Professional Documents

Culture Documents

14 29 1 SM

14 29 1 SM

Uploaded by

Pendra NugrahaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14 29 1 SM

14 29 1 SM

Uploaded by

Pendra NugrahaCopyright:

Available Formats

Applications of Modified Atmosphere......... (P. Wullandari and D.

Fithriani)

APPLICATION OF MODIFIED ATMOSPHERE PACKAGING (MAP)

ON FRESH FISH

Aplikasi Pengemasan dengan Atmosfir Termodifikasi (MAP) pada Ikan Segar

Putri Wullandari and Diini Fithriani1)

1)

Research Institute for Fisheries Post-harvest Mechanization

*Correspondence author: Putri Wullandari, KS. Tubun Petamburan VI Jakarta Pusat 10260, E-mail: utides@gmail.com

ABSTRACT

Packaginghasmanyfunctions,e.g.ascontainment,toprotectproductsfromphysicaldamage,

andfromH2O,O2,andCO2exposure,aswellastoattracttheconsumers.Basedonthetechnology,

packaging can be divided into 3 types i.e. passive packaging, active packaging, and smart

packaging. Modified Atmosphere Packaging (MAP) is the most common active packaging found

inthemarket.MAP hasbeenusedto extendtheshelflifeofseveralfishsuch as rawwhiting(cod

family), mackerel, salmon fillet, cod fillet, fresh bluefin tuna fillet, etc. MAP which was combined

with freeze-chillinghas beenproved toextend theshelf life of raw whiting,mackerel,and salmon

fillet. MAP also increased cod fillets shelf life up to 20 days, whiting fillets packed in 100% CO2

andstoredat4Ctemperatureupto15days.MAPcombinedwithantioxidantonfreshbluefintuna

fillets stored at 3C for 18 days wasable to extend productsshelf life from 2 days (control) to 18

days, meanwhile 100% N2 in packaging has protective effect on haemoglobin and lipid oxidation.

Packaging innovationsand ingenuity willcontinuously develop MAPthatis oriented for consumer,

enhance the product, environmentally responsive, friendly, and cost effective.

Keywords: active packaging, modified atmosphere packaging, fresh fish product

ABSTRAK

Pengemasan memiliki banyak fungsi, yaitu sebagai wadah, melindungi produk dari kerusakan

fisik, paparan H 2O, O 2 , dan CO 2 , dan untuk menarik konsumen. Berdasarkan teknologi

pengemasannya, kemasan dapat dibagi menjadi 3, yaitu kemasan pasif, kemasan aktif, dan

kemasan pintar. Salah satu contoh pengemasan aktif yang sudah dikenal di masyarakat adalah

Modified Atmosphere Packaging (MAP). MAP telah banyak digunakan untuk memperpanjang

umur simpan beberapa jenis ikan segar, seperti whiting (sejenis cod), mackerel, filet salmon,

filet cod, filet tuna sirip biru, dan yang lainnya. Penggunaan MAP yang dikombinasikan dengan

penyimpanan beku dapat memperpanjang umur simpan whiting, mackerel, dan fillet salmon.

Filet ikancod yangdikemas denganMAP memiliki umur simpan 20 hari sedangkanumur simpan

filet whitingyang dikemas dalam100% CO2 dan disimpanpada suhu 4C bisamencapai15 hari.

MAP yang dikombinasikan dengan antioksidan pada filet tuna sirip biru yang disimpan pada

suhu 3C selama 18 hari dapat memperpanjang umur simpan dari 2 hari (kontrol) menjadi 18

hari, dan kandungan 100% N2 dalam kemasan memiliki efek protektif terhadap haemoglobin dan

oksidasi lemak. Inovasi dan kreativitas dalam pengembangan teknologi pengemasan akan terus

menyediakan MAP yang berorientasi pada keinginan konsumen, pengembangan produk, ramah

lingkungan, dan hemat biaya.

Kata Kunci: pengemasan aktif, pengemasan atmosfir termodifikasi, produk ikan segar

INTRODUCTION

Foodpackagingservesto protectthe products

againstdeteriorativeeffects,containingtheproduct,

communicatingtotheconsumerasamarketingtool,

and provide consumers with ease of use and

convenience. Main paradigm that changes in

packagingisthechangefrompassivepackaginginto

activepackaging(Yamet al.,2005).Moreoversearch

forinnovationinfoodandbeveragespackagingalways

continued,duetoconsumersneedsanddemands

thatisaffectedwithchangesinglobaltrend,likethe

increasingoflifeexpectancy(Lord,2008).

Activepackagingisan innovativeconceptthat

described as a packaging form where packaging,

39

Squalen Vol. 7 No. 1, May 2012: 39-49.

product,andenvironmentinteracttoextendproducts

shelflife,safetyandsensoryproperties.Thistypeof

packagingusuallybecomesveryimportantinfresh

food(Labuza&Breene,1989inHutton,2003).Active

packagingleadstothecombinationofseveraladditives

into packaging system. These additives can be

attachedintoinnerpackagesorcombinedwiththe

packagingmaterials,aimedtomaintainorincrease

productqualityandshelflife.Activepackaginghasa

roleinproductpreservationbesidesprovidinginert

barrierfromtheenvironment(Hutton,2003).Active

packagingisnotanewthing,butitsadvantagesin

terms of quality and economic value is the latest

developmentinfoodpackagingindustry.Oneofactive

packagingtypeisModifiedAtmospherePackaging

(MAP).MAPistheremovaland/orreplacementofthe

atmospheresurroundingtheproductbeforesealingin

vapor-barriermaterials(McMillinet al.,1999).MAP

canbevacuumpackaging(VP),whichremovesmost

of theairbeforetheproductisenclosedinbarrier

materials,orformsofgasreplacement,whereairis

removedbyvacuumorflushingandreplacedwith

anothergasmixturebeforepackagingsealinginbarrier

materials.Theheadspaceenvironmentandproduct

maychangeduringstorageinMAP,butthereisno

additionalmanipulationoftheinternalenvironment

(McMillinet al.,1999)

The example of active packaging on fisheries

productisthecombinationofMAPwithantioxidantbasedactivepackagingonfreshbluefintunafillets

storedat3Cfor18days.Activepackagingfilmswere

produced by embedding -tocopherol into an

unstabilizedlowdensitypolyethylene(LDPE)matrix

atthreeconcentrations(0.1%,0.5%,1%).Theratio

betweenthevolumeofgasandweightoffoodproduct

(V/Wratio)was 2.5:1.Theresultshows that MAP

canextendproductshelflifefrom2days(control)to

18days.100%N2inpackageshasprotectiveeffect

on haemoglobin and lipid oxidation. Active film

packagingcanreducelipidoxidation,andcombination

effectofMAPandantioxidantcanbeusedtoextend

theshelflifeofrawfish(Torrieriet al.,2011).

MAPalsousedinpre-rigorfilletfarmedAtlantic

cod(Gadus morhua)storedat0Candthequality

wasdeterminedthroughsensoryevaluationofraw

odour as well as chemi cal, physi cal, and

microbiologicalanalysis.Codwaspackagedunder

gastoproductratioof2:1andCO2,O2andN2were

analysedafter7,10and14daysofstorage.Theresult

showsthattheweightedoptimumgasmixtureforMA

packagingoffarmedcodwasdeterminedtobe63ml/

100 ml O 2 and 37 ml/100 ml CO 2, aerobic and

psychrotrophic plate count decreased, and H2Sproducingbacteriawerenotpresentornotableto

grow under thedifferent gas mixtures(Sivertsvik,

2006).

40

This article will discuss about MAP and its

applicationforfisheriesproductsinceMAPiswidely

knownasoneofthemethodswhichpotentialtoextend

fisheriesproductshelflife.

FISHERIES PRODUCT CHARACTERISTICS

Fishqualitydeterioratesrapidlyandtheshelflife

isreducediftheyarenothandledandstoredproperly.

Itwasreportedthattherateofspoilagedoublesevery

5.5Criseintemperature.

Spoilageoffishandshellfishresultedfrom the

changesiscausedby3majormechanisms,i.e:

1.Thebreakdownoftissuebythefishsownenzymes

(cellautolysis).Cellautolysisisthedegradation

ofnucleotides(ATP-relatedcompounds)whichis

caused by autolytic enzymes. The autolytic

changes arecontributingto spoilagemainlyby

makingcatabolitesavailableforbacterialgrowth

(Huss,1995inGram&Huss,1996).

2.Thegrowthofmicroorganism.Microorganismthat

usuallygrowinaerobicallystoredfishisGramnegativepsychrotrophicnon-fermentingrods.Thus,

underaerobicicedstorage,thefloraiscomposed

almost exclusively of Pseudomonas sp. and

S.putrefaciens(Gram&Huss,1996).

3.Oxidativereactions.Lipidoxidationproducesoff

flavoursthatsmellstronglyduringpeelingandmay

betastedeveninthepeeledproduct(Baket al.,

1999). Packaging in modified atmospheres

depletedofoxygenmayimprovecolourstability

andpreventlipidoxidationinchill-storedshrimps

(Sivertsvik,1995).

MAP can be used to supress the spoilage

microorganismandoxidativereactionsbutdoesnt

havedirecteffecttoautolysis(Mulan&McDowellin

Coleset al.,2003).MAPmustbecombinedwithother

preservationtechnique,likerefrigeration,toovercome

cellautolysismechanism.Thereareseveralimportant

specificintrinsicfactorsinfishwhichgreatlyinfluence

thespoilageoffish,i.e:

1.Thepoikilothermnatureofthefishanditsaquatic

environment.Thepoikilothermnatureoffishallows

bacteriawithabroadtemperaturerangetogrow.

Forexample,themicrofloraoftemperatewaterfish

isdominatedbypsychrotrophicGram-negative,

rod-shapedbacterialikePseudomonas, Moraxella,

Acinetobacter, Shewanella, Flavobacterium,

Vibrionaceae andAeromonadaceae, butGrampositiveorganismssuchasBacillus,Micrococcus,

Clostridium, Lactobacillus andCorynebacterium

canalsobefoundinvaryingproportions(Liston,

1980inGram&Huss,1996).

Applications of Modified Atmosphere......... (P. Wullandari and D. Fithriani)

2.AhighpostmortempHintheflesh(usually>6.0).

Thisfactorhasimportantconsequencesforthe

microbiologyoffishamongsotherfactorsbecause

it allows the pH sensitive spoilage bacteria

Shewanella putrefaciens togrow.

3.ThepresenceoflargeamountsofNon-proteinnitrogen(NPN).

4.Thepresenceoftrimethylamineoxide(TMAO)as

partoftheNPNfraction(Gram&Huss,1996)

Generally,themajorspoilagebacteriafoundon

processedfishareanaerobsincludingPseudomonas,

Moraxella, Acinetobacter, Flavobacterium, and

Cytophagaspecies.Thereareseveralmicroorganisms

thatareofparticularimportancewhendealingwith

MAPfishproducts,includingC. botulinum(Mulan&

McDowellinColeset al.,2003).

As mentioned earlier, spoilage on fish mainly

caused by microorganisms, so the control of

microorganisms growth is one of the success

parameter of activ e packaging technology.

Microorganismscanbefoundattheoutersurface(skin

andgill)andincolonoflivefish(Sivertsvik,2003).

Meanwhile, themicrobesthat exists inside the

bodyoffreshshrimpareaerobicspoilagebacteria

including Pseudomonas, Achromobact er,

FlavobacteriumandMicrococcus(Lu,2009);andthe

spoilagebacteriathatexistsincapturedshrimpare

Shewanella putrefaciens and Pseudomonas spp.

(Chinivasagamet al., 1996; Matches, 1982in Lu,

2009). The action of autolysis by inner proteases

togetherwithmelanosisresultsininferiorqualityin

shrimpattheearlyperiodofstoragewhilebacterial

spoilagemakestheshrimpdeteriorateduringtimetermstorage(Martinez-Alvarezet al.,2005in Lu,

2009).Therefore,weneedtoaddpreservativethatis

combinedwithMAP.

The concern about the use of MAP on fishery

productshastodowiththefactthatnonproteolytic

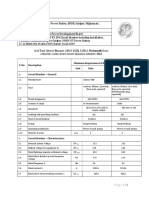

Table1.Fisheriesproductandtheirsuitablepackagingform/material

No

Fishe rie s

Product Type

The Alte ra tion During

Product Stora ge

Suita ble Pa cka ging Form /

Ma te ria l

1.

Freshfish

dehydration,fatoxidation,bacterial

andchemicalspoilage

doublewalledinsulatedmoulded

plasticcontainers(lighterinweight,

hygienicandeasilywashable,and

providegoodinsulation)

mouldedcontainerm adefrom

expandedpolystyrene(verylightin

weight,provideverygoodinsulating

propertiesandcanbecleanedeasily

bywashing)

2.

desiccation,discolorationand

Battered and

b readed seafood developm entofrancidity

products

therm oform edcontainers,polyvinyl

chloride(PVC),highimpact

polystyrene(HIPS)andHDPE

3.

Frozenproduct

Dehydrationanddiscoloration

plasticfilmpouches

4.

Driedfishery

product

pronetoeasyentryofinsects,

rodentsandotherpestsandhighly

sensitivetochangesinrelative

humidity

LDPE/polypropylene(PP),

polyethyleneterephthalate

(PET)/LDPElaminatepouches

5.

Cannedfish

dehydration,andtheproductcoloris Aluminiumcontainersandpull-tab

gettingdarkerduringstorage

polymer-coatedtin-freesteelcans

6.

Freeze dried

product

rancidityandabsorptionofmoisture

Paper/aluminiumfoil/LDPElaminates

orm etallisedPET/LDPElaminated

pouches

7.

Chitin/chitosan

moisturegain,microbialandinsect

attack

HDPEwovengussetedbaglaminated

with100gaugeLDPEliner

Source:Gopal,2011.

41

Squalen Vol. 7 No. 1, May 2012: 39-49.

Figure1.ShrimpinplasticbagandbeingfreezedinIndividuallyQuickFrozen(IQF)(SaudiFisheriesCompany,

2005).

botulismstrains are found inwaters and theycan

grow at temperatures <4C (Jay, 2011). Fisheries

productandtheirsuitablepackagingform/material

isshowninTable1.TheexampleofMAPfisheries

productpackagingisshowninFigure1.

MODIFIED ATMOSPHERE PACKAGING (MAP)

TheobjectiveofMAPdesignistodefineconditions

thatwillcreatetheatmospherebestsuitedforthe

extendedstorageofagivenproductwhileminimising

thetimerequiredtoachievethisatmospherecondition

(Mahajanet al.,2007).Theatmospheregasconsists

of78.08%N2,20.96%O2,and0.03%CO2.Many

foodproductsarerapidlydamagedwhenstoredin

openair,thisisduetoreactionwithoxygenandthe

growthofaerobicmicroorganismlikebacteria(Mulan

&McDowellin Coleset al.,2003).

StorageunderMAPwillextendtheshelflifeand

delayingtherateofspoilage.ThesuccessofMAPin

extendingseafoodshelflifedependsonmanyfactors,

includinggoodinitialproductquality,goodhygiene

duringslaughter,correctpackingmaterialselection,

packingequipment,appropriategasmixtureandgasto-product volume (g/p) ratio for the product, and

maintenanceoftheprocesstemperatures(Sivertsvik,

2007 in Fernandez et al., 2009). In addition, the

amountofCO2dissolvedintotheproductandthe

storage temperature are the most critical factors

(Rotabakket al.,2008inFernandezet al.,2009).

Gases Used in MAP

TherearefewgasesthatinvolvedinMAP,which

areNitrogen(N2),Oxygen(O2),Carbondioxide(CO2),

Carbonmonoxide(CO),andArgon(Ar).Nitrogenand

42

Argon are gases that used to create anaerobic/

microaerophiliccondition(iftheoxygenisremoved)

(Regenstein,2006in Otwellet al.,2006).Nitrogen

doesnotsupportthegrowthofaerobicmicrobesbut

doesntpreventthegrowthofanaerobicmicrobes.

Besidesthat,N2isusedtomaintainthebalanceof

gaspressureinthepackaging(MulanandMcDowell

inColeset al.,2003).BonoandBadalucco(2012)

reportedthatstripedredmullettreatedwithozonated

water(0.3mgL-1)andpackagedunderMAP(50%N2

and50%O2)cansignificantlydelayedthebacterial

growthandthegrowthlevelsremainedrelativelylow

untilday10(<6logCFUg-1).

Oxygenpromotesseveraltypesofdeteriorative

reactionsinfoodsincludingfatoxidation,browning

reactions, and pigment oxidation. Therefore, to

increase the shelf life of foods, the package

atmosphereshouldcontainalowconcentrationofO2.

Insomefoods,lowconcentrationofO2resultingin

qualityandsafetyproblems,sothismustbetaken

intoaccountwhenselectingthegaseouscomposition

forpackagedfood(Mulan&McDowellinColeset al.,

2003). One way to reduce the O2 composition in

packagingisbyusingO2absorber.Oxygenabsorber

willactivelyreducetheO2concentrationinpackaging

head space until 0.01%, therefore it can prevent

oxidationandmicroorganismegrowth(Hurmeet al.,

2002).

Carbondioxide has negative effect to some

microbes if used in sufficient quantities, and it is

soluble in water to form mild acid, like HCO3 or

carbonicacid.ThismeansthatCO2canmigrateto

fishandhaspositiveimpact,asantimicrobialagent

(Regenstein, 2006 in Ot well et al., 2006).

Carbondioxide is mostly present in the greatest

Applications of Modified Atmosphere......... (P. Wullandari and D. Fithriani)

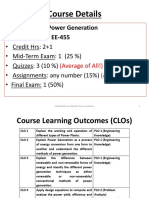

Figure2.Rigidtraypackagingforsandwich(Anon.a,2012).

quantityinMAP.Guldageret al.(1998)reportedthat

Pacificwhitingfilletpackedin100%CO2andkeptat

4C has shelf life up to 15 days. Meanwhile,

combinationofMAPwithsuper-chilingcanextend

theshelflife,i.eofAtlanticsalmon(Salmo salar)fillets.

ThesampleswiththehighestCO2concentration(90%)

andgas-to-productratio(g/pratio)of2.5showedthe

highestshelflife:22daysvs.11days(controlsample)

basedonmicrobialanalysis(Fernandezet al.,2009).

Carbonmonoxidehasalowsolubilityinwterbut

relativelysolubleinsomeorganicsolvents.Theuse

ofcarbonmonoxideinMAP(CO-MAP)wasapproved

bytheUSFDA(2002,2004)formasterbagsandretail

packages.Thecarbonmonoxideisusuallyusedin

meat packed with MAP because it binds to the

pigmentmyoglobin,formingcarboxymyoglobin.This

formofmyoglobinexhibitsacherryredcolorsimilar

tothatofoxymyoglobin,thereducedformofmyoglobin

withboundoxygen(Jeong&Claus,2011).

Selection of Packaging Materials for MAP

SelectionofPackagingMaterialsforMAPisaimed

tomantainthequalityandsafetyofpackedproduct.

Flexible and semi-rigid laminated plastics are the

commonmaterialsusedforMAP.Laminatedplastic

ismadefrompolyethylene(PE),polypropylene(PP),

polyamide(nilon),polyethylene terephthalate(PET),

polyvinyl chloride (PVC), polyvinylidene chloride

(PVdC),andethylene vinyl alcohol(EVOH).Meanwhile

rigidandsemirigidplasticismadefrom PP,PET,

unplasticizedPVC,andexpanded polystyrene.MAP

canbeachievedbyuseofpolymericfilmswheregas

transmissionratethroughthefilm,productrespiration,

carbondioxideandoxygenlevelswithinthepackage

arerelatedbyasimplematerialbalance(Henig&

Gilbert,1975inChristieet al.,1995).

TheexampleofMAPpackagingmaterialsused

forsndwich,isshowninFigure2.Thecoverismade

fromaluminiumfoilwhilethebodyismadefromrigid

tray.

Storage temperature is never constant in the

distribution chain of fresh produce. Due to the

temperaturedependenceoftherespirationrate(R)

and of the gas permeability of a packaging film,

fluctuating temperatures result in changes of the

internalO2andCO2concentrations(yO2andyCO2)

(Jacxsenset al.,2000).

The Equipment Used for MAP Application

TheEquipmentusedforMAPApplicationare:

a.Chambermachine

Preformedhigh-barrierbagsaremanuallyplaced

withinthechamberbeforeevacuation,back-flushing

withthedesiredgasmixture,andheatsealing(Anon

b, 2012). This machine (Fig. 4) is widely used in

Indonesiabecauseitislaborintensive,cheap,can

be usedforbigpacksbutitrelativelyneedsmore

timetooperate.

Theproducttobepackagedisputintoafilmpouch

andplacedinthevacuumchamber.Whenthelidhas

beenclosed,thedesiredlevelofvacuumisproduced

inboththevacuumchamberandthepouch.Thepouch

isthensealedinavacuum(vacuumpackage)orthe

chamber(andthusthepouchaswell)isfilledwitha

MAPgasbeforethesealingoperation.Theexample

of chamber machine and digital control panel of

chambermachinesareshowninFig.5.

b.Snorkelmachine

Snorkelmachineoperateswithoutchamberand

usingpouch.Bag-in-boxbulkproductsandretailpacks

insidebigpackscanbeproducedusingthismachine

(Mulan&McDowellinColeset al.,2003)

43

Squalen Vol. 7 No. 1, May 2012: 39-49.

Figure3.Gasexchangeinamodifiedatmospherepackagecontainingfreshproduct(Mahajanet al.,2007).

Figure4.ChamberMachines(Anon.,2012c)

In this machines, preformed plastic bags are

positionedona heatseal mandrel,thentheair is

removedusingretractablesnorkelsformingavacuum

condition.Thevacuumplasticbagsarethenbackflushedwithadesiredgasmixtureandsealed.Snorkel

machinesisshowninFig.6.

c.Form-fill-sealtraymachines

Formfillseal(FFS)machineformspouchfrom

continuedrollstocklayer.FFSmachineconsistsof

3types,whichareHorizontalFormFillSeal(HFFS),

VerticalFormFillSeal(VFFS),andThermoformForm

FillSeal(TFFS).

(a)

HFFSmachinescanoverwrapapre-filledtrayof

product.Theairfromthepackageisremovedbya

pulseofgasorcontinuousgasflushing,howevergas

mixturescontaininglevels>21%O2cannotbeused

duetotheuseofhotsealingjawsattheendofthe

machine.

VFFSmachineformsatube,itisthenfilledwith

product(inmostcasesdroppedfromanoverhead

multi-weigher),purgedwithgasandthensealed.At

thesametimefilmistransportedverticallydownwards.

Meanwhile in the TFFS machine, packaging

materialisheatedintheformingdieandformedinto

pockets/trays.Theformedpocketsarethenloaded

(b)

Figure5.(a)Digitalcontrolpanelofchambermachines,(b)Chambermachines (Anon.,2012b).

44

Applications of Modified Atmosphere......... (P. Wullandari and D. Fithriani)

Figure6.SnorkelMachines(Anon.,2012c).

manuallyorautomatically.Thetopwebofpackaging

material(lidfilm)coversthefilledpockets/trays.The

airisevacuatedfromthesealingdieandprotective

gas is added. Then the pack is sealed by the

applicationofheatandpressure.ThermoformForm

FillSeal(TFFS)isshowninFig.7.

d.Sealing

Filmfactor(thicknessandtreatmenttoitssurface)

andplasticcomposition(resintype,molecularweight

distribution,andadditionalsubstances)willdetermine

thesettingofsealingmachine(Mulan&McDowellin

Coleset al.,2003).

FDAcomplianthygienicsealingmaterialsrange

fromgradesofethylenepropylenerubber(EPDM),

acrylonitrilebutadienerubber(NBR),siliconerubber

(VMQ),fluoroelastomer(FKM),HydrogenatedNitrile

Rubber (HNBR) and perfluoroelastomer (FFKM)

(Warren,2008).Sealingmaterialsandtheirsuitability

touseindifferentfoodstuffsisshowninTable2.

Thesepackaging materials alsohavedifferent

endurancetosealingtemperature,forexamplethe

endurancetosealingtemperatureofFFKMis3100C

andVQMis60oC(Warren,2008).

e.Cutting

Thelastpackagingstageistoseparatethewhole

packagesintoindividualpackages.Thiscanbedone

usingthreeways,whicharediecutting,longitudinal

andtransversecutting(Mulan&McDowellinColes

et al.,2003).

MAP APPLICATION IN FRESH FISH

Packagingprocessforfish,especiallyfreshfish,

highly depends on thetemperature. Thecommon

packagingtemperatureisabout0C(32F)orlower.

The lower the temperature, the slower is the

deteriorationreaction.

MAPapplicationforfisheriesproductpreservation

has been widely known. It can be used alone or

combined with other preservation technique like

freeze-chillingwhichisabletoextendtheshelflifeof

pacificwhiting,mackerelandsalmonfillet(Faganet

Figure7.ThermoformFormFillSeal(TFFS)(Anon.,2012c).

45

Squalen Vol. 7 No. 1, May 2012: 39-49.

Table2.Sealingmaterialsandtheirsuitabilitytouseindifferentfoodstuffs

ASTM

D1418

Suitability for Use

Material Description

Material

Type

Dry Aqueous Fatty

Food

Food

Food

Chloroprenerubber

Acrylonitrilebutadiene

rubber

EPDM

Ethylenepropylene

rubber

VMQ

Siliconerubber

FKM

Fluoroelastomer

HNBR

Hydrogenatednitrile

rubber

FFKM

Perfluoroelastomer

CR

NBR

Note: Generallysuitable,*Couldbesuitable,dependentongrade(Source:Warren,2008).

al., 2004).Anotherexample ofMAPapplicationin

fisheriesproducthasbeenreportedPacificwhiting

filletpackedin100%CO2andkeptat4Chasshelf

lifeupto15days(Guldageret al.,1998).

ThecombinationofMAPwithrefrigerationalso

showspositiveeffecttocodfilletquality,especiallyto

fresh-rawcod.Shorttermfrozenstorageofcodfor6

weeksat-20Cor-30Csubstantiallyreducedthe

numberofP.phosphoreum.Thisspecificspoilage

organismwasnotdetectedduringchillstorageofcod

filletspreviouslyfrozenandstoredat-20C(Boknaes

et al.,2000inTorrieriet al.,2011).

ThecombinationofMAPwithsuper-chilingcan

extendtheshelflifeofAtlanticsalmon(Salmo salar)

fillets.ThesampleswiththehighestCO2concentration

(90%)andgas-to-productratio(g/pratio)of2.5showed

thehighestshelflifewhichis22dayswhilecontrol

sample remains only 11 days based on microbial

analysis (Fernandez et al., 2009). Superchilling is

anothertechniqueusedtoinhibitmostautolyticand

microbialreactions(Huss,1995).Several typesof

coolingsystems(-4Cto0C)havebeen used for

superchillingofseafoodproductsincludingtheuseof

flakeiceorslurryice(Losadaet al.,2006;Zenget al.,

2005)andsubzerotemperaturesduringstorage(-2C)

(Sivertsviket al.,2003).

Quality Analysis of MAP Product

Some physical and chemical tests have been

performedtoanalyzeMAPproduct,suchascolor,

46

trimethylamine, water content, total viable count,

peroxide value, odor, etc. Torrieri et al. (2011)

measuredpHusingpHmeter,colorwithcolorimeter,

andThiobarbituricAcidReactiveSubstances(TBARS)

usingextractionprocedurefromLemon(1975)and

Kilic&Richards(2003).

Torrieriet al.(2011)reportedthatthepHoffresh

bluefintunafilletswasconstantthroughoutstorage

with no differences among samples. The TBARS

valuesofsamplespackedwith100%N2werelower

thanthoseof control samples, thus 100% N2 was

chosen as the optimal atmosphere to pack the

product.SamplespackedinMAP100%N2showed

nochangeincolourduringstorage(p>0.05),thus

indicatingaprotectiveeffectofthisatmosphereon

colour change; so 100% N2 atmosphere was the

optimal atmospherein whichto pack the product.

Moreover,thefinalreportshowedthatthecombined

useofMAPandactivefilmresultedinalessoxidized

productafter18daysofstorageat3C.

Meanwhile, some physical tests have to be

performedtoensurethequalityofMAPpackaging,

suchas:

1.Heatintegrityofpackagingseal.Heatintegrityof

packaging seal is measured using destructive

(basedonimmersingpacksinwaterandchecking

forescapinggasbubblesaroundtheseal)andnon

destructivetest(basedonmeasuringchangesin

pressuregeneratedbypacks undervacuum in

sealedchambers)(Mulan&McDowellinColeset

al.,2003).

Applications of Modified Atmosphere......... (P. Wullandari and D. Fithriani)

2.Transmissionrateandpermeabilityofpackaging

film. Transmission rate and permeability of

packagingfilmismeasuredusingisostaticmethod

(both sides of the test film are maintained by

passingtestgascontinuouslyononesideofthe

filmwhileinertcarriergascontinuouslyremoves

permeantfromtheothersideofthefilm)(Mulan&

McDowellinColeset al.,2003).

3.Compositionofpackheadspace.Theanalysisfor

compositionofpackheadspaceisperformedusing

O2andCO2headspaceanalyzerforMAP(Fig.8).

APPLICATION OF MAP IN INDONESIA

Indonesiahasahightemperatureandhumidity,

thereforeMAPapplicationcanbeveryinterestingand

becomeacompromisingopportunityforfoodindustries

todevelopMAPusinglocalcomponentsandbased

onenvironmentalcharacteristicorconsumendemand.

MAPinIndonesiaismainlyusedforfreshfruits,

becausefreshfruitsarehighlyperishable.Freshfruits

stillundergorespirationprocessafterbeingharvested.

This respiration produced simple molecules that

reducefreshfruitsquality.Temperatureisoneofthe

importantfactortodeterminerespirationrate.The

higherthetemperature,thefasteristherespiration

rate. Therefore MAP is needed to modify the

atmosphereinsidethefreshfruitspackagesinorder

tomaintainfreshfruitsquality(Hadisumarto,1997).

An exampleof MAP infruit has been done by

Hidayat(2005),MAPcombinedwithlowtemperature

storagewasusedtomaintainthequalityoframbutan

(Nephelium lappaceum, Linn).Theresultsshowsthat

minimally-processedrambutanpackedwithstretch

films(initialconcentration:2-4O2,14-17%CO2)and

storedat10Chasshelflifeupto8days.

However the application of MAP to fresh fish

productsinIndonesiaisrarelyused,butithaspotency

tobedevelopedinthefuturebecauseithasmany

advantagesespeciallytoextendshelflifeoffreshfish

products.

The Future of MAP

Trendsintheevolutionoffoodpackaginghasbeen

changingsincedecades,startedfromconvenience

and marketing orientation in the 1960s; weight,

sustainable resources, and energy savings in the

1970s; saf ety and quality in the 1980s;

environmentalimpactinthe1990s;andsafetyand

securityinthe2000s(Han,2005inMcMilin,2008).

The key to successful packaging is selection of

materials and designs, which meet the needs of

product characteristics, marketing considerations

including distribution and consumer needs,

environmentalandwastemanagementissues,and

cost(Marsh&Bugusu,2007).

Consumersdemandsformoreenvironmentally

friendlypackagingandmorenaturalproductswillalso

create increased demand for packaging from

biodegradable and renewable resources (Cutter,

2006).Organic-basedmaterialsmaybeanaerobically

degraded while biodegradable polymers from

replenishable agricultural feedstocks, animal

sources,marinefoodprocessingindustrywastes,or

microbial sources are being developed (Marsh &

Bugusu,2007).

Nowadays,theequipmentwidelyusedinIndonesia

ischamber-typemachines,becauseithasthesame

principle as vacuum packaging machine. The

differenceisthatchamber-typemachinescanfillor

replace thegas insidethe pack. Inthe futureit is

expected that another MAP machines (chamber

machines, snorkel machines, form-fill-seal tray

machines,sealing,andcuttingmachines) andother

packagingmaterial(suchaspolymerfilms)canbe

usedinIndonesia.

CONCLUSION

Modified Atmosphere Packaging (MAP) is an

active packaging technology that can be used to

extendfreshfishsshelflife.MAPcanbeusedalone

orcombinedwithotherpreservationtechnique,

likefreezechilling,refrigeration,andalsocombined

withantioxidant, bactericides, andozone.In MAP

application,gascompositionorgasmixtureshould

be well defined, since every gases havedifferent

characteristics.

ThepackagingmaterialsusedforMAPinIndonesia

usuallyareflexibleandsemi-rigidlaminatedplastic.

ThereareseveralMAPmachinesusuallyusedinfood

industries,butinIndonesiachamber-typemachines

areusuallyused.Inthefutureitisexpectedthatother

MAP machines (chamber machines, snorkel

machines,form-fill-sealtraymachines,sealing,and

cuttingmachines) andotherpackagingmaterial(such

aspolymerfilms)canbeusedinIndonesia.

REFERENCES

Anonim. 2011. Pengemasan. Retrieved from http://

id.wikipedia.org/wiki/Pengemasan.Accessed on 15

Maret2012.

Anonymous. 2012a. Packaging Related Machine.

Retrieved from http://www.diytrade.com/ china/pd/

7180952/Modified_Automosphere_Packaging_

Machine.html.Accessed on24 Maret2012.

47

Squalen Vol. 7 No. 1, May 2012: 39-49.

Anonymous. 2012b. Modified atmosphere Packaging

Machines. Retrieved from http://sevana.co.in/

modi_atmospherel.html. Accessed on 17 Februari

2012.

Anonymous.2012c.Guide to MAP.Retrievedfromhttp://

www. airproducts. ae/food /MAP /guide-to-MAP/MAPmachines.asp.Accessed on 24 Maret 2012.

Bak, L.S., Andersen, A.B., Andersen, E.M., and G.

Bertelsen. 1999. Effect of modified atmosphere

packaging on oxidative changes in frozen stored cold

water shrimp (Pandalus borealis). Food Chemistry.

64: 169175.

Bono,G.andCinziaBadalucco.2012.Combining ozone

and modified atmosphere packaging (MAP) to

maximize shelf life and quality of striped red mullet

(Mullus surmuletus). LWT-Food Science and

Technology.47:500504.

Chinivasagam,H.N.,Bremner,A.H.,Thrower,S.J.,and

Nottingham, S. M. 1996. Spoilage pattern of five

species of Australian prawns: deterioration is

influenced by environment of capture and mode of

storage. J. of Aquatic Food Product Technology. 5:

2550.

Christie, G.B.Y., Macdiarmid, J.I., Schliephake, K., and

Tomkins, R.B. 1995. Determination of film

requirements and respiratory behaviour of fresh

produce in modified atmosphere packaging.

Postharvest Biology and Technology.6:4154.

Coles,Richard,McDowell,Derek,andKirwan,M.J.2003.

Food Packaging Technology. Blackwell Publishing

Ltd,Australia.

Cutter,C.N.2006.Opportunitiesforbio-basedpackaging

technologiestoimprovethequalityandsafetyoffresh

and further processed muscle foods. Meat Science.

74: 131142.

Fagan, J.D., Gormleya, T.R., and Mhuircheartaigh,

M.M.U. 2004. Effect of modified atmosphere

packaging with freeze-chilling on some quality

parameters of raw whiting, mackerel and salmon

portions. Innovative Food Science and Emerging

Technologies. 5: 205214.

Fernndez,K.,Aspe,E.,andRoeckel,M.2009.Shelflife

extension on fillets ofAtlantic Salmon (Salmo salar)

using natural additives, superchilling and modified

atmosphere packaging. Food Control. 20: 1036

1042

Gopal, and Srinivasa,T.K.2011. Packaging of Fish and

Fishery Products. Downloaded from http://

www.worldfoodscience.org/cms/?pid=1005100.

Accessed on 16 juni2011.

Gram, Lone, and Hans Henrik Huss, 1996.

Microbiological spoilage of fish and fish products.

International Journal of Food Microbiology.(33):121

137.

Guldager, H.S., Bkns, N., sterberg, C., Nielsen, J.,

and Dalgaard, P. 1998. Thawed cod fillets spoil less

rapidly than unfrozen fillets when stored under

modified atmosphere at 2C. J. of Food Protection.

61 (9): 11291136.

Hadisumarto dan Triyanto, 1997. Modifikasi Atmosfer

dalam Pengemasan untuk Buah Segar. Buletin

Penelitian.XIX(2).

48

Ode, H.L. 2005. Penyimpanan Buah Rambutan

(Nephelium lappaceum, Linn.) Terolah Minimal

dalam Kemasan Atmosfer Termodifikasi. Thesis.

Sekolah Pascasarjana Institut Pertanian Bogor,

Bogor

Hurme, E.,T.S-Malm, Ahvenainen, R., and Nielsen, T.

2002. Active and Intelligent Packaging. In: Minimal

Processing Technologies in Food Industry.

Huss, H.H. 1995. Quality and quality changes in fresh

fish. In Food and Agricultural organization of United

Nations,(paper,F.T.,Ed.).FAO,Rome.

Hutton, T. 2003. Food packaging: An introduction. Key

topics in food science and technology-Number 7.

Chipping Campden, Gloucestershire, UK: Campden

and Chorleywood Food Research Association

Group,108pp.

Jacxsens, L., Devlieghere, F., Rudder, T. D., and

Debevere, J. 2000. Designing equilibrium modified

atmosphere packages for fresh-cut vegetables

subjected to changes in temperature. LebensmittelWissenschaft Und-Technologie, 33, 178"187.

Jay,andJames,M.2011.Food Preservation with Modified

Atmospheres. Modern Food Microbiology, sixth

edition.APAC Publishers, Singapore.

Jeong,Youn,J.,andClaus, J.R.2011. Color stability of

ground beef packaged in a low carbon monoxide

atmosphere or vacuum.Meat Science. 87:16.

Killic, M.B. and Richards, M.P. 2003. Lipid oxidation in

poultry dner kebab: pro-oxidative anti-oxidative

factors.J. of Food Science.68:686689.

Lemon,1975.An improved TBA Test for Rancidity.New

Series Circular No. 51, Halifax Laboratory, Halifax,

Nova Scotia, Canada.

Lord,J.B.2008.The Food Industry In The United States:

Developing New Food Products For A Changing

Market Place.2nd ed.BocaRaton,CRSPress.p 1

23.

Losada,V.,Rodriguez,A.,Ortiz,J.,andAubourg,S.P.2006.

Quality enhancement of canned sardine (Sardina

pilchardus) by a preliminary slurry ice chilling

treatment. European Journal of Lipid Science and

Technology.108 (7):598605.

Shengmin,Lu.2009.Effects of bactericides and modified

atmosphere packaging on shelf life of Chinese

shrimp (Fenneropenaeus chinensis). LWT-Food

Science and Technology.42:286291.

Mahajan,P.V.,Oliveira,F.A.R.,Montanez,J.C.,andJ.Frias,

2007. Development of user-friendly software for

design of modified atmosphere packaging for fresh

and fresh-cut produce.Innovative Food Science and

Emerging Technologies 8: 8492.

Marsh,K.andBugusu,B.2007.Food packaging Roles,

materials, and environmental issues. Food Science,

72(3):R39R55.

Martinez-A lvarez, O., Lopez-Caballero, M.E., Montero,

P., and Gomez-Guillen, M.C. 2005. A 4hexylresorcinol-based formulation to prevent

melanosis and microbial growth in chilled tiger

prawns (Marsupenaeus j aponicus) from

aquaculture.J. of Food Science.70:M415M422.

Applications of Modified Atmosphere......... (P. Wullandari and D. Fithriani)

McMillin,andKenneth,W.2008.W hereisMAPGoing?A

review and future potential of modified atmosphere

packagingformeat. Meat Science.80:p. 4365.

McMillin, K. W., Huang, N.Y., Ho, C.P., and Smith, B.S.

1999. Quality and shelf-life of meat in case-ready

modified atmosphere packaging. In Y. L. Xiong, F.

Shahidi, and C. T. Ho (Eds.), Quality attributes in

muscle foods(pp.7393).NewYork:ACSSymposium

Series, Plenum Publishing Corporation.

Otwell, Steven W., Kristinsson, Hordur G., and Murat O.

Balaban.2006.Modified Atmospheric Processing and

Packaging of Fish. Blackwell Publishing, USA

SaudiFisheriesCompany.2005.Individuallyquickfrozen

(IQF).Retrieved from http://www.saudi-fisheries.com/

EN/Company/Products/iqf.htm. Accessed on 21

March2012

Sivertsvik, M. (1995). Shell-on shrimps packed in

modified atmosphere.Info.Norcon-serv.No.9.Report

(in Norwegian).

Sivertsvik, M., Rosnes, J.T., and Kleiberg, G.H. 2003.

Effect of modified atmosphere packaging and

superchilled storage on the microbial and sensory

quality ofAtlantic salmon (Salmo salar) fillets. J. of

Food Science.68 (4):14671472.

Sivertsvik, and Morten. 2006. The optimized modified

atmosphere for packaging of pre-rigor filleted farmed

cod (Gadus morhua) is 63 ml/100 ml oxygen and 37

ml/100 ml carbon dioxide.LWT Food Science and

Technology.40(3):430480.

SystechInstrumen,LtdandIllinoisInstrument,Inc.2010.

OxygenandCarbondioxideHeadspaceGasAnalyzer.

Downloaded from http://www.systechillinois.com/en/

o x y ge n -a n d -ca rb o n -d io x i d e -h ea d s p a c e -g a s a n a l y z e r -g a s p a c e - a d v a n c e -m i c r o _ 2 9 . h t m l .

Accessed July 29,2012

Torrieri, Elena, Carlino, Pier Antimo, Cavella Silvana,

Fogliano, Vincenzo, Attianese, Illaria, Buonocore,

Giovanna Giuliana, dan Paolo Masi, 2011. Effect of

ModifiedAtmosphere and Active Packaging on The

Shelf Life of Fresh Bluefin Tuna Fillets. J. of Food

Engineering. 105 (3): 429435.

US FDA. 2002. United States Food and Drug

Administration.Agency responseletter GRAS notice

No. GRN 000083. W ashington, D.C., USA

Downloadedfrom:http://www.cfsan.fda.gov/rdb/opag083.html.Accessed July 29, 2012

US FDA. 2004. United States Food and Drug

Administration.Agency response letter.GRAS notice

No. GRN 000143. W ashington, D.C., USA

Downloaded from http://www.fda.gov/Food/

F o o d I n g r e d i e n t s P a c k a g i n g /

GenerallyRecognizedasSafeGRAS/GRASListings/

ucm153974.htm. Accessed July 29, 2012.

Warren,Peel.2008. Sealing for the food and beverage

industry. SealingTechnology. 2008 (9):1114.

Yam,K.L.,Takhistov,P.T.,andMiltz,J.,2005.Intelligent

packaging: Concepts and applications. Journal of

Food Science.70(1):110.

Zeng,Q.Z.,Thorarinsdottir,K.A.,andOlafsdottir,G.2005.

Quality changes of shrimp (Pandalus borealis) stored

under different cooling conditions.J. of Food Science.

70 (7): S459S466.

49

Squalen Vol. 7 No. 1, May 2012: 39-49.

INFORMASI PUBLIKASI PERPUSTAKAAN

BALAI BESAR PENELITIAN DAN PENGEMBANGAN PENGOLAHAN PRODUK DAN

BIOTEKNOLOGI KELAUTAN DAN PERIKANAN

BUKU BARU

1.

TheMicrobiologyofSafeFood/BL/Stephen/2010

2.

Sanitation:CleaningandDisinfectioninTheFoodIndustry/Jian/2010/JW

3.

SeafoodEcolabeling/2008/Phillips/Blw

4.

HandbookofSeafoodQuality,SafetyandHealthApplication/BLW/Kazuo/2011

5.

FishProcessing:Sustainability&NewOpportunities/WP/Hall/2011

6.

InPackProcessesFood:ImprovingQuality/WP/Phillip/2008

7.

EnvironmentalEffectsonSeafoodAvailability,SafetyandQuality/WP/Kozon/2011

8.

FishCanningHandbook/2010/WI/Bratt

9.

EnvironmentallyCompatibleFoodPackaging/WP/Chiellini/New

10. MicrobialSafetyofFreshProduct/Blw/Xuetong/2009

11. NondestructiveEvaluationofFoodQuality2009/spr/by:jha

12. ControlofFishQuality4thed/FNB/Connell

13. PrinciplesofFoodToxicology/Pussa/CRC/2008

14. FoodSafetyForthe21stCenturyManagingHACCP/2011/WI/Wallance

15. IntroductiontoFoodToxicology2ed/Takayuki/AP

16. PrinciplesofMicrobiologicalofTroubleshootinginTheIndusFoodProcessEnviron/10/Spr/Jeffrey

17. IngredientsinMeatProducts:Properties,FunctionalityandApplication/Spr/2009/Tarte

18. HandbookofFirezenFoodProcessingandPackaging2ed/2012/Sun/CRC

19. JurnalPengelolaanHasilPerikananIndonesiaVol.13no.2Tahun2010,Vol.14no.1Tahun2011(dari

MasyarakatPengolahanHasilPerikananIndonesia/MPHPI)

20. BAWALVol.3No.4,2011(dariPusatPenelitianPengelolaanPerikanandanKonservasiSumber

DayaIkan)

21. JurnalStandarisasiVol.13No.1dan2,Tahun2011(dariBSN)

22. MinabahariEdisiJuni,Juli,November2011(dariPusdatin)

23. TROBOSedisiAgustus,Oktober,November,Desember2011danJanuari2012(dariPTJAPFA

ComfeedIndonesiaTbk)

24. JornalPustakawanIndonesiaVol.10no.2,2010(PerpustakaanIPB)

25. SINERGIedisiIII/2011(ITJENKKP)

26. WartaPasarIkanedisiAgustus2011vol.96(DitjenP2HP)

27. BUDIDAYATahunke-9edisi16,17,19Tahun2011(DirjenBudidaya)

28. JurnalPenelitianPerikananIndonesia(Puslitpengembangankonservasisumberdayaikan)

29. BuletinTeknikLitkayasaSumberdayaPenangkapan(Puslitpengembangankonservasisumberdaya

ikan)

30. IndonesianFisheriesResearchJournal(Puslitpengembangankonservasisumberdayaikan)

50

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Wbs and Division of Work Excel Spread Sheet1Document12 pagesWbs and Division of Work Excel Spread Sheet1Adrian Christian Lee100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- bq270v eDocument8 pagesbq270v eOdil0% (1)

- Guwahati Conference Circular 1Document5 pagesGuwahati Conference Circular 1Phyoben S OdyuoNo ratings yet

- A Broadband Planar Magic-T Using Microstrip-Slotline TransitionsDocument6 pagesA Broadband Planar Magic-T Using Microstrip-Slotline TransitionsSarvesh HireNo ratings yet

- PL2303 G Series ManualDocument1 pagePL2303 G Series ManualGesiNo ratings yet

- UNIT 1-PHY 131 Chapter 2 - Introduction To VectorsDocument35 pagesUNIT 1-PHY 131 Chapter 2 - Introduction To VectorscharlieNo ratings yet

- The Thai Spirit House: by Marisa Cranfill YoungDocument2 pagesThe Thai Spirit House: by Marisa Cranfill Youngsian017No ratings yet

- 145kV GTP BPDBDocument4 pages145kV GTP BPDBJRC TestingNo ratings yet

- Case Studies On Environmental Due Diligence English VersionDocument43 pagesCase Studies On Environmental Due Diligence English Versionsatarupa BandyopadhyayNo ratings yet

- CH 5 MatlabDocument77 pagesCH 5 MatlabAqib AliNo ratings yet

- JDZX22G-35 Catalog EN 20160314Document2 pagesJDZX22G-35 Catalog EN 20160314RonnyNo ratings yet

- Qaballah and Tarot: A Basic Course in Nine Lessons Lesson III-bbDocument50 pagesQaballah and Tarot: A Basic Course in Nine Lessons Lesson III-bbPolaris93100% (1)

- Internal Combustion Engine Layout and ConfigurationDocument11 pagesInternal Combustion Engine Layout and ConfigurationKathija SumanNo ratings yet

- Nasib Ahmad Faqirzada Resume CVDocument4 pagesNasib Ahmad Faqirzada Resume CVNasib Ahmad FaqirzadaNo ratings yet

- KoldamDocument13 pagesKoldamHarpreet SinghNo ratings yet

- Unit 4 Notes GDJPDocument2 pagesUnit 4 Notes GDJPAnanth VelNo ratings yet

- Lesson 1 Definition Characteristics and Branches of PhilosophyDocument55 pagesLesson 1 Definition Characteristics and Branches of PhilosophyJhasmin GierranNo ratings yet

- Ef 2000 TestingDocument12 pagesEf 2000 TestingLeiser HartbeckNo ratings yet

- PHD Thesis Cell CultureDocument5 pagesPHD Thesis Cell Culturefc4qgsp7100% (2)

- Epas G9 M Q3 W7-W8Document4 pagesEpas G9 M Q3 W7-W8ALLYSSA MAE PELONIANo ratings yet

- 1 - Aqueduct RETROSPECTOSDocument10 pages1 - Aqueduct RETROSPECTOSirving.barrios.vzlaNo ratings yet

- Fastback Slowback Soakback-CSURApr2014 RVHDocument14 pagesFastback Slowback Soakback-CSURApr2014 RVHJuan PabloNo ratings yet

- Mba Group ActivityDocument14 pagesMba Group ActivitySHERYL SHEKINAH E ARCH-2019 BATCHNo ratings yet

- 1980 Garelli Engine Manual PDFDocument56 pages1980 Garelli Engine Manual PDFAnonymous YWDOAtINo ratings yet

- Generator Breaker Equipped With Vacuum InterruptersDocument4 pagesGenerator Breaker Equipped With Vacuum InterruptersVenna Karthik ReddyNo ratings yet

- Octavius Tea OfflineDocument7 pagesOctavius Tea Offlineapi-323468541No ratings yet

- Sto. Niño Academy of Bamban, Inc.: The Roar Learning Guide SeriesDocument3 pagesSto. Niño Academy of Bamban, Inc.: The Roar Learning Guide SeriesJerome Neil DayritNo ratings yet

- 613 Ebce 67 CB 7 DDocument2 pages613 Ebce 67 CB 7 DTheerapong ChansopaNo ratings yet

- Lecture-1 Introduction To Power Generation and Electrical Power SystemsDocument30 pagesLecture-1 Introduction To Power Generation and Electrical Power SystemsArishaNo ratings yet

- Group1 OB Ward-Case StudyDocument10 pagesGroup1 OB Ward-Case StudyAnthony Seth AguilandoNo ratings yet