Professional Documents

Culture Documents

BPVC Ix Qw-484a PDF

BPVC Ix Qw-484a PDF

Uploaded by

prem nautiyalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BPVC Ix Qw-484a PDF

BPVC Ix Qw-484a PDF

Uploaded by

prem nautiyalCopyright:

Available Formats

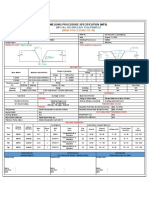

FORM QW-484A SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)

Welders name

Identification no.

Test Description

Test coupon

Identification of WPS followed

Specification and type/grade or UNS Number of base metal(s)

Production weld

Thickness

Testing Variables and Qualification Limits

Welding Variables (QW-350)

Actual Values

Range Qualified

Welding process(es)

Type (i.e.; manual, semi-automatic) used

Backing (with/without)

Plate

Pipe (enter diameter if pipe or tube)

Base metal P-Number to P-Number

Filler metal or electrode specification(s) (SFA) (info. only)

Filler metal or electrode classification(s) (info. only)

FIller metal F-Number(s)

Consumable insert (GTAW or PAW)

Filler Metal Product Form (solid/metal or flux cored/powder) (GTAW or PAW)

Deposit thickness for each process

Process 1

3 layers minimum

Process 2

3 layers minimum

No

No

Yes

Yes

Position qualified (2G, 6G, 3F, etc.)

Vertical progression (uphill or downhill)

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Transfer mode (spray/globular or pulse to short circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN)

RESULTS

Visual examination of completed weld (QW-302.4)

Transverse face and root bends [QW-462.3(a)]

Longitudinal bends [QW-462.3(b)]

Side bends (QW-462.2)

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)]

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d)]

Pipe specimen, macro test for fusion [QW-462.5(b)]

Type

Result

Type

Macro examination (QW-184)

Result

RT

Alternative Volumetric Examination Results (QW-191):

Fillet weld fracture test (QW-181.2)

Fillet welds in plate [QW-462.4(b)]

Plate specimen, macro test for fusion [QW-462.5(e)]

Type

or UT

Result

(check one)

Length and percent of defects

Fillet welds in pipe [QW-462.4(c)]

Fillet size (in.)

Concavity/convexity (in.)

Other tests

Film or specimens evaluated by

Company

Mechanical tests conducted by

Laboratory test no.

Welding supervised by

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization

Date

(07/13)

Certified by

You might also like

- Supplement To Materials and Processes For NDT TechnologyDocument76 pagesSupplement To Materials and Processes For NDT TechnologyTC Capulcu Mustafa M100% (5)

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- WPQ TemplateDocument1 pageWPQ Templatejoshrathburn1980No ratings yet

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- PT Outline Training LV IIIDocument2 pagesPT Outline Training LV IIITrung Tinh HoNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNo ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- NCTL Project: Proposal Welding Procedure SpecificationDocument4 pagesNCTL Project: Proposal Welding Procedure SpecificationRotimi Shitta-BeyNo ratings yet

- Appendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Document14 pagesAppendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Jobaer ShaonNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- 2019 Key Changes Section IX PDFDocument55 pages2019 Key Changes Section IX PDFRachel ThompsonNo ratings yet

- Ttransition JointsDocument15 pagesTtransition JointsAdil HasanovNo ratings yet

- ASME U StampDocument12 pagesASME U StampShaheen Andre ChikkuNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- Pipe Clamps For Welding Alignment (DWT Babcock) 3Document2 pagesPipe Clamps For Welding Alignment (DWT Babcock) 3Daniel AriefinNo ratings yet

- Welding Inspection: BS 499 Part 2 Course Reference WIS 5Document11 pagesWelding Inspection: BS 499 Part 2 Course Reference WIS 5aezeadNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- Tolerances For Pressure VesselsDocument2 pagesTolerances For Pressure VesselsolekNo ratings yet

- Asme Section Ix-Welding - Practice Quest PDFDocument3 pagesAsme Section Ix-Welding - Practice Quest PDFRajesh KumarNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- PQR - WPQ Witness ReportDocument1 pagePQR - WPQ Witness Reportsdkeskar40No ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- Ultrasonic Phased Array ApplicationsDocument26 pagesUltrasonic Phased Array ApplicationsLương Hồ VũNo ratings yet

- Weld Repair ProcedureDocument6 pagesWeld Repair ProcedurePramod AthiyarathuNo ratings yet

- Twi Impact TestingDocument17 pagesTwi Impact TestingchungndtNo ratings yet

- Penetrants TESTINGDocument86 pagesPenetrants TESTINGsankaran_muthukumarNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Ut 4 PDFDocument42 pagesUt 4 PDFtusharNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- 3g Tar WPQTR Form Aws d1.1Document2 pages3g Tar WPQTR Form Aws d1.1Scott AdkinsNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WPS-GMAW-IN06 (Total)Document4 pagesWPS-GMAW-IN06 (Total)Wellington S. FrançaNo ratings yet

- RT Asme IxDocument3 pagesRT Asme Ixhernando gelves100% (1)

- WPSGMAW90 102011ExamplePDFDocument1 pageWPSGMAW90 102011ExamplePDFBhavani PrasadNo ratings yet

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- ASNT Calculator GuideDocument14 pagesASNT Calculator GuidevasanthNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Blank Sample WPS Form (SAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (SAW) Welding Procedure Specification (WPS)GMNo ratings yet

- 08 Omniscan ConventionsDocument11 pages08 Omniscan ConventionsLương Hồ VũNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- Basc QB 2Document3 pagesBasc QB 2prabhakaran.SNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- ts203 PDFDocument45 pagests203 PDFSergio AlejandroNo ratings yet

- Senior Welding Inspection: Weld Procedures Course Reference WIS 10Document21 pagesSenior Welding Inspection: Weld Procedures Course Reference WIS 10Harkynollar HarkyntehyeNo ratings yet

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Document11 pagesCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruNo ratings yet

- Company Name Key Information Questions Answers File Reference Reviews & ApprovalsDocument7 pagesCompany Name Key Information Questions Answers File Reference Reviews & ApprovalsMAT-LIONNo ratings yet

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- Inspection In Manufacturing A Complete Guide - 2020 EditionFrom EverandInspection In Manufacturing A Complete Guide - 2020 EditionNo ratings yet

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- Suggested Wps Forms ASME - IX 2010Document5 pagesSuggested Wps Forms ASME - IX 2010Ajay ChodankarNo ratings yet

- Ultrasonic Test ReportDocument4 pagesUltrasonic Test ReportTC Capulcu Mustafa MNo ratings yet

- Evolution of The Ultrasonic Inspection of Heavy Rotor Forgings Over The Last DecadesDocument9 pagesEvolution of The Ultrasonic Inspection of Heavy Rotor Forgings Over The Last DecadesTC Capulcu Mustafa MNo ratings yet

- Steinmueller Engineering Produktbroschuere Steam GenerationDocument7 pagesSteinmueller Engineering Produktbroschuere Steam GenerationTC Capulcu Mustafa MNo ratings yet

- Steinmueller Engineering Produktbroschuere After Sales ServicesDocument5 pagesSteinmueller Engineering Produktbroschuere After Sales ServicesTC Capulcu Mustafa MNo ratings yet

- Energy From Waste: We Make The World A Cleaner PlaceDocument28 pagesEnergy From Waste: We Make The World A Cleaner PlaceTC Capulcu Mustafa MNo ratings yet

- Weld Failures A CompendiaryDocument3 pagesWeld Failures A CompendiaryTC Capulcu Mustafa MNo ratings yet

- Flue Gas Cleaning: We Make The World A Cleaner PlaceDocument32 pagesFlue Gas Cleaning: We Make The World A Cleaner PlaceTC Capulcu Mustafa MNo ratings yet

- Sti Mod.2 TK 02 Caculation SheetDocument1 pageSti Mod.2 TK 02 Caculation SheetTC Capulcu Mustafa MNo ratings yet

- WPS PQR Checklist 2014Document2 pagesWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Biological Treatment of Organic Waste: We Make The World A Cleaner PlaceDocument8 pagesBiological Treatment of Organic Waste: We Make The World A Cleaner PlaceTC Capulcu Mustafa MNo ratings yet

- Moeller Technology in Power Plants 2016Document8 pagesMoeller Technology in Power Plants 2016TC Capulcu Mustafa MNo ratings yet

- Nozzle Design - The Weak Point of Every Equipment - Training & EngineeringDocument11 pagesNozzle Design - The Weak Point of Every Equipment - Training & EngineeringTC Capulcu Mustafa M0% (1)

- Cored Wires For Joining BÖHLER PDFDocument6 pagesCored Wires For Joining BÖHLER PDFTC Capulcu Mustafa MNo ratings yet

- Schaeffler DiagramDocument9 pagesSchaeffler DiagramAji Ashiq75% (4)

- FM 23-10Document8 pagesFM 23-10feralmuttNo ratings yet