods nowadays are the direct

application to agricultural soils and storage in evaporation ponds, which produces sludge (18).

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

26

In Sfax region, which represents the main production zone of olive oil in Tunisia, the frequently mechanism of

OMWW management is the storage in evaporation ponds. The water is evaporated by sunlight during all the year,

creating sludge which is disposed. This method needs large areas of arable land and dont respect environment (19).

In this work, we proposed to study to evolution of OMWW management between two seasons 2003-2004 and 20052006 by using PCA technique.

2. METHODOLOGY

2.1.

STUDY AREA:-Sfax is located in the South of Tunisia, situated to 34 43' in North latitude and to 1041' in

longitude. It is limited by Mahdia to the North, Kairouan, Sidi Bouzid and Gafsa to the west, Gabes to the South and

finally the Mediterranean to the East. This region is made up 13 delegations (Fig: I). It has been chosen for its big

contribution to olive production, its triturating capacity and its OMWW production. The public institutions will solve

the OMWW problems.

Fig I: Location of Sfax

2.2.

DATA COLLECTION: -Data used in this paper were collected through two exhaustive investigations of the

functional oil mills of the region during the seasons 2003 04 (20) and 2005 06 (21). These investigations have

been conducted using questionnaires which were distributed to oleifactors and completed by direct contact of them.

Variables collected from oleifactors were relative to the localisation of the oil mills (Mahres city, Graba city, Gremda

road, Jbeniana city), their vocation (urban or rural environment), their triturating system (Continuous Chain, others

(classic, super-pressure, mixed)), their triturating capacity, their OMWW evacuation (Agareb tank, Mahres tank,

Graba tank and tanks owned by oleifacors) and the source of provision in olives to triturate (Table: I).

Variable

Signification

Activate continuous variables

C4

Mills located in Mahres

C6

Mills located in Graba

C7

Urban area

C8

Rural area

C9

Continuous Chain

C10

Other triturating system

C13

Triturating capacity per day (%)

C15

Agareb tank

C16

Mahres tank

C17

Graba tank

C18

Owned tanks inside Sfax region

Illustrative continuous variables

C3

Mills located in Gremda road

C5

Mills located in Jbeniana

C14

Provision in olives from Sfax (%)

Table I: List of different variable used on PCA

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

27

2.3.

STATISTICAL ANALYSIS: -PCA is a data reduction technique whereby new variables (principal

components or factors) are calculated from linear combinations of the original variables. The first principal

component, or factor, accounts for the greatest variability in the data, and there can be an infinite number of new

factors with each accounting for less data variability than the previous (22). Factor loadings are correlation

coefficients between the original variables and factors. They are frequently used in the literature to investigate the

processes that control data variability. Factor scores indicate how strongly individual samples are associated with each

factor (1), and thus can be used to investigate similarities between oil mills. Consequently similar characteristics of

these oil mills will have similar scores and may therefore have similar behaviour.

The use of PCA to examine environmental datasets has increased significantly over recent years [(23), (24),

(25)]. Although PCA and other multivariate techniques are powerful exploratory tools, they can also rapidly generate

large volumes of data when they are over-used; their application is inconsistent and if there is poor understanding of

their limitations and data requirements (22).

In this work, the statistical software SPAD 5.5 is applied to classify these 14 variables to 11 activate

continuous variables and 3 illustrative continuous variables (Table: I) with the purpose of creating a typology relative

to OMWW management. The distinction between activate and illustrative variables was based on the percentage

contribution of every variable on the axis definition. So the high contribution percentage define activate continuous

variables and the illustrative one were defined by the authors because they proposed that these variables have an

important effect in the statistical study.

Hierarchical Classification was also used, to create classes with individuals who have correlated variables. It was

applied on the coordinates of the 236 individuals on the four first axis retained by the PCA. Hierarchical Classification

is a group of multivariate techniques whose primary purpose is to assemble objects based on the characteristics they

possess (26).

3. RESULTS ANS DISCUSSION

3.1. EVOLUTION OF THE GEOGRAPHICAL REPARTITION: -The study of the oil mills geographical

distribution in Sfax during the seasons 2003 04 and 2005 06 (Fig: II) reveals that they keep the big

concentration in urban environment.

Fig II: The new creation of oil mills

It represents 46.73% in the first season and 48.75% in the second one (Fig: III). The new oil mills were

concentrated essentially on the peri-urban environment, defined as zones located within the distance of about 10 and

20 Km from the Sfax city, and on the delegation of Jbeniana which is located in the north-east part of Sfax.

28

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

180

160

140

oil-mills

120

100

2003 - 04

2005 - 06

80

60

40

20

0

Urban

Rural

Peri-urban

Localization

Fig III: Evolution of oil mills localisation

3.2.

EVOLUTION OF THE TRITURATING SYSTEM: -The olive triturating is consisting on extracting oil

olives. This operation is divided into four stages: crushing, malaxation, separation solid /liquid and separation

oil/water. The triturating operation can be done according to three different systems: the traditional one, which is

classic (Cl), the super-pressure one (SP) and the continuous one (CC). Some mills are composed by the combination

of two systems (called mixed system) such as CC and Cl.

In Sfax, the classic mills are very important in the two seasons (Fig: IV) but the triturating capacity of the

continuous mills is very important in the two seasons, too (Fig: V).

Number of oil-mills 03-04

Number of oil-mills 05-06

180

160

140

Number of oil mills

120

100

80

60

40

20

0

Continuous chain

(CC)

Classic (Cl)

Super pressure

(SP)

Mixed :(CC + Cl)

Mixed :(CC + SP)

Mixed :(Cl + SP)

Mixed :(CC +Cl +

SP)

Triturating system

Fig IV: Evolution of oil mills number

In spite of the reduction in the full number of the functional mills, the practical triturating capacity per day

increased. It has been progressed from 9967 to 11825.5 tons/day (Fig: V), between 2003-2004 and 2005-2006, due to

the modifications of the triturating system from traditional to continuous.

29

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

Triturating capacity 03-04

Triturating capacity 05-06

6000

Triturating capacity (tons/day)

5000

4000

3000

2000

1000

0

Continuous chain

(CC)

Classic (Cl)

Super pressure

(SP)

Mixed :(CC + Cl)

Mixed :(CC + SP)

Mixed :(Cl + SP)

Mixed :(CC +Cl +

SP)

Triturating system

Fig V: Evolution of triturating capacity

3.3. EVOLUTION OF THE OMWW PRODUCTION: -The classic (Cl) system and the super-pressure (SP)

system generate a quantity of OMWW with a ratio of 0.4 and 0.5 respectively.The three-phase continuous

centrifugation, in which high volume of water is added to the crushed olives, generate three phases: olive oil, pulp

(~50% moisture), and OMWW. A ratio of 1 1.2 m3 OMWW per ton of olives is typical (27).

Today, a new system called two-phase process is being introduced in modern mills. This process yields

relatively small volumes of semi-solid waste with 60 70% moisture [(27), (28), (29)]. This system is rarely used in

our study region thats why we dont consider it in our work.

The increase of the practical triturating capacity per day is accompanied by the production of an enormous OMWW

quantity (Fig: VI).

OMWW production 03-04

OMWW production 05-06

6000

OMWW production (ton/day)

5000

4000

3000

2000

1000

0

Continuous chain

(CC)

Classic (Cl)

Super pressure

(SP)

Mixed :(CC + Cl)

Mixed :(CC + SP)

Mixed :(Cl + SP)

Mixed :(CC +Cl +

SP)

Triturating system

Fig VI: Evolution of OMWW production

The estimation of the OMWW quantity depends on several parameters of which the number of workdays, the

number of work-periods per day, the triturating capacity and the OMWW coefficient of production according to the

system. For the two seasons 2003 04 and 2005-06, qualified respectively by good and mean, these data are

summarized in table II.

30

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

Triturating

Number

of mills

Number of

workdays

Number of workperiods

OMWW

Coefficient

production

Triturating

Capacity

(Ton/day)

OMWW quantity

(Ton/season)

System

0304

05-

Min

Max

Moy

Min

Max

Moy

Continuous

Chain (CC)

Classic (Cl)

83

Super

pressure

(SP)

Mixed :

CC+SP

Mixed :

CC+Cl

Mixed :

SP+Cl

Mixed :

CC+Cl+SP

Total

0304

97

50

180

122

1.5

2.79

153

120

45

180

120

2.76

0.5

49

42

60

180

115

2.8

0.4

32

90

195

141

2.5

2.92

21

75

150

100

61

120

180

140

98

98

98

320

305

06

3814

05-06

03-04

05-06

5613,5

686520

636907.1

3153

2437

283770

134522.4

1044

363

708,5

2236,5

75168

30418.267

0.7

49549.5

214856.082

2.78

0.75

1249

536

140512.5

37252

2.83

0.45

254

294

20574

17472.42

0.63

90

9967

11825,5

5556,6

1071588.6

0

793893.14

Table II : Parameters en relation with the OMWW production

OMWW quantities produced from the continuous system were calculated as follows:

In the season 2003 04, identified as a good one, the number of work-periods was maximum so it was 3. Thus, the

triturating capacity was 3814 ton/day. The workdays were 180. The triturating capacity in this period was 180 x 3814

= 686520 ton/season. Since the OMWW coefficient production for the continuous system is 1, then the OMWW

quantity was 686 520 ton/season

3.4. OMWW MECHANISM OF EVACUATION FOR THE TWO SEASONS 2003-04 AND 2005-2006: In the

period between the two seasons studied, the OMWW management was largely changed. This change can be related to

the quality of the countryside. Indeed, olive-growing production in 2003 - 04 was very important (464 000 tons) but it

was average during 2005 06 (235 000 tons). The PCA results confirm that localization, triturating system and

OMWW evacuation are the most determining variables.

3.5. PCA ANALYSIS: -For the two seasons 2003 04 and 2005-06, these variables are represented on the 5 main

axes retained in this analysis with respectively 91.17% and 91.54 % of the total inertia (Table: III, Table: IV).

Variables

Coordinates

PC2

(Axis 2)

PC1

(Axis 1)

Activate continuous variables

C4

C6

C7

C8

C9

C10

C13

C15

C16

C17

C18

Illustrative continuous variables

C3

C5

C14

Variance (%)

PC3

(Axis 3)

PC4

(Axis 4)

-0.54

-0.28

0.94

-0.94

0.27

-0.27

0.12

0.93

-0.27

-0.53

-0.56

0.34

-0.33

0.15

-0.15

-0.82

0.82

-0.08

0.19

-0.21

0.41

-0.41

0.72

-0.26

0.07

-0.07

0.50

-0.50

0.12

0.04

-0.18

0.69

-0.34

-0.15

-0.69

-0.09

0.09

0.06

-0.06

-0.29

-0.09

-0.78

-0.08

0.47

0.40

-0.39

-0.41

34.79

0.03

-0.20

0.00

18.63

0.04

-0.24

-0.12

15.82

-0.01

0.35

0.00

13.27

Table III: Variables coordinates on four significant principal components for the season 2003-04

(Table given by the software SPAD 5.5)

Variables

Coordinates

31

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

PC1

(Axis 1)

Activate continuous variables

C5

C7

C8

C9

C10

C11

C14

C16

C17

C18

C19

Illustrative continuous variables

C4

C6

C15

Variance (%)

PC2

(Axis 2)

PC3

(Axis 3)

PC4

(Axis 4)

-0.56

-0.30

0.94

-0.94

0.34

-0.34

0.15

0.93

-0.54

-0.28

-0.42

-0.17

0.54

-0.10

0.10

0.79

-0.79

0.16

-0.16

-0.19

0.52

0.23

-0.68

0.43

-0.05

0.05

-0.46

0.46

-0.09

-0.01

-0.71

0.33

0.27

0.34

0.51

0.19

-0.19

-0.21

0.21

0.25

0.19

0.28

0.64

-0.56

0.40

-0.34

-0.33

34.79

0.00

0.00

-0.01

18.24

-0.04

0.17

0.10

16.12

0.06

-0.31

-0.05

13.24

Table IV: Variables coordinates on four significant principal components for the season 2005-06

(Table given by the software SPAD 5.5)

The axis 1 (Oil mills localisation and OMWW management) presents 34.79% for the first season and 34.79 % for the

second one of the total inertia. Urban environment is positively well correlated with Agarebs landfill. These last

variables are negatively correlated to rural environment which is positively correlated with Mahres, Graba, Mahres

landfill, Grabas landfill and owned landfills (Table: III, Table IV).

The axis 2 (The triturating system) presents 18.63% for the first season and 18.24 % for the second one of the

total inertia. It opposes the chains continuous mills to the other systems (classic, super-pressure, mixed) (Table: III,

Table IV).

The axis 3 (OMWW evacuation in Mahres) presents 15.82 % for the first season and 16.12 % for the second

one of the total inertia. It is defined by two variables well correlated which are MAHRES and BMAHRES (Table: III,

Table IV).

The axis 4 (OMWW evacuation in Graba) presents 13.27% for the first season and 13.24 % for the second

one of the total inertia. It is defined by two variables well correlated which are GRAIBA and BGRAIBA (Table: III,

Table IV).

The axis 5 (the triturating capacity) presents 8.65% for the first season and 9.14 % for the second one of the total

inertia. It defined the triturating

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

32

Fig VII: Factorial distribution on the variable space on the plan 1 x 2 on 2003 04

For better refining the above-mentioned groupings, the recourse to plane projections is of a great interest.

Figures VII and VIII included the factorial distribution of the variables in the 12 plan. they showed a distribution of

four variables groups. The first one was representative of the urban area and Agareb tank (C7 and C15). The second

one was related negatively and represented variables relatives to rural area and OMWW evacuation in this area (C6,

C8, C17, C18). The third one showed variables relative to mills located in Mahres and Mahres tank. The last one

presented two negatively correlated variables (the classic triturating system and the continuous one).

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

33

Fig IIX: Factorial distribution on the variable space on the plan 1 x 2 on 2005 06

3.4. THE ASCENDING HIERARCHICAL CLUSTER RESULTS: The ascending hierarchical cluster, carried out

on the coordinates of the 236 individuals on the 5 main axes selected, allowed the identification of 5 homogeneous

classes of oleifactors (Fig: IX, Fig: X).

Fig IX: Projection of the five classes on the two first main axis on 2003-04

34

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

Fig X: Projection of the five classes on the two first main axis on 2005 06

This cutting corresponds to a variance between classes about 90.77% of the original variance which means a

good homogeneity between individuals of the same class.

The study of the individuals in classes reveals that they keep the same number between the two seasons (Fig:

XI).

2003/2004

2005/2006

120

100

80

60

40

20

0

Class 1

Class 2

Class 3

Class 4

Class 5

Fig XI: Variation of oleifactors number

The stability rate is defined as a ratio of the common individuals belonging to class 1 (on 05/06) by

individuals belonging to class 1 (on 03/04).

The study of this rate (Fig: XII) showed that the stability depends on the triturating system and OMWW

evacuation.

35

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

0,90

0,80

0,70

0,60

0,50

Stability rate

0,40

0,30

0,20

0,10

0,00

class 1

class 2

class 3

class 4

class 5

Fig XII: variation of the stability rate

In fact, the triturating system in the first and the second class is conserved. However, in the third class, we

note that 13 oil mills were continuous on 03/04 and they were transformed on other system (especially mixed (CC +

Cl)) on 05/06). In the fourth and fifth classes, the configuration of the triturating system is conserved too (Fig: XIII).

120

100

80

2003/2004 CC

2003/2004 Others

2005/2006 CC

2005/2006 Others

60

40

20

0

Class 1

Class 2

Class 3

Class 4

Class 5

Fig XIII: Variation of the triturating system between the two seasons 03/04 and 05/06

-On the other hand, the OMWW management is conserved on the classes 1, 2 and 3 (Fig.XIV).

120

100

80

Class 1

Class 2

Class 3

Class 4

Class 5

60

40

20

0

Agareb's tank

owned tank

Mahres'tank

2003/2004

Graba's tank

Agareb's tank

owned tank

Mahres'tank

Graba's tank

2005/2006

Fig XIV: Variation of the OMWW management between the two seasons 03/04 and 05/06

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

36

On the fourth class, oleifactors who evacuated their OMWW in Agareb tank changed and evacuated it in Graba

tank due to the long distance which separates oil mills and the tank. On the fifth class, some oleifactors evacuated their

OMWW on owned tanks that are not in conformity with the standards on 03/04 but they change and evacuated it on

tanks located within the neighbour regions which are controlled by government. In addition to environmental

problems, OMWW management in owned tanks according to standards requires a high cost.

4.

CONCLUSION: The olive mill waste water (OMWW) management in Sfax region (Tunisia) has several

mechanisms. We studied the evolution of these forms between two different seasons (2003 04 and 2005 06). In the

first season, we inventoried 381 oil-mills, 3 collective landfills and other individual landfills owned by oleifactors in

order to create a data base relative to Sfax mills by using the tool Geographical Information Systems (GIS).

Georeferencing that has been established on 2003-04, was actualized during the season 2005 06 (referencing

the oil-mills and the newly created landfills).

Statistical analysis was based on the Principal Components Analysis (PCA) and the Hierarchical Classification

(HC) for the elaboration of a mills typology. This typology, defined by structural, functional and spatial variables,

allows a better understanding of the evolution of the mechanisms of the OMWW management in Sfax and shows that

the olive growing (OMWW quantity) is the principal factor reflecting this evolution.

Results of the principal component analysis (PCA) and the Hierarchical Classification showed distinctly

different elemental associations between oleifactors.

OMWW is evacuated in collective tanks of Agareb, Mahres, Graba and individual tanks but they have some

environmental problems. Although Agareb tank is arranged, it has a bed smell, a proliferation of insects, a lateral outflows and infiltrations. Mahres tank, wich is poorly maintained, is located on the coast thus OMWW can contaminate

sea water. Concerning Graiba tank, it is too close some streams.

REFERENCES:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Reid, MK., Spencer, KL, 2009, Use of principal components analysis (PCA) on estuarine sediment datasets: The effect of

data pre-treatment, Environmental Pollution, 157, 2275-2281.

Boruvka, L., Vacek, O., Jehlika, J, 2005, Principal component analysis as a tool to indicate the origin of potentially toxic

elements in soils, Geoderma, 128, 289-300.

Manly, BFJ., 1997, Multivariate Statistical Methods: A primar, Second ed. Chapman and hall, London.

Chen, K., Jiao, JJ., Huang, J., Huang, R., 2007, Multivariate statistical evaluation of trace elements in groundwater in

coastal area in Shenzhen, China, Environmental Pollution, 147, 771-780.

Kuppusamy, MR., Giridhar, VV., 2006, Factor analysis of water quality characteristics including trace metal speciation in

the coastal environmental system of Chennai Ennore, Environmental International ,32, 174-179.

Zhang, Ch., 2006, Using multivariate analyses and GIS to identify pollutants and their spatial patterns in urban soils in

Galway, Ireland, Environmental Pollution, 142, 501-511.

Emmerson, RHC., O'Reilly-Wiese, SB., Macleod, CL., Lester, JN., 1997, A multivariate assessment of metal distribution in

inter-tidal sediments of the Blackwater Estuary, UK, Marine Pollution Bulletin, 34, 960-968.

Spencer, KL., 2002, Spatial variability of metals in the inter-tidal sediments of the Medway Estuary, Kent, UK, Marine

Pollution Bulletin, 44, 933- 944.

Yawei, W., Lina, L., Jianbo, S., Guibin, J., 2005, Chemometrics methods for the investigation of methylmercury and total

mercury contamination in mollusks samples collected from coastal sites along the Chinese Bohai Sea, Environmental

Pollution, 135, 457-467.

Sierra, J., Mart, E., Montserrat, G., Cruaas, R., Garau, MA., 2001, Characterisation and evolution of a soil affected by

olive mill wastewater disposal, Science of the Total Environment, 279, 207-214.

Rinaldi, M., Rana, G., Introna, M., 2003, Olive-mill wastewater spreading in southern Italy: effects on a durum wheat crop,

Field Crop Research, 84, 319-326.

Paredes, C., Cegarra, J., Roig, A., Snchez-Monedero, MA., Bernal, MP., 1999, Characterization of olive mill wastewater

(alpechin) and its sludge for agricultural purposes, Bioresource Technology, 67, 111-115.

Lpez-Pieiro, A., Murillo, S., Barreto, C., Muoz, A., Rato, JM., Albarrn, A., Garca, A., 2007, Changes in organic matter

and residual effect of amendment with two-phase olive-mill waste on degraded agricultural soils, Science of the Total

Environment, 378:84-89.

Jarboui, R., Chtourou, M., Azri, Ch., Gharsallah, N., Ammar, E., 2010, Time-dependent evolution of olive mill wastewater

sludge organic and inorganic components and resident microbiota in multi-pond evaporation system, Bioresource

Technology, 101, 5749-5758.

Fiestas Ros De Ursinos, JA., Borja, Padilla, R., 1992, Use and treatment of olive mill wastewater: current situation and

prospects in Spain, Grasas y aceites, 43, 101-106.

Martinez Nieto, L., Garridi-Hoyos, SE., Camacho Rubio, F., Garcia-Pareja, MP., Ramos-Cormenzana, A., 1993, The

biological purification of waste products from olive oil extraction, Bioresource Technology, 43, 215-219.

Gargouri, K., Serbaji, M., Barone, E., 2006, Assessment of soil fertility variation in an olive orchad and its influence on

th

th

olive tree nutrition, Olivebioteq, November 5 10 Mazara del Vallo, Marsala (Italy), 99 105

Paredes, MJ., Moreno, E., Ramos-Cormenzana, A., Martinez, J., 1987, Characteristics of soil after pollution with waste

waters from olive oil extraction plants, Chemosphere, 16, 1564-1572.

Ramos-Cormenzana, A., Monteoliva-Sanchez, M., Lopez, MJ., 1995, Bioremediation of alpechin, International

Biodeterioration and biodegradation, 35, 249-269.

Sahnoun, H., Karray, B., Serbaji, MM., Mcanismes de Gestion des Margines en Tunisie: Une Vision Multidimensionnelle

de la Problmatique des Margines Sfax, Confrence Francophone ESRI, 11-12 October, Paris.

H. Sahnoun et al. / International Journal of Advancement in Earth and Environmental Sciences, Vol.1, No. 2

37

21. Sahnoun, H., Serbaji MM., Karray, B., Medhioub, K., 2013, Olive Mill Waste Water Management Study by Using Principal

Component Analysis, International Journal of Geosciences, 4, 444-453

22. Webster, R., 2001, Statistics to support soil research and their presentation, European Journal of soil Science, 52, 331340.

23. Ouali, A., Azri, Ch., Medhioub, K., Ghrabi, A., 2009, Descriptive and multivariable analysis of the physico-chemical and

biological parameters of Sfax wastewater treatment plant, Desalinisation, 246, 496-505.

24. Ellouze, M., Azri, Ch, Abida, H., 2009, Spatial Variability of Monthly and Annual Rainfall Data over Southern Tunisia,

Atmospheric Research, 93, 832-839.

25. Jarboui, R., Sellami, F., Azri, Ch., Gharsallah, N., Ammar, E., 2010, Olive mill wastewater evaporation management using

PCA method: Case study of natural degradation in stabilization ponds (Sfax, Tunisia), Journal of Hazardous Materials,

176, 992-1005.

26. Shrestha, S., Kazama, K., 2007, Assessment of Surface Water Quality Using Multivariate Statistical Techniques: A Case

Study of the Fuji River Basin, Japan, Environmental Modelling and Software, 22, 2, 464-475.

27. Azbar, N., Bayram, A., Filibeli, A., Muezzinoglu, A., Sengul, F., Ozer, A., 2004, A review of waste management options in

olive oil production, Critical Reviews in Environmental Science and technology, 34, 209- 247

28. Saviozzi, A., Levi-Minzi, R., Cardelli, R., Biasci, A., Riffaldi, R., 2001, Suitability of moist olive pomace as soil amendment,

Water Air Soil Pollution, 128, 13-22

29. Cayuela, ML., Millner, PD., Meyer, SLF, Roig, A., 2008, Potential of olive mill waste and compost as biobased pesticides

against weeds, fungi and nematodes, Sciences of the Total Environment, 399, 11-18.

You might also like

- Triune Brain in EvolutionDocument307 pagesTriune Brain in Evolutionjavier1974100% (2)

- P020090715579672240844 PDFDocument22 pagesP020090715579672240844 PDFTiruneh GANo ratings yet

- Accepted Manuscript: Journal of The Saudi Society of Agricultural SciencesDocument15 pagesAccepted Manuscript: Journal of The Saudi Society of Agricultural SciencesTimotius Candra KusumaNo ratings yet

- Determination of Growth Stage-Specific Crop Coefficients (K) of Sunflowers (Helianthus Annuus L.) Under Salt StressDocument17 pagesDetermination of Growth Stage-Specific Crop Coefficients (K) of Sunflowers (Helianthus Annuus L.) Under Salt StressLuis Rey Pinzón MartínezNo ratings yet

- Fertility Management in The Tropical Andean Mountains:: (Tropandes)Document3 pagesFertility Management in The Tropical Andean Mountains:: (Tropandes)Jorge QuebecNo ratings yet

- Ground Water10-Chapter-2 PDFDocument62 pagesGround Water10-Chapter-2 PDFshobhitNo ratings yet

- Ecological Indicators: SciencedirectDocument11 pagesEcological Indicators: SciencedirectAizaz AliNo ratings yet

- Abdullaev, Ul Hassan, Jumaboev - 2007 - Water Saving and Economic Impacts of Land Leveling The Case Study of Cotton Production in TajikiDocument13 pagesAbdullaev, Ul Hassan, Jumaboev - 2007 - Water Saving and Economic Impacts of Land Leveling The Case Study of Cotton Production in TajikiHüseyin ErdikliNo ratings yet

- Landfill Site Selection With GIS Based MDocument13 pagesLandfill Site Selection With GIS Based McourtoiNo ratings yet

- Kundan, 2018Document14 pagesKundan, 2018Diana RoseroNo ratings yet

- Jato-Espino Charlesworth Perales - Prediction of Evapotranspiration in A Mediterranean Region Usi...Document60 pagesJato-Espino Charlesworth Perales - Prediction of Evapotranspiration in A Mediterranean Region Usi...sallykerry75No ratings yet

- Mapping of Yield, Economic Return, Soil Electrical Conductivity, and Management Zones of Irrigated Corn For SilageDocument10 pagesMapping of Yield, Economic Return, Soil Electrical Conductivity, and Management Zones of Irrigated Corn For SilagesasaesdesNo ratings yet

- Sensors 17 01104Document25 pagesSensors 17 01104sheikhali9180No ratings yet

- Agriculture 12 01168 v2Document17 pagesAgriculture 12 01168 v2Shahab AdlNo ratings yet

- Assessment of Land Use and Land Cover Changes in Pangari Watershed Area (MS), India, Based On The Remote Sensing and GIS TechniquesDocument12 pagesAssessment of Land Use and Land Cover Changes in Pangari Watershed Area (MS), India, Based On The Remote Sensing and GIS TechniquesPranjoy SarkerNo ratings yet

- Anis Chikhaoui-Al ModelisationDuRisqueDrosionHydriqueParUSLEMyBouchetaDocument22 pagesAnis Chikhaoui-Al ModelisationDuRisqueDrosionHydriqueParUSLEMyBouchetabougheraraNo ratings yet

- Moriondo2007 PDFDocument9 pagesMoriondo2007 PDFTiruneh GANo ratings yet

- Monroy 2000Document14 pagesMonroy 2000Val OsornioNo ratings yet

- Irrigation Water Management in The Nile Delta Using Gis TechnologyDocument27 pagesIrrigation Water Management in The Nile Delta Using Gis TechnologyNoha AbdulwarthNo ratings yet

- 2014-Implementing The DPSIR Framework To Link Water Quality of Rivers To Land Use - Methodological Issues and Preliminary Field TestDocument18 pages2014-Implementing The DPSIR Framework To Link Water Quality of Rivers To Land Use - Methodological Issues and Preliminary Field TestSaid RamdlanNo ratings yet

- Comparison of Contingent Valuation and Choice Experiment in Solid Waste Management Programs in MacaoDocument13 pagesComparison of Contingent Valuation and Choice Experiment in Solid Waste Management Programs in MacaoAshu TyagiNo ratings yet

- Parameterization and Comparison of The AquaCrop and MOPECO Models ForDocument14 pagesParameterization and Comparison of The AquaCrop and MOPECO Models ForLuciano Quezada HenriquezNo ratings yet

- Bouman Etal 1999Document19 pagesBouman Etal 1999DewaNo ratings yet

- LOLDocument8 pagesLOLjaya razoNo ratings yet

- Review On The Impacts of Waste Disposal Sites in The PhilippinesDocument8 pagesReview On The Impacts of Waste Disposal Sites in The PhilippinesRANJIT ANDREI ROBLENo ratings yet

- PRI 11 2014 LalandeDocument18 pagesPRI 11 2014 LalandeNu LeeNo ratings yet

- 264 XXXIII-part7Document8 pages264 XXXIII-part7Sanjeev KumarNo ratings yet

- Global Agricultural Land Use Data For Climate ChanDocument26 pagesGlobal Agricultural Land Use Data For Climate ChanMesfin HaileNo ratings yet

- Sources, Composition, Disposal, Recycling, and Valorization: Solid Waste IssueDocument10 pagesSources, Composition, Disposal, Recycling, and Valorization: Solid Waste IssueBeah Francia De la CruzNo ratings yet

- Vol 24 Issue 15 Abbas AminiDocument19 pagesVol 24 Issue 15 Abbas AminiRockstarNo ratings yet

- Articulo 6Document14 pagesArticulo 6Anita LinaresNo ratings yet

- Remote Sensing: Continuous Monitoring of Cotton Stem Water Potential Using Sentinel-2 ImageryDocument18 pagesRemote Sensing: Continuous Monitoring of Cotton Stem Water Potential Using Sentinel-2 ImageryKarem Meza CapchaNo ratings yet

- Use of The Contingent Valuation Method in The Assessment of A Landfill Mining ProjectDocument7 pagesUse of The Contingent Valuation Method in The Assessment of A Landfill Mining ProjectBambang WalidNo ratings yet

- Water 11 01805 v2Document24 pagesWater 11 01805 v2calvin amecuNo ratings yet

- 12 - Modelling Impacts of Dryland Sugarcane On Streamflows in A Water Stressed Catchment in KwaZulu-NatalDocument8 pages12 - Modelling Impacts of Dryland Sugarcane On Streamflows in A Water Stressed Catchment in KwaZulu-NatalGeorgiana PantaziNo ratings yet

- Statistical Analysis of Recent Rainfall Variability and Trend Using A Merged Gauge and Satellite Time Series Data For The Cotton Zone of MaliDocument8 pagesStatistical Analysis of Recent Rainfall Variability and Trend Using A Merged Gauge and Satellite Time Series Data For The Cotton Zone of MaliMamta AgarwalNo ratings yet

- Flood Plain Analysis and Flow Simulation of River Using Hec Ras ModelDocument10 pagesFlood Plain Analysis and Flow Simulation of River Using Hec Ras Modelyaseen90azizNo ratings yet

- 34IJEAB 102202123 ComparativeDocument12 pages34IJEAB 102202123 ComparativeIJEAB JournalNo ratings yet

- Generation and Composition of Municipal Solid Waste (MSW) in Muscat, Sultanate of OmanDocument7 pagesGeneration and Composition of Municipal Solid Waste (MSW) in Muscat, Sultanate of OmanNaah MkwizuNo ratings yet

- A2 Applications of Apparent Soil Electrical Conductivity in Precision AgricultureDocument10 pagesA2 Applications of Apparent Soil Electrical Conductivity in Precision AgricultureMauricio Castro FrancoNo ratings yet

- Shri Saibaba Institute of Engineering Research and Allied Sciences B.E. (Mechanical) 1Document20 pagesShri Saibaba Institute of Engineering Research and Allied Sciences B.E. (Mechanical) 1ankush belkarNo ratings yet

- Contrerasetal2018 PLOSOne PDFDocument27 pagesContrerasetal2018 PLOSOne PDFdcontreNo ratings yet

- FFP 775Document8 pagesFFP 775OLA OLANo ratings yet

- Evaluation of Biological Removal Efficiency in A UCT Process Treating Municipal Wastewater During Start-Up StageDocument6 pagesEvaluation of Biological Removal Efficiency in A UCT Process Treating Municipal Wastewater During Start-Up StageRose AdelineNo ratings yet

- RahulDocument12 pagesRahulMallela SrikanthNo ratings yet

- Effect of Pipes Installation by Modified Machine For Subsurface Drip Irrigation System On Maize Crop Yield CostsDocument10 pagesEffect of Pipes Installation by Modified Machine For Subsurface Drip Irrigation System On Maize Crop Yield CostsMohammad Khusnun Ni'amNo ratings yet

- Multi-Temporal Analysis of Remotely Sensed Information Using WaveletsDocument9 pagesMulti-Temporal Analysis of Remotely Sensed Information Using WaveletsAndrei ȘtefanNo ratings yet

- Uribe N. Spatio-Temporal Critical Source Areas PatternsDocument14 pagesUribe N. Spatio-Temporal Critical Source Areas PatternsnataliaNo ratings yet

- Agricultural Water Management: SciencedirectDocument12 pagesAgricultural Water Management: SciencedirectAarish MaqsoodNo ratings yet

- 10.1007@s41748 019 00088 yDocument13 pages10.1007@s41748 019 00088 yPranjoy SarkerNo ratings yet

- Article 9 JSSM Volume 16 Number 7 October 2021Document14 pagesArticle 9 JSSM Volume 16 Number 7 October 2021R RenegadeNo ratings yet

- Ijerph 17 00283Document19 pagesIjerph 17 00283IlhamSutamiNo ratings yet

- Remote Sensing Techniques in Olive Farms in Arid Regions of TunisiaDocument10 pagesRemote Sensing Techniques in Olive Farms in Arid Regions of TunisiaTunde KallaiNo ratings yet

- Assessing Total Factor Productivity and Efficiency Change For Farms Participating in Grain For Green Program in ChinaDocument8 pagesAssessing Total Factor Productivity and Efficiency Change For Farms Participating in Grain For Green Program in China李莉No ratings yet

- Targeted Land Management Strategies Could Halve Peatland Fire Occurrences in Central Kalimantan, IndonesiaDocument11 pagesTargeted Land Management Strategies Could Halve Peatland Fire Occurrences in Central Kalimantan, IndonesiaardikaNo ratings yet

- Nepal Casestudy1 Multifuel Power ProjectDocument13 pagesNepal Casestudy1 Multifuel Power ProjectAbhishek Man ShresthaNo ratings yet

- Rusle HaouzDocument14 pagesRusle Haouzelmazi mohamedNo ratings yet

- Agronomy 10 01681 v2Document16 pagesAgronomy 10 01681 v2Andres Felipe Morales AguirreNo ratings yet

- Soils as a Key Component of the Critical Zone 2: Societal IssuesFrom EverandSoils as a Key Component of the Critical Zone 2: Societal IssuesGuillaume DhérissardNo ratings yet

- Gross Pollutant Traps to Enhance Water Quality in MalaysiaFrom EverandGross Pollutant Traps to Enhance Water Quality in MalaysiaNo ratings yet

- (Kenneth Tan) Pharmacologic Management For Cardiogenic Shock - EBM or Gut FeelDocument21 pages(Kenneth Tan) Pharmacologic Management For Cardiogenic Shock - EBM or Gut FeelAdriana VillarrealNo ratings yet

- Diasorin Company Presentation Eng March 2022 1Document13 pagesDiasorin Company Presentation Eng March 2022 1Yaser MNo ratings yet

- Lab 3Document23 pagesLab 3qvk8yy9pxcNo ratings yet

- Jean Piaget Stages of Cognitive DevelopmentDocument21 pagesJean Piaget Stages of Cognitive DevelopmentVirginie PrnNo ratings yet

- Ob AssignmentDocument4 pagesOb AssignmentZubair ZiaNo ratings yet

- Save EarthDocument2 pagesSave EarthAncient Sadist100% (1)

- Bmedsc Year 3 Medical Science Electives in Semester 1Document2 pagesBmedsc Year 3 Medical Science Electives in Semester 1BittuNo ratings yet

- Recent Trends in Insulin Drug Delivery SystemDocument39 pagesRecent Trends in Insulin Drug Delivery Systemandry natanel tonyNo ratings yet

- Theory and Instrumentation of GC IntroductionDocument13 pagesTheory and Instrumentation of GC Introductionaugur886No ratings yet

- Hematology - KitProtocol - List of TIC KitsDocument3 pagesHematology - KitProtocol - List of TIC Kitsuzair.narcNo ratings yet

- Word Formation PaperDocument24 pagesWord Formation PaperElsa GloriaNo ratings yet

- Journal of Biochips & Tissue ChipsDocument11 pagesJournal of Biochips & Tissue ChipsomicspublishinggroupNo ratings yet

- The Cell Theory Activity 1 and 2Document3 pagesThe Cell Theory Activity 1 and 2Reynabele CarinoNo ratings yet

- DNA Structure and FunctionDocument42 pagesDNA Structure and FunctionBenjamin Fernandez Jr.No ratings yet

- tmp5F29 TMPDocument82 pagestmp5F29 TMPFrontiersNo ratings yet

- Microbial Transformation of Metals (Review)Document6 pagesMicrobial Transformation of Metals (Review)H15H4MNo ratings yet

- ScenarDocument41 pagesScenarwizard1111iam100% (7)

- Lsu Internship ReportDocument37 pagesLsu Internship ReportNaresh ReddyNo ratings yet

- Open AscensionWorkbookI (1) 8Document691 pagesOpen AscensionWorkbookI (1) 8f57jpz22wyNo ratings yet

- Pages From Glencoe - Chemistry - Matter and Change Mcgraw 2008 CH 1Document26 pagesPages From Glencoe - Chemistry - Matter and Change Mcgraw 2008 CH 1api-261034721No ratings yet

- Anatomy McqsDocument20 pagesAnatomy McqsKishore SainaneeNo ratings yet

- Studies On Biology, Seed Dispersal and Host Interaction of Dendrophthoe Falcata (L.F.)Document7 pagesStudies On Biology, Seed Dispersal and Host Interaction of Dendrophthoe Falcata (L.F.)Sittie Janna DidaagunNo ratings yet

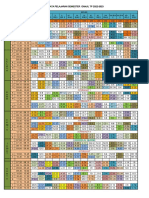

- Roster Pelajaran SMT Genap TP 2022-2023Document10 pagesRoster Pelajaran SMT Genap TP 2022-2023Kadal KodokNo ratings yet

- Perbandingan Manfaat Klinis Senam Merpati Putih Dengan Senam Asma Indonesia Pada Penyandang AsmaDocument9 pagesPerbandingan Manfaat Klinis Senam Merpati Putih Dengan Senam Asma Indonesia Pada Penyandang Asmadini kusmaharaniNo ratings yet

- Orphanage Cum Old Age Home: Amruta Prakash BedmuthaDocument2 pagesOrphanage Cum Old Age Home: Amruta Prakash BedmuthaNamrata Bhandari100% (1)

- Humoral Immunity B CellDocument11 pagesHumoral Immunity B CellAbod AbodNo ratings yet

- Chapter 20 - 1 Fluid and Electrolyte BalanceDocument10 pagesChapter 20 - 1 Fluid and Electrolyte Balancekristinaf1224No ratings yet

- Eggshell PDFDocument13 pagesEggshell PDFJanelle PornobiNo ratings yet

- The AnswersDocument3 pagesThe AnswersSHAHD WALIDNo ratings yet