Professional Documents

Culture Documents

Sow NRV 2016

Uploaded by

mohamadhakim.19789Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sow NRV 2016

Uploaded by

mohamadhakim.19789Copyright:

Available Formats

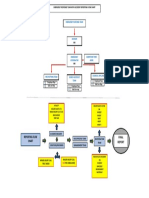

DESIGN & FABRICATION OF NON RETURN VALVE

FOR R-200

1.0 INTENT

1.1

Petronas Chemicals Polyethylene Sdn Bhd (hereinafter referred to as PCPSB) intends to call quotation

for the design and fabrication of the non return valve at the dip pipe of R-200 (hereinafter referred to as

the WORKS) at Polyethylene plant.

1.2

The quotation shall be based on lump sum.

2.0

CONTRACTORS SCOPE OF WORK

2.1

CONTRACTOR shall be responsible for detail mechanical design which includes the preparation of

mechanical design calculation and engineering drawing to the latest edition of design code and

standard requirement and PETRONAS Technical Standard.

2.2

Supply all required manpower, materials, tools and equipment for the design, fabrication, inspection,

testing and quality of workmanship of two (2) unit Non Return Valve (NRV).

2.3

CONTRACTOR shall fabricate two (2) unit of non-return valve as per approved drawing.

2.4

Carry out the required testing for the NRV i.e pop test and leak test. The test shall be witnessed by

PCPSB personnel. It is CONTRACTORs duty to inform PCPSB the testing date(s).

2.5

Deliver the completed unit to PCPSBs maintenance workshop.

2.6

Prepare the AS-BUILT drawing. Submission of AS-BUILT drawing shall be in 3 copies of A4 size.

Softcopy shall be submitted in CD in Auto-CAD format.

2.7

CONTRACTOR shall supply the material upon approval from PCPSB with complete mill certificate.

3.0

DESIGN OF NON RETURN VALVE

3.1

CONTRACTOR shall design the new NRV using following drawings as basis:

I. R-200 drawing

Ii. FBM-001 drawing

3.2

The new NRV shall be coated with stellite at the contact area between poppet and housing.

CONTRACTOR shall advise / propose the amendment / change required for the stellite coating

application. CONTRACTOR shall discuss and obtain PCPSBs approval for the change prior start of

fabrication.

3.3

CONTRACTOR shall submit the stellite coating procedure to PCPSB for approval prior start of coating.

3.4

CONTRACTOR shall ensure the provided spring shall be fit for following work intent:

- able to start open at 5.0 barg

- full open at 5.5 barg

- re-sit with zero leak at 4.5 barg.

3.4

Sizing of the spring shall be as such there is enough clearance between following parts, to ensure they

are not easily stucked while in operations:

- between spring and housing and

- between spring and poppet

The spring specification shall be clearly stipulated in the drawing detail.

3.5

Material of construction of the NRV parts will be as follows or as per approved drawing:

i. Housing - SS 316

ii. Poppet - SS304

iii. Nut - SS 316

DESIGN & FABRICATION OF NON RETURN VALVE

FOR R-200

iv. Spring - SS302

v. Seats Stellite 06 and Viton Rubber

For any deviation from the above, CONTRACTOR shall obtain PCPSBs prior approval.

3.6

All design data including spring selection and stellite coating selection shall be provided in the MDR

(Manufacturing Data Record).

4.0 SUBMISSION OF BID.

4.1

ITEM

BIDDER shall submit quotation in following cost breakdown:

Work Description

Supply, fabricate and deliver poppet

Supply, fabricate and deliver housing

Produce new drawing

Spring

Coating

Testing

Please indicate additional cost if applicable.

Unit

price

TOTAL

You might also like

- Alignment Report PDFDocument4 pagesAlignment Report PDFmohamadhakim.19789No ratings yet

- Project Schedule - Bar Chart - DalakDocument3 pagesProject Schedule - Bar Chart - Dalakmohamadhakim.19789No ratings yet

- Supplier Punch List Form: (With Equipment Description, Tag Number/valve Code, Photo and Quantity)Document2 pagesSupplier Punch List Form: (With Equipment Description, Tag Number/valve Code, Photo and Quantity)mohamadhakim.19789No ratings yet

- Shell Test For Ball ValveDocument40 pagesShell Test For Ball Valvemohamadhakim.19789No ratings yet

- Provision of Refurbishment of Taa Wag Charge Pump Unit, 684-3-P-700B FOR TAPIS D PLATFORM (KHL/AFS P-265/ITB-069) / MSB-SV-18-0012Document1 pageProvision of Refurbishment of Taa Wag Charge Pump Unit, 684-3-P-700B FOR TAPIS D PLATFORM (KHL/AFS P-265/ITB-069) / MSB-SV-18-0012mohamadhakim.19789No ratings yet

- Offshore PPE RequirementDocument2 pagesOffshore PPE Requirementmohamadhakim.19789No ratings yet

- HSE Committee ChartDocument1 pageHSE Committee Chartmohamadhakim.197890% (1)

- Table 6 Leakage Rate 5.9.2.2 API 6DDocument2 pagesTable 6 Leakage Rate 5.9.2.2 API 6Dmohamadhakim.19789No ratings yet

- Production Schedule - Bar ChartDocument1 pageProduction Schedule - Bar Chartmohamadhakim.19789No ratings yet

- Emergency Response Team: Reporting Flow ChartDocument1 pageEmergency Response Team: Reporting Flow Chartmohamadhakim.19789No ratings yet

- CRSDocument1 pageCRSmohamadhakim.19789No ratings yet

- Test Procedure of A10VSO28DFLR Macrospec Mac 18 2 PDFDocument1 pageTest Procedure of A10VSO28DFLR Macrospec Mac 18 2 PDFmohamadhakim.19789No ratings yet

- Material Test Certificate SummaryDocument1 pageMaterial Test Certificate Summarymohamadhakim.19789No ratings yet

- Endurance Test Report 72hrDocument1 pageEndurance Test Report 72hrmohamadhakim.19789No ratings yet

- 19.4.1 MYTZ-MP-VDDET-120003 R50 Code 1Document2 pages19.4.1 MYTZ-MP-VDDET-120003 R50 Code 1mohamadhakim.19789No ratings yet

- Technical Query: Dulang EwagDocument3 pagesTechnical Query: Dulang Ewagmohamadhakim.19789No ratings yet

- 18 - 161 - 10 - 1 RcaDocument3 pages18 - 161 - 10 - 1 Rcamohamadhakim.19789No ratings yet

- Endurance Test Report 48hrDocument1 pageEndurance Test Report 48hrmohamadhakim.19789No ratings yet

- Valve Misalignment Rectification: RBR Job No.Document3 pagesValve Misalignment Rectification: RBR Job No.mohamadhakim.19789No ratings yet

- Maintenance Check Sheet 2015 - 21.03.2016Document1 pageMaintenance Check Sheet 2015 - 21.03.2016mohamadhakim.19789No ratings yet

- Appendix 1: Technical ProposalDocument4 pagesAppendix 1: Technical Proposalmohamadhakim.19789No ratings yet

- Endurance Test Report 24hrDocument1 pageEndurance Test Report 24hrmohamadhakim.19789No ratings yet

- 16.0108 Progress Activity 01Document1 page16.0108 Progress Activity 01mohamadhakim.19789No ratings yet

- Testingggg HydrotestDocument1 pageTestingggg Hydrotestmohamadhakim.19789No ratings yet

- 2 - Layout Plan For HTDocument1 page2 - Layout Plan For HTmohamadhakim.19789No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Secureworks E1 LearningfromIncidentResponseJan-Mar22Document12 pagesSecureworks E1 LearningfromIncidentResponseJan-Mar22TTSNo ratings yet

- Dwnload Full Financial Accounting 12th Edition Thomas Test Bank PDFDocument35 pagesDwnload Full Financial Accounting 12th Edition Thomas Test Bank PDFhetero.soothingnnplmt100% (15)

- Career CenterDocument5 pagesCareer Centerapi-25949018No ratings yet

- Family Chapter Revision GuideDocument9 pagesFamily Chapter Revision GuidePuss BootNo ratings yet

- Resolution Approving and Endorsing The CbydpDocument2 pagesResolution Approving and Endorsing The CbydpMa Elena Llunado83% (6)

- Jurisprudence Renaissance Law College NotesDocument49 pagesJurisprudence Renaissance Law College Notesdivam jainNo ratings yet

- School Calendar Version 2Document1 pageSchool Calendar Version 2scituatemarinerNo ratings yet

- Divine Word University of Tacloban vs. Secretary of Labor and Employment, G. R. No. 91915, Sept. 11, 1992, 213 SCRA 759Document3 pagesDivine Word University of Tacloban vs. Secretary of Labor and Employment, G. R. No. 91915, Sept. 11, 1992, 213 SCRA 759Maria Celiña PerezNo ratings yet

- CounterfeitingDocument21 pagesCounterfeitingnujahm1639No ratings yet

- Project Report On Comparative Analysis of 4-Stroke BikesDocument72 pagesProject Report On Comparative Analysis of 4-Stroke BikesvinnetTNo ratings yet

- Universidad Autónoma de Nuevo Léon Preparatoria 15, Unidad MaderoDocument4 pagesUniversidad Autónoma de Nuevo Léon Preparatoria 15, Unidad MaderoCarlos Lopez cortezNo ratings yet

- RP FinalDocument125 pagesRP FinalAditya SoumavaNo ratings yet

- Programme - IIMADocument13 pagesProgramme - IIMAArun SharmaNo ratings yet

- OSH Standards 2017Document422 pagesOSH Standards 2017Kap LackNo ratings yet

- Executive SummaryDocument3 pagesExecutive SummaryyogeshramachandraNo ratings yet

- Balaristha DoshaDocument4 pagesBalaristha DoshaAstroSunilNo ratings yet

- Civil Procedure (Revision 2020) (Session 3)Document11 pagesCivil Procedure (Revision 2020) (Session 3)JosephNo ratings yet

- Việt Anh Topic 2Document1 pageViệt Anh Topic 2Jeremi Linh NguyễnNo ratings yet

- Goodyear (Veyance)Document308 pagesGoodyear (Veyance)ZORIANNYEGLNo ratings yet

- Religion and The Romantic MovementDocument7 pagesReligion and The Romantic Movementnuntiainfo7398No ratings yet

- Consumer Reports Lesson Plan: Purchasing Products: VocabularyDocument10 pagesConsumer Reports Lesson Plan: Purchasing Products: VocabularyEmmanuel DianaNo ratings yet

- Exordium Examples HSDocument2 pagesExordium Examples HSMihaela Constantina VatavuNo ratings yet

- Bjorkman Teaching 2016 PDFDocument121 pagesBjorkman Teaching 2016 PDFPaula MidãoNo ratings yet

- Shaykh Rabee Advises Before He RefutesDocument7 pagesShaykh Rabee Advises Before He Refuteshttp://AbdurRahman.orgNo ratings yet

- Carnival Internet Package Price Up To 100 Mbps Speed Best Internet Provider 2Document1 pageCarnival Internet Package Price Up To 100 Mbps Speed Best Internet Provider 2Jahidul Hasan NumanNo ratings yet

- Synopsis Movie Ticket BookingDocument18 pagesSynopsis Movie Ticket BookingRaj Bangalore17% (6)

- NEM326 HW 1 PDFDocument2 pagesNEM326 HW 1 PDFyaprak dönerNo ratings yet

- 5Document31 pages5Alex liao0% (1)

- PM Debug InfoDocument1,221 pagesPM Debug InfoRAMIRO MNo ratings yet

- Claire Churchwell - rhetORICALDocument7 pagesClaire Churchwell - rhetORICALchurchcpNo ratings yet