Professional Documents

Culture Documents

BPC solvent extraction

Uploaded by

rajeevup2004Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BPC solvent extraction

Uploaded by

rajeevup2004Copyright:

Available Formats

Bateman Pulsed Columns

Bateman Litwins Advanced Technologies Division provides state-of-the-art solvent extraction

know-how and technologies.

The Bateman Pulsed Column (BPC) is a highly efficient cost-effective contactor which enhances

solvent extraction (SX) during extraction, stripping and scrubbing or washing processes.

Advantages of the BPC

Continuous and multi-stage

extraction process

Handling of liquids with

suspended solids

A safer and more environmentally

friendly process

Free from moving internal parts

A fully automated system

Lower maintenance and operating costs

Dramatically reduces floor

space needs

Applications of BPC

Bateman Pulsed Columns can enhance most

industrial SX processes, particularly those with

a fast rate of mass transfer.

Minerals processing: uranium, nickel, cobalt,

zinc, titanium

Chemical industry: nitric, phosphoric and

hydrochloric acids

Environmental protection: recovery of nitrates,

sulfuric acid, cyanides, and halides

Additional applications include pharmaceutical,

food and petroleum industries

Bateman Litwins Test and Design Capabilities

The BPC technology is backed up by Bateman Litwins comprehensive range of services, starting

with bench scale exploratory tests through to pilot scale test work, culminating in the design,

construction and commissioning of full scale solvent extraction plants. An essential component

of this service is the experience of Bateman Litwin engineers in the field of solvent extraction and

access to pulsed column pilot plants.

How the BPC Works

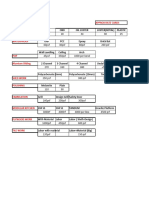

A Bateman Pulsed Column consists of a large diameter vertical pipe filled

alternatively with disc & doughnut shaped baffles which facilitate contact

between the immiscible liquids as they pass through the column.

The heavy (aqueous) phase enters through a disperser at the top of the column

and the light (organic solvent) phase enters through a similar device near the

bottom. A decanter at each end of the column permits the liquids to coalesce

and be decanted separately. When the solvent phase is continuous the interface

between the phases is in the lower decanter and when the aqueous phase is

continuous, it is in the upper decanter.

The columns are pulsed by blowing air at the required amplitude and frequency

of the pulses which are controlled using four-way solenoid valves.

Four-Way Valve

Interface Level Measuring Element

Upper Decanter

Air Vessel

Hold-Up

Measuring Element

Internals Disc & Doughnuts

Pulsation Leg

Bateman Litwin

Headquarters

Haaksbergweg 59

1101 BR Amsterdam,

The Netherlands

Tel: +31-20-564-0491

Fax: +31-20-564-0490

Control Valve

Lower Decanter

Litwin

13-15, rue Edouard Manet

92504 Rueil Malmaison

Cedex, France

Tel: +33 (0)1 72 25 52 52

Fax: +33 (0)1 72 25 52 90

WengFu, China, Purified Phosphoric Acid SX plant

Regional offices:

Goro Nickel, New Caledonia, Nickel/Cobalt SX plant

Chile, Italy, Kazakhstan,

Morocco, Nigeria,

Russia, Romania,

Slovakia, Switzerland,

the Middle East, USA

Selected Projects

Olympic Dam Operations, Australia, Uranium SX plant

www.bateman-litwin.com

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- EXPERIMENT and Latest EquipmentDocument10 pagesEXPERIMENT and Latest EquipmentMaria Cecille Sarmiento GarciaNo ratings yet

- FMSP 2Document40 pagesFMSP 2مصطفى عمرNo ratings yet

- 5 VsDocument4 pages5 VsAdhitomoWirawanNo ratings yet

- Ultrasonic Cleaning: One of The Major Applications of High Power UltrasonicDocument41 pagesUltrasonic Cleaning: One of The Major Applications of High Power UltrasonicVijay Rajaindran100% (1)

- 02 - DILG - Salintubig - Components of Water Supply SystemDocument43 pages02 - DILG - Salintubig - Components of Water Supply SystemTarhata KalimNo ratings yet

- F1-28 Cavitation DemonstrationDocument3 pagesF1-28 Cavitation DemonstrationFornade Andrei100% (1)

- Method of Statement For Cleaning Flushing and Passivation of Chilled Water PipingDocument10 pagesMethod of Statement For Cleaning Flushing and Passivation of Chilled Water PipingMYKNo ratings yet

- Cleaning & Flushing of CHW PipingDocument9 pagesCleaning & Flushing of CHW PipingNikhil JadhavNo ratings yet

- Reducing Particulate Emissions with a TurboVenturi ScrubberDocument10 pagesReducing Particulate Emissions with a TurboVenturi Scrubberjosedalceggio1955No ratings yet

- BF610Document4 pagesBF610Prasad KulkarniNo ratings yet

- Diaphragm Pump CharacteristicsDocument9 pagesDiaphragm Pump CharacteristicslamiaNo ratings yet

- HVAC Chilled Water Cleaning ProcessDocument7 pagesHVAC Chilled Water Cleaning Processarshad iqbalNo ratings yet

- Dissolved Air Flotation SystemDocument4 pagesDissolved Air Flotation SystemHari Dwipayanto DwipayantoNo ratings yet

- Mecawber DenseveyorDocument4 pagesMecawber DenseveyorkanthmekalaNo ratings yet

- Clearvue Pump: SpecificationsDocument2 pagesClearvue Pump: SpecificationsRichard BakerNo ratings yet

- Gas UnitDocument4 pagesGas UnitZalina SamsuddinNo ratings yet

- Fluid purification solution for hydraulic oils, lubricants and coolant fluidsDocument8 pagesFluid purification solution for hydraulic oils, lubricants and coolant fluidshaggNo ratings yet

- Column Internals Regarding-EnDocument44 pagesColumn Internals Regarding-Enmansih457100% (1)

- Equipments Used in Mass and Heat Transfer in Pharmaceutical IndustryDocument14 pagesEquipments Used in Mass and Heat Transfer in Pharmaceutical IndustryM Aftab ShabirNo ratings yet

- Controll Valve PresentatonDocument26 pagesControll Valve Presentatonchayan_m_shahNo ratings yet

- Cleaning and Passivation of Chilled Water PipingDocument13 pagesCleaning and Passivation of Chilled Water PipingtonylyfNo ratings yet

- x11 ModularDocument4 pagesx11 ModularHao XuNo ratings yet

- Introduction To Process Plant Layout & Piping DesignDocument91 pagesIntroduction To Process Plant Layout & Piping DesignRaj Kamal0% (1)

- M-1-40 WATER TREATMENT - VNGDC-TD-M-01-DSC-DC-0001-new UpdateDocument3 pagesM-1-40 WATER TREATMENT - VNGDC-TD-M-01-DSC-DC-0001-new UpdateEurotech purchasing04No ratings yet

- A Guide To Clean in Place (CIP)Document6 pagesA Guide To Clean in Place (CIP)Dominic TolentinoNo ratings yet

- Pipe Flow Fundamentals Rev 0Document81 pagesPipe Flow Fundamentals Rev 0junaediwendiNo ratings yet

- Column PresentationDocument27 pagesColumn PresentationTaifurNo ratings yet

- Aptech Advances in Pneumatic Conveying EditorialDocument17 pagesAptech Advances in Pneumatic Conveying EditorialMinh Tú PhạmNo ratings yet

- Pipe Flow Fundamentals Rev 0Document81 pagesPipe Flow Fundamentals Rev 0junaediwendi100% (1)

- Denseveyor Brochure1Document4 pagesDenseveyor Brochure1rumabiswas853100% (1)

- Distillation Column Tray Selection & Sizing - 1 - Separation Technologies PDFDocument22 pagesDistillation Column Tray Selection & Sizing - 1 - Separation Technologies PDFmehul10941100% (1)

- SOLTEQDocument4 pagesSOLTEQRobert GilmoreNo ratings yet

- Solex DWHX Commercial Pump StationDocument3 pagesSolex DWHX Commercial Pump StationDan JungNo ratings yet

- General Plumbing KnowledgeDocument6 pagesGeneral Plumbing KnowledgeobNo ratings yet

- STA-C Series - Super Trident Sewage Treatment PlantDocument2 pagesSTA-C Series - Super Trident Sewage Treatment Plantanandsharma123No ratings yet

- Instrumentation Advance Course Part 2Document69 pagesInstrumentation Advance Course Part 2FACE BOOKNo ratings yet

- Wastewater TreatmentDocument49 pagesWastewater TreatmentAshwani Kumar Pati TripathiNo ratings yet

- Sample Securitiser: Pressure Facility Re-InventedDocument4 pagesSample Securitiser: Pressure Facility Re-InventedMiguelNo ratings yet

- Oxygen and Others Measurement Extraction Boiler by SWANengDocument5 pagesOxygen and Others Measurement Extraction Boiler by SWANengJimmyJhoeNo ratings yet

- MX Zonecheck PDFDocument2 pagesMX Zonecheck PDFNarendra Reddy BhumaNo ratings yet

- Pipeline Engineering Training ManualDocument25 pagesPipeline Engineering Training ManualEhigiator Joseph80% (5)

- Manual Columna de FlotaciónDocument40 pagesManual Columna de FlotaciónpaulinaNo ratings yet

- Hanshin 2519-3241VHDocument7 pagesHanshin 2519-3241VHnotaden1849No ratings yet

- 4 - L55 Unit Operations Lab - Data SheetsDocument30 pages4 - L55 Unit Operations Lab - Data SheetsalijadoonNo ratings yet

- Tecma Technical Handbook - Guide for Designers, Builders & OperatorsDocument18 pagesTecma Technical Handbook - Guide for Designers, Builders & OperatorsSaul Moises Mondaca PereiraNo ratings yet

- Banco Hidraulico ReporteDocument5 pagesBanco Hidraulico ReporteJuan Diego Citalan AguilarNo ratings yet

- 4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsDocument48 pages4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsZain Ali100% (1)

- SO 401B Concrete enDocument8 pagesSO 401B Concrete enknchnNo ratings yet

- Pressure Test Flushing Pickling PassivationDocument12 pagesPressure Test Flushing Pickling PassivationVidal Choque N.100% (1)

- Vector Brochure PDFDocument11 pagesVector Brochure PDFDoDuyBacNo ratings yet

- Terrain Drainage Design Dubai MunicipalityDocument16 pagesTerrain Drainage Design Dubai MunicipalityChamara Chinthaka Ranasinghe100% (2)

- (SS0V003) Uni-Directional Sphere Type ProverDocument2 pages(SS0V003) Uni-Directional Sphere Type ProverRoberto Carlos TeixeiraNo ratings yet

- Method of Statement For Cleaning of Chilled Water PDFDocument11 pagesMethod of Statement For Cleaning of Chilled Water PDFgaineyskNo ratings yet

- Method Statement For Cleaning Flushing and Passivation of Chilled Water PipingDocument14 pagesMethod Statement For Cleaning Flushing and Passivation of Chilled Water PipingTawrez KhatibNo ratings yet

- C Series: Cage Design Control ValvesDocument6 pagesC Series: Cage Design Control Valvesdnageshm4n244No ratings yet

- 11 Law Liquid-Liquid Extraction Equipment JDL 3-2-09Document14 pages11 Law Liquid-Liquid Extraction Equipment JDL 3-2-09Sunds SundNo ratings yet

- Refining Topsoe Reactor InternalsDocument8 pagesRefining Topsoe Reactor InternalsGopiNo ratings yet

- HFD Catalog SentinelDocument12 pagesHFD Catalog SentinelGuido Moreno PeredoNo ratings yet

- Returning Zero When A Referenced Cell Is Blank (Microsoft Excel)Document4 pagesReturning Zero When A Referenced Cell Is Blank (Microsoft Excel)rajeevup2004No ratings yet

- Coal Flotation-Technical ReviewDocument3 pagesCoal Flotation-Technical Reviewrajeevup2004No ratings yet

- Best Practices For Design of Slurry Flow DistributionsDocument11 pagesBest Practices For Design of Slurry Flow Distributionsfelipe muñozNo ratings yet

- Calculation of Specific Surface: S, I S I P, IDocument1 pageCalculation of Specific Surface: S, I S I P, Irajeevup2004No ratings yet

- E PUB 02 0005 - v02 Distribution Systems Part 1Document2 pagesE PUB 02 0005 - v02 Distribution Systems Part 1rajeevup2004No ratings yet

- Stroke IndicatorDocument2 pagesStroke Indicatorrajeevup2004No ratings yet

- 2382-Trellex HoseSystem ENDocument8 pages2382-Trellex HoseSystem ENrajeevup2004No ratings yet

- Leaflet UFS Screen 4284 en LowresDocument2 pagesLeaflet UFS Screen 4284 en Lowresrajeevup2004No ratings yet

- E PUB 02 0006 - v01 Splitter Boxes Part 1Document2 pagesE PUB 02 0006 - v01 Splitter Boxes Part 1rajeevup2004No ratings yet

- TeeteredBedSeparators PresentationDocument30 pagesTeeteredBedSeparators Presentationrajeevup2004No ratings yet

- Elutriation by MintekDocument12 pagesElutriation by Mintekrajeevup2004No ratings yet

- Oil-Resistant Rubbers: Machine DesignDocument5 pagesOil-Resistant Rubbers: Machine Designrajeevup2004No ratings yet

- Financial Analysis RatiosDocument1 pageFinancial Analysis Ratiosrajeevup2004No ratings yet

- Acid Number Guide: Understanding AN TestsDocument11 pagesAcid Number Guide: Understanding AN Testsrajeevup2004No ratings yet

- O&M Manual of Micron Motion Flowmeter PDFDocument80 pagesO&M Manual of Micron Motion Flowmeter PDFrajeevup2004No ratings yet

- PQ Liquid Sodium and Potassium Silicates - Storage and HandlingDocument9 pagesPQ Liquid Sodium and Potassium Silicates - Storage and HandlingxiaoNo ratings yet

- Linatex Premium Rubber Spec SheetDocument1 pageLinatex Premium Rubber Spec Sheet_Asylum_No ratings yet

- Storage - Guideline - Storing GuidlinesDocument1 pageStorage - Guideline - Storing Guidlinesrajeevup2004No ratings yet

- Sodium Silicate HandbookDocument24 pagesSodium Silicate Handbookrajeevup2004No ratings yet

- ABON RollerscreenDocument6 pagesABON Rollerscreenrajeevup2004No ratings yet

- Acid Number Vs PHDocument2 pagesAcid Number Vs PHrajeevup2004No ratings yet

- Beamex White Paper - Weighing Scale Calibration ENGDocument8 pagesBeamex White Paper - Weighing Scale Calibration ENGabthakurNo ratings yet

- Centrifugal Slurry Pump StandardDocument4 pagesCentrifugal Slurry Pump StandardLuis Enrique Yactayo SullerNo ratings yet

- Landed Price CalcDocument1 pageLanded Price Calcrajeevup2004No ratings yet

- Silicon Carbide PresentationDocument12 pagesSilicon Carbide Presentationrajeevup2004No ratings yet

- Belt Filter Cloth Brochure - SaferDocument11 pagesBelt Filter Cloth Brochure - Saferrajeevup2004No ratings yet

- Classify spiral classifiers with SEO-optimized titleDocument4 pagesClassify spiral classifiers with SEO-optimized titlerajeevup2004No ratings yet

- Bucket Elevator Design Centrifugal Vs ContinuousDocument3 pagesBucket Elevator Design Centrifugal Vs Continuousrajeevup2004No ratings yet

- Bucket Elevator BasicsDocument3 pagesBucket Elevator Basicsrajeevup2004No ratings yet

- Thermal PropertiesDocument14 pagesThermal PropertiesLivian TeddyNo ratings yet

- TLE9 Q1 WK1-editedDocument26 pagesTLE9 Q1 WK1-editedMichael AmoresNo ratings yet

- Alloys & Strengthening: Lecture 10. Introduction & The Equilibrium Phase DiagramDocument23 pagesAlloys & Strengthening: Lecture 10. Introduction & The Equilibrium Phase DiagramHenry HarrodNo ratings yet

- Pheonwj M Spe 0025 1Document48 pagesPheonwj M Spe 0025 1Iksan Adityo Mulyo100% (1)

- SCH3U0 Stoichiometry LabDocument12 pagesSCH3U0 Stoichiometry Lab732185No ratings yet

- ISC ChemistryDocument8 pagesISC Chemistrysamrounder100% (3)

- Lubricating Oil Properties and ManufactureDocument4 pagesLubricating Oil Properties and ManufactureGhazy alshyalNo ratings yet

- Preservative in Personal Care PDFDocument91 pagesPreservative in Personal Care PDFJuliardosJ.M.LubisNo ratings yet

- 8 Msds MSDSDocument21 pages8 Msds MSDSoddyNo ratings yet

- Carbohydrate ChemistryDocument78 pagesCarbohydrate ChemistryNikhil NathNo ratings yet

- UDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IDocument4 pagesUDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IrambinodNo ratings yet

- Grade 7 Learning Module Prototype 1Document9 pagesGrade 7 Learning Module Prototype 1Espie Rose DumalagNo ratings yet

- Use of N2 Gas For Purging in GTAW of SSDocument4 pagesUse of N2 Gas For Purging in GTAW of SSrondulf goNo ratings yet

- Chemolube H - Product DescriptionDocument6 pagesChemolube H - Product DescriptionJulio VargasNo ratings yet

- Awt 11 SDS 4001Document14 pagesAwt 11 SDS 4001Vyrax FalconNo ratings yet

- Comparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialsDocument1 pageComparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialskapilNo ratings yet

- Process of Production CS2 PDFDocument9 pagesProcess of Production CS2 PDFDinii Lathiifah PertiwiNo ratings yet

- Treating Technologies of Shell Global Solutions For Natural Gas and Refinery Gas StreamsDocument19 pagesTreating Technologies of Shell Global Solutions For Natural Gas and Refinery Gas StreamsPrasad ChakkrapaniNo ratings yet

- College BFA 2021Document35 pagesCollege BFA 2021Dinesh WaranNo ratings yet

- Ch-6 Q AnsDocument4 pagesCh-6 Q AnshhhNo ratings yet

- Miscellaneous Information: R 1.987 Cal/mole°k 8.314 J/mole°K Absolute Zero - 273.15°C 1 Joule 0.239 CaloriesDocument32 pagesMiscellaneous Information: R 1.987 Cal/mole°k 8.314 J/mole°K Absolute Zero - 273.15°C 1 Joule 0.239 CalorieswastequestNo ratings yet

- Ammonia: Valves For Ammonia ServiceDocument2 pagesAmmonia: Valves For Ammonia ServiceArun Babu0% (1)

- PPH 4069Document1 pagePPH 4069tranoNo ratings yet

- Rate CardDocument6 pagesRate CardRavi SrivastavaNo ratings yet

- Wireline Logging Using ExcelDocument2 pagesWireline Logging Using ExcelYoussef ElbouazaouiNo ratings yet

- Patent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentsDocument9 pagesPatent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentschecolonoskiNo ratings yet

- 6.0 ELECTROCHEMISTRYDocument35 pages6.0 ELECTROCHEMISTRYwb4qv7yzvzNo ratings yet

- Stability of Phases The Si-C-N-0 System: Harue Wada, Ming-Jong Wang, and Tseng-Ying Tien"Document4 pagesStability of Phases The Si-C-N-0 System: Harue Wada, Ming-Jong Wang, and Tseng-Ying Tien"radoslavoffNo ratings yet

- 2016 Progress in Non-Isocyanate Polyurethanes Synthesized PDFDocument38 pages2016 Progress in Non-Isocyanate Polyurethanes Synthesized PDFPilar MayaNo ratings yet

- Test 2 CHM572 June 2024Document3 pagesTest 2 CHM572 June 2024NUR AINA SYAHMINA MOHD AMRANNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Napoleon's Buttons: 17 Molecules That Changed HistoryFrom EverandNapoleon's Buttons: 17 Molecules That Changed HistoryRating: 4 out of 5 stars4/5 (25)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingFrom EverandIt's Elemental: The Hidden Chemistry in EverythingRating: 4 out of 5 stars4/5 (10)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableFrom EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableNo ratings yet

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (150)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)