Professional Documents

Culture Documents

Microfabrication Technologies Course

Uploaded by

mohitsinghal25Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microfabrication Technologies Course

Uploaded by

mohitsinghal25Copyright:

Available Formats

Mechanical Engineering and Mechanics

MEM 417/800 Introduction to Microfabrication

Fall 2006/Spring 2007

Designation:

Elective

Catalog Description: Covers fundamentals and applications of major microfabrication technologies

such as photolithography, wet and dry etching, metal and dielectric deposition,

soft lithography, polymer micromachining, and wafer bonding.

Prerequisite:

None

Textbook:

Fundamentals of Microfabrication, Marc Madou, CRC Press, 2nd edition.

Objectives:

1.

2.

3.

4.

5.

6.

7.

Topics:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Class Schedule:

Explain the photochemistry, materials, and processes of photolithography and

analyze the resolution, sensitivity, and photoresist profile for positive and

negative photoresist processes.

Describe isotropic and anisotropic wet etching techniques; explain the effects of

etch parameters on etch rate, selectivity, and anisotropy; and classify etch stop

techniques.

Explain the physics and chemistry of plasma etching and deposition techniques

and compare dry and wet etching techniques in terms of etch rate, selectivity and

anisotropy.

Classify thin-film (metals and dielectrics) deposition techniques and compare

them in terms of film quality and residual stress.

Describe surface micromachining techniques and different wafer bonding

techniques.

List polymer micromachining techniques and identify their applications.

Design the microfabrication process flow and the photomasks for diverse final

products considering process compatibility and manufacturability.

Introduction to Microelectronics and MEMS

Photolithography

Lab#1 Phitolithography

Wet bulk micromachining

Lab#2 Wet etching

Dry bulk micromachining

Thin-film deposition techniques

Surface micromachining and wafer bonding

Polymer micromachining and electroplating

Lab#3 Polymer micromachining

3 hours/week lecture (3 credits); 3 laboratory classes

Contribution to Professional Component:

Prepares students for the second MEMS course, Microfluidics and Lab on a Chip.

RELATION TO ABET CRITERIA 3 OUTCOMES:

0 = No content; 1 = Some content; 2 = Significant content

Outcomes a - k

Content

a. An ability to apply knowledge

of mathematics, science and

engineering

b. An ability to design and

conduct experiments as well

as to analyze and interpret data

c. An ability to design a system,

component or process to meet

desired needs

Explanation

This course requires the students to

develop a general understanding of

microfabrication technologies. The

students learn to apply and synthesize

their knowledge of engineering and

sciences.

Evidence

Lecture

notes,

Homework,

Lab report,

Final exam

The students learn to interpret

experimental results through lab classes.

Lab report

The students learn to design MEMS and

their fabrication processes.

Homework,

Final exam

NA

e. An ability to identify,

formulate and solve

engineering problems

The problems in homework and exam

require students to identify and solve

engineering problems related to

microfabrication.

Homework,

Final exam

f. An understanding of

professional and ethical

responsibility

This is emphasized as part of the

engineers overall responsibility.

Classroom

discussion

g. An ability to communicate

effectively

The students learn writing skill through lab

report and paper review report.

Lab report,

Paper review

report

The impact of MEMS and microfabrication Classroom

on the society is discussed.

discussion

The need for lifelong learning of emerging

technologies is emphasized.

j. A knowledge of contemporary

issues

NA

k. An ability to use the

techniques, skills and modern

engineering tools necessary for

engineering practice

Diverse microfabrication techniques and

equipment are used in laboratory classes.

d. An ability to function on

multidisciplinary teams

h. The broad education necessary

to understand the impact of

engineering solutions in a

global/societal context

i. A recognition of the need for

and an ability to engage in

lifelong learning

Prepared by:

Dr. Hongseok (Moses) Noh, 15 November 2006

Classroom

discussion

Lab report

You might also like

- Clothing - Female - Stays - English & AmericanDocument220 pagesClothing - Female - Stays - English & AmericanThe 18th Century Material Culture Resource Center100% (28)

- Microsoft Excel 2010 Core Textbook PDFDocument288 pagesMicrosoft Excel 2010 Core Textbook PDFHassan Mehmood50% (2)

- Transient Overvoltage ProtectionDocument41 pagesTransient Overvoltage Protectionshadi22No ratings yet

- EEE325 - Physical Electronics Course OverviewDocument5 pagesEEE325 - Physical Electronics Course OverviewAlena BělaNo ratings yet

- Nonlinear Differential Equations in Micro/nano Mechanics: Application in Micro/Nano Structures and Electromechanical SystemsFrom EverandNonlinear Differential Equations in Micro/nano Mechanics: Application in Micro/Nano Structures and Electromechanical SystemsNo ratings yet

- Training HiPath 4000 V3.0Document38 pagesTraining HiPath 4000 V3.0Zaenal Saefudin100% (1)

- Pee Notes PDFDocument213 pagesPee Notes PDFUpender Rao SunkishalaNo ratings yet

- Physics Lab Manual - 2021-22Document38 pagesPhysics Lab Manual - 2021-22Aneesh KhandveNo ratings yet

- Course Outcomes of Material Science LabDocument3 pagesCourse Outcomes of Material Science LabMitesh KumarNo ratings yet

- Fabrication Course OutlineDocument4 pagesFabrication Course OutlineOmarNo ratings yet

- UntitledDocument146 pagesUntitledhumanities sciencesNo ratings yet

- Master Chemical Engineering CoursesDocument23 pagesMaster Chemical Engineering Courseskiranpatil1014532No ratings yet

- An Expert System For Identifying Steels and Cast Irons (1994)Document5 pagesAn Expert System For Identifying Steels and Cast Irons (1994)Javi DoorsNo ratings yet

- POs COs 06-InstituteofEngineeringandTechnologyDocument169 pagesPOs COs 06-InstituteofEngineeringandTechnologyAbhinavNo ratings yet

- MSE Materials Science ResearchDocument5 pagesMSE Materials Science ResearchJohn_AdaNo ratings yet

- PC LAB Workbook - 17.12.2016Document71 pagesPC LAB Workbook - 17.12.2016y satishkumarNo ratings yet

- Course Syl Lab UsDocument2 pagesCourse Syl Lab UsJorge RodríguezNo ratings yet

- MSM Lab Manual - 2021-22Document61 pagesMSM Lab Manual - 2021-22Divyaraj VaghelaNo ratings yet

- Bioen 492 - Surface Analysis Techniques and ApplicationsDocument4 pagesBioen 492 - Surface Analysis Techniques and ApplicationsMahir MahmoodNo ratings yet

- Gujarat Technological UniversityDocument7 pagesGujarat Technological Universitydnow4pNo ratings yet

- Amme1362 Course OverviewDocument9 pagesAmme1362 Course OverviewjulianhamamaNo ratings yet

- Mannual - Pages MPMCDocument4 pagesMannual - Pages MPMCRoshan DodiyaNo ratings yet

- MA2004 Engineering Materials and Manufacturing Processes 23082021Document7 pagesMA2004 Engineering Materials and Manufacturing Processes 23082021Aloysius TobiasNo ratings yet

- App - Chem New MaterialDocument117 pagesApp - Chem New MaterialMadhavarao MaddisettyNo ratings yet

- Engg Physics & Engg Chemistry ManualDocument142 pagesEngg Physics & Engg Chemistry ManualDr. ASHISH SINGHNo ratings yet

- Antony Course File TemplateDocument65 pagesAntony Course File TemplateKumari PanimalarNo ratings yet

- Advanced Material Chemistry Digital NotesDocument82 pagesAdvanced Material Chemistry Digital Notesharshitjoshi200417No ratings yet

- Mme 2503Document6 pagesMme 2503Farith AhmadNo ratings yet

- National University of Engineering College of Geological, Mining and Metallurgical Engineering Metallurgical Engineering ProgramDocument3 pagesNational University of Engineering College of Geological, Mining and Metallurgical Engineering Metallurgical Engineering ProgramJhair JhamidhNo ratings yet

- GIET Engineering College Civil Engineering Course PlanDocument11 pagesGIET Engineering College Civil Engineering Course PlanKashyap ChintuNo ratings yet

- MMEE 415 - Introduction To NanotechnologyDocument6 pagesMMEE 415 - Introduction To NanotechnologyResego PhiriNo ratings yet

- Program Outcomes (Pos) Electronics and Communication Engineering Graduates Will Be Able ToDocument19 pagesProgram Outcomes (Pos) Electronics and Communication Engineering Graduates Will Be Able ToParanthaman GNo ratings yet

- OutlineDocument4 pagesOutlineRajib BaruaNo ratings yet

- Microwave & Optical Communication Lab Manual - SRMDocument102 pagesMicrowave & Optical Communication Lab Manual - SRMwizardvenkat100% (6)

- Mwoc Iv-1Document199 pagesMwoc Iv-1revathiNo ratings yet

- Electrical & Electronic Engineering Program School of Engineering & Information Technology Universiti Malaysia SabahDocument4 pagesElectrical & Electronic Engineering Program School of Engineering & Information Technology Universiti Malaysia Sabahram010No ratings yet

- Microwave Circuit Design and TestingDocument7 pagesMicrowave Circuit Design and TestingmuktikantaNo ratings yet

- MA505-N-C Modern Manufacturing ProcessesDocument3 pagesMA505-N-C Modern Manufacturing Processeshrana287No ratings yet

- MICROWAVE LAB RECORD FinalDocument41 pagesMICROWAVE LAB RECORD FinalMathiNo ratings yet

- Ece18r221 CP PDFDocument8 pagesEce18r221 CP PDFkingraajaNo ratings yet

- Course Objectives and OutcomesDocument39 pagesCourse Objectives and OutcomesUpender Rao SunkishalaNo ratings yet

- Relay and High Voltage Laboratory 15eel77 PDFDocument95 pagesRelay and High Voltage Laboratory 15eel77 PDFM.KNo ratings yet

- 4 - B - Tech - Mechanical Engg - 4th Year Pages 57Document57 pages4 - B - Tech - Mechanical Engg - 4th Year Pages 57Aniket JhaNo ratings yet

- GTU Nanotechnology Course Overviews ApplicationsDocument3 pagesGTU Nanotechnology Course Overviews ApplicationsAroh ShrivastavaNo ratings yet

- Ptam CP 25.7.22Document8 pagesPtam CP 25.7.22SAMUEL SANJAY RAJA R MECHNo ratings yet

- EC8761 Advanced Communication Lab ManualDocument105 pagesEC8761 Advanced Communication Lab ManualPurushothaman ANo ratings yet

- Materials Sceince and TechnologyDocument18 pagesMaterials Sceince and TechnologyRajareddyDuddekuntaNo ratings yet

- IE LAB ManualDocument76 pagesIE LAB ManualKaustubh SreekharNo ratings yet

- Main Surface Engineering ProcessesDocument3 pagesMain Surface Engineering ProcessesChennai RajaNo ratings yet

- GTU Nanotechnology Course OverviewDocument3 pagesGTU Nanotechnology Course OverviewKashyap TailorNo ratings yet

- M SC Physics Syllabus&SchemeDocument20 pagesM SC Physics Syllabus&SchemeTejas ChuteNo ratings yet

- "Arsenic Reduction From Water": Rutika Patil Mayur Sawant Smitesh Shirke Parag Ganagaram JuvatkarDocument39 pages"Arsenic Reduction From Water": Rutika Patil Mayur Sawant Smitesh Shirke Parag Ganagaram JuvatkarMayur SawantNo ratings yet

- Electronic Materials SyllabusDocument3 pagesElectronic Materials SyllabusAbdullah100% (1)

- 08.807 MWandOptical Manual v1.2 FacultyDocument88 pages08.807 MWandOptical Manual v1.2 Facultydeeparahul2022No ratings yet

- Course Registration PlanDocument3 pagesCourse Registration PlanUtcha-uea CheawchanNo ratings yet

- Vaughan 2011 MicromechanicalDocument252 pagesVaughan 2011 MicromechanicalEduardo RechNo ratings yet

- Emt & TL Course FileDocument42 pagesEmt & TL Course FileSuraj KumarNo ratings yet

- Mse 4793Document3 pagesMse 4793aeromatNo ratings yet

- Engineering Mathematics I & II Course OverviewDocument23 pagesEngineering Mathematics I & II Course OverviewS.m. ChandrashekarNo ratings yet

- Ece 3-1 Lab ManualDocument269 pagesEce 3-1 Lab ManualIrmsts NetNo ratings yet

- Ace Pre Gate 2017 EeDocument60 pagesAce Pre Gate 2017 Eemohitsinghal25No ratings yet

- Electrical Machines KSTDocument8 pagesElectrical Machines KSTmohitsinghal25No ratings yet

- CamScanner Document ScansDocument47 pagesCamScanner Document Scansmohitsinghal25No ratings yet

- Analog Electronics Unit 1Document32 pagesAnalog Electronics Unit 1mohitsinghal25No ratings yet

- TRANSIENT (Full Concept in 1 Hour)Document19 pagesTRANSIENT (Full Concept in 1 Hour)mohitsinghal25No ratings yet

- 4077 FaDocument16 pages4077 Famohitsinghal25No ratings yet

- Signals and Systems K-Notes (EE) PDFDocument29 pagesSignals and Systems K-Notes (EE) PDFgunjan bharadwaj100% (2)

- Electrical Report at BHEL HaridwarDocument48 pagesElectrical Report at BHEL Haridwarप्रतीक सिंहNo ratings yet

- Educatio N: Awards & Distinction: Aditya RajDocument2 pagesEducatio N: Awards & Distinction: Aditya Rajmohitsinghal25No ratings yet

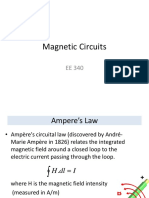

- EE 340 - Magnetic Circuits PDFDocument26 pagesEE 340 - Magnetic Circuits PDFmohitsinghal25No ratings yet

- 3C7Document2 pages3C7mohitsinghal25No ratings yet

- Untitled DocumentDocument1 pageUntitled Documentmohitsinghal25No ratings yet

- Electrical EngineeringDocument2 pagesElectrical EngineeringSantosh SandyNo ratings yet

- Lec 1Document35 pagesLec 1mohitsinghal25No ratings yet

- Electrical Engineering Technical Electives and Focus AreasDocument2 pagesElectrical Engineering Technical Electives and Focus Areasmohitsinghal25No ratings yet

- Pemikiran Pendidikan Ki. Hajar Dewantara Dan Relevansinya Dengan Kurikulum 13Document30 pagesPemikiran Pendidikan Ki. Hajar Dewantara Dan Relevansinya Dengan Kurikulum 13ranti panguNo ratings yet

- Bec Form 137Document2 pagesBec Form 137patrickkayeNo ratings yet

- Jennifer Alexandra Souter: Education The University of ExeterDocument3 pagesJennifer Alexandra Souter: Education The University of Exeterjs379No ratings yet

- Questionnaire FinalDocument7 pagesQuestionnaire Finalapi-676636026No ratings yet

- Parkland Fuel Corp Job Application Form CompanyDocument3 pagesParkland Fuel Corp Job Application Form Companymohammed akbar aliNo ratings yet

- 1NC Pre-empts Theory Violation ClaimsDocument3 pages1NC Pre-empts Theory Violation ClaimsJack WilsonNo ratings yet

- Introduction to Symposium on Public Service Motivation ResearchDocument3 pagesIntroduction to Symposium on Public Service Motivation ResearchHumberto RiveraNo ratings yet

- Healthcare Quality Excellence - BrochureDocument9 pagesHealthcare Quality Excellence - BrochureHaitham AhmedNo ratings yet

- SodaPDF-converted-PANA LA PAGINA 436 High-Quality, High-Volume Spay and NeuterDocument860 pagesSodaPDF-converted-PANA LA PAGINA 436 High-Quality, High-Volume Spay and NeuterAndreea MayaNo ratings yet

- Lesson Plan 5Document3 pagesLesson Plan 5api-283599791No ratings yet

- Interview Questions MariamDocument2 pagesInterview Questions Mariamapi-273019508No ratings yet

- Transcriptreport - 2021-05-19t101026Document1 pageTranscriptreport - 2021-05-19t101026api-550145489No ratings yet

- CG EnglishDocument460 pagesCG EnglishDiona A. PalayenNo ratings yet

- LESSON PLAN - PRINCIPLES OF MANAGEMENT (GE/IC - 1) - BCA 1ST SEM 2022-25Document5 pagesLESSON PLAN - PRINCIPLES OF MANAGEMENT (GE/IC - 1) - BCA 1ST SEM 2022-25sumitadhar05No ratings yet

- Foreword by Alexis Fink: SearchDocument2 pagesForeword by Alexis Fink: SearchSkyblackPeruNo ratings yet

- Artefact 2 Assin 1 Submit e Portfolio PDFDocument31 pagesArtefact 2 Assin 1 Submit e Portfolio PDFapi-252544392No ratings yet

- Bennett,+R.+E.+ 2011 +Formative+AssessmentDocument22 pagesBennett,+R.+E.+ 2011 +Formative+AssessmentDalit Ben-BasatNo ratings yet

- Philippine Professional Standards for Teachers GuideDocument12 pagesPhilippine Professional Standards for Teachers GuideAniaNo ratings yet

- Book - KVM en PDFDocument174 pagesBook - KVM en PDFbonilla03No ratings yet

- Best Beginner Guitar Books for KidsDocument3 pagesBest Beginner Guitar Books for Kidstvis MusicNo ratings yet

- ABA in OBMDocument10 pagesABA in OBMQuésia CataldoNo ratings yet

- Leder Helmut - A Model of Aesthetic Appreciation and Aesthetic JudgmentsDocument20 pagesLeder Helmut - A Model of Aesthetic Appreciation and Aesthetic JudgmentsLeon StefanijaNo ratings yet

- Types of Assessment Instruments For English Language LearningDocument19 pagesTypes of Assessment Instruments For English Language LearningShayra CastilloNo ratings yet

- Kalkhaire Shubham V.Document2 pagesKalkhaire Shubham V.Cĥĕťáń ŤĩķámNo ratings yet

- Curriculum Planning Map Prek 2Document2 pagesCurriculum Planning Map Prek 2api-351422384No ratings yet

- The "7 C S of Communication To Improve The Teaching Communication SkillsDocument2 pagesThe "7 C S of Communication To Improve The Teaching Communication Skillsmanish bhardwajNo ratings yet

- National Policy On EducationDocument9 pagesNational Policy On Educationapi-247249589No ratings yet