Professional Documents

Culture Documents

Sugarcane Intro

Uploaded by

doraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sugarcane Intro

Uploaded by

doraCopyright:

Available Formats

OBJECTIVE:

1. To synthesis crystallised suger from sugarcane juice.

2. To study the percentage yield of the sugar obtained from fresh sugarcane juice.

3. To investigate the physical properties of sugar.

INTRODUCTION:

Sugar is a broad term applied to a large number of carbohydrates present in many

plants and characterized by a more or less sweet taste. The primary sugar, glucose, is a

product of photosynthesis and occurs in all green plants. In most plants, the sugars occur as a

mixture that cannot readily be separated into the components. In the sap of some plants, the

sugar mixtures are condensed into syrup. Juices of sugarcane (Saccharum officinarum) and

sugar beet (Beta vulgaris) are rich in pure sucrose, although beet sugar is generally much less

sweet than cane sugar. These two sugar crops are the main sources of commercial sucrose.

For centuries before crystallised sugar was produced, it was not plentiful as it is today

and honey was used for sweetening in most parts of the world. In some places, raw sugar

cane was chewed to extract its sweetness. Sugar cane is a grass that can grow nearly 20 feet

tall. When harvested, the leaves are removed and the stalks are cut and squeezed to extract

the juices that will later be processed into sugar. In sugar cane processing plants, the juice is

cleaned with lime (a mineral similar to chalk), and then the water is boiled off, leaving a

sugar syrup. Unlike evaporating salt / water mixtures, evaporating sugar syrup to retrieve

sugar crystals is a bit more complex. Sugar processing plants will often add sugar dust to the

saturated syrup to help initiate the crystallization process. After crystals have formed, the

sugar is then tossed, dried, and later refined into table sugar. The byproduct of sugar

processing is molasses, which is either used for cattle food or alcohol distillation.

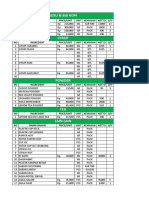

Figure 1: The flowchart of sugar processing from sugarcane

To synthesis sugar, sugar cane must be crushed to extract the juice. The crushing

process must break up the hard nodes of the cane and flatten the stems. The juice is collected,

filtered and sometimes treated and then boiled to drive off the excess water. The dried cane

residue (bagasse) is often used as fuel for this process. Moreover, the remaining liquid is

allowed to set into a solid mass known as jaggery, gur, chancaca or panela.

In this experiment, the sugarcane juice is cleaned with calcium hydroxide before

evaporating it to concentrate the sweetness. The Ca(OH)2 is derived from quick lime, calcium

oxide or CaO, by adding water. That reaction sequence is: CaO + H2O Ca(OH)2. Then,

the sugarcane juice is heated to 75 C, which, combined with the slaked lime, decomposes

the enzymes that would break down the sugar. The predominant enzyme is invertase, a large

molecule that splits the disaccharide, sucrose or table sugar, into two monosaccharides,

glucose and fructose. Boiling greatly increases the concentration of sugar, they can dissolve

much sugar in boiling water, but as the solution cools, sugar crystallizes out. At this stage, the

sugar is brown due to the presence of traces of the mother liquor (molasses). The

concentrated syrup is then evaporated for 7 days and the sugar is formed.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Confectionary - NotesDocument72 pagesConfectionary - NotesManthan Wankhede100% (5)

- Quit Sugar for Good - An 8-Week Plan to Feel AmazingDocument41 pagesQuit Sugar for Good - An 8-Week Plan to Feel AmazingRuth Osborn50% (2)

- Aspen SimulationDocument25 pagesAspen SimulationDineshNo ratings yet

- Correspondence Table 2009 PSIC Vs Ammended 1994 PSIC1Document53 pagesCorrespondence Table 2009 PSIC Vs Ammended 1994 PSIC1Renato E. Reside Jr.No ratings yet

- Design of Pyrolysis ReactorDocument72 pagesDesign of Pyrolysis Reactork_asiamah201296% (27)

- 69 Sugar CookeryDocument21 pages69 Sugar CookeryChristopher Peralta Caparas II100% (1)

- Lemon EclairDocument4 pagesLemon EclairPetreNo ratings yet

- Éclairs With Mango and Passion FruitDocument8 pagesÉclairs With Mango and Passion FruitidaniachavesNo ratings yet

- 10 Unknown Health Benefits of Cobra Vine Seeds That Rarely GrowDocument8 pages10 Unknown Health Benefits of Cobra Vine Seeds That Rarely GrowRheaMaePagaranOnyot100% (1)

- 02 - Food-Guideline-for-WildFit-Week-3Document5 pages02 - Food-Guideline-for-WildFit-Week-3Cami IvanNo ratings yet

- Diffusion - HandoutDocument19 pagesDiffusion - HandoutOmar Ahmed ElkhalilNo ratings yet

- Experiment: Soil Chemical Analysis - Calcium CarbonateDocument5 pagesExperiment: Soil Chemical Analysis - Calcium CarbonatedoraNo ratings yet

- Cellulose Nanocomposites PDFDocument52 pagesCellulose Nanocomposites PDFMustafa ÇiçeklerNo ratings yet

- TEMPO-mediated Oxidation of Polysaccharides: Survey of Methods and ApplicationsDocument18 pagesTEMPO-mediated Oxidation of Polysaccharides: Survey of Methods and ApplicationsdoraNo ratings yet

- CompletedDocument34 pagesCompleteddoraNo ratings yet

- Py Calculation SheetDocument14 pagesPy Calculation SheetdoraNo ratings yet

- Chapter 2Document2 pagesChapter 2doraNo ratings yet

- Ethene to Ethylene Oxide Process FlowDocument1 pageEthene to Ethylene Oxide Process FlowdoraNo ratings yet

- Experiment 5Document14 pagesExperiment 5doraNo ratings yet

- Total Energy Usage and Waste GeneratedDocument3 pagesTotal Energy Usage and Waste GenerateddoraNo ratings yet

- Optimized DesignDocument5 pagesOptimized DesigndoraNo ratings yet

- CHP 1+ Chp2Document20 pagesCHP 1+ Chp2doraNo ratings yet

- Ice Handout2Document17 pagesIce Handout2Camilo Jose100% (2)

- Laboratory Report Industrial Chemistry (Ep 201)Document1 pageLaboratory Report Industrial Chemistry (Ep 201)doraNo ratings yet

- Report FormatDocument3 pagesReport FormatdoraNo ratings yet

- Lab Report: Synthesis and Identification of PolymersDocument6 pagesLab Report: Synthesis and Identification of PolymersdoraNo ratings yet

- Ý ÓÈ-ÇаøÁ ¿ À ®Á - 2-2013-01ÇÐ ÂDocument1 pageÝ ÓÈ-ÇаøÁ ¿ À ®Á - 2-2013-01ÇÐ ÂdoraNo ratings yet

- BACHELOR THESIS - Centrifugal Pumps - Christian Allerstorfer (m0535041) v1.3 PDFDocument40 pagesBACHELOR THESIS - Centrifugal Pumps - Christian Allerstorfer (m0535041) v1.3 PDFIjabiNo ratings yet

- NylonDocument16 pagesNylonAnirudh Murali0% (1)

- Tutorial 2 Material Balance Non-Reactive On Single UnitDocument11 pagesTutorial 2 Material Balance Non-Reactive On Single UnitdoraNo ratings yet

- EV101 L0 IntroductionDocument17 pagesEV101 L0 IntroductiondoraNo ratings yet

- Chapt 05 PDFDocument25 pagesChapt 05 PDFdoraNo ratings yet

- Shreve Chemical Process Industries Fifth EdDocument808 pagesShreve Chemical Process Industries Fifth EddoraNo ratings yet

- Smith CH 01Document20 pagesSmith CH 01Chan Hyun ParkNo ratings yet

- Tutorial 2 Material Balance Non-Reactive On Single UnitDocument11 pagesTutorial 2 Material Balance Non-Reactive On Single UnitdoraNo ratings yet

- Honey's antimicrobial properties and microbial contentDocument7 pagesHoney's antimicrobial properties and microbial contentVidianka RembulanNo ratings yet

- 2005 Broadfoot Improving The Quality of C Sugar Magma For UsDocument10 pages2005 Broadfoot Improving The Quality of C Sugar Magma For UsnghiNo ratings yet

- 7 - Isso Format QP - Set-2Document7 pages7 - Isso Format QP - Set-2pavanvanguriNo ratings yet

- Business PlanDocument90 pagesBusiness PlanJustine CapunongNo ratings yet

- Cost Beverages Kopi GedhonganDocument315 pagesCost Beverages Kopi GedhonganKopi GedhonganNo ratings yet

- Market Analysis of "The Sugarcane Juice"Document12 pagesMarket Analysis of "The Sugarcane Juice"ankita sharmaNo ratings yet

- Case Study of WaterDocument10 pagesCase Study of WaterabzNo ratings yet

- Yacon SyrupDocument40 pagesYacon SyrupTrilceNo ratings yet

- 2007 Naics Us CodeDocument29 pages2007 Naics Us CoderajbharadwajNo ratings yet

- Body PartDocument73 pagesBody PartRekha RamannavarNo ratings yet

- Chia Water: LemonDocument10 pagesChia Water: LemonAdrian MiraflorNo ratings yet

- Philippine National Standards FOR Coconut Sap Sugar Philippine National Standards FOR Coconut Sap SugarDocument29 pagesPhilippine National Standards FOR Coconut Sap Sugar Philippine National Standards FOR Coconut Sap SugarAnonymous ExHdC8No ratings yet

- Food Technology TrendDocument56 pagesFood Technology TrendBambang NurhadiNo ratings yet

- Review of Energy Management at NoodsbergDocument3 pagesReview of Energy Management at Noodsbergbonginkosi mathunjwaNo ratings yet

- Film Review The Sugar FilmDocument1 pageFilm Review The Sugar FilmRhyl Jife Paglumotan MaantosNo ratings yet

- Crystallization Process GuideDocument6 pagesCrystallization Process GuideabuahnfNo ratings yet

- Disaccharide - An Overview - ScienceDirect TopicsDocument11 pagesDisaccharide - An Overview - ScienceDirect TopicsLord ASBNo ratings yet

- Vanilla CakeDocument2 pagesVanilla Cakeginny87No ratings yet

- Sugar Production Business PlanDocument18 pagesSugar Production Business PlanmitchmubsNo ratings yet

- Biofuels of IndiaDocument18 pagesBiofuels of IndiaNishant GuptaNo ratings yet