0% found this document useful (0 votes)

125 views4 pagesBuckling Resistance in Compression Members

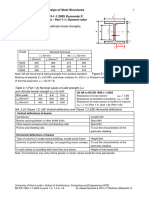

This document provides guidance on assessing the buckling resistance of compression members. It states that the design compression force must not exceed the design buckling resistance, which is calculated using the member's cross-sectional properties, yield strength and a reduction factor obtained from buckling curves. It provides equations to calculate the buckling resistance and defines the parameters used, including the slenderness ratio and imperfection factor which determine the applicable buckling curve. Tables are included specifying which buckling curve to use for different cross-section types.

Uploaded by

Anonymous omGSHUEQCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

125 views4 pagesBuckling Resistance in Compression Members

This document provides guidance on assessing the buckling resistance of compression members. It states that the design compression force must not exceed the design buckling resistance, which is calculated using the member's cross-sectional properties, yield strength and a reduction factor obtained from buckling curves. It provides equations to calculate the buckling resistance and defines the parameters used, including the slenderness ratio and imperfection factor which determine the applicable buckling curve. Tables are included specifying which buckling curve to use for different cross-section types.

Uploaded by

Anonymous omGSHUEQCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd