SPP1 Jacket Inplace Analysis Report

Uploaded by

AnjuSPP1 Jacket Inplace Analysis Report

Uploaded by

AnjuPage

1 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

SPP1 JACKET INPLACE ANALYSIS

Sections modified under this revision (for details see page 2): 1

D0 14/01/2002 SNS NBR KHSS ISSUE FOR REVIEW & COMMENTS

Rev Date Name Signature Name Signature Name Signature STATUS

DD/MM/YY WRITTEN CHECKED APPROVED

REVISIONS

Sections changed in last revision are identified by a line in the right margin

RE: SPP1 JACKET INPLACE ANALYSIS

Page

2 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

REVISION HISTORY

Rev Section Modification

D0 Issued For Review & Comments

RE: SPP1 JACKET INPLACE ANALYSIS

Page

3 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

CONTENTS

SECTION PAGE

1.0 INTRODUCTION 5

2.0 SUMMARY 6

3.0 SCOPE 7

4.0 CODES, STANDARDS AND REFERENCES 8

5.0 PARAMETERS, AND CRITERIA 9

6.0 METHODOLOGY 12

7.0 RESULTS AND CONCLUSIONS 13

7.1 Loads and Weight Summary 13

7.2 Member Unity Check Summary 15

7.3 Joint Punching Shear Checks 16

7.4 Members Unity Check Plots 17

7.5 Deflected Shape Plots 18

7.6 Pile Load Summary 19

8.0 RECOMMENDATIONS 20

9.0 APPENDIX –A: ANALYSIS MODEL

9.1 Computer Model

9.1.1 Model Plots

9.1.2 Material Properties

9.1.3 Member Effective Lengths

9.1.4 Mmeber Offsets

9.1.5 Corrosion Allowance

9.1.6 Contingencies

RE: SPP1 JACKET INPLACE ANALYSIS

Page

4 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.2 Applied Loads and Hydrostatic Properties

9.3 Input Data Files

9.4 Cd and Cm Calculations

9.5 Selection of Wave Theories

9.6 Calculation of DAF

10.0 APPENDIX B : COMPUTER OUTPUT RESULTS

10.1 Seastate Output

10.2 Member Unity Check Output

10.3 Joint Punching Shear Check Output

10.4 Hydrostatic Collapse Check Output

10.5 PSI Output and Plots

10.6 Dynamic Analysis Inputs and Outputs

11.0 APPENDIX C : REFERENCE DRAWINGS

12.0 APPENDIX D : EXTRACT FROM SOIL INVESTIGATION REPORT

RE: SPP1 JACKET INPLACE ANALYSIS

Page

5 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

1.0 INTRODUCTION

Shell Exploration B. V. has awarded the EPICM contract for Soroosh and Nowrooz Fields

Development Project to NPCC. The project consists of following structures, which are to be installed

in the of Soroosh and Nowrooz fields:

Soroosh Field

- Soroosh Wellhead platform (SWP-2) topside.

- Soroosh Living Quarter Platform (SLQ) substructure and topside.

- Soroosh Production Platform (SPP-1) substructure and topside.

- Soroosh Production Platform 2 (SPP-2) substructure and topside.

- SWP-1 to SPP-1 bridge.

- SPP-1 to SPP-2 bridge.

- NPP-2 to NLQ bridge.

Nowrooz Field

- Nowrooz Wellhead platform (NWP-1) topside.

- Nowrooz Living Quarter Platform (NLQ) substructure and topside.

- Nowrooz Wellhead Production Platform 2 (NPP-2) substructure and topside.

- NPP-2 to NLQ bridge.

This document presents the Inplace Analysis for the SPP1 Jacket, located at a water depth of 41.2m.

The Document has the following sections:

Section 2 provides the summary and Section 3 gives scope of this document. Section 4 gives the list of

various codes, standards and references used in the analysis. Section 5 outlines the parameters and

criteria used. Section 6 gives the analysis methodology adopted. Section 7 contains the results and

conclusions. Recommendations are mentioned in Section 8. Computer modelling and design

parameters are defined in Appendix-A, computer output results are included in Appendix-B. Reference

drawings are included in Appendix-C. Extract from Soil Investigation Report is included in Appendix-D.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

6 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

2.0 SUMMARY

The jacket and pile structure is adequate for the in-service conditions of the platform in both operating

and extreme storm conditions. All the members and joints are safe for the loads considered.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

7 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

3.0 SCOPE

This report presents the in-place structural analysis of the jacket.

The deck members are included in the computer model together with the jacket in order to generate the

true stiffness of the platform, however results are not reported for the deck structure in this report.

The main objective of the analysis is to ensure that the structural configuration and the constituent

elements satisfy Strength, Stability and Serviceability criteria as laid down in the Structural Design

Specification and the Design Codes.

Following miscellaneous designs are included in a separate report under the heading SPP1 Jacket

Miscellaneous Design document no.111-M-RP-55013.

a) Vortex Shedding and Wave Slam Checks

b) Crown shim Plate Design

RE: SPP1 JACKET INPLACE ANALYSIS

Page

8 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

4.0 CODES, STANDARDS AND REFERENCES

The platform has been designed in accordance with the latest editions and related amendments of the

following:

4.1 API-RP 2A, Latest Edition, “ Recommended Practice for Planning, Designing & Constructing Fixed

Offshore Platforms (WSD)”.

4.2 AISC, 9th Edition, “ Manual of Steel Construction “ Allowable Stress Design.

4.3 SACS (Structural Analysis Computer Software) Release 5.1.

4.4 Specification for Structural Design , SHELL Document No. NS/EST/SP/G0XX/03261/D4 Rev. D4.

4.5 Geotechnical Data and Engineering Analysis for the Soroosh Field, Soroosh-Norooz Integrated

Development, Persian Gulf, Report No. N-3851/01.

4.6 Structural Design Specification issued by TP Doc. No. NS/EST/DB/G0XX/50001/D0, Rev-D0

4.7 Following NPCC Drawings:

111-M-55721 : Framing Elevation at Row A

111-M-55722 : Framing Elevation at Row B

111-M-55723 : Framing Elevation at Row 1

111-M-55724 : Framing Elevation at Row 2

111-M-55725 : Framing Elevation at Row 3

111-M-55726 : Framing Plan @ EL. (+) 6.000m

111-M-55727 : Framing Plan @ EL. (-) 10.000m

111-M-55728 : Framing Plan @ EL. (-) 25.100m

111-M-55729 : Framing Plan @ EL. (-) 40.885m

111-M-55740 : Pile Make-up and Details

RE: SPP1 JACKET INPLACE ANALYSIS

Page

9 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

5.0 PARAMETERS AND CRITERIA

The analysis has been performed in accordance with the Structural Design Specification Document No.

NS/EST/SP/GOXX/03261/D4, Rev. D4, Codes and Reference as mentioned and limited to the

following considerations:

5.1 Only main framing and secondary members of the structure that contributes to the global stiffness of

the structure are included in the analysis.

5.2 The topside structural framing members are included in the model in order to simulate the global

stiffness of the platform. Boat landing members are considered as dummy or non-structural elements,

which are modeled for the purposes of calculating environmental forces only. Risers are modeled as

appurtenance structure. The hydrodynamic loads on these appurtenance structures are transferred to

the jacket members and the appurtenances are deleted after the load transfer.

5.3 All applied loads and its combinations foreseen during the life of the structure have been considered as

specified in the Loads and Load Combination Table of the Structural Design Specification.

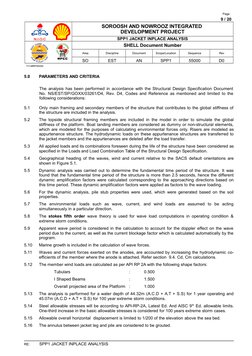

5.4 Geographical heading of the waves, wind and current relative to the SACS default orientations are

shown in Figure 5.1.

5.5 Dynamic analysis was carried out to determine the fundamental time period of the structure. It was

found that the fundamental time period of the structure is more than 2.5 seconds, hence the different

dynamic amplification factors were calculated corresponding to the approaching directions based on this

time period. These dynamic amplification factors were applied as factors to the wave loading.

5.6 For the dynamic analysis, pile stub properties were used, which were generated based on the soil

properties.

5.7 The environmental loads such as wave, current, and wind loads are assumed to be acting

simultaneously in a particular direction.

5.8 The stokes fifth order wave theory is used for wave load computations in operating condition &

extreme storm conditions.

5.9 Apparent wave period is considered in the calculation to account for the doppler effect on the wave

period due to the current, as well as the current blockage factor which is calculated automatically by the

program.

5.10 Marine growth is included in the calculation of wave forces.

5.11 Waves and current forces exerted on the anodes, are accounted by increasing the hydrodynamic co-

efficients of the member where the anode is attached. Refer section 9.4. Cd, Cm calculations.

5.12 The member wind loads are calculated as per API RP 2A with the following shape factors:

Tubulars : 0.500

I Shaped Beams : 1.500

Overall projected area of the Platform : 1.000

5.13 The analysis is performed for a water depth of 44.32m (A.C.D + A.T + S.S) for 1 year operating and

45.07m (A.C.D + A.T + S.S) for 100 year extreme storm conditions.

5.14 Steel allowable stresses will be according to API-RP-2A, Latest Ed. And AISC 9 th Ed. allowable limits.

One-third increase in the basic allowable stresses is considered for 100 years extreme storm cases.

5.15 Allowable overall horizontal displacement is limited to 1/200 of the elevation above the sea bed.

5.16 The annulus between jacket leg and pile are considered to be grouted.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

10 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

5.17 The analysis has been performed using Pile-Soil-Structure interaction facility available in the SACS

software. Non linear simulation of the pile elements are considered.

5.18 Contingency on the weights is considered as mentioned in the structural design specification. Details

are provided in Section 9.1.6.

5.19 Equipment, Piping, Electrical & Instrumentation weights are considered both for the present and future

equipment. Operating contents weight is considered under a separate load case.

5.20 An air gap of 1.5m between the bottom portion of the lower deck beam and the to of 100 year wave

crest is maintained.

5.21 Wind speed for 1 minute average for 100 year and 1 year storm is considered for the Jacket In-service

Analysis.

5.22 3 Nos. of 16” risers & 1 No. of 8” riser, 1 No. of 10” J-tube and 1 No. of 24” cassion are modeled as

appurtenances structure. The risers do no participate in the stiffness of structure. They are deleted after

the load transfer. The J-tube is connected to the jacket members by welded connection.

5.23 SPP1 jacket location soil data is considered in preparing the P-Y, T-Z & Q-Z data for PSI input file.

5.24 Wave theories were selected based on the API-RP-2A criteria and included in section 9.0.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

11 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

Figure 5.1: Wind, Wave and Current Directions

RE: SPP1 JACKET INPLACE ANALYSIS

Page

12 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

6.0 METHODOLOGY

The structural analysis for SPP1 platform has been performed using SACS (Structural Analysis

Computer System ) program modules. The main input files compatible to SACS to run the analysis are:

The model input file-which contains general information of the computer model viz., the geometry,

member sizes, materials, loads and load combinations and analysis options.

The following SACS Program Modules have been used:

The “ SEASTATE” module has been used to generate dead weight and buoyancy of the modeled

members. It also computers environmental loading (wave, current and wind) on the structure . The

SEASTATE run will finally combine basic load cases (users input or generated) to from various load

combinations required in the analysis.

The “SACS IV” which refers to three of the program modules of SACS system, namely the pre-

processor, the solver and the post-processor modules perform the general purpose static structural

analysis.

The inplace analysis has been carried out for the maximum water depth only, however, the buoyancy

has been calculated based on the lowest water depth i.e to get the maximum axial load on the piles. In

the analysis, minimum water depth has not been considered, since the tension load for the pile is not

the governing criteria for this platform.

The member and joint code checks based on API-RP- 2A and AISC codes are finally evaluated.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

13 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

7.0 RESULTS AND CONCLUSIONS

The structural members and joints of the SPP1 Jacket as shown in the structural arrangement drawings

enclosed in Section 11.0 have been checked for global in-service analysis during normal operating

storm and extreme storm conditions. The following results are obtained:

- All AISC member stress ratios and pile stress ratios are lower than 1.00.

- All API joint punching ratios are lower than 1.00.

- All deflections are within allowable limits.

- The vertical pile penetration is 80.0m.

Therefore, all structural members of the jacket have adequate size to withstand the imposed design

loads on the structure.

7.1 Loads and Weight Summary

Load Weight Excluding

Description Load ID

Case Contingency (KN)

D001 Dead and buoyancy loads of main structure DS1-DRY

40980.863

J001 Jacket non modelled weight

i) Anodes (submerged wt.) (168 nos.) ANNODE 436.8

ii) Crown shim plates CROWN-PL 63.0

iii) Lifting & Upending eyes UPEN-EYE 50.0

iv) Mudmat plates and sections (submerged wt.)

MUDMAT 637.13

v) Riser Clamps RISERCL 80.0

vi) Pile spacers PILSPACR 14.4

vii) Grating and handrail on top of jacket 51.21

JKT-WALK

ix) Grout Lines GRUTLINE 101.27

x) Riser dead wt (16”), 3 Nos RISER-DW 226.8

ix) Riser dead wt (8”) RISER-DW 32.2

TOTAL 1692.82

D002 Deck secondary structure DS2-DRY 6853.9

D003 Deck tertiary structure dry DS3-DRY 733.4

Total Dry Weight of Structure 50261.0

Total Gross Dry Weight of Structure with Contingency ( 15 % ) 57800.00

D004 Deck architectural bulk dry DAB-DRY 1775.8

D005 Deck electrical bulk dry DEB-DRY 866.4

D006 Deck HVAC bulk dry DHB-DRY 96.0

D007 Deck instrumentation bulk DIB-DRY 384.64

D008 Deck piping bulk DPB-DRY 10339.5

D009 Deck piping bulk content DPB-CON 2872.71

RE: SPP1 JACKET INPLACE ANALYSIS

Page

14 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

D010 Deck safety bulk dry DSB-DRY 96.42

D011 Deck bridges dry weight DBG-DRY 2365.04

D012 Deck bridges content DBG-CON 568.0

D013 Deck primary structure DS1-CON 210.0

D014 Flare piping bulk dry FPB-DRY 149.4

D015 Deck mechanical item- dry DMI-DRY 21637.4

D016 Deck mechanical item- content DMI-CON 16617.6

D017 Deck mechanical item- future DMI-FUT 4385.1

D018 Deck mechanical item- dry DEI-DRY 511.93

D019 Deck safety item dry DSI-DRY 25.51

D020 Deck safety item-content DSI-CON

D021 Cellar deck live load D-LL-CD 14009.4

D022 Flare live load F-LL 324.0

D025 Deck wind operating along –X DWOP-X 1337.84

D026 Deck wind operating –Y DWOP-Y 1031.68

D027 Deck crane lifted object DCRN-X 9182.1 KN-M

D028 Deck crane lifted object DCEN-Y 9182.1 KN-M

D034 Deck crane lifted object DCRN-W 306.1

D035 Deck boom moment along - X DCB-X 7210.4 KN-M

D036 Deck boom moment along –Y DCB-Y 7210.4 KN-M

D037 Deck secondary structure DS2-FUT 323.83

D038 Deck live load on laydown D-LL-L 11214.7

D039 Cellar deck live load –future D-LL-CDF 325.76

D040 Mezzanine deck live load D-LL-MZ 13333.3

D041 Main deck live load – future D-LL-MDF 2568.95

D042 Main deck live load D-LL-MD 19043.87

D043 Weather deck live load – future D-LL-WDF 728.1

D044 Weather deck live load D-LL-WD 7347.3

D049 Deck instrumentation- dry DII-DRY 81.73

D050 Deck wind operating future DXOP-X-F 95.6

D051 Deck main structure future DS1-FUT 60.0

D053 Flare mechanical item – dry FMI-DRY 19.62

D054 Flare piping bulk- content FPB-CON 29.88

D055 Flare wind operating along-X FWOP-X 126.62

D056 Flare wind operating along-Y FWOP-Y 126.62

Total Dry Weight of Equipment 38349.4

Total Gross Dry Weight of Equipment with Contingency ( 20 % ) 46019.3

Total Content Weight of Equipment 24989.3

Total Gross Content Weight of Equipment with Contingency ( 20 % ) 29987.2

Total Net Weight 113599.7

Total Gross Weight 133806.5

RE: SPP1 JACKET INPLACE ANALYSIS

Page

15 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

7.2 Member Unity Check Summary

The following pages are extract from the computer output results showing the maximum unity check

for each member group of the jacket. Maximum UCR value for jacket members is 0.773 and for piles it

is 0.81.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

16 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

7.3 Joint Punching Shear Checks

The following pages are extract from the computer output results showing the punching shear check

for all tubular joint connections of the jacket.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

17 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

7.4 Members Unity Check Plots

The following pages show the plots of maximum unity check ratio > 0.4 each member at plan and

elevation view of the jacket.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

18 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

7.5 Deflected Shape Plots

The following pages show deflected shape plots of the platform for various load combinations which

gives maximum deflection. The maximum permissible horizontal displacement is /200, i.e., 125.0

m/200 = 62.50 cm > 57.20 cm ( load combination C021 ), hence O.K.

The maximum deflection in the deck main truss joint is 15.5 cm.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

19 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

7.6 Pile Load Summary

The following pages are extract from the computer output results showing the maximum pile head

forces and ultimate load. The vertical pile penetration is 80.0m obtained from the ultimate axial pile

capacity curves.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

20 / 20

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

8.0 RECOMMENDATIONS

The jacket members (legs, cans & braces and the piles ) are safe for the in-service condition of the

platform based of on the soil data of SPP1 location.

Though 76m of penetration is sufficient for pile capacity mobilisation, the piles are provided up to 80m

penetration to allow for any subsequent increase in loads or for checking against Earthquake loads.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.0 APPENDIX –A: ANALYSIS MODEL

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.1 Computer Model

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.1 Computer Model

The jacket including the deck is modeled into a geometrical space frame as one combined structure

consisting of joints and elements. All primary and secondary members of the structure are modeled

except those members that do not contribute to the structural stiffness. These members are accounted

as joint or member loads.

Boat landing members are modeled as dummy members. These members transfer the dead and

hydrodynamic loads onto the jacket members without participating in the analysis. The risers are

modeled as appurtenance structures. The appurtenance structures transfer only hydrodynamic loads

onto the jacket. The density of these appurtenance members are given very small. The riser gravity

loads are applied as joint loads at the hanger clamp location.

9.1.1 Model Plots

The analysis model consist of combined structure of the jacket and the topside. The following pages

show the plots of joint and members of the jacket.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

Group Label Plots

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

Joint Number Plots

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.1.2 Material Properties

Material properties of the steel are input in the group card of the SACS input file to be used in the

calculation of allowable stresses of the member.

Member Category Material Type Yield Strength (MPa)

Joint Cans BS 7191 355 EMZ 345

355 16mm

Saw Tubulars BS 7191 355C/E

345, 16 < T < 40

Seamless Tubulars BS 7191 355C/E 355 16mm

345, 16 < T < 40

Young’s Modulus = 21000 Kn/cm2

Poisson’s Ratio = 0.30

Shear Modulus = 7890 Kn/cm2

Steel Density in air = 77.00 Kn/m3

9.1.3 Member Effective Length

The effective buckling length of the member used in the calculation of axial allowable compressive

stresses are in accordance with the recommendation of API-RP-2A. These factors are input relative to

its local Y and Z axes of the member. The effective buckling length is calculated as the K-factor

multiplied by the unbraced length of the member relative to in-plane or out-of-plane buckling.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.1.4 Member Offsets

Offsets of the member showing eccentricities from the centreline are defined in the model. When these

members are offset, the program creates a rigid link between the neutral axis of the member end and

the joint where it is connected, thus the internal stresses will be transferred completely to that joint.

9.1.5 Corrosion Allowance

Steel corrosion allowance of 6mm is applied to the jacket legs and diagonal bracings at the splash

zone area, i.e. between (+) 4.75 m and (-) 0.81 m levels. Tubular properties where corrosion

allowance is applicable is calculated as follows:

Outside diameter = uncorroded outside dia - 2T

Wall thickness = uncorroded wall thickness - T

where, T = corrosion allowance, i.e., 6mm for jacket legs and brace members

The weight of the members in the splash zone is considered same as that of the uncorroded

members, by increasing the density of the particular segment.

9.1.6 Contingencies

Suitable contingencies as mentioned in the structural design specification are considered

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.2 Applied Loads and Hydrostatic Properties

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.2 Applied Loads and Hydrostatic Properties

9.2.1 Computer Generated Load

This includes the modeled structural weight of the jacket and topside including the effect of buoyancy

and marine growth. The weight of the risers are included under the non-generated dead loads. The

density of the risers are given very low value, so that the weight contribution is removed.

Buoyancy of the jacket is calculated based on the water depth of 41.2 m.

The water depth calculated for the calculation of the for the current and wave forces is as given

below :

For Storm condition

Water Depth w.r.t. LAT = 41.20 m

Astronomical tide = 3.87 m

and Storm tide

Total water depth for storm condition = 45.07 m

For Operating condition

Water Depth w.r.t. LAT = 41.20 m

Astronomical tide = 3.12 m

and Storm stide

Total water depth for storm condition = 44.32 m

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.2.2 Jacket Non-Generated Load

These loads refer to the weight of the items of the jacket that are not modeled. These items are

considered as joint or member loads acting vertically in the direction of the gravity. The details of these

loads are provided in section 7.1.

9.2.3 Topside Loads

The topside model and loads are prepared by Technip (POC) as the topside design is in their scope

and forwarded to NPCC for stitching it to the jacket. These loads refer to the weight of the items of the

topside that are not modeled. These items are considered as joint or member loads acting vertically in

the direction of the gravity. The details are provided in section 7.1.

9.2.4 Equipment Dry Weight

All the equipment dry and operating weights, piping dry and operating weights are given in section 7.1.

9.2.5 Live Loads

The live loads have been considered as per the Structural Design Specification.

9.2.6 Environmental Loads

Waves

100 year wave direction (directions from)

Heading(from) N NE E SE S SW W NW

Height(m) 8.50 5.40 5.70 10.20 7.30 5.60 6.40 11.0

Period(s) 10.10 8.40 8.60 10.90 9.50 8.50 9.00 11.30

1 year wave direction (directions from)

Heading(from) N NE E SE S SW W NW

Height(m) 2.30 2.10 1.70 6.50 1.80 1.60 3.60 5.40

Period(s) 6.30 6.10 5.80 9.10 5.80 5.70 7.20 8.40

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

Currents

Current Velocity m/sec (100 year storm)

Heading(to) N NE E SE S SW W NW

Surface 0.552 0.298 0.563 1.070 0.662 0.331 0.442 0.795

Mid depth 0.500 0.270 0.510 0.970 0.600 0.300 0.400 0.720

Sea Bed 0.324 0.175 0.330 0.630 0.390 0.195 0.260 0.467

Current Velocity m/sec (1 year operating)

Heading(to) N NE E SE S SW W NW

Surface 0.441 0.232 0.419 0.880 0.519 0.265 0.364 0.662

Mid depth 0.400 0.210 0.380 0.800 0.470 0.240 0.330 0.600

Sea Bed 0.260 0.136 0.246 0.520 0.305 0.155 0.214 0.390

Wind :

Wind Velocity m/sec (100 year storm) @ 10 m

Heading(from) N NE E SE S SW W NW

V1min 24.9 22.5 23.6 30.5 27.0 20.6 24.0 31.5

Wind Velocity m/sec (1 year operating) @ 10 m

Heading(from) N NE E SE S SW W NW

V1min 15.5 10.4 16.3 20.1 11.8 10.8 16.2 20.0

Figure 5.1 shows the schematic diagram of the approach of wind, current, and waves relative to the

SACS default coordinates and structure origin. 8 directions are considered in the analysis which

corresponds to 8 environmental load cases. Wind, current and waves are assumed to be acting

simultaneously.

9.2.7 Marine Growth

All submerged members of the jacket are exposed to marine growth as follows:

From (+) 3.00 to (-) 2.50 = 25 mm Radial

From (-) 2.5 to (-) 41.2 = 12.5 mm Radial

9.2.8 Hydrodynamic Coefficients

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

Basic Drag and Inertia coefficients used to evaluate wave forces on cylindrical surfaces are as follows:

Smooth Surface Rough Surface

Drag Coefficient Cd 0.65 1.05

Inertia Coefficient Cm 1.60 1.20

Wave and current forces exerted on the anodes are accounted by increasing the coefficient of drag

and inertia of the member where the anodes are attached.

Wave and current forces exerted on the gratings, handrails and other non-modelled members are also

accounted for, by increasing the Cd and Cm values of the tubular members. The details are provided

in section 9.4.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.2.9 Load Cases and Load Combination Table

Basic load cases and their combinations are tabulated in the following table. The load combinations

used in the analysis combine topsides loads and environmental loads.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

SPP1 PLATFORM

BASIC LOAD CASES AND COMBINATIONS

LOAD DESCRIPTION % FOR COMBINATION NUMBER

CASE C001 C002 C003 C004

#

D001 Dead and Buoyancy loads of 100

main structure

J001 Jacket non modeled weight 100

D002 Deck secondary structure 100

D003 Deck tertiary structure dry 100

D004 Deck architectural bulk dry 100

D005 Deck electrical bulk dry 100

D006 Deck HVAC bulk dry 100

D007 Deck instrumentation bulk 100

D008 Deck piping bulk 100

D009 Deck piping bulk content 100

D010 Deck safety bulk dry 100

D011 Deck bridges dry weight 100

D012 Deck bridges content 100

D013 Deck primary structure 100

D014 Flare piping bulk dry 100

D015 Deck mechanical item- dry 100

D016 Deck mechanical item- 100

content

D017 Deck mechanical item- future 100

D018 Deck mechanical item- dry 100

D019 Deck safety item dry 100

D020 Deck safety item-content 100

D021 Cellar deck live load 100

D022 Flare live load 100

D034 Deck crane lifted object 100

D035 Deck boom moment along - X

D036 Deck boom moment along –Y

D038 Deck live load on laydown 100

D039 Cellar deck live load –future 100

D040 Mezzanine deck live load 100

D041 Main deck live load – future 100

D042 Main deck live load 100

D043 Weather deck live load - future 100

D044 Weather deck live load 100

D049 Deck instrumentation- dry 100

D053 Flare mechanical item - dry 100

D054 Flare piping bulk- content 100

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

SPP1 PLATFORM

ADDITIONAL LOAD COMBINATIONS

LOAD DESCRIPTION % FOR COMBINATION NUMBER

CASE C005 C006 C007 C008 C009 C010

#

D025 Wind operating along -X 100

D026 Wind operating along -Y 100

D055 Flare wind operating along - X 100

D056 Flare wind operating along - Y 100

C001 Self weight of structure 115 110

C002 Dry weight of equipment 120 120

C003 Weight of contents 120 120

C004 Live load 35 25

C005 Total operating load

C006 Total storm load

C007 Operating Wind load -X 245.6

C008 Operating Wind load – Y 245.6

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

SPP1 PLATFORM

LOAD COMBINATIONS FOR OPERATING STORM CONDITIONS

LOAD DESCRIPTION % FOR COMBINATION NUMBER

CASE C011 C012 C013 C014 C015 C016 C017 C018

#

D035 Deck boom moment along - X 100 70.7 -70.7 -100 -70.7 70.7

D036 Deck boom moment along –Y 70.7 100 70.7 -70.7 -100 -70.7

E001 Environmental-operating-0.0 deg 113.1

E002 Environmental-operating-45 deg 124.1

E003 Environmental-operating-90 deg 156.1

E004 Environmental-operating-135 deg 143.0

E005 Environmental-operating-180 deg 111.0

E006 Environmental-operating-225 deg 143.0

E007 Environmental-operating-270deg 145.7

E008 Environmental-operating-315 deg 141.6

C005 Total operating load 100 100 100 100 100 100 100 100

C007 Operating wind - X 100 70.7 -70.7 -100 -70.7 70.7

C008 Operating wind -Y 70.7 100 70.7 -70.7 -100 -70.7

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

SPP1 PLATFORM

LOAD COMBINATIONS FOR EXTREME STORM CONDITIONS

LOAD DESCRIPTION % FOR COMBINATION NUMBER

CASE C021 C022 C023 C024 C025 C026 C027 C028

#

D035 Deck boom moment along - X 100 70.7 -70.7 -100 -70.7 70.7

D036 Deck boom moment along –Y 70.7 100 70.7 -70.7 -100 -70.7

E011 Environmental-storm-0.0 deg 106.8

E012 Environmental-storm-45 deg 114.0

E013 Environmental-storm-90 deg 119.3

E014 Environmental-storm-135 deg 112.4

E015 Environmental-storm-180 deg 107.4

E016 Environmental-storm-225 deg 115.6

E017 Environmental-storm-270deg 119.9

E018 Environmental-storm-315 deg 113.0

C006 Total storm load 100 100 100 100 100 100 100 100

C009 Storm wind - X 100 70.7 -70.7 -100 -70.7 70.7

C010 Storm wind - Y 70.7 100 70.7 -70.7 -100 -70.7

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.3 Input Data Files

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.3.1 SACS Input Data File

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.3.2 PSI Input Data File

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.4 Cd and Cm Calculations

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.5 Selection of Wave Theories

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

SELECTION OF WAVE THEORY

ONE YEAR OPERATING STORM CASE

From Wave Time Water Surface V1/gT D/ Tapp/T Tapp D/gTapp2 H/gTapp2 Applicable

ht H period T depth D current gT2 wave theory

(m) (sec) (m) velocity

V1(m/sec)

N 2.3 6.3 44.32 0.519 0.0084 0.114 1.049 6.61 0.103 0.0054 Stokes 5th

NE 2.1 6.1 44.32 0.265 0.004 0.121 1.026 6.26 0.115 0.0055 Stokes 5th

E 1.7 5.8 44.32 0.364 0.006 0.134 1.038 6.02 0.125 0.0048 Stokes 5th

SE 6.5 9.1 44.32 0.662 0.0074 0.05 1.044 9.5 0.05 0.007 Stokes 5th

S 1.8 5.8 44.32 0.441 0.008 0.134 1.052 6.1 0.121 0.0049 Stokes 5th

SW 1.6 5.7 44.32 0.232 0.004 0.139 1.025 5.84 0.132 0.0048 Stokes 5th

W 3.6 7.2 44.32 0.419 0.006 0.09 1.035 7.45 0.08 0.0066 Stokes 5th

NW 5.4 8.4 44.32 0.880 0.011 0.06 1.062 8.92 0.06 0.0069 Stokes 5th

100 YEAR EXTREME STORM CASE

From Wave Time Water Surface V1/gT D/gT2 Tapp/ Tapp D/gTapp2 H/gTapp2 Applicable

ht H period T depth D current T wave theory

(m) (sec) (m) velocity

V1(m/sec)

N 8.5 10.1 45.07 0.662 0.007 0.05 1.04 10.51 0.04 0.0078 Stokes 5th

NE 5.4 8.4 45.07 0.331 0.004 0.07 1.024 8.60 0.06 0.0074 Stokes 5th

E 5.7 8.6 45.07 0.442 0.005 0.06 1.032 8.87 0.058 0.0074 Stokes 5th

SE 10.2 10.9 45.07 0.795 0.0074 0.04 1.046 11.4 0.035 0.008 Stokes 5th

S 7.3 9.5 45.07 0.552 0.006 0.05 1.036 9.84 0.047 0.0077 Stokes 5th

SW 5.6 8.5 45.07 0.298 0.004 0.05 1.021 8.68 0.06 0.0076 Stokes 5th

W 6.4 9.0 45.07 0.563 0.006 0.06 1.038 9.34 0.053 0.0075 Stokes 5th

NW 11.0 11.3 45.07 1.07 0.009 0.04 1.059 11.97 0.032 0.0078 Stokes 5th

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

9.6 Calculation of DAF

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

10.0 APPENDIX B : COMPUTER OUTPUT RESULTS

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

10.1 Seastate Output

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

10.2 Member Unity Check Output

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

10.3 Joint Punching Shear Check Output

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

10.4 Hydrostatic Collapse Check Output

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

10.5 PSI Output and Plots

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

10.6 Dynamic Analysis Inputs and Outputs

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

11.0 APPENDIX C : REFERENCE DRAWINGS

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

PILE SELF WEIGHT CALCULATION

PILE DIA(CM) THICKNESS(CM) LENGTH(M) UNIT WT.(KG/M) WEIGHT(KN)

182.9 5.0 20.0 2194.0 438.8

182.9 3.0 60.0 1331.0 798.6

TOTAL 1237.4

WEIGHT OF THE SOIL PLUG = 1784.0 KN

SO, TOTAL WEIGHT = 1237.4+1784.0=3021.4 KN =3.1 MN

100 YEAR STORM CASE – GOVERNING COMPRESSIVE LOADS (MN)

A1 A2 A3 B1 B2 B3

PILE JOINT NUMBERS 101 109 119 181 189 199

MAXIMUM COMPRESSIVE LOAD (MN) 29.7 27.7 29.7 34.99 32.31 34.1

SELF WEIGHT (MN) 3.1 3.1 3.1 3.1 3.1 3.1

FACTOR OF SAFETY ( required ) 1.5 1.5 1.5 1.5 1.5 1.5

ULTIMATE LOAD (MN) 47.65 44.65 47.65 55.59 49.97 54.25

ULTI. AXIAL PILE CAP. AT 80 M DEPTH (MN) 74.0 74.0 74.0 74.0 74.0 74.0

F.O.S AVAILABLE 2.39 2.56 2.39 2.03 2.09 2.08

1 YEAR STORM CASE – GOVERNING COMPRESSIVE LOADS (MN)

A1 A2 A3 B1 B2 B3

PILE JOINT NUMBERS 101 109 119 181 189 199

MAXIMUM COMPRESSIVE LOAD (MN) 28.1 27.2 25.4 32.4 32.00 30.1

SELF WEIGHT (MN) 3.1 3.1 3.1 3.1 3.1 3.1

FACTOR OF SAFETY ( required ) 2.0 2.0 2.0 2.0 2.0 2.0

ULTIMATE LOAD (MN) 59.3 43.9 53.9 67.9 67.1 48.25

ULTI. AXIAL PILE CAP. AT 80 M DEPTH (MN) 74.0 74.0 74.0 74.0 74.0 74.0

F.O.S AVAILABLE 2.52 2.6 2.79 2.19 2.2 2.35

SO. THE VERTICAL PILE PENETRATION PROVIDED OF 80.0 M IS O.K.

RE: SPP1 JACKET INPLACE ANALYSIS

Page

SOROOSH AND NOWROOZ INTEGRATED

DEVELOPMENT PROJECT

SPP1 JACKET INPLACE ANALYSIS

SHELL Document Number

Area Discipline Document Scope/Location Sequence Rev

SO EST AN SPP1 55000 D0

111-MRP55000

12.0 APPENDIX D :

EXTRACT FROM SOIL INVESTIGATION REPORT

RE: SPP1 JACKET INPLACE ANALYSIS

You might also like

- On-Bottom Stability Check of Wellhead Jacket in Gulf of Thailand - Offshore Structural CornerNo ratings yetOn-Bottom Stability Check of Wellhead Jacket in Gulf of Thailand - Offshore Structural Corner17 pages

- Inplace Analysis: Check Print For Submission To Client As RequiredNo ratings yetInplace Analysis: Check Print For Submission To Client As Required4 pages

- Wave-Induced Fatigue in Offshore StructuresNo ratings yetWave-Induced Fatigue in Offshore Structures14 pages

- Computer Program for Jacket Structure Analysis100% (2)Computer Program for Jacket Structure Analysis25 pages

- Check List For Jacket Lift & Upending Analysis: Project Client Model File NameNo ratings yetCheck List For Jacket Lift & Upending Analysis: Project Client Model File Name2 pages

- On Bottom Stability Analysis and Mudmat DesignNo ratings yetOn Bottom Stability Analysis and Mudmat Design9 pages

- Dropped Object To Using The Non-Linear Dynamic AnalysisNo ratings yetDropped Object To Using The Non-Linear Dynamic Analysis18 pages

- Joint Numbering Checklist for EngineeringNo ratings yetJoint Numbering Checklist for Engineering3 pages

- REFERENCE - Fatigue Assessment Analysis of Offshore StructuresNo ratings yetREFERENCE - Fatigue Assessment Analysis of Offshore Structures20 pages

- Rise Up Boat Landing - Tla - Rev 0 - LatestNo ratings yetRise Up Boat Landing - Tla - Rev 0 - Latest12 pages

- Notes On SACS Ring Analysis - For UsersNo ratings yetNotes On SACS Ring Analysis - For Users14 pages

- Offshore Structures Strength Assessment Guide100% (1)Offshore Structures Strength Assessment Guide77 pages

- Offshore Jacket Platform Static AnalysisNo ratings yetOffshore Jacket Platform Static Analysis11 pages

- Check List For Jacket Seismic Analysis: Revision Originator Date Checker Date Revision Originator Date Checker DateNo ratings yetCheck List For Jacket Seismic Analysis: Revision Originator Date Checker Date Revision Originator Date Checker Date2 pages

- Pile Group Effects in Offshore Engineering100% (1)Pile Group Effects in Offshore Engineering46 pages

- C004B-MFP-STR-01 Loadout Coordination Manual For MFP Jacket, Piles & Deck Rev. 0100% (2)C004B-MFP-STR-01 Loadout Coordination Manual For MFP Jacket, Piles & Deck Rev. 0142 pages

- CD CM Overrides For Report Conductor Shielding Factor100% (1)CD CM Overrides For Report Conductor Shielding Factor2 pages

- Offshore Platform Design Analysis ReportNo ratings yetOffshore Platform Design Analysis Report60 pages

- FE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (2) - MMC Oil & Gas EngineeringNo ratings yetFE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (2) - MMC Oil & Gas Engineering2 pages

- Principles and Applications of Geometric Proportions in Architectural DesignNo ratings yetPrinciples and Applications of Geometric Proportions in Architectural Design7 pages

- Linear Transformation of Poisson Distribution: DR Richard KenderdineNo ratings yetLinear Transformation of Poisson Distribution: DR Richard Kenderdine4 pages

- Linear and Quadratic Functions ExercisesNo ratings yetLinear and Quadratic Functions Exercises3 pages

- General Training Listening Answers 1 - 5No ratings yetGeneral Training Listening Answers 1 - 51 page

- Solid Slab Superstructure - 11.4m Span Design LRFD-1No ratings yetSolid Slab Superstructure - 11.4m Span Design LRFD-120 pages

- EMATA, JENNIE MAE U. (Kinetics of Particles Newton's 2nd Law and Dynamic Equilibrium)No ratings yetEMATA, JENNIE MAE U. (Kinetics of Particles Newton's 2nd Law and Dynamic Equilibrium)10 pages

- Examination Guidelines for Metal FormingNo ratings yetExamination Guidelines for Metal Forming6 pages

- 02 Shaft Grouted Frictional Minipile (2017)No ratings yet02 Shaft Grouted Frictional Minipile (2017)2 pages

- First Semester Final Examination Timetable Fas, Fast, Fesh and Feng 20 - 24 October 2025No ratings yetFirst Semester Final Examination Timetable Fas, Fast, Fesh and Feng 20 - 24 October 20257 pages

- Practical Schedule of BSCG & BSCM For TEPE 2025No ratings yetPractical Schedule of BSCG & BSCM For TEPE 20252 pages

- Continuous-Time Signal Frequency AnalysisNo ratings yetContinuous-Time Signal Frequency Analysis14 pages

- Light Reflection and Refraction ActivitiesNo ratings yetLight Reflection and Refraction Activities2 pages