Professional Documents

Culture Documents

Din 28086

Uploaded by

Fer VFOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din 28086

Uploaded by

Fer VFCopyright:

Available Formats

Visser & Smit Hanab

Visser & Smit Hanab Installatie B.V.

Postbus 2104

1960 GC Heemskerk

Telefoon: 0251-257100

Telefax: 0251-248746

E-mail: heemskerk@vshanab.nl

DESIGN CALCULATIONS

Manuf. serial No. :

Equipment

: E510002

: C-11053-A/B/C/D

Client

Requisition no

Client Ref. No.

Client Doc. No.

: CHEVRON TRANSPORCYCLONE

: B13-0004-MEC-REQ-HSM-M4010-110001-001

: OGPA090245

:

Contents

Page

Description

3

Conclusion

Shell Vessel (C.S.)

P355 NH/NL1

Nozzle N3

Nozzle N6

Nozzle N7

Nozzle N8

Manhole M1

Nozzle K1A

Nozzle K1B

Nozzle K2A

Nozzle K2B

Combined openings shell vessel (CS)

1

1

2

4

6

8

10

12

14

16

18

20

22

Head Top vessel (CS), OD 970 x 35 maf, P355 NH/NL1

Nozzle N4B

27

30

Head Bottom vessel (CS), OD 970 x 35 maf, P355 NH/NL1

Nozzle N5

32

35

Shell Vessel (Duplex A928 Cl.I, UNS S31803), OD 323,9 x 12,7

Nozzle N1 (Duplex A928 Cl.I, UNS S31803), OD 168,3 x 10,97

37

39

Cone

41

Duplex 1.4462

47

WRC Calculations Nozzle loads

Trunnion Calculations

Lifting / Tailing Lug Vessel Acc. DIN 28086

Lifting Lug Duplex Calc. Acc. DIN 28086

Bracket Calculation

A333 Gr.6

P355 NH/NL1

Duplex 1.4462

P265 GH

93

94

95

96

Calc.No.:

E510002

Issue:

Issued by:

P.Berghuis

Date: 6/1/2010

Checked:

H. Honig

Date: 6/1/2010

Aproved:

M. Bart

Date: 6/1/2010

07/18/2016

07/18/2016

Visser Smit Hanab Installatie B.V.

Postbus 2104 1960 GC Heemskerk

Tel. 0251-257100 Fax. 0251-248746

Description:

This document describes the mechanical calculation of the vessel C-10053

General:

Design Software

Design Code

Design Pressure

Design Temperature

Corrosion Allowance

: CEA CODEX, version 2009

: EN 13445

:

135 Barg

:

-20 / +100 C

:

3.0 mm

Only for C.S.

Main dimensions

Shell Vessel (C.S.),

OD 970 x 35 mm

Head Top vessel (CS),

OD 970 x 35 mm MAF

Head Bottom vessel (CS),

OD 970 x 35 mm MAF

TL-TL, 2400 mm

Manhole 20"-900# RTJ

Process- and instr. nozzles:

2"-1500# RTJ

3"-900# RTJ

8"-900# RTJ

12"-900# RTJ

Shell Vessel (Duplex 1.4462),

OD 323,9 x 12,7

Process nozzles:

6"-900# RTJ

12"-900# RTJ

VISSER & SMIT HANAB B.V.

HEEM SKERK HOLLAND

NAMEPLATE FST

Conclusion:

The vessel, see drawing E510002-1002 rev.4,

satisfies for the stated design conditions according EN-13445.

07/18/2016

Page 1

Visser Smit Hanab Installatie B.V.

Postbus 2104 1960 GC Heemskerk

Tel. 0251-257100 Fax. 0251-248746

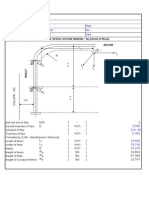

TRUNNIONS acc. DIN 28086

TWO POINT LIFT on

DEVICE NUMBER

PART

CALCULATED BY

POSITION

MATERIAL TRUNNIONS

45 Degrees (max. 45 degrees)

E51002

C-10053-A/B/C/D (TRUNNION)

PB

Upper part vessel (C.S.)

A333 Gr.6

Rm = 415 N/mm^2 Re20 = 240 N/mm^2

1

2

3

4

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Impact weight of tankm

Safety Factor

a

Vertical force

Fv

Horizontal force

Fh

Number of trunnions n

Force per trunnion

Fe

23

Quotint Sb;all / Sb

24

25

Weld seam

26

27

28

29

Horizontal force

Vertical force

Section modulus

Sectional area weld

Fx

Fy

Ws

As

Fx = SINangle * Fe

Fy = COSangle *Fe

30

Bending stress

Sb

Sb = Fx * h/Ws

31

Tensile stress

St

St = Fy/As

15.6 N/mm^2

32

33

34

Shear stress

T = Fx / As

15.6 N/mm^2

Combined stress

Scom Scom = SQR((Sb+St)^2+t^2)

35

Allowable stress

Sall

36

Quotint Sb;all / Sb

Lifting trunnion

Length of trunnion

Ouside diameter

Wallthickness

Weld thickn.

d

du

s

a

Lifting trunnion

Torgue length

Bending moment

Sect. modulus

Bending stress

Tensile stress

2c

Mb

Wx

Sb

St

empty weight

Fv = m*a*9.8

Fh = m*a*9.8

Fe = (Fv^2+Fh^2)^0,5/n

150

114.3

13.5

8

2c = d

Mb = Fe*d

Sb = Mb / Wx

St = (Fe/2)/(s*b)

Combined stress

Scom Scom=Sb + St

Yield stress material Re

A 333 - 6

Allowable stress

Sall

Sy*2/3 or 0,44*St

Date : 07/18/2016

4900

2

96040

96040

2

67911

(must be > 1)

Sy*2/3 or St / 3

(must be > 1)

150

10186580.3

96711.9

105.3

22.0

kg

N

N

N

mm

mm

mm

mm

mm

Nmm

mm^3

N/mm^2

N/mm^2

127.3 N/mm^2

240.0

160.0 N/mm^2

1.26 OK

48020.0

48020.0

2763542.2

3073.7

N

N

mm^3

mm^2

2.6 N/mm^2

24.0 N/mm^2

138.3 N/mm^2

5.76 OK

Page : 93

Visser Smit Hanab Installatie B.V.

Postbus 2104 1960 GC Heemskerk

Tel. 0251-257100 Fax. 0251-248746

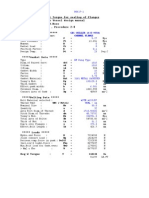

LIFTING LUGS acc. DIN 28086

LIFTING / TAILING

POINT LIFT on

DEVICE NUMBER

PART

CALCULATED BY

POSITION

MATERIAL LUGS

45 Degrees (max. 45 degrees)

E51002

C-10053-A/B/C/D (TAILING LUG)

PB

Upper part vessel (C.S.)

P355 NH/NL1 (+20 degr.C)

Rm = 490 N/mm^2 Re20 = 345 N/mm^2

1

2

3

4

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Impact weight of tankm

Safety Factor

a

Vertical force

Fv

Horizontal force

Fh

Number of lugs

n

Force per lug

Fe

24

25

26

27

28

29

30

31

32

33

34

35

36

Quotint Sb;all / Sb

37

Quotint Sb;all / Sb

Lifting lug

Width

Thickness

Hole diameter

Heigth

Weld thickn.

w

s

d

h

a

Lifting lug

Torgue length

Bending moment

Sect. modulus

Bending stress

Tensile stress

2c

Mb

W

Sb

St

empty weight

Fv = m*a*9.8

Fh = m*a*9.8

Fe = (Fv^2+Fh^2)^0,5/n

140

20

50

140

8

2c = (w+d)/2

Mb = Fe*2c/8

W = (s * b^2)/6

Sb = Mb / W

St = (Fe/2)/(s*b)

Combined stress

Scom Scom=Sb + St

Yield stress material Re

P355 NH/NL1

Allowable stress

Sall

Sy*2/3 or 0,44*St

(must be > 1)

Weld seam

Horizontal force

Vertical force

Section modulus

Sectional area weld

Bending stress

Tensile stress

Shear stress

Fx

Fy

Ws

As

Sb

St

T

Combined stress

Allowable stress

Scom Scom = SQR((Sb+St)^2+t^2)

Sall

Sy*2/3 or St / 3

Date : 07/18/2016

4967

2

97353

97353

2

68839

Fx = SINangle * Fe

Fy = COSangle *Fe

Sb = Fx * h/Ws

St = Fy/As

T = Fx / As

(must be > 1)

95

817464.4

6750.0

121.1

38.2

kg

N

N

N

mm

mm

mm

mm

mm

mm

Nmm

mm^3

N/mm^2

N/mm^2

159.3 N/mm^2

345 N/mm^2

215.6 N/mm^2

1.35 OK

48676.6

48676.6

87383.5

2816.0

78.0

17.3

17.3

N

N

mm^3

mm^2

N/mm^2

N/mm^2

N/mm^2

96.8 N/mm^2

163.3 N/mm^2

1.69 OK

Page : 94

Visser Smit Hanab Installatie B.V.

Postbus 2104 1960 GC Heemskerk

Tel. 0251-257100 Fax. 0251-248746

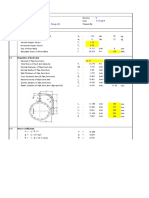

LIFTING LUGS acc. DIN 28086

TWO POINT LIFT on

DEVICE NUMBER

PART

CALCULATED BY

POSITION

MATERIAL LUGS

45 Degrees (max. 45 degrees)

E51002

C-10053-A/B/C/D (LIFTING LUG)

PB

Top part vessel (stack)

Duplex 1.4462 (+20 degr.C)

Rm = 650 N/mm^2 Re20 = 450 N/mm^2

1

2

3

4

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Impact weight of tankm

Safety Factor

a

Vertical force

Fv

Horizontal force

Fh

Number of lugs

n

Force per lug

Fe

24

25

26

27

28

29

30

31

32

33

34

35

36

Quotint Sb;all / Sb

37

Quotint Sb;all / Sb

Lifting lug

Width

Thickness

Hole diameter

Heigth

Weld thickn.

w

s

d

h

a

Lifting lug

Torgue length

Bending moment

Sect. modulus

Bending stress

Tensile stress

2c

Mb

W

Sb

St

empty weight

Fv = m*a*9.8

Fh = m*a*9.8

Fe = (Fv^2+Fh^2)^0,5/n

60

12

30

100

6

2c = (w+d)/2

Mb = Fe*2c/8

W = (s * b^2)/6

Sb = Mb / W

St = (Fe/2)/(s*b)

Combined stress

Scom Scom=Sb + St

Yield stress material Re

Super Duplex 32750 (1.4410)

Allowable stress

Sall

Sy*2/3 or 0,44*St

(must be > 1)

Weld seam

Horizontal force

Vertical force

Section modulus

Sectional area weld

Bending stress

Tensile stress

Shear stress

Fx

Fy

Ws

As

Sb

St

T

Combined stress

Allowable stress

Scom Scom = SQR((Sb+St)^2+t^2)

Sall

Sy*2/3 or St / 3

Date : 07/18/2016

560

2

10976

10976

2

7761

Fx = SINangle * Fe

Fy = COSangle *Fe

Sb = Fx * h/Ws

St = Fy/As

T = Fx / As

(must be > 1)

45.0

43656.8

450.0

97.0

21.6

kg

N

N

N

mm

mm

mm

mm

mm

mm

Nmm

mm^3

N/mm^2

N/mm^2

118.6 N/mm^2

450 N/mm^2

286.0 N/mm^2

2.41 OK

5488.0

5488.0

14736.0

1008.0

37.2

5.4

5.4

N

N

mm^3

mm^2

N/mm^2

N/mm^2

N/mm^2

43.0 N/mm^2

216.7 N/mm^2

5.03 OK

Page : 95

Visser Smit Hanab Installatie B.V.

Postbus 2104 1960 GC Heemskerk

Tel. 0251-257100 Fax. 0251-248746

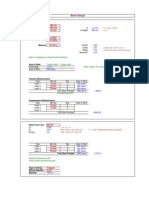

BRACKETS acc. EN13445

FOUR POINT LIFT on 0 Degrees (vertical lift)

DEVICE NUMBER

PART

CALCULATED BY

POSITION

MATERIAL BRACKETS

1

2

3

4

5

6

7

7

8

9

10

11

12

13

14

15

16

17

18

E51002

C-10053-A/B/C/D (BRACKET)

PB

Upper part vessel (C.S.)

P265 GH (+20 degr.C)

Rm = 410 N/mm^2 Re20 = 265 N/mm^2

Impact weight of tankm

Impact weight water m

Impact weight sand m

Impact weight instr. m

Safety Factor

a

Vertical force

Fv

Horizontal force

Fh

Number of lugs

n

Force per bracket

Fe

Bracket

Width (Plate 1)

Height (Plate 1)

Width (Plate 2)

Height (Plate 2)

Width (Plate 3)

Height (Plate 3)

Length of bracket

Weld thickn.

Date : 07/18/2016

w1

h1

w2

h2

w3

h3

l

a

empty weight

full load with water

half load with sand

load of instrumentation

Fv = m*a*9.8

Fh = m*a*9.8/2

Fe = (Fv^2+Fh^2)^0,5/n

4900

1700

2253

300

2

179389

89695

4

50141

15

280

220

20

15

280

446

8

kg

kg

kg

kg

N

N

N

mm

mm

mm

mm

mm

mm

mm

mm

Page : 96

Visser Smit Hanab Installatie B.V.

Postbus 2104 1960 GC Heemskerk

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Calculation of profile section module of support bracket

Cross section area Plate I:

A = w1*h1

Cross section area Plate II:

A = w2*h2

Cross section area Plate III:

A = w3*h3

Total cross section area A =

59

60

61

62

63

64

65

66

67

68

69

70

71

Quotint Sb;all / Sb

72

Quotint Sb;all / Sb

Tel. 0251-257100 Fax. 0251-248746

4200.0

4400.0

4200.0

12800.0

mm^2

mm^2

mm^2

mm^2

Calculation distance of center of gravity to underside of base Plate II

Distance ctr. of G z(I) x A(I)

= z(I) = 160

672000 mm

Distance ctr. of G z(II) x A(II)

= z(II) = 10

44000 mm

Distance ctr. of G z(III) x A(III) = z(III) = 160

672000 mm

Total z x A

1388000 mm

Distance center of G z(tot) = (z x A) / A totaal

Distance between z (plate) and Z(tot):

a(I) = z(tot) - z(I)=

a(II) = z(tot) - z(II) =

a(III) = z(tot) - z(III) =

Calculation moment of enertia of bracket

I = 1/12 x b x h + a x A

Ix (I) =

Ix (II) =

Ix (III) =

Ix total =

Largest metal distance e1 =

(see sketch)

Profile section module Wb total = Ix total / e1

Calculation bracket

Torgue length

Bending moment

Sect. modulus

Bending stress

Tensile stress

2c

Mb

W

Sb

St

2c = (w+d)/2

Mb = Fe*a

W = (s * b^2)/6

Sb = Mb / W

St = (Fe/2)/(s*b)

Combined stress

Scom Scom=Sb + St

Yield stress material Re

P265 GH

Allowable stress

Sall

Sy*2/3 or 0,44*St

(must be > 1)

Weld seam

Horizontal force

Vertical force

Section modulus

Sectional area weld

Bending stress

Tensile stress

Shear stress

Fx

Fy

Ws

As

Sb

St

T

Combined stress

Allowable stress

Scom Scom = SQR((Sb+St)^2+t^2)

Sall

Sy*2/3 or St / 3

Date : 07/18/2016

Fx = Fh/n

Fy = Fv/n

Sb = Fx * h/Ws

St = Fy/As

T = Fx / As

(must be > 1)

108.4 mm

51.6 mm

98.4 mm

51.6 mm

38606504

42782409

38606504

119995417

mm4

mm4

mm4

mm4

mm4

191.6 mm

626403 mm

140

22362774.4

626403.5

35.7

3.9

mm

Nmm

mm^3

N/mm^2

N/mm^2

39.6 N/mm^2

265 N/mm^2

176.7 N/mm^2

4.46 OK

22423.6

44847.3

510413.4

39808.0

0.9

1.1

0.6

N

N

mm^3

mm^2

N/mm^2

N/mm^2

N/mm^2

2.1 N/mm^2

136.7 N/mm^2

65.62 OK

Page : 96

Visser Smit Hanab Installatie B.V.

Postbus 2104 1960 GC Heemskerk

Tel. 0251-257100 Fax. 0251-248746

73

74

75

76

Conditions of applicability (EN 13445-3:2002 Iss.1, par. 16.10.3)

16.10.3 a Bracket type C (16.10-1)

en =

s - corr.all. - mat.def.

Deq =

OD - 2* en

77

78

79

80

(must be 0,001 ; 0,05)

Quotint en / Deq

16.10.3 b Support type C (16.10-1)

h1 =

g=

81

82

83

Quotint g / h1

(must be 0,2 ; 1)

16.10.3 d With reinforcing plate

e2 = 20 35

NOT OK

84

b3 = 350 < 1,5 * h1 = 1,5*300 = 450

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

31.2

907.6

0.034 OK

300.0 mm

185.0 mm

0.6 OK

--> without reinf.

OK

OK

b2 = 250 0,6 * b3 = 0,6 * 350 =210

16.10.3 e The bracket is connected to a cylindrical or a conical shellon cilindrical shell

16.10.3 f The local bracket force Fi acts parallel to the shell axis

16.10.4

Applied forces

Ma =

0

n=

4

Fv =

179389 N

16.10-1 Fv1 = Fv / n

44847 N

16.10-2 Fhi = Fh / n

22424 N

16.10.5 Load limits of the shell

Bracket type C (no renforcing plate)

16.10-3 = h1 / (Deq * ea)^0,5

1.783

16.10-4 k16 = 1 / (0,36 + 0,40 + 0,02 ^2)^0,5

0.938

16.10-5 1 = min {0,08 ; 0,30}

0.143

16.6.6

Bending Limit Stress

K2 = 1,25 * design condition

= 13,5 N/mm^2

m = my = * Deq / (2 * ea)

196.4 N/mm^2

f = 204,2 N/mm^2 (shell, calculation)

16.6.8 2 = m / (K2 * f)

0.77

16.6.7 K1 = (1 - 2^2)/((1/3+1*2)+((1/3+1*2)^2+(1-2^2)*1^2)^0,5)

0.46

16.6-6 b all = K1 * K2 * f

116.4 N/mm^2

16.10-9 a1 = 398

h = 0,5 * 300 = 150

a1,eq = a1 + Fhi * h / Fvi

473.0

16.10-10 Fi,max = b all * ea^2 * h1/ (k16 * a1,eq)

76604.0

min [1 ; 0,5 + g/h1]

1.12 --> 1

113 Fv1 Fi max

114

115

448 1,12*76604 = 85796

OK

116 Design of bracket satisfies

117 for the stated design conditions according EN-13445.

Date : 07/18/2016

Page : 96

You might also like

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- Saddle v1-5: Fixed Saddle Sliding SaddleDocument9 pagesSaddle v1-5: Fixed Saddle Sliding Saddleduf fuNo ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationAliNo ratings yet

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaNo ratings yet

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- Lifting Analysis - TrunnionDocument3 pagesLifting Analysis - TrunnionMudasir MughalNo ratings yet

- Davit With ElbowDocument2 pagesDavit With ElbowSajal Kulshrestha100% (4)

- Ejma7r2 Bellows Worksheet-1Document11 pagesEjma7r2 Bellows Worksheet-1odormicchiNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document30 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)fsijest50% (4)

- CAL-ST-070!17!01 Rev01 Shipping Saddles CalculationDocument11 pagesCAL-ST-070!17!01 Rev01 Shipping Saddles CalculationgiubelloNo ratings yet

- Channel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionDocument6 pagesChannel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionGaurav BedseNo ratings yet

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- PD5500 - 133 - RectangularFlange CalculationDocument9 pagesPD5500 - 133 - RectangularFlange CalculationDarshan PanchalNo ratings yet

- WRC-107 Lifting Lugs - Vert. Vessel Horz. LiftDocument5 pagesWRC-107 Lifting Lugs - Vert. Vessel Horz. LiftManoj MulikNo ratings yet

- Calculation of Davit ArmDocument1 pageCalculation of Davit ArmpiziyuNo ratings yet

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- Calculation of Lifting ForcesDocument9 pagesCalculation of Lifting ForcesprantikduarahNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- Ad2000 B13Document2 pagesAd2000 B13akisdassasNo ratings yet

- 1.0 Load On Davit: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document1 page1.0 Load On Davit: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)miteshpatel191No ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- (DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enDocument6 pages(DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enNaveen Suresh KumarNo ratings yet

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm Calculationnitin400No ratings yet

- Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument8 pagesMethods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaNo ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Solution: WE1 12 Nov 2008Document9 pagesSolution: WE1 12 Nov 2008aauppalNo ratings yet

- WRC 297Document9 pagesWRC 297akisdassasNo ratings yet

- 28 Roark Flat PlatesDocument4 pages28 Roark Flat PlatesJorge Silva100% (1)

- Crossover Area Calc For Floating HeadDocument2 pagesCrossover Area Calc For Floating HeadRitesh VishambhariNo ratings yet

- Calculation For Quick Opening Closure: Design ConditionDocument5 pagesCalculation For Quick Opening Closure: Design ConditionA.K.100% (3)

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocument10 pagesFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNo ratings yet

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Manhole DavitDocument2 pagesManhole DavitgaratetaNo ratings yet

- FlangeCalculationASMEVIII Version5Document3 pagesFlangeCalculationASMEVIII Version5alvinchuan100% (1)

- Ped Eam-0526-24-1-2006-03Document6 pagesPed Eam-0526-24-1-2006-03nathachaiNo ratings yet

- Davit With ElbowDocument2 pagesDavit With Elbownitin400No ratings yet

- Saddle LoadsDocument11 pagesSaddle LoadsAnthony Dudley0% (1)

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Document2 pagesBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikNo ratings yet

- Bolt Torq. (Moss+Farr)Document9 pagesBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- Rectangular Tank Calc - STDDocument24 pagesRectangular Tank Calc - STDrustamriyadiNo ratings yet

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- ASME DIV 2 Class 1 Vs Class 2Document3 pagesASME DIV 2 Class 1 Vs Class 2Idris SiddiquiNo ratings yet

- .Document7 pages.Darshan Panchal100% (1)

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Zick Analysis For Saddle SupportDocument8 pagesZick Analysis For Saddle Supportfuransu777100% (1)

- 14 Design of Pile Cap: L T L TDocument4 pages14 Design of Pile Cap: L T L Tdik_gNo ratings yet

- Calculation - MWIDocument9 pagesCalculation - MWIfarhan_82No ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- SSB L SectionDocument20 pagesSSB L SectionMuhammad Azeem KhanNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous nwByj9L100% (2)

- Welding - Recommendations For Welding of Metallic MaterialsDocument6 pagesWelding - Recommendations For Welding of Metallic MaterialsFer VF100% (2)

- Eleksol 270w Policristalina PDFDocument2 pagesEleksol 270w Policristalina PDFFer VFNo ratings yet

- Böhler HL 51 T-MC: Seamless Cored WireDocument2 pagesBöhler HL 51 T-MC: Seamless Cored WireFer VFNo ratings yet

- Gear Racks Product Catalog EN PDFDocument31 pagesGear Racks Product Catalog EN PDFFer VFNo ratings yet

- Eleksol 270w Policristalina PDFDocument2 pagesEleksol 270w Policristalina PDFFer VFNo ratings yet

- Preiss Core Standards in The Pressure Equipment Area 4668Document42 pagesPreiss Core Standards in The Pressure Equipment Area 4668Mukund KashyapNo ratings yet

- Pipes. Pressure and Wall Thickness of A Straight Pipe. ASME B31.1 and B31.3Document100 pagesPipes. Pressure and Wall Thickness of A Straight Pipe. ASME B31.1 and B31.3safiragina100% (1)

- Pipes. Pressure and Wall Thickness of A Straight Pipe. ASME B31.1 and B31.3Document100 pagesPipes. Pressure and Wall Thickness of A Straight Pipe. ASME B31.1 and B31.3safiragina100% (1)

- Parallel Pin Din 6325-2.5X12 PDFDocument1 pageParallel Pin Din 6325-2.5X12 PDFFer VFNo ratings yet

- FD67Document2 pagesFD67Fer VFNo ratings yet

- ISO 9001 & 14001 Company Rex Sealing & Packing Industries PVT LTDDocument3 pagesISO 9001 & 14001 Company Rex Sealing & Packing Industries PVT LTDFer VFNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Fer VFNo ratings yet

- Intralox Plastic Chains: Series 820 Series 821 Series 831Document1 pageIntralox Plastic Chains: Series 820 Series 821 Series 831Fer VFNo ratings yet

- Bearing Fits BrgfitsDocument10 pagesBearing Fits BrgfitsAl7amdlellahNo ratings yet

- 653 230rev0Document2 pages653 230rev0Fer VFNo ratings yet

- Anchor Bolt Design Rev 1aDocument1 pageAnchor Bolt Design Rev 1aFer VFNo ratings yet

- Site Activities BD and SulzerDocument10 pagesSite Activities BD and SulzerFer VFNo ratings yet

- Preiss Core Standards in The Pressure Equipment Area 4668Document42 pagesPreiss Core Standards in The Pressure Equipment Area 4668Mukund KashyapNo ratings yet

- Site Activities BD and SulzerDocument10 pagesSite Activities BD and SulzerFer VFNo ratings yet

- Sheet 4 To 9Document6 pagesSheet 4 To 9Fer VFNo ratings yet

- Standard 2004Document18 pagesStandard 2004Fer VFNo ratings yet

- Trunnion PDFDocument7 pagesTrunnion PDFSajal KulshresthaNo ratings yet

- La Ko Sure Unsa NiDocument3 pagesLa Ko Sure Unsa NiJeromeNo ratings yet

- Acording To AsmeDocument3 pagesAcording To AsmeFer VFNo ratings yet

- Blank Thickness CalculatorDocument4 pagesBlank Thickness CalculatorbkprodhNo ratings yet

- Hydrogen Carbon NanotubesDocument10 pagesHydrogen Carbon NanotubesFer VFNo ratings yet

- Atmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)Document18 pagesAtmospheric Storage Tanks Venting Required API 2000 (6th ED 2009)ganeshdhageNo ratings yet

- AB&CO Electrical Process Air Heaters: Preliminary Calculation of Prices & DimensionsDocument2 pagesAB&CO Electrical Process Air Heaters: Preliminary Calculation of Prices & DimensionsGeorge ConstantineNo ratings yet

- Acording To AsmeDocument3 pagesAcording To AsmeFer VFNo ratings yet

- Key Length CalculatorDocument2 pagesKey Length CalculatorFer VFNo ratings yet