Professional Documents

Culture Documents

Technology Transfer in Pharmaceutical Industry Facts and Steps Involved

Technology Transfer in Pharmaceutical Industry Facts and Steps Involved

Uploaded by

Hitesh VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technology Transfer in Pharmaceutical Industry Facts and Steps Involved

Technology Transfer in Pharmaceutical Industry Facts and Steps Involved

Uploaded by

Hitesh VermaCopyright:

Available Formats

REVIEW ARTICLE

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

Journal home page: http://www.ajptr.com/

Technology Transfer in Pharmaceutical Industry; Facts and Steps

Involved

Manish Singh Manral1, Bharat Prashar1, Yakub Sheikh1*

1. Manav Bharti University, Solan, H.P., India

ABSTRACT

Technology transfer plays a vital role in the process of drug discovery to the product

development and the full scale commercialization. The article attempts to discuss about the

technology transfer process, steps involved in technology transfer, reasons for using technology

transfer, importance of technology transfer and the issues involved in the technology transfer in

the pharmaceutical industry.

Keywords: Technology transfer, Steps involved, Scale up, Exhibit.

*Corresponding Author Email: yakub.sheikh05@gmail.com

Received 5 June 2012, Accepted 14 June 2012

Please cite this article in press as: Sheikh Y et al., Technology Transfer in Pharmaceutical Industry;

Facts and Steps Involved. American Journal of PharmTech Research 2012.

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

INTRODUCTION

Technology transfer is the practice of transferring scientific findings from one organization to

another for further development, So that new products such as medicines, educational tool,

electronic devices, safety equipment and health services can become available to the public.

Technology transfer is the intersection between business, science, engineering, law and

government.1, 2

Technology transfer is both integral and critical to the drug discovery and development process

for new medicinal product. This process is important for to elucidate necessary information for

technology transfer from R & D (Research &Development) to PDL (process development

laboratory) and for development of existing products to the production for commercialization.

Technology Transfer is helpful to develop dosage forms in various ways like it provides

efficiency in process, helps to maintain quality of product, helps to achieve standardized process,

which in turn facilitates timely & cost effective production.3, 4

Technology transfer usually involves some source of technology that possess specialized

technical skills, which transfers the technology to a target group that do not possess those

specialized technical skills, and who therefore cannot create the tool themselves. Technology

transfer often involves the licensing of intellectual property rights and extending property rights

and technical expertise to developing firms.20

In the pharmaceutical industry, technology transfer refers to the processes of successful

progress from drug discovery to product development, clinical trials and ultimately full-scale

commercialization. It is the process by which an original innovator of technology makes its

technology available to commercial partner that will exploit the technology.

So, there are 3 standards in the definition of technology:

First, knowledge must be systematic. This means that it must be organized in terms of

providing solutions to problems.

Second, knowledge must exist in certain places like in someones head or in documents, and

must be able to be presented, so no matter what it means it must be able to be transferred

from one person to another.

Third, it must have purpose-orientation, so that it can be utilized for useful purposes in

industry, farming, and commercial fields.5

It is a systematic procedure that is followed in order to pass the documented knowledge and

experience gained during development and or commercialization to an appropriate, responsible

www.ajptr.com

74

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

and authorized party. Technology transfer embodies both the transfer of documentation and the

demonstrated ability of the receiving unit (RU) to effectively perform the critical elements of the

transferred technology, to the satisfaction of all parties and any applicable regulatory bodies.6

Transfer of technology requires a documented, planned approach using trained and

knowledgeable personnel working within a quality system, with documentation of data covering

all aspects of development, production and quality control. Usually there is a sending unit (SU),

a receiving unit (RU) and the unit managing the process, which may or may not be a separate

entity.7

In recent years, there is a growing awareness that an appropriate transfer of manufacturing

technologies (technology transfer) is important to upgrade drug quality as designed during R&D

to be a final product during manufacture as well as assure stable quality transferred for many

reasons between contract giver and contract acceptor during manufacture. The drug quality, it is

desired to make sure 5 Ws and 1 H, that is what, when and why information should be

transferred to where and by whom and how to transfer, then share knowledge and information of

the technology transfer each other between stake holders related to drug manufacturing.8

Technology transfer in pharmaceutical industry:

In the pharmaceutical industry technology transfer refers to the processes that are needed for

successful progress from drug discovery to product development, to clinical trials to full scale

commercialization or it is the process by which a developer of technology makes its technology

available to commercial partner that will exploit technology. In pharmaceutical industry

preparation of dosage form needs scale up in/at several stages, such as small scale laboratory

development from 0.5-2kg batch can be scaled up to 5-10 kg and then to 20-100 kg on a pilot

scale. Production scale can typically range from 200 kg to greater than 1000 kg. Technology

transfer involves manufacturing drug product with increasing batch sizes on larger equipment or

using continuous processing on pilot scale equipment. Generally scale up involves the transfer of

technology and the transfer of knowledge that has been accumulated during the small scale

development of product and processes. It is important to realize that good communication is

critical for formulation and process transfer to be successful. It is essential for a researcher or

developer of technology to make available this technology to another persons to exploit for the

progress of development of technology and for exploitation of a technology in different fields of

applications and to make is use with another organization that may have better manufacturing

capability, marketing capability and commercial capability. In the pharmaceutical industry,

75

www.ajptr.com

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

technology transfer by collaborating with other departments and other organizations to

commercialize a pharmaceutical product is a common process.9, 10, 11

TECHNOLOGY TRANSFER IN INDIAN PHARMACEUTICAL INDUSTRY

The pharmaceutical industry is a technology-intensive, science-based industry, with

biotechnology playing an ever-increasing role in its development a feature of the industry that

has grown in importance in recent years. 15

Ballance, Pogany and Forstner (1992) have presented a typology of the world's pharmaceutical

industries. They identified 10 countries (all of them developed) as "countries with a sophisticated

pharmaceutical industry and a significant research base". The next group of 17 countries was

identified as "countries with innovative capabilities". India is one of the countries in this group.

While these countries are not active in discovering new molecular entities they have the

technological capability to either develop innovative processes or improved formulations of

already discovered drugs. 15

During the 1990s policies relating to transfer of technology have been liberalized in the form of

easier procedures, removal of restrictions on royalty or technical fee payments, removal of

restrictions on inclusion of restrictive clauses in arrangements, and no scrutiny for repeated

imports, among others. However, all these measures have failed to increase the number of

collaboration agreements in the Indian pharmaceutical industry. According to Narsalay (2000),

there were a total of 187 technical collaboration approvals in the drug industry during 19911999, which constituted 3.1 per cent of all the technical collaboration agreements approved

during that period. This is a very small figure for such a technology-intensive sector.15

Effective Factors in Technology Transfer

In the technology transfer process, the entire elements of the technology triangle (Technical,

Organizational and Cultural aspects) are to be transferred into organizations and not impose them

solely into technologys hardware parts. Thus, they should be fully cognizant of their capabilities

and requirements before launching technology transfer. Actually, technological evaluation,

requirements and capacities recognition and selection of technology methods are of vital

importance in the technology transfer process. Thus, awareness of effective factors on

technology transfer is of great importance for technology recipients.12, 14, 18

REASONS FOR TECHNOLOGY TRANSFER18,19, 15

There may be many reasons why a developer of the technology might consider making its

technology available to another person to exploit, instead of exploiting the technology itself.

www.ajptr.com

76

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

Some of these are:

Forming alliances with partners that can progress the development of the technology to

take it to marketThe developer of the technology might have the resources to take the technology to

particular state of development, such as up to animal studies and toxicology studies, but

does not have the resources to take the technology through its clinical and regulatory

phases, and must collaborate with another organization to take it through these phases,

and into the market.

Forming alliances with partners with manufacturing capabilityThe developer of the technology may have taken the technology to a state of development

so that it is near market ready, but does not have the clean room manufacturing capability

or resources to manufacture the product, and must partner with another organization that

dose have that capability.

Forming alliances with partners with marketing and distribution capabilityThe developer of the technology may have fully developed the technology and even have

obtained regulatory approvals and product registrations for the product to be sold, but it

lacks the marketing and distribution channels to give it a marking capability and must

collaborate with another organization that doses have that capability.

Exploitation in a different field of applicationThe developer of the technology might be capable of exploiting the technology itself in

the field of diagnostic applications, and may grant exploitation right to commercial

partner for the exploitation of therapeutics applications. By transferring the technology

for the use in another field of application to another person, the developer of the

technology creates another income stream from the exploitation that takes place on that

takes place in that other field.

No Commercial capabilityThe developer of the technology may be research institute of a university, which does not

have the capability to exploit commercially at all, and need to collaborate with another

organization that does have that capability. In the exploitation of pharmaceutical

products, technology transfer by collaborating with this way to bring a pharmaceutical

product to market is common feature of the industry.

77

www.ajptr.com

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

Importance of Technology Transfer in Pharmaceutical Industry 19

To elucidate necessary information to transfer technology from R&D to actual

manufacturing by sorting out various information obtained during R&D;

To elucidate necessary information to transfer technology of existing products between

various manufacturing places;

To exemplify specific procedures and points of concern for the two types of technology

transfer in the above to contribute to smooth technology transfer. This is applies to the

technology transfer through R&D and production of drug (chemically synthesized drug

substances and drug products) and the technology transfer related to post-marketing

changes in manufacturing places.

STEPS IN TECHNOLOGY TRANSFER15, 19

Technology Transfer is not a single way process. Whether a tablet, a Transdermal patch, a

topical ointment, or an inject able, the transformation of a pharmaceutical prototype into a

successful product requires the cooperation of many individuals.

The classic view of a flow from basic to applied technology is a great oversimplificationsometimes, e.g. problems or insights arising at the production level give rise to new ideas that

contribute to fundamental basic advance. At least in some sectors, close links between the basic

researchers and manufacturing experts, and even marketing personnel contribute to

competitiveness and advancement.

During development of a formulation, it is important to understand procedure of operations used,

critical and non-critical parameters of each operation, production environment, equipment and

excipient availability, which should be taken into account during the early phases of

development of formulation, so that successful scale up can be carried out. Appropriate care

during technology transfer is important to enhance drug quality as developed by R & D in final

formulation as well as to assure quality for predetermined period of time. The various steps

involved in technology transfer are given below:

Development of Technology by R & D 13, 15, 19

Design of procedure and selection of excipients by R & D:

Selection of materials and design of procedures is developed by R & D on the basis of

innovator product characteristics. For this different tests and compatibility studies are

done.

Identification of specification and quality by R & D:

www.ajptr.com

78

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

Generally it should be considered by R & D that quality of product should meet the

specifications of an innovator product. For this different stability studies are carried out

for innovator product and for product which is to be manufactured.

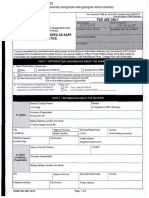

Technology transfer from R & D to production:

R & D provides technology transfer dossier (TTD) document to product development

laboratory, which contains all information of formulation and drug product as given

below:

Master formula card (MFC) includes product name along with its strength,

generic name, MFC number, page number, effective date, shelf life and market.

Master packaging card gives information about packaging type, material used for

packaging, stability profile of packaging and shelf life of packaging.

Master formula describes formulation order and manufacturing instructions.

Formulation order and Manufacturing Instructions gives idea of process order,

environment conditions required and manufacturing instructions for dosage form

development.

Specifications and standard test procedure (STPs) helps to know active

ingredients and Excipients profile, in-process parameters and specifications,

product release specification and finished product details.

OPTIMIZATION AND PRODUCTION13

Validation studies: Production is implemented after validation studies that can verify that

process is able to stabilize the product based on transferred manufacturing formula.

While the manufacturing department accepting technology is responsible for validation,

the research and development department transferring technology should take

responsibility for validation such as performance qualification, cleaning validation, and

process validation which are unique to subject drugs.

Scale up for production: Scale up involves the transfer of technology during the small

scale development of the product and processes. It is essential to consider the production

environment and system during development of process. Different operations e.g.

dispensing, sifting, blending, compaction/dry granulation/wet granulation, compression,

coating are used in the formulation of solid dosage form. From blending to film coating,

each process is easy for pharmaceutical professionals to be absorbed in the particular part

of the manufacturing process for which they are directly responsible. Operators

79

www.ajptr.com

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

concentrate on keeping their segment of the production process running smoothly. But

the whole manufacturing line can be improved, even before production begins, if

technology transfer is implemented thoughtfully. Effective technology transfer helps to

provide process efficiency and control and maintain product quality

Technology Transfer Documentation13

Technology transfer documentation is generally interpreted as document indicating contents of

technology transfer for transferring and transferred parties. Each step from R & D to production

should be documented, task assignments and responsibilities should be clarified and acceptance

criteria for completion of technology transfer concerning individual technology to be transferred.

It is duty of quality assurance department to check and approve the documentation for all

processes of technology transfer.

Development report: The ultimate goal for successful technology transfer is to have

documented evidences. The R & D report is a file of technical development, and the

research and development department is in charge of its documentation. This report is an

important file to indicate rationale for the quality design of drug substances and drug

specifications and test methods. The development report before the approval inspection,

although the development report is not prerequisite for the application for approval, it can

be used at the preapproval an inspection as valid document for quality design of new

drug. In addition, this report can be used as raw data in case of post-marketing

technology transfer. The development report contains data of pharmaceutical

development of new drug substances and drug products at stages from early development

phase to final application of approval, information of raw materials and components,

rational for dosage form & formula designs and design of manufacturing methods,

change in histories of important processes and control parameters, stability profile,

specifications and test methods of drug substances, intermediates, drug products, raw

materials, and components, which also includes validity of specification range of

important tests such as contents impurities and dissolution, rational for selection of test

methods, reagents and, columns, and traceability of raw data of those information.

Technology transfer plan: The technology transfer plan is to describe items and contents

of technology to be transferred and detailed procedures of individual transfer and transfer

schedule, and to establish judgment criteria for the completion of the transfer. The

transferring party should prepare the plan before the implementation of the transfer and

reach an agreement on its contents with the transferred party.

www.ajptr.com

80

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

Report: Report completion of technology transfer is to be made once data are taken

accordingly to the technology plan and are evaluated to confirm that the predetermined

judgment criteria are met. Both transferring and transferred parties can document the

technology transfer report; however, they should reach an agreement on its contents.

Exhibit: After taking scale up batches of the product, manufacturing of exhibit batches

take place. In case of exhibit, batch sizes are increased along with equipments and their

processes involved. They are done for filing purposes in different regulatory agencies.

CONCLUSION16,17

Effective technology transfer is critical to success in pharmaceutical industry. In pharmaceutical

industry technology transfer can be defined as the transfer of scientific information, a capability

or a technological basis associated with a drug or a pharmaceutical procedure from a donor side

(knowledge center) to a receptor side (drug manufacturing plant) implying a positive experience

learned and realized by both sides and complying all the regulatory requirements in terms of

Efficacy, Quality and Safety.

A healthy communication between different countries and different organizations are the key to

the success of Technology transfer and development. So, the knowledge and information should

be transferred equally and continuously from transferring party to the transferred party, this will

help in the product manufacturing process and thus the development of both the parties.

REFERENCES:

1. Domb E. Using TRIZ to Accelerate Technology Transfer in the Pharmaceutical Industry;

PGTJ 2004; 3-5.

2. http://www.research.cornell.edu/cotab

3. Reamer A. Icerman L and Youtie J. Technology Transfer and Commercialization: Their

Role in Economic Development, EDA Public documents 2003

4. Patel DS. An overview for pharmaceutical industry. IBAP 2010; 1-10.

5. http://aspx?ContentID=193

6. www.gsk.com/policies

7. Technology 4sme.net/images/pdf%20floder/ttps_ http://www.chapter_3.pdf.

8. ISPE Good practice guide. Technology transfer. Tampa, F.L. International Society for

Pharmaceutical Engineering, 2003.

9. Janodia MS, Sreedhar D, Ligade VS, Pise A and Udupa N. Facts of Technology transfer:

A perspective of Pharmaceutical industry, J. Intellectual property rights 2008; 28-34.

81

www.ajptr.com

Sheikh et. al.,

Am. J. PharmTech Res. 2012; 2(4)

ISSN: 2249-3387

10. Ruegger CE, Royce AE and Mollan MJ, Wagner RF, Valazza SJ and Mecadon MR.

Scale up of Solid Dosage Forms 2006

11. Mendes PC. Licensing and Technology Transfer in the pharmaceuticals Industry Cited

2010.

12. Reamer A. Icerman L and YoutieJ. Technology Transfer and Commercialization:Their

Role in Economic Development 2003.

13. Singh A and Aggarwal G. Technology Transfer in Pharmaceutical Industry: A

Discussion. IJPBS. 2009; 1-3.

14. Mahboudi Mand Ananthan BR.Effective factors in technology transfer in the

Pharmaceutical Industries of Iran: A Case study. The IUP Journal of Knowledge

Management 2010; 1-2.

15. Biswajit D and Rao N. Transfer of Technology for Successful Integration into the Global

Economy: A Case Study of the Pharmaceutical Industry in India. UNCTAD 2002.

16. Luis Alberto del Ro, Nuria Salazar, Carmen Trives, Guidelines for a pharmaceutical

technology transfer towards a drug manufacturing plant, Bol. Soc. Qum. Mx. 2007.

17. Del Rio, L.A. Ind. Farm. 2001. 64-68.

18. Bateni M. Selection of Appropriate Technology for Developing Countries, Tadbir. 2000;

108.

19. http://www.amuasi-paper-edited.pdf.

20. www.ncbi.nlm.nih.gov/pubmed/12613797

www.ajptr.com

82

You might also like

- Pharmaceutical Facilities: Design, Layouts and ValidationFrom EverandPharmaceutical Facilities: Design, Layouts and ValidationRating: 4 out of 5 stars4/5 (6)

- Dokumen - Pub Foundations of Nursing in The Community Community Oriented Practice 4 9780323100946Document726 pagesDokumen - Pub Foundations of Nursing in The Community Community Oriented Practice 4 9780323100946Nia Singh0% (1)

- Aseptic and Sterile Processing: Control, Compliance and Future TrendsDocument2 pagesAseptic and Sterile Processing: Control, Compliance and Future TrendsTim Sandle100% (1)

- Principles of Parenteral Solution Validation: A Practical Lifecycle ApproachFrom EverandPrinciples of Parenteral Solution Validation: A Practical Lifecycle ApproachIgor GorskyRating: 5 out of 5 stars5/5 (2)

- Technology Transfer in Pharmaceutical IndustryDocument24 pagesTechnology Transfer in Pharmaceutical IndustryPranjal100% (2)

- Tech Transfer 1Document6 pagesTech Transfer 1Rajesh KesarlaNo ratings yet

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsFrom EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsRating: 5 out of 5 stars5/5 (2)

- Modified Release Drug ProductsDocument58 pagesModified Release Drug Productsmailtorubal2573100% (2)

- Sterile Dosage FormsDocument45 pagesSterile Dosage Formsrajgornaresh100% (5)

- Pharmaceutical Microbiology MSCDocument17 pagesPharmaceutical Microbiology MSCTim Sandle100% (1)

- QA PharmaceuticalDocument413 pagesQA Pharmaceuticalalhalili100% (9)

- Pharmaceutical Packaging Technology: Pharmaceutical Packaging TechnologyFrom EverandPharmaceutical Packaging Technology: Pharmaceutical Packaging TechnologyRating: 3.5 out of 5 stars3.5/5 (2)

- Gemmotherapy For Everyone Extract PDFDocument26 pagesGemmotherapy For Everyone Extract PDFHunor Ladó100% (1)

- BS Pharm 1 Course SyllabusDocument2 pagesBS Pharm 1 Course SyllabusMarecar100% (2)

- MedicationsDocument13 pagesMedicationsReynaKatNo ratings yet

- Tech TransferDocument51 pagesTech Transferkunalprabhu148No ratings yet

- Technology Transfer in Pharmaceutical IndustryDocument5 pagesTechnology Transfer in Pharmaceutical IndustryGursharanjit Singh ShinhNo ratings yet

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesFrom EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNo ratings yet

- How to Integrate Quality by Efficient Design (QbED) in Product DevelopmentFrom EverandHow to Integrate Quality by Efficient Design (QbED) in Product DevelopmentNo ratings yet

- Sterile Dosage Forms - 0 PDFDocument85 pagesSterile Dosage Forms - 0 PDFShalimashalu100% (1)

- Dosage Form DesignDocument19 pagesDosage Form DesignAnimikh RayNo ratings yet

- Formulation and Development in Pharmaceutical IndustryDocument11 pagesFormulation and Development in Pharmaceutical Industrydeepak GuptaNo ratings yet

- CHAPTER 1 Preformulation StudiesDocument18 pagesCHAPTER 1 Preformulation Studieskartik sharmaNo ratings yet

- Sterile ProductsDocument24 pagesSterile ProductsHaroon Rahim100% (1)

- Technology Transfer Challenges in Pharmaceutical IndustryDocument32 pagesTechnology Transfer Challenges in Pharmaceutical Industrygino100% (2)

- Sterile Manufacturing-Facility & DesignDocument45 pagesSterile Manufacturing-Facility & DesignMd Saiful islam Bhuiyan100% (1)

- Sterile Opthalmic Preparations PDFDocument6 pagesSterile Opthalmic Preparations PDFSundariNo ratings yet

- Sterile Pharmaceutical ProductsDocument62 pagesSterile Pharmaceutical ProductsTaesup Byun50% (6)

- Sterile Parenteral Product (Review) PDFDocument8 pagesSterile Parenteral Product (Review) PDFdianiNo ratings yet

- PROCESS VALIDATION OF ORAL SOLID DOSAGE FORM. TABLET-An Overview PDFDocument16 pagesPROCESS VALIDATION OF ORAL SOLID DOSAGE FORM. TABLET-An Overview PDFAndy Rojas100% (1)

- Sterile Ophthalmic Preparations and Cont PDFDocument7 pagesSterile Ophthalmic Preparations and Cont PDFRaedMohNo ratings yet

- Use of Technology in Pharmaceutical Industry in BangladeshDocument4 pagesUse of Technology in Pharmaceutical Industry in BangladeshFuhad Ahmed100% (3)

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Document8 pagesHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Quang Hiếu NgôNo ratings yet

- Preview Book Introduction HPLCDocument29 pagesPreview Book Introduction HPLCarun231187No ratings yet

- Quality by Design Approaches For Topical Dermatological Dosage FormsDocument19 pagesQuality by Design Approaches For Topical Dermatological Dosage FormsDoinița UrsuNo ratings yet

- GMP New PDFDocument51 pagesGMP New PDFMeha RajNo ratings yet

- Formulation and DevelopmentDocument38 pagesFormulation and Developmentapi-3810976100% (2)

- Preformulation NotesDocument19 pagesPreformulation NotesAnkit Arora67% (3)

- 74 Pharmaceutical Process A ValidationDocument16 pages74 Pharmaceutical Process A ValidationPaulNo ratings yet

- Drug Product Registration in Semi-Regulated MarketDocument6 pagesDrug Product Registration in Semi-Regulated MarketshrikantmsdNo ratings yet

- Aseptic Processing of Parenteral ProductsDocument50 pagesAseptic Processing of Parenteral ProductsHanuma KanthetiNo ratings yet

- Pharmaceutics IntroductionDocument9 pagesPharmaceutics IntroductionVIJAY KUMAR TIRUKKACHINo ratings yet

- Chapter 17 Sterile ProductsDocument28 pagesChapter 17 Sterile ProductsM Imran SajidNo ratings yet

- Techniques of SolubilizationDocument33 pagesTechniques of SolubilizationSreekanth NamaNo ratings yet

- Sterility TestingDocument14 pagesSterility TestingsusubiribiNo ratings yet

- Pilot Plant Scale Up of Inject Able Sand Liquid OralsDocument38 pagesPilot Plant Scale Up of Inject Able Sand Liquid OralsPradeep BhimaneniNo ratings yet

- Drug Development ProcessDocument14 pagesDrug Development Processsnaren76100% (1)

- Pharmaceutical Industry ReportDocument52 pagesPharmaceutical Industry ReportEr Akhilesh Singh100% (1)

- Sustained ReleaseDocument59 pagesSustained ReleaseDipankar Sarkhel100% (1)

- Abbreviations Used in The Pharmaceutical IndustryDocument8 pagesAbbreviations Used in The Pharmaceutical Industryatul8295No ratings yet

- Report On PreformulationDocument9 pagesReport On PreformulationH FaithNo ratings yet

- Pharmaceutical PRODUCT DEVELOPMENT FLOWCHARTDocument2 pagesPharmaceutical PRODUCT DEVELOPMENT FLOWCHARTAsif Hussain100% (15)

- Particle Monitoring Requirements in Pharmaceutical CleanroomsDocument7 pagesParticle Monitoring Requirements in Pharmaceutical CleanroomsananthNo ratings yet

- Development and Manufacturing of Injectable (Parenteral) Drug Products UnitDocument10 pagesDevelopment and Manufacturing of Injectable (Parenteral) Drug Products UnitParul SrivastavaNo ratings yet

- Parenteral Products: The Preparation and Quality Control of Products for InjectionFrom EverandParenteral Products: The Preparation and Quality Control of Products for InjectionNo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- How to Develop Robust Solid Oral Dosage Forms: From Conception to Post-ApprovalFrom EverandHow to Develop Robust Solid Oral Dosage Forms: From Conception to Post-ApprovalNo ratings yet

- Tablet PressDocument14 pagesTablet Pressmeacno100% (1)

- TERP 10 Edition 66Document3 pagesTERP 10 Edition 66meacnoNo ratings yet

- Certificate of IncorporationDocument1 pageCertificate of IncorporationmeacnoNo ratings yet

- Natural Law CritiqueDocument3 pagesNatural Law CritiquemeacnoNo ratings yet

- Avapro (Irbesartan)Document2 pagesAvapro (Irbesartan)ENo ratings yet

- Absorption: Scheme Demonstrating The Dynamic Relationship Between The and TheDocument19 pagesAbsorption: Scheme Demonstrating The Dynamic Relationship Between The and Theheyyo ggNo ratings yet

- GelucierDocument7 pagesGelucierAmina Neelam IrfanNo ratings yet

- Procedure Checklist Chapter 37, Skill 37-01: Reconstituting and Withdrawing Medication From A VialDocument2 pagesProcedure Checklist Chapter 37, Skill 37-01: Reconstituting and Withdrawing Medication From A VialNursyNurseNo ratings yet

- مسائل جابتر 1Document2 pagesمسائل جابتر 1لقاء زياد طارقNo ratings yet

- Regulatory Approval FrameworkDocument85 pagesRegulatory Approval FrameworkAmer RahmahNo ratings yet

- 2668 2680Document13 pages2668 2680Bhavya ParmarNo ratings yet

- GRAS Notice GRN 853 Lysozyme Produced by Trichoderma ReeseiDocument41 pagesGRAS Notice GRN 853 Lysozyme Produced by Trichoderma Reeseigabriela_moron_aNo ratings yet

- Manual For Medicines Good DispensingDocument114 pagesManual For Medicines Good DispensingJosh SorianoNo ratings yet

- Test Bank For Pharmacology For Nurses 2nd Canadian Edition by AdamsDocument11 pagesTest Bank For Pharmacology For Nurses 2nd Canadian Edition by AdamsRobert Booth100% (40)

- Ich M4Q Common Technical Document For The Registration of Pharmaceuticals For Human Use - QualityDocument22 pagesIch M4Q Common Technical Document For The Registration of Pharmaceuticals For Human Use - QualityShiraz KhanNo ratings yet

- Reviewer Chapter 35 MedicationsDocument4 pagesReviewer Chapter 35 MedicationsKeren GaciasNo ratings yet

- Sustained Release Dosage FormsDocument46 pagesSustained Release Dosage FormsMehak LubanaNo ratings yet

- Carboprost 1Document3 pagesCarboprost 1angerson5100% (1)

- What Are Immunosuppressants?Document3 pagesWhat Are Immunosuppressants?ghifaryNo ratings yet

- Cancer Lung Chemotherapy Regimen 3.4 March 2015Document69 pagesCancer Lung Chemotherapy Regimen 3.4 March 2015Jenny MárquezNo ratings yet

- Drugs & DosagesDocument6 pagesDrugs & DosagesMaui GamutanNo ratings yet

- Case Study Diabetes MellitusDocument31 pagesCase Study Diabetes Mellitusrmarty_35No ratings yet

- Formulation Stabilisation and Encapsulation of Bacteriophage For Phage TherapyDocument34 pagesFormulation Stabilisation and Encapsulation of Bacteriophage For Phage TherapyGerman GodiNo ratings yet

- LuyaDocument105 pagesLuyaKaye FCNo ratings yet

- Modul English 1 - MuklaDocument13 pagesModul English 1 - MuklaFia Nur HaryaniNo ratings yet

- Antibiotics in Oral & Maxillofacial SurgeryDocument50 pagesAntibiotics in Oral & Maxillofacial SurgerysevattapillaiNo ratings yet

- Shiela BugokDocument4 pagesShiela Bugokberttesting13No ratings yet

- Product Monograph Atripla (Emtricitabine - Tenofovir D. F. - Efavirenz)Document70 pagesProduct Monograph Atripla (Emtricitabine - Tenofovir D. F. - Efavirenz)tartaruga_tartarugaNo ratings yet

- Drug Study FinalsDocument4 pagesDrug Study FinalsKathleen Dela CruzNo ratings yet

- 1556106759progressive Distributor 2015 20151018 114420Document24 pages1556106759progressive Distributor 2015 20151018 114420Kamel NaitNo ratings yet