Professional Documents

Culture Documents

Selection of Power Trafo

Uploaded by

ravi0 ratings0% found this document useful (0 votes)

12 views5 pagesselection power trafo

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentselection power trafo

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views5 pagesSelection of Power Trafo

Uploaded by

raviselection power trafo

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

Selecting, sizing transformers for commercial

buildings

While commercial building designs change, their electrical loads remain

fundamentally unchanged. Properly sizing and selecting transformers ensures

that these loads are accommodated.

By Ralph Baeza, PE, LEED AP, TLC Engineering for Architecture, Miami

06/09/2011

Share

Transformers, along with other power distribution apparatus, remain a

fundamental component in electrical systems distribution for commercial

buildings. This article presents several useful design concepts for selecting

and sizing transformers in the design of electrical systems for commercial

buildings.

Transformers change voltage levels to supply electrical loads with the

voltages they require. They supply the required incoming electrical service

to the buildings. Transformer primary and secondary voltages can be

2,400; 4,160; 7,200; 12,470; and 13,200 for 15-kV Class, and 120, 208,

240, 277, and 480 for 600-V Class.

Transformers are located either outdoors or inside buildings in an electrical

room or other areas as permitted by code. The electrical phase

characteristics associated with the transformers primary side is 3-phase, 3wire or Delta connected. The secondary is 3-phase, 4-wire or Wye

connected.

Construction types

There are different construction types for transformers used in commercial

buildings. Our understanding of their general characteristics will allow the

designer and end user to make the proper selection for the electrical

system application. Following are some of the transformer types available

in the industry along with a few of their characteristics:

Ventilated dry-type transformers are

ventilated by air, use larger space for clearance, and use different

insulating materials to augment the dielectric strength of the air. They

contain an enclosure surrounding the windings for their mechanical

protection and the safety of personnel. This type is the most common to be

used in the building indoor electrical system distribution. See Table 1 for

typical dry-type transformer ratings, dimensions, and weights.

Sealed dry-type transformers are similar to dry type in most of their

characteristics. The difference is they contain an enclosed tank with

nitrogen or other dielectric gas to protect the windings. They can be

installed outdoors or indoors. They are useful in areas with a corrosive or

dirty atmosphere.

Cast-coil transformers are constructed with the primary and secondary

windings encapsulated in reinforced resin. They can be installed where

moisture or airborne contaminants exist.

Nonventilated dry-type transformers are similar to the ventilated type but

are totally enclosed. This type can be installed in areas with corrosive or

dirty atmospheric conditions where it would be impossible to use a

ventilated-type transformer.

Oil-filled transformers are constructed with the windings encased in an oiltight tank filled with insulating mineral oil. It is good practice to regularly test

this type of transformer in order to determine dielectric breakdown, which

affects its useful life.

Application types

There are different ways in which transformers are installed and used as

part of a commercial building electrical system. These application types

include:

Indoor distribution transformers are used with panelboards and are

separately mounted to supply the specific electrical load requirements in a

system-specific application within the system distribution. Several

transformer types rated higher than 600 V for oil insulated type, higher than

35,000 V for dry type, and other transformers rated higher than 600 V are

required to be located in vault rooms, which must be built with fire-rated

enclosures depending on the transformer type and applicable local

authority requirements, when indoors. Transformers that are not over 600 V

and are part of the indoor building electrical system distribution have both

primary and secondary voltages below 600 V with the most common

voltage level change from 480 V to 208 Y/120 V.

Pad-mounted transformers are installed outside and are considered the

first option for supplying service entrance voltage to the building electrical

system based on the project size and requirements. They typically have

primary voltages higher than 600 V and secondary voltages lower than 600

V with compartments for the associated protective devices assembled in an

integral tamper-resistant and weatherproof unit.

In addition, the size of the commercial facility will determine the appropriate

approach for designing the electrical distribution system for the specific

application. In this electrical system design, the transformer can be used as

part of a substation, primary unit substation, secondary unit substation, or

network configuration.

Sizing

The electrical size of the transformer load is rated in kVA. This rating

provides the associated power output delivered for a specific period by the

loads connected to the transformer on the secondary side of the

equipment. The loads, which are calculated as part of the building electrical

system design phase, are shown in the construction documents respective

equipment schedules in VA or kVA.

A general approach to determining transformer capacity and selecting the

proper rating for the design application is to obtain the calculated design

load from the respective electrical schedule and add 20% spare capacity

for future load growth to be shown in the equipment schedule, unless

otherwise directed by the facility based on design parameters. For

example, the code-based demand load of a 208 Y/120 V, 3-phase, 4-wire

panelboard is 42 kVA, which does do not include spare capacity for future

growth. Therefore, the transformer size required for converting the system

voltage from 480 V, 3-phase, 3-wire to 208 Y/120 V, 3-phase, 4-wire is:

Transformer size in kVA = 42 kVA x 1.25 = 52.5 kVA

Therefore, a 75 kVA transformer would be selected for this application out

of the available standard ratings for a 480 V primary to 208 Y/120 V

secondary. The most common building industry standard ratings are 3, 6, 9,

15, 30, 37.5, 45, 75, 112.5, 150, 225, 300, 500, 750, and 1,000 kVA.

The above simple calculation meets the intent to achieve the normal life

expectancy of a transformer, which is based on the following basic

conditions:

The transformer is equal to or less than its rated kVA and rated

voltage.

The average temperature of the cooling air during a 24-hour period is

86 F.

The temperature of the cooling air at no time exceeds 104 F.

Selecting

Transformer selection starts with the kVA rating required to supply the loads

connected in the electrical system. Another consideration for indoor

distribution transformers is the type of load: linear or nonlinear. Linear loads

include resistive heating and induction motors; nonlinear loads are

produced by electronic equipment that contributes to the distortion of the

electrical power signals by generating harmonics. The harmonics resulting

from nonsinusoidal currents generate additional losses and heating of the

transformer coils, which reduce the transformer life expectancy.

Indoor transformers for nonlinear loads can be selected with a K rating,

which allows the transformer to withstand nonlinear conditions in the

electrical system. K-rated transformers do not mitigate or eliminate

harmonics. However, they do protect the transformer itself from damage

caused by harmonics. For harmonic mitigation, K-rated transformers can

be combined with harmonic filters or chokes. For linear load applications,

transformers should be selected with lower core losses. Other factors that

should be considered in selecting transformers are voltage ratings for both

primary and secondary, voltage taps, efficiency, impedance value, type of

cooling and temperature rise, voltage insulation class, basic impulse level,

and sound level.

You might also like

- Sizing Transformers For Commercial BuildingsDocument5 pagesSizing Transformers For Commercial BuildingsAnthony Arugay100% (1)

- 120 - Jimboy ElectrcicytDocument7 pages120 - Jimboy Electrcicytjaime garciaNo ratings yet

- Transformer Substation: Alternating-Current CircuitDocument5 pagesTransformer Substation: Alternating-Current CircuitessamNo ratings yet

- Power AssignmentDocument8 pagesPower AssignmentHaseeb AdilNo ratings yet

- Unit4 Transformer SelectionDocument2 pagesUnit4 Transformer SelectionMulugeta AbrhaNo ratings yet

- Distribution TransformersDocument4 pagesDistribution Transformersbsee40% (1)

- Arc 407 Note A-1Document35 pagesArc 407 Note A-1Godwin EkotechNo ratings yet

- Installation of Distribution-to-Utilization Voltage TransformersDocument7 pagesInstallation of Distribution-to-Utilization Voltage TransformersadauNo ratings yet

- Transformers and Regulators: (LTC) - This Feature inDocument8 pagesTransformers and Regulators: (LTC) - This Feature inSuroj JiansuwanNo ratings yet

- Grid-Tie Inverter - WikipediaDocument4 pagesGrid-Tie Inverter - WikipediaChandra Djaya EffendieNo ratings yet

- Power - Distribution Transformers @2020V2Document34 pagesPower - Distribution Transformers @2020V2Musfiqul AzadNo ratings yet

- EE13Document10 pagesEE13kentcarlopaye08No ratings yet

- Transformers For Wind Turbine Power ProjectsDocument8 pagesTransformers For Wind Turbine Power Projectssalemg82No ratings yet

- Transformador PrincipalDocument20 pagesTransformador PrincipalCarmen Diaz FloresNo ratings yet

- Lab Assingment Name: Umar Rahman Reg Nos: Fa18-Epe-015 Subject: Electric Machine Submitted T0: Sir Ali Muhammad DATE 4/10/2020Document13 pagesLab Assingment Name: Umar Rahman Reg Nos: Fa18-Epe-015 Subject: Electric Machine Submitted T0: Sir Ali Muhammad DATE 4/10/2020Maooz JanNo ratings yet

- Transformers and Tapchangers Version EDocument81 pagesTransformers and Tapchangers Version Emartinez_josel100% (1)

- Captive Motor-Transformer PDFDocument11 pagesCaptive Motor-Transformer PDFAmorn Thumrat100% (1)

- BUILDING SERVICES IIQuestion BankDocument37 pagesBUILDING SERVICES IIQuestion BankSiva RamanNo ratings yet

- Design EngineeringDocument6 pagesDesign EngineeringNoel JenningsNo ratings yet

- Synergy TransformerDocument2 pagesSynergy TransformerKrupal MehtaNo ratings yet

- Application of Standard Dry Type Transformers in An Electrical SystemDocument3 pagesApplication of Standard Dry Type Transformers in An Electrical SystemBhavya SriNo ratings yet

- Electrical Substation: 1 Elements of A SubstationDocument7 pagesElectrical Substation: 1 Elements of A SubstationgloriafindelinNo ratings yet

- Transformadores Factor KDocument3 pagesTransformadores Factor KLuis Aguirre FloresNo ratings yet

- O & M of Sub-Station Equipment: Narender Kumar Me Mba MieDocument31 pagesO & M of Sub-Station Equipment: Narender Kumar Me Mba MiewaleedalzaidiNo ratings yet

- SubstationsDocument34 pagesSubstationsBeen Carlo De JasminNo ratings yet

- Wind Power GenerationDocument25 pagesWind Power GenerationAbhishek SoodNo ratings yet

- Grid-Tie Inverter - Wikipedia, The Free EncyclopediaDocument5 pagesGrid-Tie Inverter - Wikipedia, The Free EncyclopediaOluwafemi Samuel AdesanmiNo ratings yet

- Transformer Selection and CalculationDocument12 pagesTransformer Selection and Calculationjbebin0% (1)

- Distribution SubstationDocument31 pagesDistribution SubstationAadya100% (1)

- Cne Micro ProjectDocument7 pagesCne Micro Projectjadhavayush590No ratings yet

- Name: Shoaib AhmedDocument41 pagesName: Shoaib AhmedSagar AliNo ratings yet

- Electrical Substation (GRID) : Generating Station SwitchyardsDocument21 pagesElectrical Substation (GRID) : Generating Station SwitchyardsTariqNo ratings yet

- UEP Bulletin 1724E-300Document222 pagesUEP Bulletin 1724E-300mamtaskydesignerNo ratings yet

- White Paper Managing Transmission Voltages in Power Systems With Air Core Shunt ReactorsDocument8 pagesWhite Paper Managing Transmission Voltages in Power Systems With Air Core Shunt ReactorsMuh'dAmin Adize IdrisNo ratings yet

- Cascaded H Bridge Multilevel Inverter Modelling and SimulationDocument34 pagesCascaded H Bridge Multilevel Inverter Modelling and SimulationPriyanka GuptaNo ratings yet

- Review and Comparison of High Efficiency High Power Boost DC/DC Converters For Photovoltaic ApplicationsDocument8 pagesReview and Comparison of High Efficiency High Power Boost DC/DC Converters For Photovoltaic ApplicationsmaazNo ratings yet

- Basics of Medium-Voltage Wiring For PV Power Plant AC Collection SystemsDocument15 pagesBasics of Medium-Voltage Wiring For PV Power Plant AC Collection Systemsdanisweet100% (1)

- InvertersDocument30 pagesInvertersterryhoNo ratings yet

- Capacitor SelectionDocument72 pagesCapacitor SelectionSatyendra Kumar100% (2)

- SUBstation Equipmens TLDocument12 pagesSUBstation Equipmens TLJecer Casipong NuruddinNo ratings yet

- Tender Dry Type TransDocument19 pagesTender Dry Type Transdk010784No ratings yet

- Current Transformer: Profile No.: 273 NIC Code: 27102Document14 pagesCurrent Transformer: Profile No.: 273 NIC Code: 27102Rama SubrahmanyamNo ratings yet

- Transformers: Ensuring Efficient Electrical System DesignDocument2 pagesTransformers: Ensuring Efficient Electrical System DesignMohamedAhmedFawzyNo ratings yet

- Switchyard FinalDocument6 pagesSwitchyard FinalPritam SamantaNo ratings yet

- Tarea ProteccionesDocument8 pagesTarea Proteccionesjuan carlos moreno morenoNo ratings yet

- 01 Power Unit Connections (Overview)Document6 pages01 Power Unit Connections (Overview)Jemellee BautistaNo ratings yet

- InverterDocument7 pagesInvertermaryam_dNo ratings yet

- Project - On Power Sub StationDocument22 pagesProject - On Power Sub StationRavi KumarNo ratings yet

- High Voltage & Power System ProtectionDocument17 pagesHigh Voltage & Power System ProtectionDipok Chandra PalNo ratings yet

- Sri RamachandranDocument7 pagesSri RamachandranNavaneethakrishnan MurugesanNo ratings yet

- Final LessonDocument21 pagesFinal LessonEstifane VelosoNo ratings yet

- Mobile Substations Design and Primary ComponentsDocument12 pagesMobile Substations Design and Primary ComponentsmercedesbestsupplierNo ratings yet

- Shunt Reactors White Paper GEA31994 PDFDocument8 pagesShunt Reactors White Paper GEA31994 PDFAndré LuizNo ratings yet

- Coren Write UpDocument20 pagesCoren Write UpBabatunde MartinsNo ratings yet

- Automatic Power Factor CorrectionDocument14 pagesAutomatic Power Factor CorrectionlearningboxNo ratings yet

- Siemens TransformerDocument12 pagesSiemens TransformerPrashant RajputNo ratings yet

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesFrom EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Power Electronics and Energy Conversion Systems, Fundamentals and Hard-switching ConvertersFrom EverandPower Electronics and Energy Conversion Systems, Fundamentals and Hard-switching ConvertersNo ratings yet

- PEECC Equipment ListDocument1 pagePEECC Equipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- RMS Area RequirementDocument4 pagesRMS Area RequirementraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument4 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument4 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- CT 1Document2 pagesCT 1raviNo ratings yet

- CTDocument2 pagesCTMuthu PandiNo ratings yet

- CTDocument2 pagesCTMuthu PandiNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- CT 1Document2 pagesCT 1raviNo ratings yet

- Electrical Control Building Eqipment ListDocument2 pagesElectrical Control Building Eqipment ListraviNo ratings yet

- CTDocument2 pagesCTMuthu PandiNo ratings yet

- CTDocument2 pagesCTMuthu PandiNo ratings yet

- CTDocument2 pagesCTMuthu PandiNo ratings yet

- CTDocument2 pagesCTMuthu PandiNo ratings yet

- CT 1Document2 pagesCT 1raviNo ratings yet

- AsbcnxxkkmnnnnDocument1 pageAsbcnxxkkmnnnnraviNo ratings yet

- CTDocument2 pagesCTMuthu PandiNo ratings yet

- RAGAMSDocument4 pagesRAGAMSraviteja86No ratings yet

- 1.3 Hydraulic PumpsDocument15 pages1.3 Hydraulic Pumpsdoan lucNo ratings yet

- s67 Rosen Thermo - Hi.pvc Iz 2018 enDocument34 pagess67 Rosen Thermo - Hi.pvc Iz 2018 enSomea NoneaNo ratings yet

- SimulationDocument56 pagesSimulationErica SalasNo ratings yet

- 1 CathDocument12 pages1 CathHashem AlsmadiNo ratings yet

- T1 SeriesDocument1 pageT1 SeriesFabricio GonçalvesNo ratings yet

- Automatic Shutter Series: FV-20AU9T/FV-25AU9T/ FV-30AU9TDocument1 pageAutomatic Shutter Series: FV-20AU9T/FV-25AU9T/ FV-30AU9TmevanditaNo ratings yet

- Remy Hvh250 Application Manual: Preliminary Draft Hvh250 Motormanual20110407.Doc Page 1 of 31Document31 pagesRemy Hvh250 Application Manual: Preliminary Draft Hvh250 Motormanual20110407.Doc Page 1 of 31David WalshNo ratings yet

- Energies 14 04973Document19 pagesEnergies 14 04973roméo legueNo ratings yet

- 〈85〉 Bacterial Endotoxins TestDocument6 pages〈85〉 Bacterial Endotoxins Testahmed sonyNo ratings yet

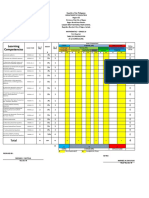

- Learning Competencies: TotalDocument4 pagesLearning Competencies: TotalLaira Joy Salvador - ViernesNo ratings yet

- Dynamic Analysis of Gear Shifting MechanismDocument4 pagesDynamic Analysis of Gear Shifting MechanismMr. S. Thiyagu Asst Prof MECHNo ratings yet

- BalancesDocument8 pagesBalancescchauling6841No ratings yet

- C Atomic StructureDocument34 pagesC Atomic StructureMarshmalloowNo ratings yet

- World's Leading Supplier of Infrared (IR) Receivers: OptoelectronicsDocument4 pagesWorld's Leading Supplier of Infrared (IR) Receivers: OptoelectronicsHenry ChanNo ratings yet

- 480-1 (Manski, Northwestern) PDFDocument3 pages480-1 (Manski, Northwestern) PDFInvestNo ratings yet

- 07 VariablesDocument3 pages07 VariablesBaneeIshaqueKNo ratings yet

- Biochem Laboratory ReviewerDocument6 pagesBiochem Laboratory Reviewer202370092No ratings yet

- Capaciter Working PrincipalDocument2 pagesCapaciter Working PrincipalSanjivee SachinNo ratings yet

- 22 - GIS Testing PDFDocument9 pages22 - GIS Testing PDFwaqas_a_shaikh4348No ratings yet

- Test Section 2 QuizDocument5 pagesTest Section 2 QuizDavidNo ratings yet

- HX 16-Data SheetDocument2 pagesHX 16-Data SheetRaul SebastiamNo ratings yet

- Lesson Plan Limits of AccuracyDocument1 pageLesson Plan Limits of AccuracyJonathan Robinson100% (2)

- AWS TCO WorkSpacesDocument16 pagesAWS TCO WorkSpacessantuchetuNo ratings yet

- Datasheet 40192BMS (Com Clock) )Document12 pagesDatasheet 40192BMS (Com Clock) )vanmarteNo ratings yet

- 3 Chrono VisualizationDocument24 pages3 Chrono VisualizationVikramnath VenkatasubramaniNo ratings yet

- It Skills NotesDocument29 pagesIt Skills Notesjuttahtsham160No ratings yet

- Schneider Acti9 Protection CatalogueDocument92 pagesSchneider Acti9 Protection CatalogueRashikNo ratings yet

- Antioxidants - MELROB - RubberDocument6 pagesAntioxidants - MELROB - RubberMarcos ROSSINo ratings yet

- Mancova GuidanceDocument39 pagesMancova GuidancePhilemon NshimiyimanaNo ratings yet