Professional Documents

Culture Documents

How To Make Cylinder Specimen of Concrete For Compression Test - A Civil Engineer PDF

How To Make Cylinder Specimen of Concrete For Compression Test - A Civil Engineer PDF

Uploaded by

aankur guptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Make Cylinder Specimen of Concrete For Compression Test - A Civil Engineer PDF

How To Make Cylinder Specimen of Concrete For Compression Test - A Civil Engineer PDF

Uploaded by

aankur guptaCopyright:

Available Formats

HowtomakeCylinderspecimenofconcreteforcompressiontest

LitonBiswas

ConcreteTechnology,HowtoGuide,Test

Nocomments

Compressiontestisdoneforknowingthecompressivestrengthofhardenedconcrete.Forthispurpose,

concretecubetestorconcretecylindertestisdoneinlaboratory.But,concretecylinderorcubefortesting

ismadeonsite.

Apparatusformakingconcretecylinder:

Cylindermould(100mmX200mmor150mmX300mmor300mmX600mm)

Bullednosedrod(16mmdia&600mmlong)

Steelfloat

Proceduresofmakingconcretecylinder:

Step1:CleantheCylindermouldproperlyandapplyacoatofformoilontheinnersurfaceofmould.

Butnoexcessoilshouldbevisibleoninnersurface.

Step2:Fixthenuts&boltstightlywithbaseplateandnogapsshouldbewithinthepartsofcylinder

mould.

Step3:Itisnecessarythatthecylindermouldshouldbeplacedonaclean,level&firmsurface.

Step4:Concreteforspecimenshouldbecollectedfromthreeorfourrandommixes.

Step5:Placeconcreteintothemouldineachlayerofmaximum50mmthick&compacteachlayerat

least30blowsof16mmrod.

Step6:Leveloffthetopwiththesteelfloat&cleananyconcretefromaroundthemouldandleavethe

mouldundisturbedfor24hours.

Step7:Givenumber&castingdateofthespecimensonthetopsurfaceafter90minutes.

Step8:After810hoursthemouldshouldbecoveredwithdamphessaincloth(jutecloth)butno

watershouldfallonthesurfaceofthespecimen.Surfacecanbecoveredwithpolythene.

Step9:After24hoursthespecimenshouldbeuncovered&removedfromthemould.Theconcrete

isstillweakatthisstage.So,shouldbehandledcarefully.

Step10:Toremovespecimenfrommouldloosenallbolts&nuts,sideoffthebaseplate&thentop

themouldgentlytofreethespecimen.

Step11:Justafterremovalfrommouldthespecimenshouldbeputstraightintoatankofcleanwater.

Thespecimenshouldbefullysubmergedunderwater.

Step12:After28days,sendthespecimentothetestinglaboratorytodeterminethecompressive

strengthofconcrete.

You might also like

- Cylinder Mould (100mm X 200mm or 150mm X 300mm or 300mm X 600mm) Bulled-Nosed Rod (16mm Diam. & 600mm Long) Steel FloatDocument3 pagesCylinder Mould (100mm X 200mm or 150mm X 300mm or 300mm X 600mm) Bulled-Nosed Rod (16mm Diam. & 600mm Long) Steel FloatStain HecNo ratings yet

- Concrete Test Cube ProcedureDocument4 pagesConcrete Test Cube ProcedureEE007CA67% (6)

- CongretetestingDocument11 pagesCongretetestingBatepola BacNo ratings yet

- A Simple Guide To Concrete Cube TestingDocument7 pagesA Simple Guide To Concrete Cube TestingJaneshaNo ratings yet

- MODULE-5-TESTING-FOR-CONCRETE SDocument11 pagesMODULE-5-TESTING-FOR-CONCRETE SMarc AndrewNo ratings yet

- Slump Test Report PMMDocument7 pagesSlump Test Report PMMLuqman Yusof83% (12)

- Compressive Strength Testing ModDocument4 pagesCompressive Strength Testing ModGernevie Charlie GohNo ratings yet

- C1610C1610MDocument4 pagesC1610C1610MJorge Luis Arevalo LopezNo ratings yet

- QHelp A Simple Guide To Concrete Cube TestingDocument4 pagesQHelp A Simple Guide To Concrete Cube TestingShahril ZainulNo ratings yet

- Cube Compressive Strenght TestDocument6 pagesCube Compressive Strenght TestMM tarasNo ratings yet

- C3 Fresh and Hardened Concrete TestDocument11 pagesC3 Fresh and Hardened Concrete TestSyukri Abd KadirNo ratings yet

- C3-Fresh & Harden Concrete TestDocument12 pagesC3-Fresh & Harden Concrete TestMuhamad Farhan100% (1)

- Making Test Cubes From Fresh ConcreteDocument4 pagesMaking Test Cubes From Fresh Concretesjpaul197367% (6)

- A Simple Guide To Concrete Cube TestingDocument4 pagesA Simple Guide To Concrete Cube TestingmsohaibazizNo ratings yet

- Slump Test REPORTDocument5 pagesSlump Test REPORTLove Rosiee100% (1)

- Concrete Slump TestDocument11 pagesConcrete Slump TestMarie Fe Bermido100% (1)

- C 1610 - C1610M-06 STM For Static Segregation of Self-Consolidating Concrete Using Column Technique PDFDocument4 pagesC 1610 - C1610M-06 STM For Static Segregation of Self-Consolidating Concrete Using Column Technique PDFpatriciovernal67% (3)

- TCVN 3105.1993 Heavyweight Concrete Compound and Heavyweight Concrete - Samling, Making and Curing of Test SpecimensDocument6 pagesTCVN 3105.1993 Heavyweight Concrete Compound and Heavyweight Concrete - Samling, Making and Curing of Test SpecimensNgo Tien VinhNo ratings yet

- Sharjah Civil Engineering NotesDocument30 pagesSharjah Civil Engineering NotesSUNDARNo ratings yet

- Questions in Building Technology IIIDocument3 pagesQuestions in Building Technology IIIImadeldein SalihNo ratings yet

- Tests For Concrete - NotesDocument31 pagesTests For Concrete - Notessrushtideokar0537No ratings yet

- Reference Notes - Tests For ConcreteDocument21 pagesReference Notes - Tests For ConcreteMitali KhedkarNo ratings yet

- Testing Fresh Concrete. Slump TestDocument6 pagesTesting Fresh Concrete. Slump TestkhaledNo ratings yet

- Grouts Standards and TestingDocument12 pagesGrouts Standards and TestingmithileshNo ratings yet

- BS 1881-Part 102-83Document10 pagesBS 1881-Part 102-83karuna346No ratings yet

- Errors of Observation in Concrete Testing LabsDocument30 pagesErrors of Observation in Concrete Testing LabsSuryasis Dasgupta25% (4)

- The Slump Test Is A Simple and Widely Used Test in The Field of Concrete Technology To Measure The Workability of Fresh ConcreteDocument2 pagesThe Slump Test Is A Simple and Widely Used Test in The Field of Concrete Technology To Measure The Workability of Fresh ConcreteIkechukwu OkekeNo ratings yet

- Common Mistake by Engineers During RCC WorksDocument4 pagesCommon Mistake by Engineers During RCC WorksAnonymous P7VckOJZUgNo ratings yet

- Making & Curing Compressive Strength of Cylinderial Concrete C 39Document6 pagesMaking & Curing Compressive Strength of Cylinderial Concrete C 39YasirNo ratings yet

- Cone (300mm X 200mm X 100mm) : Apparatus Used in TestDocument1 pageCone (300mm X 200mm X 100mm) : Apparatus Used in TesttopukuetNo ratings yet

- Concrete Tests: 6.1. Slump TestDocument6 pagesConcrete Tests: 6.1. Slump TestThreelakshanaNo ratings yet

- Cement PPT ArunDocument10 pagesCement PPT ArunAbhishek SharmaNo ratings yet

- CONCRETEDocument3 pagesCONCRETESamantha CruzNo ratings yet

- Tank Erection Manual 2010Document17 pagesTank Erection Manual 2010kaijuNo ratings yet

- Importance of Practical Training 9Document27 pagesImportance of Practical Training 9Javaid SalamNo ratings yet

- CT SMB Module 3Document31 pagesCT SMB Module 3sankarsanasahoo690No ratings yet

- Inspection Checklist For Concrete Placement Pre & Post PlacementDocument4 pagesInspection Checklist For Concrete Placement Pre & Post PlacementUsman ShahidNo ratings yet

- TestDocument23 pagesTestAGunaSekaranNo ratings yet

- Concrete Slump Test or Slump Cone TestDocument4 pagesConcrete Slump Test or Slump Cone TestEljoy C. AgsamosamNo ratings yet

- Aashto T 119Document6 pagesAashto T 119Regen BasiñoNo ratings yet

- Slump TestDocument4 pagesSlump TestAndrian AbanillaNo ratings yet

- 3.4. Molding, Compaction and Curing of ConcreteDocument7 pages3.4. Molding, Compaction and Curing of ConcreteThant ZinNo ratings yet

- 3 Methods of Determining Workability of ConcreteDocument4 pages3 Methods of Determining Workability of Concretesuryakantame100% (1)

- Basic Civil Engineering Lab-2-1Document8 pagesBasic Civil Engineering Lab-2-1KUNDAN SHARMANo ratings yet

- Slump TestDocument4 pagesSlump TestJec SepradoNo ratings yet

- Concrete Slump Test: From Wikipedia, The Free EncyclopediaDocument5 pagesConcrete Slump Test: From Wikipedia, The Free EncyclopediaJenny Ann ValderramaNo ratings yet

- Concrete Slump TestDocument19 pagesConcrete Slump TestGhayas Ud-din DarNo ratings yet

- Tex-447-A, Making and Curing Concrete Test SpecimensDocument12 pagesTex-447-A, Making and Curing Concrete Test SpecimensjulsNo ratings yet

- Fresh ConcreteDocument34 pagesFresh Concreteahmedalkastawy19No ratings yet

- Test For Properties of Cement: Physical & ChemicalDocument4 pagesTest For Properties of Cement: Physical & ChemicalmuqeetNo ratings yet

- Flow Table Is1199Document3 pagesFlow Table Is1199CgpscAspirantNo ratings yet

- CementDocument13 pagesCementaishasiddikashaik2005No ratings yet

- Standard Consistency For CementDocument6 pagesStandard Consistency For CementTokki TokkiNo ratings yet

- Azar Blocks GuidelinesDocument5 pagesAzar Blocks GuidelinesAHMED SOHELNo ratings yet

- Things Site Engineer Must Know After Civil..Document6 pagesThings Site Engineer Must Know After Civil..ergvdfwdbwergweNo ratings yet

- How to Build a Global Model Earthship Operation I: Tire WorkFrom EverandHow to Build a Global Model Earthship Operation I: Tire WorkNo ratings yet

- Cabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingFrom EverandCabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingNo ratings yet

- Concrete-Block Manufacture - Processes and MachinesFrom EverandConcrete-Block Manufacture - Processes and MachinesRating: 5 out of 5 stars5/5 (1)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

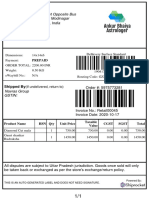

- Shipping Label 64856712 1904177051736 PDFDocument1 pageShipping Label 64856712 1904177051736 PDFaankur guptaNo ratings yet

- Shiprocket Manifest: To Be Filled by Delhivery Surface Standard Logistics ExecutiveDocument1 pageShiprocket Manifest: To Be Filled by Delhivery Surface Standard Logistics Executiveaankur guptaNo ratings yet

- Plain Cement Concrete (PCC) - How To Produce and Construct - A Civil EngineerDocument3 pagesPlain Cement Concrete (PCC) - How To Produce and Construct - A Civil Engineeraankur guptaNo ratings yet

- Shiprocket Manifest: To Be Filled by Delhivery Surface Standard Logistics ExecutiveDocument1 pageShiprocket Manifest: To Be Filled by Delhivery Surface Standard Logistics Executiveaankur guptaNo ratings yet

- Batch TransferDocument2 pagesBatch Transferaankur guptaNo ratings yet

- How To Make RCC Bottom Slab of UGWT - A Civil EngineerDocument2 pagesHow To Make RCC Bottom Slab of UGWT - A Civil Engineeraankur guptaNo ratings yet

- How To Plaster On Surface - A Civil Engineer 1Document2 pagesHow To Plaster On Surface - A Civil Engineer 1aankur guptaNo ratings yet

- A Checklist For Brick Flat Soling - A Civil EngineerDocument2 pagesA Checklist For Brick Flat Soling - A Civil Engineeraankur guptaNo ratings yet

- Basic Construction Process of RCC Column - A Civil EngineerDocument3 pagesBasic Construction Process of RCC Column - A Civil Engineeraankur guptaNo ratings yet

- 6 Steps Preparation Before Pouring Concrete - A Civil Engineer PDFDocument3 pages6 Steps Preparation Before Pouring Concrete - A Civil Engineer PDFaankur guptaNo ratings yet