Professional Documents

Culture Documents

CP 91

Uploaded by

Anonymous mNQq7ojCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CP 91

Uploaded by

Anonymous mNQq7ojCopyright:

Available Formats

SINGAPORE STANDARD

CP 91 : 2001

(ICS 13.110)

CODE OF PRACTICE FOR

Lockout procedure

Published by

Singapore Productivity and Standards Board

2 Bukit Merah Central

Singapore 159835

PSB Website: www.psb.gov.sg

Standards Website: www.standards.org

SINGAPORE STANDARD

CP 91 : 2001

(ICS 13.110)

CODE OF PRACTICE FOR

Lockout procedure

All rights reserved. Unless otherwise specified, no part of this Singapore

Standard may be reproduced or utilised in any form or by any means,

electronic or mechanical, including photocopying and microfilming, without

permission in writing from the Singapore Productivity and Standards Board at

the address below:

Director

Centre for Standardisation

Singapore Productivity and Standards Board

2 Bukit Merah Central

Singapore 159835

Telephone: 2786666

Telefax: 2786667

Email: cfs@psb.gov.sg

ISBN 9971-67-871-3

CP 91 : 2001

Contents

Page

Foreword

CODE OF PRACTICE

0

Application

Scope

Definitions

Lockout policy and procedure

Requirements for lockout procedure

12

Implementation of lockout procedure

12

Special lockout considerations

14

ANNEXES

A

Sample lockout procedure

16

Examples of tagging devices

18

FIGURES

1

Lockout procedure for electrical energy source

10

Lockout procedure for hydraulic-pneumatic energy source

11

CP 91 : 2001

Foreword

This Code of Practice was prepared by the Technical Committee on General Safety under the direction

of the Industrial Safety Standards Committee.

This code provides recommendations and guidelines for safety requirements on the control of energy

during construction, servicing or maintenance of machines. The aim is to prevent any unexpected

energisation or start up of machines, or release of stored energy that could cause injury to employees.

This code is intended for factory occupiers, factory owners, safety officers and all those concerned

directly or indirectly where exposure exists due to their involvement with work in progress.

This code covers the policy, requirements and implementation of lockout procedure. Special lockout

considerations on group, external personnel and shift/personnel changes are also recommended in the

guidelines.

In preparing this code, reference was made to the following publications:

1.

ANSI Z244.1 : 1982

American National Standard for personnel protection lockout/tagout

of energy sources - minimum safety requirements

2.

OSHA Regulations (Standards-29 CFR-1910.147) The control of hazardous energy

(lockout/tagout)

NOTE

1.

Singapore Standards are subject to periodic review to keep abreast of technological changes and new

technical developments. The revisions of Singapore Standards are announced through the issue of

either amendment slips or revised editions.

2.

Compliance with a Singapore Standard does not exempt users from legal obligations.

CP 91 : 2001

Code of practice for lockout procedure

0

Application

This code applies to the control of energy during construction, servicing or maintenance of machines.

Scope

This code covers the construction, servicing or maintenance of machines where any unexpected

energisation or start up of the machines, or release of stored energy could cause injury to employees.

It establishes minimum performance requirements for the control of such hazardous energy.

Definitions

2.1

Affected employee

An employee who is required to operate or use a machine on which construction, servicing or

maintenance is being performed under lockout, or who is required to work in an area in which such

construction, servicing or maintenance is being performed.

2.2

Authorised employee

A person who locks out machines in order to perform construction, servicing or maintenance on that

machine. An affected employee becomes an authorised employee when that employee's duties

include construction, servicing or maintenance covered under this code.

2.3

Construction, servicing and/or maintenance

Workplace activities such as constructing, erecting, installing, setting up, commissioning, repairing,

adjusting, inspecting, modifying, operating, and maintaining and/or servicing machines or equipment.

These activities include lubrication, cleaning or unjamming of machines or equipment and making

adjustments or tool changes, where the employee may be exposed to the unexpected energisation or

start-up of the equipment or release of hazardous energy.

2.4

Energised

Connected to an energy source or containing residual or stored energy.

2.5

Energy isolating device

A mechanical device that physically prevents the transmission or release of energy, including but is not

limited to the following:

(a)

a circuit breaker;

(b)

an isolating switch;

(c)

a line valve;

You might also like

- 11 Create WBS PDFDocument10 pages11 Create WBS PDFKhanh Dinh Duy100% (1)

- Rele Micon Schneider Vamp-11F PDFDocument538 pagesRele Micon Schneider Vamp-11F PDFDivanil Marins100% (1)

- SS Catalogue 2008 - Final CoverDocument168 pagesSS Catalogue 2008 - Final CoverBryan TungNo ratings yet

- Kapil DhamaDocument2 pagesKapil DhamaStatusPediaNo ratings yet

- Building Electrical Inspection ChecklistDocument2 pagesBuilding Electrical Inspection Checklistkhrayzie bhoneNo ratings yet

- Singapore Transmission - Code Jan 2008Document107 pagesSingapore Transmission - Code Jan 2008aanatharatchaganNo ratings yet

- Engineering Boy - How To Calculate The Maximum Demand and The Total Connected LoadDocument1 pageEngineering Boy - How To Calculate The Maximum Demand and The Total Connected LoadAnonymous mNQq7oj100% (1)

- Examples of Surge Protective Device SPD Applications in 230Document18 pagesExamples of Surge Protective Device SPD Applications in 230Gia BảoNo ratings yet

- Permit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedDocument3 pagesPermit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedJohn BusherNo ratings yet

- Electrical Codes PDFDocument16 pagesElectrical Codes PDFcosmin1991No ratings yet

- Electrical HazardsDocument56 pagesElectrical HazardsZainorin AliNo ratings yet

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 23035 2022-05-14 ECD Workshop-Route To Professional Engineer R6-Compressed2Document158 pagesD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 23035 2022-05-14 ECD Workshop-Route To Professional Engineer R6-Compressed2nyuusterNo ratings yet

- Transformers Stray LossDocument34 pagesTransformers Stray LossPop GabrielNo ratings yet

- Procedure For Assessment of Protection Relay Testing Engineers DCRPDocument8 pagesProcedure For Assessment of Protection Relay Testing Engineers DCRPMohamed Wahid100% (1)

- Surge Protection Over Voltage DevicesDocument24 pagesSurge Protection Over Voltage Devicesnooruddinkhan1No ratings yet

- R8005C MvawDocument20 pagesR8005C MvawRinda_RaynaNo ratings yet

- FAT Procedures: 1-ObjectiveDocument6 pagesFAT Procedures: 1-ObjectiveMohammad YaseeenNo ratings yet

- CSC 326 Transformer Protection Ied Technical Application Manual v1 02Document329 pagesCSC 326 Transformer Protection Ied Technical Application Manual v1 02rommel76No ratings yet

- Indian Roads Congress-Public Safety Standards of IndiaDocument6 pagesIndian Roads Congress-Public Safety Standards of IndiaBhavsar NilayNo ratings yet

- 8BK88PLUSDocument8 pages8BK88PLUSSwapnil PatilNo ratings yet

- Process Flow of T&C of GCPV in Malaysia PDFDocument1 pageProcess Flow of T&C of GCPV in Malaysia PDFMohd Izham IdrisNo ratings yet

- ST Cogen & Distribution LicenceDocument24 pagesST Cogen & Distribution LicenceDistrict EnergyNo ratings yet

- SolkorR RF Op RecsDocument14 pagesSolkorR RF Op Recsrashid rahmanNo ratings yet

- Earthing, Bonding, Lightning Surge ProtectionDocument2 pagesEarthing, Bonding, Lightning Surge ProtectionKonda SrinivasNo ratings yet

- Lightning Protection System Installation Works Inspection ChecklistDocument1 pageLightning Protection System Installation Works Inspection ChecklistReda HamedNo ratings yet

- Chapter 16 - Electrical SafetyDocument41 pagesChapter 16 - Electrical SafetyDinesh PanchalNo ratings yet

- Schneider Startup Test ProcedureDocument45 pagesSchneider Startup Test ProcedureJonathan Feruelo100% (1)

- Lightning Protection Application Guide PDFDocument23 pagesLightning Protection Application Guide PDFSaswita Sakti100% (1)

- Overhead Tranmission Line DesignDocument28 pagesOverhead Tranmission Line DesignJose ManjooranNo ratings yet

- S.O.W Between Sdi, Msog & AcidchemDocument4 pagesS.O.W Between Sdi, Msog & AcidchemSIVANo ratings yet

- Total Technical Specs PDFDocument259 pagesTotal Technical Specs PDFBhavesh KeraliaNo ratings yet

- ABW Air Circuit BreakerDocument28 pagesABW Air Circuit BreakerDerargh100% (1)

- Is 2309 1989Document72 pagesIs 2309 1989Jagdish PalariyaNo ratings yet

- Schneider Electric: Easergy P3U30 LED Labels PrintoutDocument2 pagesSchneider Electric: Easergy P3U30 LED Labels PrintoutPeter Paul Condinato100% (1)

- NFPA 70B 2023 - New Guidelines For Electric InspectionsDocument2 pagesNFPA 70B 2023 - New Guidelines For Electric InspectionsAM KANo ratings yet

- Method Statement - Line Impedance Measurement - Single Line Circuit and Double Line CircuitDocument14 pagesMethod Statement - Line Impedance Measurement - Single Line Circuit and Double Line CircuitAnonymous wx4I4YQONo ratings yet

- Electrical Safety Laws 2019Document4 pagesElectrical Safety Laws 2019mamillapalli sri harshaNo ratings yet

- Transmission Code 2014Document106 pagesTransmission Code 2014Thet ThetNo ratings yet

- Arc FlashDocument7 pagesArc FlashGhulam MustaqeemNo ratings yet

- MV Switchgear CT Inspection and Test Procedure: October 2019Document6 pagesMV Switchgear CT Inspection and Test Procedure: October 2019sabamalar100% (1)

- PCS-915 Bus Bar RelayDocument268 pagesPCS-915 Bus Bar RelayKishore KumarNo ratings yet

- 7PG21 Solkor RF Complete Technical ManualDocument78 pages7PG21 Solkor RF Complete Technical ManualBasil M TNo ratings yet

- LSIS Vacuum ContactorDocument36 pagesLSIS Vacuum ContactoredgarcooNo ratings yet

- Communication Training ReportDocument33 pagesCommunication Training ReportkakagoNo ratings yet

- Arc Flash Analysis: Electrical SafetyDocument16 pagesArc Flash Analysis: Electrical SafetyOsha InstructorsNo ratings yet

- Conventional Lightning Protection System ComponentsDocument34 pagesConventional Lightning Protection System ComponentsGia BảoNo ratings yet

- Preventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFDocument6 pagesPreventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFSatadal DashNo ratings yet

- Analysis and Optimization of 132KV Grid Using ETAP PDFDocument6 pagesAnalysis and Optimization of 132KV Grid Using ETAP PDFAlejandro PalaciosNo ratings yet

- Ehs 019 Houston Contactor Safety ProcedureDocument17 pagesEhs 019 Houston Contactor Safety ProcedureSayed AbbasNo ratings yet

- 1.occupational Safety and Health Administration (OSHA) Standard 29 of The Code of Federal Regulations (CFR) Part 1910.147Document8 pages1.occupational Safety and Health Administration (OSHA) Standard 29 of The Code of Federal Regulations (CFR) Part 1910.147LUKAS3589No ratings yet

- Lockout Tagout ProgramDocument9 pagesLockout Tagout Programminhduc2010100% (1)

- Lockout Tagout GuideDocument63 pagesLockout Tagout GuideEdmund Yoong100% (1)

- Lesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionDocument29 pagesLesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionCarlos LopézNo ratings yet

- PD 156Document109 pagesPD 156Hom Jyoti AdhikariNo ratings yet

- Cis WSH Cetsp27 114797 7Document77 pagesCis WSH Cetsp27 114797 7naveedNo ratings yet

- Lockout Tagout PresentationDocument70 pagesLockout Tagout PresentationBuelvas NicanorNo ratings yet

- 24.0 - Lock-Out - Tag Out (Isolation) v3.0 EnglishDocument12 pages24.0 - Lock-Out - Tag Out (Isolation) v3.0 EnglisheliezerNo ratings yet

- Revised by Njalbee 5/14Document8 pagesRevised by Njalbee 5/14Srinivas MurthyNo ratings yet

- LOTODocument29 pagesLOTOCaleb Conner100% (1)

- 091117110542preview - SS 553-2009Document6 pages091117110542preview - SS 553-2009Thanh HuuNo ratings yet

- How To Improve Solar PV Plant Performance Ratio & CUFDocument6 pagesHow To Improve Solar PV Plant Performance Ratio & CUFAnonymous mNQq7ojNo ratings yet

- Distribution System Performance Evaluation Accounting For Data UncertaintyDocument8 pagesDistribution System Performance Evaluation Accounting For Data UncertaintyAnonymous mNQq7ojNo ratings yet

- Circuit BreakerDocument15 pagesCircuit BreakerAnonymous mNQq7ojNo ratings yet

- PLCB Electrical Self Inspection ChecklistDocument3 pagesPLCB Electrical Self Inspection ChecklistAnonymous mNQq7ojNo ratings yet

- Ground Rules by John Cadick - Marine Electrical Safety - Https - WWW - Econline.com - Doc - Ground-Rules-By-John-Cadick-Marine-Electrical-0001Document16 pagesGround Rules by John Cadick - Marine Electrical Safety - Https - WWW - Econline.com - Doc - Ground-Rules-By-John-Cadick-Marine-Electrical-0001Anonymous mNQq7ojNo ratings yet

- Power System Analysis: Merger TestDocument8 pagesPower System Analysis: Merger TestAnonymous mNQq7ojNo ratings yet

- Creative Commons Attribution-Noncommercial-Sharealike LicenseDocument26 pagesCreative Commons Attribution-Noncommercial-Sharealike LicenseAnonymous mNQq7ojNo ratings yet

- Light Guide - Light Loss FactorsDocument5 pagesLight Guide - Light Loss FactorsAnonymous mNQq7ojNo ratings yet

- Power and Simplicity: Pace ScientificDocument16 pagesPower and Simplicity: Pace ScientificAnonymous mNQq7ojNo ratings yet

- Process Safety Management InspectionDocument33 pagesProcess Safety Management InspectionAnonymous mNQq7oj100% (2)

- 250.194 Grounding and Bonding of Fences and Other Metal StructuresDocument3 pages250.194 Grounding and Bonding of Fences and Other Metal StructuresAnonymous mNQq7ojNo ratings yet

- What Is The Difference Between Connected Load and Demand Load - BaytDocument1 pageWhat Is The Difference Between Connected Load and Demand Load - BaytAnonymous mNQq7ojNo ratings yet

- High Voltage Switching ProceduresDocument2 pagesHigh Voltage Switching ProceduresAnonymous mNQq7oj0% (1)

- S 70 OperationsREV 1 06Document39 pagesS 70 OperationsREV 1 06Anonymous mNQq7ojNo ratings yet

- Essentials of Facility ManagementDocument2 pagesEssentials of Facility ManagementAnonymous mNQq7ojNo ratings yet

- Building Facility Management and Services AgreementDocument25 pagesBuilding Facility Management and Services AgreementAnonymous mNQq7ojNo ratings yet

- Generator and Switchgear Servicing 16S1113Document24 pagesGenerator and Switchgear Servicing 16S1113Anonymous mNQq7ojNo ratings yet

- Power Control and Protection The Essential GuideDocument52 pagesPower Control and Protection The Essential GuideMohamed NaserNo ratings yet

- Metallurgical Factors Influencing The Machinability of Inconel 718 - SchirraDocument12 pagesMetallurgical Factors Influencing The Machinability of Inconel 718 - SchirraAntonioNo ratings yet

- Welding& Inspection WPS& WelderDocument112 pagesWelding& Inspection WPS& WelderNitesh Garg100% (7)

- KSWCFC Application 2Document2 pagesKSWCFC Application 2Clinton ThomsonNo ratings yet

- Model Scheme On Fish Cold StoragesDocument23 pagesModel Scheme On Fish Cold StoragesHarry SingadilagaNo ratings yet

- General Electric: Company OverviewDocument5 pagesGeneral Electric: Company OverviewChirag SinghalNo ratings yet

- Indian Standard - Code of Practice For Installation and Maintenance of Internal Fire Hydrants and Hose Reels On PremisesDocument33 pagesIndian Standard - Code of Practice For Installation and Maintenance of Internal Fire Hydrants and Hose Reels On PremisesDilip VemulaNo ratings yet

- Exin ISO 20000Document117 pagesExin ISO 20000alokfit100% (1)

- BCI Castings & Forgings, FinalDocument24 pagesBCI Castings & Forgings, FinalbranthamNo ratings yet

- TMX800SDocument21 pagesTMX800ScuongNo ratings yet

- GT-50 Module 1 Introduction 82 SlidesDocument81 pagesGT-50 Module 1 Introduction 82 SlideslucholadeNo ratings yet

- Data Sheet 30 - Fig TB705 Basket (Top Hat) Strainer PDFDocument1 pageData Sheet 30 - Fig TB705 Basket (Top Hat) Strainer PDFSteve NewmanNo ratings yet

- P HSSE 003 E Monitoring Contract Performance During Contr ExecutionDocument7 pagesP HSSE 003 E Monitoring Contract Performance During Contr Executionagaricus100% (1)

- Welder Id Card DhavalDocument18 pagesWelder Id Card DhavalDhaval engineeringNo ratings yet

- ISTQB Question Paper20Document53 pagesISTQB Question Paper20rashmikupsadNo ratings yet

- Revamping The Supply Chain: The Ashok Leyland Way: IntroductionDocument6 pagesRevamping The Supply Chain: The Ashok Leyland Way: IntroductionJyotiGhanchiNo ratings yet

- Friction Stir Welding Characteristics of 2219-T6 Aluminum Alloy Assisted by External Non-Rotational ShoulderDocument13 pagesFriction Stir Welding Characteristics of 2219-T6 Aluminum Alloy Assisted by External Non-Rotational ShoulderSripriyan K 100507No ratings yet

- Course Presentation IATF 16949-2016Document62 pagesCourse Presentation IATF 16949-2016Madhukar Sinha100% (6)

- ACS - ANZSCO Code Information Version 5 2019Document13 pagesACS - ANZSCO Code Information Version 5 2019rakeshNo ratings yet

- Alcohol DistillationDocument4 pagesAlcohol DistillationprocesspipingdesignNo ratings yet

- Paver Brochure 1 ZenbesDocument2 pagesPaver Brochure 1 ZenbesOng Ju EeNo ratings yet

- Excalibur 8018 C3 MRDocument2 pagesExcalibur 8018 C3 MRaxcess450No ratings yet

- AMSO User ManualDocument60 pagesAMSO User ManualJab5450No ratings yet

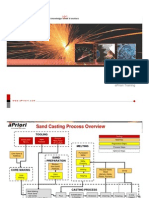

- Sand CastingDocument15 pagesSand Castingbike9915100% (1)

- A Look at The Greenfield Foundries of 2020Document12 pagesA Look at The Greenfield Foundries of 2020skluxNo ratings yet

- TATADocument25 pagesTATAanupamjeet kaur80% (5)

- lnk362 364 3310Document17 pageslnk362 364 3310achuthkumar100% (1)

- DDD Community Essay Aggregates Part 1Document6 pagesDDD Community Essay Aggregates Part 1edinathesaint100% (1)

- Testing Brush UpDocument20 pagesTesting Brush UpsrimkbNo ratings yet