Professional Documents

Culture Documents

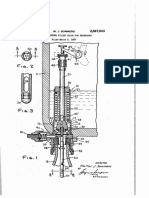

H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962

Uploaded by

Josh FullerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962

Uploaded by

Josh FullerCopyright:

Available Formats

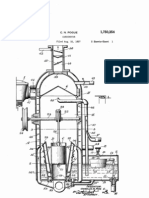

May 26, 1964 ~

H. O. PEDERSEN ETAL

3,134,353

UNDERWATER PROPULSION SYSTEM

Filed March 20, 1962

2 Sheets-Sheet 1

w@.

INVEN TORS

BY

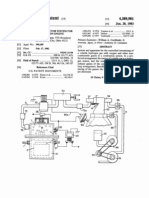

May 26, 1954

H. o. PEDERSEN ETAL

3,134,353

UNDERWATER PRoPuLsIoN SYSTEM

Filed March 20, 1962

wm

2 Sheets-Sheet' 2

mm

INVENTORS

HAAA/o/V 0. PHJQSEN

JoH/v w. co/vLo/v

KUnited States Patent .On ice

3,134,353

' , Patented May 2.6, 19`64

2

nozzle 26 whose peripherally spaced apertures 27 afford

'

communication with an enclosing low pressure chamber .

3,134,353

UNDERWATER PROPULSION SYSTEM

28. As shown in FIGURE A2, this chamber may comprise

twospherical portions 29 and 30 with adequate seals to

enable universal pivoting of the aft section 30 which is

integral with the hydrojet Water exhaust or thrust noz

zle 26 by control members (not shown) to effect steer

Haakon 0. Pedersen, Morris Plains, NJ., and .lohn VY.

,Conlon, Melbourne, Fla., assignors to Thiokol Chenn

cal Corporation, Bristol, Pa., a corporation of Delaware

' Filed Mar. 20, 1962, Ser. No. 130,978

13 Claims. (Cl. 114-20)

ing of the vehicle.

'

This. invention relates generally to a propulsion system

While the system comprising the present invention may

for'vehicles and more particularly to a hydrojet propul

be operated with other types of monopropellants, hydro

sion system which will enable vehicles to travel under

gen peroxide is preferred as a fuel becausethe steam in

Water> at high speeds and descend to great depths.

the exhaust of the turbine 20 may be condensed. As

Various types of systems have been devised for pro

shown, a tank 33 of H2O2 including a exible membrane

pelling vehicles such as submarines, torpedos, etc. under

34 is mounted in the vehicle body 10 and pressurized

Waterincluding that of pulling the sea Water into a duct 15 by helium, etc. containedgin a high pressure gas con

in the vehicle and forcing it out at the stern through a

tainer 35 by means of a conduit 36 which is provided

thrust nozzle. Also, while various means have been em

with a pressurizing valve 37 and a regulator`38.

plloyedV to force the water through the vehicle, all of these

The H2O2 propellant is connected by a conduit 39

khave the disadvantage of being handicapped in operation

having a control valve 40 to a catalyst chamber 41 Where

`as'to, quality of overall performance because of back 20 the Vhydrogen peroxidedecomposes into steam and oxygen

Vpressure which increases with depth. This is particularly

at l~390` F. The products of decomposition pass by way

true in a turbine drive system because the amount of the

of conduit 43 to the blades of the turbine 20 to rotate

V'energy that can be extracted from the drive gas is directly

it and> drive the pump 19 thus pulling sea water into

limited by the back pressure.

thevehicle body through the inlet 17 >and the conduits

-: Accordingly, the main object of -the present invention 25 18 Vand exhaustl it to the chamber l25 and out through

is to provide >an improved underwater propulsion system ~ ~`

which eliminates the above and other disadvantages of

known systems.

"

VAn important object of the present invention is to pro

. vide an improved underwater propulsion system employ-

the hydrojet nozzle 26, to _provide propulsion thrust to

the "vehicle,

'

Upon leaving the turbine, the products of decomposi

tion passby way of conduit 44 through a condenser 45 in

which sea Water is vused as a coolant just as the ,water

inga hydrojet for propulsionV and steering which leaves

pumpedvthro'ugh the inlet 17 cools the Vehicle body. v-As

a> minimum Wake to betray the passage of the vehicle.

' Another important object of the present invention is to

, provide an improved self contained, underwater hydrojet

seen in FIGURE 1, the conduit 44 includes a number of

pressurizing uid is tapped from the pump discharge. `

leaving the condenserby conduit`48 (waterand free

coils in the cooling chamber ._45 arranged in the aft por

tion

of the vehicle,thecondenser chamber being pro

propulsion system having a pressurized fuel system to 35 vided with ysea water inlet ports 46 and outlet ports 47.

drive a pump-driving turbine wherein after starting the " It will be apparent that the decomposition products

further important object ofthe present invention is

oxygen) have Vbeen significantly reduced in volume.'

This reductionV in volume facilitates the disposal of the.

which _includes Ymeans tov prevent starting of the _turbine 40 exhaust` products by the -conduit 49 through the cham

to provide an improved system of the type described

. unless water is present in the pump to permit air launch

ing of the vehicle.

ber 28 and the throat section ofthe venturi 26 which

is at low pressure.

A still further important object of the present inventionv

In order to eliminate the Wakeof the vehicle, it is

is to provide an improved system of the type described

desirable to provide means shown diagrammatically at

45

" wherein the products of combustion upon leaving the

50 in FIGURE 2, to absorb or combine with the free

turbine are condensed and then discharged into a low

oxygen leaving the condenser 45. This may comprise

pressure area to overcome the back pressure problem.

a compound having such characteristics or a burner and

Other objects and advantages of the invention will be

a source of hydrogen to burn with the oxygen, the re

come apparent during the course of the following descrip

tion.

In the drawings We have shown one embodiment of`

the invention. In this showing:

FIGURE l is a central longitudinal sectional view ofv

one form of underwater vehicle embodying the invention;

vandk

FIGURE 2 is a schematic view of the propulsion sys

'l tem.

50

sulting water being exhausted through the conduit 49.

It will be noted that a conduit 56 having a one-way valve

59 connects the water exhaust chamber 25 with the fuel

tank 33 so that once .the turbine is started, water is

used to pressurize the hydrogen peroxide by acting on

55 the membrane 34.

This enables the use of the pressur

izing gas such as helium for starting purposes only, re-A

duces the amount which must be carried, and thus more

fuel can be carried to increase lthe range of the vehicle. ,

Referring to the drawings, numeral 10 designates a

In order that a predetermined speed may be main

Vvehicle body which, as shown in FIGURE 1 for illus

tained by thev vehicle, a governor 53 is connected to the

60

trative purposes only, is that of a torpedo or underwater

turbine shaft 23 by gears 54 and is suitably connected

Vvmissile-.having a warhead 13kmounted in the forward

to the control valve 40 in the conduit 39 leading from

. en_d thereof against a bulkhead 14 closing an inner ve

hicle body 15, by augularly spaced streamlined strutsv

i ; v16.> The space between the forward end of the inner and

hydrogen peroxide supply tank 33. A safety control 55

for the fuel valve 40 is mounted on the exhaust chamber

25 and is provided withcontacts closable by sea water.

>outer bodies 15 and 10 defines an annular water inlet 65 This ensures that the turbine will not start unless water

17 ~ merging into conduits` 18 through which the water is

is present in the pump 19 fand enables the air launching `

.fpulled by the blades of a pump 19.y of the vehicle.

v

The pump 19 and a turbine 20 by which it is driven

w are fixed to a shaft 23 rotatably mounted in bearings 24

The operation of the underwater propulsion system is

believed to be apparent. The propellant tank 33 is presiv

and theV conduits 18 deliver the water fromgthe pump 70 surized upon the opening of the pressurizing fluid'valve

'- -blades into the inlet portion 25 of a cavitating venturi

37 to force the fuel to the catalyst chamber 41 as soon

3,134,353

3

erating meansV comprises a source ,of hydrogen peroxide

fuel, a catalyst chamber for eecting the decomposition

of the hydrogen peroxide into steam and free oxygen,

as the Valve 40 is openedV by the presence of water in y

the pump exhaust chamber 25. The decomposed gases

then pass to and drive the turbine 20 to drive the pump

19 which forces the sea water at great velocity through

conduits connecting said source, said chamber, said tur- .

the ~Vehicle and out the jet nozzle` 26 to furnish high

l _speed

propulsion. _

bine, and said nozzle, and means for pressurizing said

source to force said hydrogen peroxide to said catalyst "

*It' is to benoted that the described system enables

chamber.

the condensed exhaust gases from the turbine to be

7. The system asrrecited in claim 6 Vwherein said pres

discharged to a low pressure area-the chamber 25 sur-V

surizing means comprisesY a source of gas under pressure.

rounding the throat of the nozzle 26-and pass through 10 Y 8. The systernas recited in claim 6 wherein said pres

the apertures 27 and out of the nozzle. Obviously, ad

ditional cavitating venturi can be used if required to pro

surizing means comprises a conduit connecting said source ~

of hydrogen peroxide to the exhaust of said pump to

expose said hydrogen peroxide to pump pressure.

vide >additional capacity'for lowering'the turbine back

pressure during initial start and as required at great depth.

9. The system as recited in claim 6 wherein said con

' It is to be understood that the form of our invention 15 duit between said fuel source and-said chamber includes

herewith shown and described is yto be taken as a preferred

a control valve, and a control member connected with

example of the same and that Various changes in the

said -valve, and mounted in said pump and operative

upon'the presence of water in said pumpjto open said

valve- andV permit flow of fuel through said conduit.

shape, size and arrangement of parts may be resorted

to without departure from the spirit of the Vinvention or

the scope of the subjoined claims.

YWhat isV claimed is:

' f

V20

v

'

1. A propulsion system for propelling yvehicles under;

10. The system as recited in claim 6 wherein means

are provided for removing'free. oxygen as such from the

exhaust gases before passing through said venturi nozzle.

Water comprising water inlet conduits leading to' a hydro

11. vThe system as recited in claim 1 wherein said pres

sure' reducing means comprises a plurality of apertures

by for forcing water through said conduits and said-noz 25 formed peripherally >about the throat lof said venturi

zle to produce propulsive thrust, means for generating

nozzle, a chamber encloses the apertured portion there

and delivering high pressure gases to said turbine to

of, and aconduit connected to said chamber for dis

Vjet venturi exhaust nozzle, a turbine, a pump driven there

drive said pump, and means for reducing the back pres

sure `on the exhaust gases from saidrturbine at any water 'f

depth.

'

'

2. The system as recited in claim 1 wherein 'a con

denserV is provided to condense the exhaust gases before

-

exhausting through said nozzle. '

charging exhaust gases therein.

' '

12. The system as recited in claim 1 wherein said ex

30 haust nozzle is swivelly connected to the exhaust of said

pumprto effect steering of the vehicle.

f

13. VThe combination with the system as recited in l

claim 1,'of va marine vehicle body enclosing and sup

'

3. yThe system recited in claim 2 wherein said conden i ; porting the elements, v of said system

ser is Aprovided with inlet and outlet portsv arranged 35 streamlined underwater movement.

for high speed,

_

to force coolant waterthrough said condenser upon move- l

ment of the vehicle.

vReferences Cited inthe le of this patent

4. The system as recited in claim V1 wherein means are

connected to said gas generating means to prevent oper

ation of' the latter untilV water is present in said pump.

I 5. The system as recited in vclaim 1 wherein Ysaid tur

bine includes governor means connected with an opera

tive Vmeans to control said gas generating means.

6,. The system as recited in claim 1 wherein said Ygen

Y - vUNITED V'STATES PATENTS

V2,612,019

Halford ____ ________ __ sept. 3o, 1952

2,926,492

Flanagan ___________ __ Mar. 1, 1960

2,986,004

McKenney __________ __ May so, 1961V

'

661,218

FOREIGN PATENTS

'

Great'Britin '__________ Nov. 2, 1951

You might also like

- The Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827From EverandThe Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827No ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- Filed Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222Document4 pagesFiled Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222sqmiNo ratings yet

- Us 2409624Document6 pagesUs 2409624Giovanni BlancoNo ratings yet

- Carburador de Hidrógeno PatE8Document7 pagesCarburador de Hidrógeno PatE8Maximo CozzettiNo ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- S Chapter 27Document14 pagesS Chapter 27jesusalbeirourbanoviverosNo ratings yet

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Document5 pagesJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNo ratings yet

- Electrolytic Carburetor by Charles H. Garrett (Patent)Document11 pagesElectrolytic Carburetor by Charles H. Garrett (Patent)max386No ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- July 5, 1966 P. H. Koch 3,259,111 : Filed June 25, 1964Document3 pagesJuly 5, 1966 P. H. Koch 3,259,111 : Filed June 25, 1964Anonymous KzJcjGCJbNo ratings yet

- Buoyancy: The "Hidro" Self-Powered Generator of James KwokDocument14 pagesBuoyancy: The "Hidro" Self-Powered Generator of James KwokAlboresha RafidNo ratings yet

- Once Through Boiler Recirculation PumpDocument6 pagesOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்No ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- A Practical Guide To Free Energy' Devices: US Patent 642,434 12th November 1932 Inventor: Charles N. PogueDocument8 pagesA Practical Guide To Free Energy' Devices: US Patent 642,434 12th November 1932 Inventor: Charles N. PogueXavi Granados ContrerasNo ratings yet

- Byyeqwla: 2 I / I I VDocument5 pagesByyeqwla: 2 I / I I VaegosmithNo ratings yet

- CarburettorsDocument3 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Filed March 20, 1943Document8 pagesFiled March 20, 1943Andrés RamírezNo ratings yet

- Jan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LDocument6 pagesJan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LJesus ValleNo ratings yet

- Ullage CalculationDocument6 pagesUllage CalculationAamir Shahzad100% (2)

- March23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion EnginésDocument3 pagesMarch23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion Enginésmonem2014No ratings yet

- June 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951Document3 pagesJune 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951محمود محمدNo ratings yet

- In The DrawingsDocument8 pagesIn The DrawingsLalit KumarNo ratings yet

- Us 3460614Document7 pagesUs 3460614scibduser001No ratings yet

- Us 2109297Document6 pagesUs 2109297lfilippiniNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Apparatus For ElectrolysisDocument3 pagesApparatus For Electrolysissanela1615No ratings yet

- Description: (OCR Text May Contain Errors)Document3 pagesDescription: (OCR Text May Contain Errors)SachinNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Nov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Document5 pagesNov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Anggara T NugrahaNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- Hydraulic DynamometerDocument26 pagesHydraulic DynamometerhelderlpNo ratings yet

- Aug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967Document4 pagesAug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967billy dillpickerNo ratings yet

- Jan-1, 1935 - R. G. de La Mater Er Al 1,985,889Document8 pagesJan-1, 1935 - R. G. de La Mater Er Al 1,985,889lfilippiniNo ratings yet

- US1153992 - Collumn StillDocument4 pagesUS1153992 - Collumn StilletyseNo ratings yet

- Bob Neal Overunity Compression Unit - US2030759Document5 pagesBob Neal Overunity Compression Unit - US2030759John CarterNo ratings yet

- CarburettorsDocument3 pagesCarburettorsAlejandro GonzalezNo ratings yet

- P. Profos: Filed April 21, 1959Document3 pagesP. Profos: Filed April 21, 1959Anonymous KzJcjGCJbNo ratings yet

- Charles Nelson Pogue - US Patent - 1759354Document18 pagesCharles Nelson Pogue - US Patent - 1759354PM100% (1)

- Free Energy Stanley Meyer - Hydrogen Gaz Injector For Internal Combustion Engine - 4389981Document14 pagesFree Energy Stanley Meyer - Hydrogen Gaz Injector For Internal Combustion Engine - 4389981Markerter60100% (2)

- Us2277566 1Document3 pagesUs2277566 1Priya TiwariNo ratings yet

- OpenDocument9 pagesOpenchristian1777No ratings yet

- 20080012322-Vortex Flow ControlDocument10 pages20080012322-Vortex Flow Controlozland9No ratings yet

- Method For Enhanced Recovery of Viscous Oil DepositsDocument5 pagesMethod For Enhanced Recovery of Viscous Oil DepositsRishel Mae VeraNo ratings yet

- United States Patent: KiernanDocument12 pagesUnited States Patent: KiernanharisupayNo ratings yet

- United States Patent: SchwartzmanDocument4 pagesUnited States Patent: SchwartzmanJames LindonNo ratings yet

- US1926463Document3 pagesUS1926463Kamal Vijay Ram R SNo ratings yet

- Gaugler, R. S. (1944) - U.S.A. Patent No. 2350348.Document5 pagesGaugler, R. S. (1944) - U.S.A. Patent No. 2350348.pathiNo ratings yet

- Aug. 15, 1967 H. Grigull Etal 3,335,462: 152088230340. B11346 Heinz 1'12? 83Document4 pagesAug. 15, 1967 H. Grigull Etal 3,335,462: 152088230340. B11346 Heinz 1'12? 83jaydevpatelNo ratings yet

- United States Patent (19) : SwearingenDocument6 pagesUnited States Patent (19) : SwearingenNicandroGonzalesNo ratings yet

- Wwkzii: Jan. 10, 1933. R. H. FarwellDocument3 pagesWwkzii: Jan. 10, 1933. R. H. Farwellmonem2014100% (1)

- US2900999-metal SealDocument3 pagesUS2900999-metal Sealasen tsaiNo ratings yet

- W.J. Sommers: Counter-Pressure Filler Valve For Beverages Filed March 5, 1957Document3 pagesW.J. Sommers: Counter-Pressure Filler Valve For Beverages Filed March 5, 1957bimalishaNo ratings yet

- Hyper Valve PatentDocument15 pagesHyper Valve PatenttonytayicNo ratings yet

- Centrifugal CompressorDocument7 pagesCentrifugal Compressorrohan112358No ratings yet

- United States PatentDocument5 pagesUnited States PatentPraveen SinghNo ratings yet

- Water Cooled Vacuum CondensersDocument2 pagesWater Cooled Vacuum CondensersRana Mubbashir IqbalNo ratings yet

- CarburettorsDocument13 pagesCarburettorslopezramon2111No ratings yet

- Wrightbrothersplot PDFDocument1 pageWrightbrothersplot PDFJosh FullerNo ratings yet

- Lectures 2 and 3 BB1035 C15Document14 pagesLectures 2 and 3 BB1035 C15Josh FullerNo ratings yet

- Lecture 10 BB1035 C15Document9 pagesLecture 10 BB1035 C15Josh FullerNo ratings yet

- Lecture 11 BB1035 C15Document10 pagesLecture 11 BB1035 C15Josh FullerNo ratings yet

- Lecture 4 BB1035 C15Document8 pagesLecture 4 BB1035 C15Josh FullerNo ratings yet

- Lecture 9 BB1035 C15Document14 pagesLecture 9 BB1035 C15Josh FullerNo ratings yet

- Lecture 1 BB1035 C15Document11 pagesLecture 1 BB1035 C15Josh FullerNo ratings yet

- Joint Venture Accounting (JVA) : SAP AG 2002Document38 pagesJoint Venture Accounting (JVA) : SAP AG 2002Himanshu OswalNo ratings yet

- A Theoretical and Experimental Procedure For Design Optimization of CVT BeltsDocument8 pagesA Theoretical and Experimental Procedure For Design Optimization of CVT Beltsmikael bezerra cotias dos santosNo ratings yet

- 1 - JCAPS - Egate Integrator Sun SeeBeyond Integration Server, Sun SeeBeyond JMS IQ ManagerDocument5 pages1 - JCAPS - Egate Integrator Sun SeeBeyond Integration Server, Sun SeeBeyond JMS IQ Managerapi-3730244100% (1)

- 5E-MF6100K Muffle FurnaceDocument30 pages5E-MF6100K Muffle FurnaceNafian AwaludinNo ratings yet

- How Advertising Differs A Content Analysis of Traditional Print Advertising and Online Media ModelsDocument71 pagesHow Advertising Differs A Content Analysis of Traditional Print Advertising and Online Media Modelsobserverbg@gmail.comNo ratings yet

- VAG Airbag Reset ManualDocument12 pagesVAG Airbag Reset ManualGabriel DrideanuNo ratings yet

- 39 Duroxite Overlay Productslingyuen WeiExtranetDocument29 pages39 Duroxite Overlay Productslingyuen WeiExtranetGraylab TechnologiesNo ratings yet

- JQuery Set Content and AttributesDocument8 pagesJQuery Set Content and AttributesGodwin LarryNo ratings yet

- Fabrication of 2 X 1000 MT Capacity Mounded LPG Storage VesselsDocument84 pagesFabrication of 2 X 1000 MT Capacity Mounded LPG Storage VesselsMilan DjumicNo ratings yet

- Easy Opc Server v1.10 EngDocument61 pagesEasy Opc Server v1.10 EngKalauzImreNo ratings yet

- Using Atrenta Spyglass in GUI ModeDocument33 pagesUsing Atrenta Spyglass in GUI Modevenu.lancer8205100% (1)

- KyotoCooling Co-Location Impact CPXDocument6 pagesKyotoCooling Co-Location Impact CPXChris FultonNo ratings yet

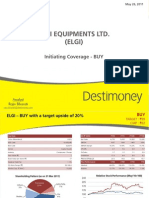

- Elgi Equipments - Initiating CoverageDocument23 pagesElgi Equipments - Initiating CoveragerabharatNo ratings yet

- Sub-Zero Refrigerator Use & CareDocument44 pagesSub-Zero Refrigerator Use & CarephilaskNo ratings yet

- SIRAJGANJDocument98 pagesSIRAJGANJAfiat KhanNo ratings yet

- Banking On BlockchainDocument28 pagesBanking On Blockchainldhutch100% (2)

- Patrol LogMgmtDocument152 pagesPatrol LogMgmtCharl11eNo ratings yet

- Lua 5.1 A Short ReferenceDocument8 pagesLua 5.1 A Short ReferenceMikhail MiguelNo ratings yet

- Putri Iona - Survey StatusDocument28 pagesPutri Iona - Survey StatusDiana Triswasti KumariNo ratings yet

- En 1555-4 (2002)Document15 pagesEn 1555-4 (2002)joaoferreiraprfNo ratings yet

- Organizing For MissionDocument2 pagesOrganizing For MissioncovchurchNo ratings yet

- Basic Calculation Practice Module 2 by Shubham JainDocument20 pagesBasic Calculation Practice Module 2 by Shubham Jainmanish.ee.2.718No ratings yet

- Specialization in TourismDocument12 pagesSpecialization in TourismItalo Arbulú Villanueva0% (1)

- Electronics Sample Paper 4 PDFDocument13 pagesElectronics Sample Paper 4 PDFNoor AhmedNo ratings yet

- Dawn C. Khan: Professional SummaryDocument2 pagesDawn C. Khan: Professional Summaryapi-93709311No ratings yet

- Literature ReviewDocument2 pagesLiterature ReviewNeeraj Singh100% (1)

- Evk1100 Schematics RevcDocument13 pagesEvk1100 Schematics RevcMuhammad FaisalNo ratings yet

- Abbey SealDocument20 pagesAbbey SealDamonNo ratings yet

- Car Top Guardrail - TSSA 245-10Document5 pagesCar Top Guardrail - TSSA 245-10jacknamasteNo ratings yet