Professional Documents

Culture Documents

Alternators

Uploaded by

Ryan CireraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alternators

Uploaded by

Ryan CireraCopyright:

Available Formats

A LT E R N AT O R S

RANGE

A A G

A A K

A A K

c o m p a c t

A A N

c o m p a c t

A A T

A LT E R N AT O R S

ISKRA

The technical performance of Iskra alternators is based on long-term relationships with the customers, their high

requirements and expectations and our own long-standing experience in development and production. We control

quality using ISO 9001 and QS-9000 standards. The entire process from customer requirement and expectation,

through development and production is planned and controlled in detail. High operating reliability is assured by

optimising the design for use in different operating conditions, together with numerous validations of different

alternators in Iskra's own laboratories and on vehicles.

Alternators are air-cooled synchronous three-phase generators with claw poles and a built-in semiconductor rectifier.

A three-phase stator winding is connected to the three-phase rectifier bridge with power rectifier or Zener diodes.

The rotor coil is connected to the slip rings with brushes that conduct the excitation current. Alternators are selfexcited through excitation diodes or they are excited directly by the battery. The voltage regulator can be either

built-in or separately mounted. The negative terminal is normally connected to the chassis.

Iskra Avtoelektrika keeps abreast of all technical innovations in the field of alternators. Its staff are aware that energy

conservation in vehicles is an absolute necessity. The results are different families of alternators designed in modern

compact versions with internal fans in parallel with families of conventional design using external fans. Modern

versions of rectifiers and specific multifunction regulators are also available.

Different versions of alternators meet very high specifications in terms of resistance to salt spray, humidity, water,

mud, dust, vibrations, high and low temperatures and aggressive liquids. They are also designed to meet electromagnetic

compatibility and other international directives and standards. They are produced using ecologically sound technologies

and environmentally friendly materials.

Iskra alternators are designed to meet a wide range of engineering specifications and applications. They are used

on petrol and diesel engines in the automotive industry, on trucks, buses, tractors, construction machinery and in

other applications. Different solutions of our alternators are defined taking into account the demands of each

application and are designed for long life, maintenance free operation under extreme conditions.

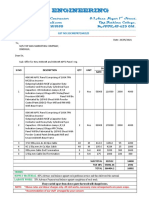

CLASSIFICATION OF ALTERNATORS

Alternators type AAG

stator diameter 108 mm

Alternators type AAK

stator diameter 125 mm

Alternators type AAK compact

stator diameter 125 mm

Alternators type AAN compact

stator diameter 142 mm

Alternators type AAT

stator diameter 165 mm

14 V , 2 8 V

A LT E R N AT O R S

ALTERNATORS 14V

100

90

80

AAN compact

70

60

7.3kg

Output in Amps. at 1800 RPM

50

AAK compact

40

AAK

30

20

5.3kg

4.7kg

AAG

3.5kg

10

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

140

150

160

Output in Amps. at 6000 RPM

ALTERNATORS 28V

100

90

AAT

80

70

60

14kg

Output in Amps. at 1800 RPM

50

AAN compact

40

7.3kg

30

AAK compact

20

5.3kg

AAK

10

AAG

4.7kg

3.5kg

0

10

20

30

40

50

Output in Amps. at 6000 RPM

60

70

80

90

100

110

120

130

A LT E R N AT O R S

AAG

APPLICATIONS

Low output powers make it possible for the

alternators to be built into systems with low

electrical requirements. Small dimensions allow

installation on all types of combustion engines

used on small tractors, small agricultural

machinery, stationary engines and some other

applications.

DESIGN

The alternator is a three-phase, 12-pole

synchronous self-excited generator with builtin rectifier and regulator and cooled by an

external fan. Various design solutions are

available depending upon the application:

insulated, marine, dustproof and other versions.

Cooling

The integral fan provides effective through cooling

of the alternator. Two different fans are available,

for CW and CCW direction of rotation.

MAIN TECHNICAL DATA

Type

AAG

Nominal voltage

14V

28V

Nominal current

33A - 50A

18A

Stator diameter

108 mm

Weight

~3.5 kg without pulley

Max. speed

18,000 RPM

Regulator

Built-in or separate

Hybrid technology

Pulleys and drive

Different types according to

end brackets

customers' requirements

Terminals

Screw and/or blade terminal

Drive end bearings

Type 6203 2RS

Rear end bearing

Type 63001

Power diodes

Press fit rectifier diodes or Zener diodes

Protection of the slip

Protected against access by a wire

rings and brushes

or splashing water (IP 44)

Protected against ingress of solid foreign

matter and powerful water jets (IP 56)

Ambient temperature

From - 40C to + 110C

Rotor

The rotor winding fixed between the claw poles

provides excitation of the alternator through slip

rings. For particularly dusty environments slip rings

and brushes are additionally protected.

Rectifier

Press fit rectifier diodes or Zener diodes are mounted

into protected heat sinks. Zener diodes protect the

loads on the vehicle against overvoltages from the

alternator.

Regulator

The regulator incorporating the brush holder is built

into the alternator. The regulator is produced using

thin-film hybrid or microelectronic technology.

Monofunction or multifunction is available

depending upon the requirements of the application.

The highest quality brushes ensure long life of the

alternator.

Brackets - Bearings - Pulleys

Brackets, bearings and pulleys are made according

to the customers requirements. A range of special

sealed bearings makes it possible to design

alternators for specific installations, operating in

the harshest conditions whilst achieving long,

maintenance free life.

Electrical terminals

Electrical terminals are according to the customers

requirements.

A LT E R N AT O R S

AAG

CROSS SECTION

Pos 1 Pulley

Pos 2 Drive end bearing

10

11

12

Pos 3 Fan

Pos 4 Drive end bracket

13

Pos 5 Stator

Pos 6 Rotor

o 108 mm

14

Pos 7 Rear bracket

Pos 8 Snap ring

15

Pos 9 Sealing felt

Pos 10 Rectifier

16

Pos 11 Slip rings

Pos 12 Terminals B+, W, D+

17

Pos 13 Capacitor

Pos 14 Rear bearing

Pos 15 Brush

Pos 16 Brush holder with voltage regulator

123 mm

Pos 17 Rubber gaskets

CHARACTERISTICS

I(A)

I(A)

20

60

18A

50A

15

45

35A

33A

30

10

15

U=const.=27V

To=23C5C

U=const.=13V

To=23C5C

0

0

0

1000 2000 3000 4000 5000 6000 7000

1000 2000 3000 4000 5000 6000 7000

n(RPM)

n(RPM)

I (A) at

1800 RPM

6000 RPM

14V 33A

1150

15

32

14V 35A

1250

13

35

14V 50A

1250

20

48

CONNECTION DIAGRAM

28V 18A

D+

B+

B- W

DREGULATOR

DF

I (A) at

n (RPM)

D+

I (A) at

I (A) at

n (RPM)

1800 RPM

6000 RPM

1200

18

A LT E R N AT O R S

AAK

APPLICATIONS

High output power alternators to satisfy the

needs for electrical energy in a wide range

of applications:

for cars

for commercial vehicles

for heavy-duty applications

for special applications

DESIGN

The alternator is a three-phase 12-pole

synchronous self-excited generator with builtin rectifier and regulator and cooled by an

external fan. Depending upon the purpose

of the installation, various versions can be

supplied: insulated, marine and other versions

according to special requirements.

Cooling

An integral fan provides effective through cooling

of the alternator. Two different fans are used

depending upon the required direction of rotation.

MAIN TECHNICAL DATA

Type

AAK

Nominal voltage

14V

28V

Nominal current

45A-80A

35A 50A

Stator diameter

125 mm

Weight

~4.7 kg without pulley

Max. speed

18,000 RPM

Regulator

Built-in or separate

Mono or multifunction

Hybrid or microelectronic

monochip technology

Pulleys and drive

Different types according to customers'

end brackets

requirements.

Terminals

Screw and/or blade terminal

Drive end bearings

Type 6203 / 6303 / 6304E / 6403-2RS

Rear end bearing

Type 6201-2RS

Power diodes

Rectifier or Zener diodes

Protection of the slip

Protected against access by a wire or

rings and brushes

splashing water (IP 44)

Rotor

With regard to the requirements of the installation

and the operating conditions, different protection

levels are provided for the slip rings and brush

compartment.

Rectifier

A three-phase bridge circuit with power rectifier

diodes and excitation diodes provides D.C. output

currents and excitation of the alternator. It is possible

to use Zener power diodes to protect loads on the

vehicle against alternator overvoltages.

Regulator

Regulator with brush holder is fitted to the alternator.

They are made in thin-film hybrid or microelectronic

technology. With regard to the requirements

of the application they may be monofunction

or multifunction. The highest quality brushes ensure

long life of the alternator.

Brackets - Bearings - Pulleys

Brackets, bearings and pulleys are made according

to the customers requirements. A range of special

sealed bearings makes it possible to design

alternators for specific installations, operating

in the harshest conditions whilst achieving long,

maintenance free life.

Protected against ingress of solid foreign

matter and powerful water jets (IP 56)

Ambient temperature

From - 40C to + 110C

Electrical terminals

Electrical terminals are according to the

customers requirements.

AAK

A LT E R N AT O R S

CROSS SECTION

Pos 1

Pulley

Pos 2

Drive end bearing

Pos 3

Fan

Pos 4

Drive end bracket

Pos 5

Stator with winding

Pos 6

Rotor

Pos 7

Rear bracket

Pos 8

Snap rings

Pos 9

Sealing felt

10

11

12

13

o 125 mm

14

15

16

Pos 10 Rectifier with diodes

Pos 11 Protective cover

17

Pos 12 Slip rings

Pos 13 Terminals B+, D+, W

18

Pos 14 Capacitor

Pos 15 Rear bearing

Pos 16 Brush

Pos 17 Brush holder with voltage regulator

135 mm

Pos 18 Rubber gaskets

CHARACTERISTICS

I(A)

I(A)

80A

80

60

75A

70

50A

65A

60

45

55A

40A

50

35A

45A

40

30

30

20

15

U=const.=13V

To=23C5C

10

U=const.=27V

To=23C5C

0

0

1000 2000 3000 4000 5000 6000 7000

1000 2000 3000 4000 5000 6000 7000

n(RPM)

I (A) at

I (A) at

n (RPM)

1800 RPM

6000 RPM

14V 45A

1000

28

45

14V 55A

1100

27

54

14V 65A

1100

30

65

14V 75A

1250

34

74

14V 80A

1350

29

80

n(RPM)

I (A) at

I (A) at

n (RPM)

1800 RPM

6000 RPM

28V 35A

1200

15

35

28V 40A

1450

12

40

28V 50A

1550

50

CONNECTION

DIAGRAMS

D+

B+

B- W

B+

DREGULATOR

BREGULATOR

DF

Multifunction

regulator

DF D+

Monofunction

regulator

EX

A LT E R N AT O R S

AAK compact

APPLICATIONS

for passenger cars

for commercial vehicles

for heavy-duty applications

for special applications

F

eatures

high specific power and efficiency

small dimensions

low weight

low noise level

higher protection against accidental contact

long life operation

DESIGN

The alternator is a three-phase, 12-pole

synchronous self-excited generator with two

internal fans and built-in regulator and rectifier.

The compact construction and carefully selected

materials assure improved technical

characteristics and long life, service free,

operation even under the harshest conditions

of high and low temperatures, salt spray,

humidity, water, dust, vibrations, aggressive

liquids.

MAIN TECHNICAL DATA

Type

AAK Compact

Nominal voltage

14V

28V

Nominal current

70A-120A

40A 60A

Stator diameter

125 mm

Weight

~5.3 kg without pulley

Max. speed

20,000 RPM

Regulator

Built-in or separate

Monofunction or multifunction

Microelectronic technology

Pulleys and drive

Different types according to customers'

end brackets

requirements.

Terminals

Screw and/or blade terminal

Drive end bearings

Type 6303, 6304E, 62304E

Rear end bearing

Type 6003

Power diodes

Press fit Zener diodes

Protection of the slip

Protected against ingress of solid foreign

rings and brushes

matter and powerful water jets (IP 56)

Ambient temperature

From - 40C to + 110C

Stator

The stator has a three-phase winding on a laminated

pack. The selected design and high filling factor of the

stator slots provides improved cooling, low noise and

high output characteristics.

Cooling

Two internal fans positioned on the claw poles provide

more effective cooling with lower noise and higher

protection against accidental contact as well as higher

output.

Rotor

Smaller slip rings provide higher brush durability, even

at high speeds. Encapsulated slip rings offer increased

durability of the alternator.

Rectifier

Sandwich construction of the rectifier with press fit

Zener diodes provides the low temperatures of the

rectifier diodes, high resistance to vibrations and

protection of loads on the vehicle against alternator

overvoltages. The installation of the rectifier on the

outer side of the rear end bracket ensures flexible

arrangement of all types of terminals.

Regulator

The regulator together with the brush holder is

assembled on the rear end bracket. Regulators use

microelectronic technology and are mono or

multifunction. The highest quality of brushes ensure

long life of the alternator.

Brackets - Bearings - Pulleys

Brackets, bearings and pulleys are made according to

the customers requirements. A range of special sealed

bearings makes it possible to design alternators for

specific installations, operating in the harshest

conditions whilst achieving long, maintenance free life.

Electrical terminals

Electrical terminals are according to the requirements

of the customers.

A LT E R N AT O R S

AAK compact

CROSS SECTION

8

9

Pos 1 Pulley

Pos 2 Drive end bearing

Pos 3 Drive end bracket

Pos 4 Stator with winding

10

o 125 mm

Pos 5 Rotor

Pos 6 Rear bracket

Pos 7 Rectifier with diodes

11

12

Pos 8 Protective cover

13

Pos 9 Terminals B+, D+, W

14

Pos 10 Rear bearing

Pos 11 Slip rings

Pos 12 Brush

Pos 13 Brush holder with voltage regulator

140 mm

Pos 14 Rubber gaskets

CHARACTERISTICS

I(A)

I(A)

120

80

120A

70

105

95A

90

80A

75

60A

55A

50A

45A

40A

60

85A

50

70A

60

40

45

30

20

30

U=const.=13V

To=23C5C

15

U=const.=27V

To=23C5C

10

0

0

0

1000 2000 3000 4000 5000 6000 7000

1000 2000 3000 4000 5000 6000 7000

n(RPM)

n(RPM)

I (A) at

I (A) at

n (RPM)

1800 RPM

6000 RPM

28V 40A

1000

23

40

28V 45A

1100

22

45

84

28V 50A

1200

22

50

42

94

28V 55A

1250

21

55

30

115

28V 60A

1400

18

60

I (A) at

1800 RPM

6000 RPM

14V 70A

1000

47

70

14V 80A

1100

40

80

14V 85A

1000

47

14V 95A

1100

14V 120A

1400

CONNECTION DIAGRAM

D+

B+

B-

DREGULATOR

DF D+

I (A) at

n (RPM)

A LT E R N AT O R S

AAN compact

APPLICATIONS

for passenger cars and commercial vehicles

with higher electrical demand

for heavy-duty applications

for special applications

F

DESIGN

The alternator is a three-phase, 12-pole

synchronous self-excited generator with two

internal fans and built-in regulator and rectifier.

The compact construction and carefully selected

materials assure improved technical

characteristics and long life, service free,

operation even under the harshest conditions

of high and low temperatures, salt spray,

humidity, water, dust, vibrations, aggressive

liquids.

MAIN TECHNICAL DATA

Type

AAN Compact

Nominal voltage

14V

28V

Nominal current

100A-150A

60A 100A

Stator diameter

142 mm

Weight

~7.3 kg without pulley

Max. speed

Regulator

eatures

high specific power and efficiency

small dimensions

low weight

low noise level

higher protection against accidental contact

long life operation

20,000 RPM

Built-in or separate

Monofunction or multifunction

Microelectronic technology

Pulleys and drive

Different types according to customers'

end brackets

requirements.

Terminals

Screw and/or blade terminal

Drive end bearings

Type 6304E, 62304E

Rear end bearings

Type 6203

Power diodes

Press fit Zener diodes

Protection of the slip

Protected against ingress of solid foreign

rings and brushes

matter and powerful water jets (IP 56)

Ambient temperature

From - 40C to + 110C

Stator

The stator has a three-phase winding on a laminated

pack. The selected design and high filling factor of the

stator slots provides improved cooling, low noise and

high output characteristics.

Cooling

Two internal fans positioned on the claw poles provide

more effective cooling with lower noise and higher

protection against accidental contact as well as higher

output.

Rotor

Smaller slip rings assure higher brush durability, even

at high speeds. Encapsulated slip rings offer increased

durability of the alternator.

Rectifier

Sandwich construction of the rectifier with press fit

Zener diodes provides for low temperatures of the

rectifier diodes, high resistance to vibrations and

protection of loads on the vehicle against alternator

overvoltages. The installation of the rectifier on the

outer side of the rear end bracket ensures flexible

arrangement of all types of terminals.

Regulator

The regulator together with the brush holder is

assembled on the rear end bracket. Regulators use

microelectronic technology and are mono or

multifunction. The highest quality of brushes ensure

long life of the alternator.

Bearings - Brackets - Pulleys

Brackets, bearings and pulleys are made according to

the customers requirements. A range of special sealed

bearings makes it possible to design alternators for

specific installations, operating in the harshest

conditions whilst achieving long, maintenance free life.

Electrical terminals

Electrical terminals are according to the requirements

of the customers.

A LT E R N AT O R S

AAN compact

CROSS SECTION

Pos 1 Pulley

Pos 2 Drive end bearing

13

Pos 3 Drive end bracket

14

Pos 4 Stator with winding

12

Pos 5 Rotor

o 142 mm

11

Pos 6 Rear bracket

Pos 7 Rectifier with diodes

10

Pos 8 Protective cover

Pos 9 Terminals B+, D+, W

Pos 10 Rear bearing

Pos 11 Slip rings

Pos 12 Brush

Pos 13 Brush holder with voltage regulator

148 mm

Pos 14 Rubber gaskets

CHARACTERISTICS

I(A)

I(A)

160

120

150A

140A

140

105

130A

120A

120

100A

90

100

75

80

60

60

45

80A

70A

30

40

U=const.=13V

To=23C5C

20

U=const.=27V

To=23C5C

15

0

0

0

1000 2000 3000 4000 5000 6000 7000

1000 2000 3000 4000 5000 6000 7000

n(RPM)

n(RPM)

I (A) at

1800 RPM

6000 RPM

14V 120A

1050

78

125

14V 130A

1050

80

134

14V 140A

1200

72

145

14V 150A

1200

74

154

CONNECTION DIAGRAM

D+

B+

B-

I (A) at

I (A) at

n (RPM)

1800 RPM

6000 RPM

28V 70A

1050

41

74

28V 80A

1250

39

85

28V 100A

1250

38

100

DREGULATOR

DF D+

I (A) at

n (RPM)

A LT E R N AT O R S

A AT

APPLICATIONS

These alternators provide very high output

power and are designed to be built into

applications requiring high consumption of

electrical energy. They were all initially designed

for installation on diesel engines in buses and

some special purpose applications.

DESIGN

The alternators are three-phase, 16-pole

synchronous generators, self-excited by a rotor

consisting of claw poles using protected slip

rings. They have a built-in rectifier and regulator

and are cooled by an external fan. Design

solutions and anticorrosion coatings as well as

specially chosen bearings ensure long life

without maintenance under normal operating

conditions. For operation in extremely hard

conditions - temperature, dust, water - it is

advisable to ventilate the alternator using a

special protection cover on the rear.

MAIN TECHNICAL DATA

Type

AAT

Nominal voltage

28V

Nominal current

75A-140A

Stator diameter

165 mm

Weight

~9.6 kg without pulley for 75A

~14.5 kg without pulley for 140A

Max. speed

9,000 RPM

Regulator

Built-in or separate

Monofunction

Hybrid technology

Pulleys and drive

Different types according to customers'

end brackets

requirements

Terminals

Screw and/or blade terminal

Drive end bearings

Type 62306-2RS

Rear end bearings

Type NU 202

Power diodes

Press fit Zener diodes

Protection of the slip

Protected against ingress of solid foreign

rings and brushes

matter and powerful water jets (IP 56)

Ambient temperature

From - 40C to + 110C

Cooling

The alternator has a built-in fan with axial - radial

blades that allow rotation in both directions. It is

also possible to use a low-noise fan with specially

shaped blades.

Stator

A three-phase stator winding with a high filling

factor of the slots and a special method of assembly

provide better cooling and high output power.

Rotor

The rotor field winding provides excitation of the

alternator through slip rings. With regard to the

installation requirements, slip rings and brushes are

protected in an enclosed environment sealed against

dust and water.

Rectifier

The rectifier stack is a three-phase bridge circuit

with built-in press fit power and excitation diodes.

Press fit Zener diodes are used to protect alternator

and loads on the vehicle against overvoltages.

Regulator

The regulator together with the brush holder is built

into the rear end bracket of the alternator. Regulators

are produced in thick-film hybrid technology.

Monofunction versions of the regulator only are

available.

Brackets - Bearings - Pulleys

The high quality specially chosen bearings provide

long service free life.

Electrical terminals

Electrical terminals are according to the customers'

requirements.

A LT E R N AT O R S

A AT

CROSS SECTION

Pulley

Pos 2

Drive end bearing

Pos 3

Fan

Pos 4

Drive end bracket

Pos 5

Stator

Pos 6

Rotor

Pos 7

Rear bracket

Pos 8

Rectifier

Pos 9

Rubber gaskets

10

11

12

13

o 165 mm

Pos 1

14

15

Pos 10 Brush

Pos 11 Brush holder with voltage regulator

16

Pos 12 Oil seal

Pos 13 Rear bearing

Pos 14 Slip rings

Pos 15 Terminals D+, B+, W

227 mm

Pos 16 Capacitor

CHARACTERISTIC

I(A)

160

140

140A

120

120A

100

105A

95A

80

75A

60

40

U=const.=28V

To=23C5C

20

0

0

1000 2000 3000 4000 5000 6000 7000

n(RPM)

I (A) at

I (A) at

n (RPM)

1800 RPM

6000 RPM

28V 75A

1000

50

75

28V 95A

950

60

95

28V 105A

900

70

105

28V 120A

1020

78

120

28V 140A

1080

90

140

CONNECTION DIAGRAM

C

B-

B+

D-

REGULATOR

DF D+

D+

product requirements form

A LT E R N AT O R S

1. CUSTOMER

Company:

Address:

Country:

Responsible person:

Phone:

Fax:

E-mail:

2. ENGINE DATA

PROJECT

Name:

inquiry

new project

modification

4 th

5 th

Brief description:

Quantity in next years: 1 st

2 nd

3 rd

APPLICATION

cars

trucks

buses

agriculture

road industry

railway

marine

other applications

ENGINE DATA

petrol

diesel

No. of cylinders

Rated output

kW

2/4 stroke

No. of valves

Compression

Displacement

Min. speed

RPM

Max. speed

Ltr.

RPM

PREDECESSOR / EQUIVALENT TYPE OF ALTERNATOR

Supplier

Type

Drawing

Mark

Release number

3. ALTERNATOR REQUIREMENTS

ELECTRICAL REQUIREMENTS

Voltage

Power

kW

A (1800 min -1 )

Current

Isolated ground

NO

YES

Electrical connections

B+ type of terminal

D+ type of terminal

W type of terminal

B- type of terminal

Other connection - terminals

Regulator voltage Ur =

Regulator:

monofunction

Description of function

V

multifunction

A (6000 min -1 )

product requirements form

A LT E R N AT O R S

MECHANICAL REQUIREMENTS FOR ALTERNATOR

Direction of alt. rotation:

clockwise

Ratio between engine and alternator:

counterclockwise

both directions

1:

Type of driving belt/ pulley:

one groove,

belt width

mm

angle

two groove,

belt width

mm

dimension between belt

angle

dimension between grooves

angle

poly V belt, number of grooves

Diameter of the pulley

mm

Belt line dimension

Type of pulley bearing

DESIGN REQUIREMENTS

Max. diameter:

mm

Max. length:

mm

Max. weight:

Please draw direction,

position of cables,

terminals (back side view)

Type of installation

Other design requirements:

Grade of protection according IP (DIN 40050): IP

Environmental conditions:

salt spray

high temperature

humidity

others

Mounting requirements: (to specify/sketch) or enclose drawing

Special requirements:

Customer test specification No.:

Safety standards:

Other standards:

Vehicle test or bench test (duration/conditions/number of samples):

Date:

Signature:

low temperature

kg

You might also like

- G65QSDocument4 pagesG65QSSamuel ZaragozaNo ratings yet

- Ap Series Exp 30-60kva 3PHDocument6 pagesAp Series Exp 30-60kva 3PHMohammed AlomaryNo ratings yet

- Load ScheduleDocument10 pagesLoad Schedulemaharot_0No ratings yet

- Single Line PLTD 1Document1 pageSingle Line PLTD 1Asri AbrialdiNo ratings yet

- G220QS - Canopy Set: PRIME KVA: 200.20 - STANDBY KVA 220.20 3800mmDocument4 pagesG220QS - Canopy Set: PRIME KVA: 200.20 - STANDBY KVA 220.20 3800mmمحمد النذيرNo ratings yet

- Neumax QT Series Quarter Turn Electric ActuatorDocument5 pagesNeumax QT Series Quarter Turn Electric Actuatornvhoang0185No ratings yet

- AIRPORTBROCHUREINTEGRODocument12 pagesAIRPORTBROCHUREINTEGROsebastianNo ratings yet

- SMU400 Catalog en Rev.BDocument2 pagesSMU400 Catalog en Rev.Blethanhtu0105No ratings yet

- Kirloskar Brushless AlternatorDocument34 pagesKirloskar Brushless AlternatorAmit Kumar VishwakarmaNo ratings yet

- A Legacy of Certainty,: Regenerated For TodayDocument4 pagesA Legacy of Certainty,: Regenerated For TodayPutri Nur Ayu AmaliaNo ratings yet

- G440QX - Canopy Set: PRIME KVA: 418.90 - STANDBY KVA 463.70 4500mmDocument4 pagesG440QX - Canopy Set: PRIME KVA: 418.90 - STANDBY KVA 463.70 4500mmsarita_hectorNo ratings yet

- Small Canopy 9-21kVADocument6 pagesSmall Canopy 9-21kVAمہرؤآنہ آبہرآهہيہمہNo ratings yet

- Features Description: LT8330 Low I Boost/SEPIC/ Inverting Converter With 1A, 60V SwitchDocument25 pagesFeatures Description: LT8330 Low I Boost/SEPIC/ Inverting Converter With 1A, 60V SwitchADRDE AGRANo ratings yet

- Price List PL-02/2013 01-09-2013: Type Ratings Icu Icu Unit RateDocument7 pagesPrice List PL-02/2013 01-09-2013: Type Ratings Icu Icu Unit RatepogisimpatikoNo ratings yet

- Motor PL - 07 29-10-07Document20 pagesMotor PL - 07 29-10-07ramolepankajNo ratings yet

- Magmotor s28Document2 pagesMagmotor s28Chuck SykesNo ratings yet

- AP Series Exp 600-700kva 3phDocument6 pagesAP Series Exp 600-700kva 3phsayadul mostafaNo ratings yet

- ASCO 7000 Withstand and Close-On RatingsDocument2 pagesASCO 7000 Withstand and Close-On Ratingsadd8742No ratings yet

- Cod280S ENDocument24 pagesCod280S ENpabloNo ratings yet

- HRVW 625 T4FDocument5 pagesHRVW 625 T4FJeremy DruffelNo ratings yet

- Rep8000 4 PDFDocument16 pagesRep8000 4 PDFjairoNo ratings yet

- AC1240 Jan 2012Document169 pagesAC1240 Jan 2012taoistpengNo ratings yet

- Vp-En SOGITECH PDFDocument8 pagesVp-En SOGITECH PDFSgk ManikandanNo ratings yet

- To Order: For 1 ReplaceDocument6 pagesTo Order: For 1 ReplaceviktorNo ratings yet

- Subfractional Permanent Magnet DC Motor - TENV, Rigid BaseDocument58 pagesSubfractional Permanent Magnet DC Motor - TENV, Rigid Baseduc minhNo ratings yet

- Autotransfer Switch Ats : Millennium Power Manufacturing CorpDocument5 pagesAutotransfer Switch Ats : Millennium Power Manufacturing CorpLeo BurnsNo ratings yet

- Baldor DC MotorsDocument58 pagesBaldor DC MotorstarraffNo ratings yet

- Circuit No. Load Description Volts VA Amperes IabDocument31 pagesCircuit No. Load Description Volts VA Amperes IabRick AlvientoNo ratings yet

- ST SeriesDocument1 pageST SeriesAchmad AnamNo ratings yet

- 82.5KVA To 200KVA, D.G.Sets, Acoustic Enclosures, AMF Panels, Control PanelDocument2 pages82.5KVA To 200KVA, D.G.Sets, Acoustic Enclosures, AMF Panels, Control PanelChockiNo ratings yet

- PKD SLDDocument1 pagePKD SLDsruthyNo ratings yet

- Zetty Catalogue 121Document1 pageZetty Catalogue 121ramukolakiNo ratings yet

- Silcostart: Static Motor Softstarter Solving Starting ProblemsDocument4 pagesSilcostart: Static Motor Softstarter Solving Starting ProblemsMohamed AlkharashyNo ratings yet

- 40 60kvar Apfc Panel May 2021Document2 pages40 60kvar Apfc Panel May 2021Maintenance Unit Anil GroupNo ratings yet

- Masterpact™ NT/NW: Universal Power Circuit BreakersDocument32 pagesMasterpact™ NT/NW: Universal Power Circuit Breakersjoaofelipe.msNo ratings yet

- 36MT10Document8 pages36MT10filipe AugustoNo ratings yet

- Marelli CatalogDocument16 pagesMarelli CatalogKamala Uma100% (1)

- ATA 24 - Cessna - Alternator Charging System 38-52-60 Amp Service - Parts Manual - D5107 - Rev 1 - 19930802Document127 pagesATA 24 - Cessna - Alternator Charging System 38-52-60 Amp Service - Parts Manual - D5107 - Rev 1 - 19930802Carlos Chavez JaramilloNo ratings yet

- Ball Valve Class 300Document1 pageBall Valve Class 300abdo elmokademNo ratings yet

- Machine TagDocument6 pagesMachine TagDanu Wahyu DalioNo ratings yet

- MRRDocument2 pagesMRRSun SunNo ratings yet

- Abb Deration TableDocument2 pagesAbb Deration TableAmr AbdelsayedNo ratings yet

- Sump Pump Critical Speeds WDS 101Document3 pagesSump Pump Critical Speeds WDS 101RANAIVOARIMANANA0% (1)

- Kap-866 Ome 171221Document43 pagesKap-866 Ome 171221Odair Fernandes de BritoNo ratings yet

- Sanch InverterDocument3 pagesSanch InverterAhmed AbdelrazekNo ratings yet

- PM300 Cla 060Document43 pagesPM300 Cla 060Gael VazquezNo ratings yet

- Oil Transformer Catalog 2010.compressedDocument8 pagesOil Transformer Catalog 2010.compressedmido2112No ratings yet

- 2PB OpampsfbDocument2 pages2PB OpampsfbXeeshan KhanNo ratings yet

- Rewinding ElectromotorDocument2 pagesRewinding ElectromotorLeo CharelNo ratings yet

- G120C Protective Device Prod Info 0618Document14 pagesG120C Protective Device Prod Info 0618AlexandreNo ratings yet

- G120C Protective Device Prod Info 0618Document14 pagesG120C Protective Device Prod Info 0618AlexandreNo ratings yet

- BifurcatedDocument4 pagesBifurcatedTanveer AzizNo ratings yet

- 220kv Greenko Feeder-2 Eqipment DetailsDocument34 pages220kv Greenko Feeder-2 Eqipment DetailsVeera ChaitanyaNo ratings yet

- Abb (Avs) Price ListDocument24 pagesAbb (Avs) Price ListS M Naveed0% (1)

- 3PoleContactors Digital PDFDocument17 pages3PoleContactors Digital PDFGunnie Pandher100% (1)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Salesforce Certified AdministratorDocument7 pagesSalesforce Certified AdministratorMurali Manohar Akula0% (1)

- TutoriaDocument351 pagesTutoriasakunthalapcsNo ratings yet

- ANSYS Simulation of MRI Device For ComplianceDocument45 pagesANSYS Simulation of MRI Device For Compliancej_c_garcia_dNo ratings yet

- Lightning DetectionDocument2 pagesLightning Detectionpemanr1914No ratings yet

- Evga Se Ebook UnlockedDocument14 pagesEvga Se Ebook UnlockedD OpferNo ratings yet

- X4029960-301 - Bus Riser+UTX - R01Document15 pagesX4029960-301 - Bus Riser+UTX - R01MUH ILHAM MARZUKINo ratings yet

- Compiler Lab VivaDocument6 pagesCompiler Lab VivaGaurav SharmaNo ratings yet

- Sentera Single Sensor User ManualDocument26 pagesSentera Single Sensor User ManualDwi WiraNo ratings yet

- Nokia 6.1 - Schematic DiagarmDocument78 pagesNokia 6.1 - Schematic DiagarmIndra KartunNo ratings yet

- Datasheet Axis q1656 Le Box Camera en US 424540Document3 pagesDatasheet Axis q1656 Le Box Camera en US 424540petereriksson.rosenforsNo ratings yet

- CNS Course Plan - Iv CDocument9 pagesCNS Course Plan - Iv CMohana SubbuNo ratings yet

- Gap Analysis: - Sources of GapsDocument19 pagesGap Analysis: - Sources of GapsBloomingdale Uttara100% (1)

- Module 8 Activities (Cyber and Digital Literacy)Document3 pagesModule 8 Activities (Cyber and Digital Literacy)John MathewNo ratings yet

- SAP GRC Access Control Implementation RoadmapDocument4 pagesSAP GRC Access Control Implementation Roadmapsekoy20122827No ratings yet

- DS FT232HDocument57 pagesDS FT232HplwrlvzxaocrejwruoNo ratings yet

- PLS2 Instruction From W451Document9 pagesPLS2 Instruction From W451Papahnya Qiana MaulinaNo ratings yet

- Soft-Switching Bidirectional DC-DC Converter Using A Lossless Active SnubberDocument9 pagesSoft-Switching Bidirectional DC-DC Converter Using A Lossless Active SnubberHsekum RamukNo ratings yet

- Computer Security EITA25: Final Exam inDocument6 pagesComputer Security EITA25: Final Exam inGeorges karamNo ratings yet

- CORBA Developer's Guide With XMLDocument295 pagesCORBA Developer's Guide With XMLDmitry SosnitskyNo ratings yet

- AONY36352: 30V Dual Asymmetric N-Channel MOSFETDocument10 pagesAONY36352: 30V Dual Asymmetric N-Channel MOSFETrobertjavi1983No ratings yet

- REspuestas Quiz CP4AUTOMATIONDocument10 pagesREspuestas Quiz CP4AUTOMATIONMax Lee100% (1)

- Irfiz 34 NDocument8 pagesIrfiz 34 NBase de DatosNo ratings yet

- Solution To Optimal Power Flow by PSODocument5 pagesSolution To Optimal Power Flow by PSOgallantprakashNo ratings yet

- Turnitin - Originality Report - BTP ReportDocument7 pagesTurnitin - Originality Report - BTP Reportatharvapatle1214129No ratings yet

- IM4A5-32 LatticeDocument62 pagesIM4A5-32 LatticeAnkitNo ratings yet

- HP Moonshot Provisiong Manager User GuideDocument44 pagesHP Moonshot Provisiong Manager User GuideBalasubramanian ReguramanNo ratings yet

- 200ma, Automotive, Ultra-Low Quiescent Current, Linear RegulatorDocument15 pages200ma, Automotive, Ultra-Low Quiescent Current, Linear RegulatorAbdul KurniadiNo ratings yet

- Cheatsheet Supervised LearningDocument4 pagesCheatsheet Supervised Learningan7l7aNo ratings yet

- Cube Iwork10 Flashing GuideDocument11 pagesCube Iwork10 Flashing Guideandrianaivo.rmanNo ratings yet

- WSDL Reading, A Beginner's GuideDocument18 pagesWSDL Reading, A Beginner's GuidePVParameswaranNo ratings yet