Professional Documents

Culture Documents

Method of Statement - Refrigerant Pipes

Uploaded by

Tiam Yee YongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method of Statement - Refrigerant Pipes

Uploaded by

Tiam Yee YongCopyright:

Available Formats

Method of Statement

Pressure (Leak) Test for Copper Refrigerant Pipes by Using Gas Nitrogen

1. At the indoor position, one end of the copper pipes to be sealed by clamping and welding.

Then, an access valve to be brazed to the other end of the copper pipes.

2. At the outdoor unit position, the suction and discharge copper pipes will be jointed

together by brazing a u-shape copper to the end of the pipes.

3. A pressure gauge is used to measure the pressure reading of the Gas Nitrogen. Connect

one charging hose to the access valve at the copper pipe and another charging hose to the

regulator of the nitrogen tank.

4. Open the regulator valve at the nitrogen tank. Open the charging valve at the pressure

gauge slowly to release the Gas Nitrogen into the copper pipe. When the pressure reading

reaches at 250 psi, close both the charging valve and regulator. Disconnect the charging

hose from the regulator.

For capillary tube, which located at the condensing unit (for 1 HP to 2.5 HP), the suction

and discharge pressure are as follow:

Suction pipe: 70 psi.

Discharge pipe: 140 psi.

5. For 3.0 HP and above, where the capillary tube is located at the indoor unit the test

pressure will be 300 psi.

6. Take the initial pressure reading. After 4 hours, take the reading again. If there is no drop

or within 5% drop of the initial reading, the copper pipe is tested with no leakage.

7. If the pressure reading is drop more than 10% of the initial reading, check every brazing

point at the copper pipe to find out the leakage point and rectify the leakage point.

8. Repeat step 4 to step 7 to retest the copper pipe. If there is no drop or within 5% drop of

the initial reading, the copper pipe is tested with no leakage.

9. Disconnect the pressure gauge from the copper pipe. Repeat the same process for the

copper pipes for every air conditioner unit.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- IJA Carpark Vent CTLG PrintDocument8 pagesIJA Carpark Vent CTLG PrintTiam Yee YongNo ratings yet

- Guidelines On Dometic Gas Piping SystemDocument30 pagesGuidelines On Dometic Gas Piping Systemg00r100% (9)

- Lead Free: Series LFN223B, LFN223BSDocument2 pagesLead Free: Series LFN223B, LFN223BSTiam Yee YongNo ratings yet

- VRV4 0215 ADocument96 pagesVRV4 0215 ATiam Yee YongNo ratings yet

- Fire RequirementsDocument47 pagesFire Requirementsfaezah adnan100% (11)

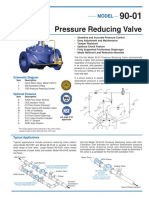

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModelTiam Yee YongNo ratings yet

- 1686-ML-Clean Agent & Fixed CO2-R00W00Document6 pages1686-ML-Clean Agent & Fixed CO2-R00W00Tiam Yee YongNo ratings yet

- 20141110-1686-ML-HR Pump (High Zones-L18 To LRL) - R00W00Document5 pages20141110-1686-ML-HR Pump (High Zones-L18 To LRL) - R00W00Tiam Yee YongNo ratings yet

- PRV 2 PDFDocument4 pagesPRV 2 PDFTiam Yee YongNo ratings yet

- Inergen Gas SystemDocument2 pagesInergen Gas SystemTiam Yee YongNo ratings yet

- 1686 ML Sprinkler Pumps Sizing R00W00Document6 pages1686 ML Sprinkler Pumps Sizing R00W00Tiam Yee YongNo ratings yet

- Pool, Jacuzzi and Water Feature Design GuideDocument194 pagesPool, Jacuzzi and Water Feature Design GuideMiguel Angel100% (1)

- C6 01 SchematicsDocument11 pagesC6 01 SchematicsTiam Yee YongNo ratings yet

- 1686 ML Sprinkler Hydraulic Calculation R00W00Document7 pages1686 ML Sprinkler Hydraulic Calculation R00W00Tiam Yee YongNo ratings yet

- Essential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignDocument52 pagesEssential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignSyed ShahbazNo ratings yet

- Asme A112 19 8M 1987 PDFDocument14 pagesAsme A112 19 8M 1987 PDFTiam Yee YongNo ratings yet

- Estimated Cooling FactorDocument2 pagesEstimated Cooling FactorTiam Yee YongNo ratings yet

- N81 RM-223 SchematicsDocument38 pagesN81 RM-223 SchematicsTiam Yee YongNo ratings yet

- n70 RM-84 Schematics 1 0Document12 pagesn70 RM-84 Schematics 1 0darkking00No ratings yet

- N71 RM 67 Schematics v2 0Document15 pagesN71 RM 67 Schematics v2 0Tiam Yee YongNo ratings yet

- Method of Statement - Testing and CommissioningDocument1 pageMethod of Statement - Testing and CommissioningTiam Yee YongNo ratings yet

- Method of Statement - Ducting InstallationDocument1 pageMethod of Statement - Ducting InstallationTiam Yee YongNo ratings yet

- Design Guidelines for Water Supply ProjectDocument5 pagesDesign Guidelines for Water Supply ProjectNyu123456No ratings yet

- Method of Statement - Drain PipesDocument1 pageMethod of Statement - Drain PipesTiam Yee YongNo ratings yet

- BS 5306-8-2000 Fire Extinguishing Installations and EquipmentDocument22 pagesBS 5306-8-2000 Fire Extinguishing Installations and EquipmentTiam Yee Yong100% (1)

- Stair Case PressurisationDocument5 pagesStair Case Pressurisationsardarmkhan100% (1)

- Smoke ControlDocument1 pageSmoke ControlTiam Yee YongNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Summer Training Report.Document29 pagesSummer Training Report.Mujtaba Siddiqui100% (6)

- Dynamic Thermal Properties Calculator - Ecobuild SummaryDocument10 pagesDynamic Thermal Properties Calculator - Ecobuild SummarySérgio GnipperNo ratings yet

- Stirling Engine Project ReportDocument39 pagesStirling Engine Project Reportapi-328800450100% (2)

- Zamil Air Conditioners: Leading Manufacturer of HVAC Systems in the Middle EastDocument23 pagesZamil Air Conditioners: Leading Manufacturer of HVAC Systems in the Middle EastgagokapalaNo ratings yet

- 00102W C G0 G000 PE SPC 0013 Rev 1 Standard Pipe SupportsDocument119 pages00102W C G0 G000 PE SPC 0013 Rev 1 Standard Pipe SupportsMurtadda MohammedNo ratings yet

- Karmasingh Phant Lift ISP BOQ PDFDocument4 pagesKarmasingh Phant Lift ISP BOQ PDFatit shresthaNo ratings yet

- Types of Foundation and Their Uses: Home About Contact Past Projects ServicesDocument34 pagesTypes of Foundation and Their Uses: Home About Contact Past Projects ServicesMitchell AndersonNo ratings yet

- ETH - 7000013952 - Civil BOQDocument39 pagesETH - 7000013952 - Civil BOQBijaya RaulaNo ratings yet

- HL2028 Touch Screen ThermostatDocument2 pagesHL2028 Touch Screen Thermostatbnx5dkq786No ratings yet

- Tensile Test Document AnalysisDocument9 pagesTensile Test Document AnalysisShajidNo ratings yet

- Courtyard As A Building Component ChettiarDocument7 pagesCourtyard As A Building Component ChettiarAkshaya MayakrishnanNo ratings yet

- ACO - Product RangeDocument216 pagesACO - Product RangeTeddy TPNo ratings yet

- Section 4 - BTB - Estimation BOQDocument351 pagesSection 4 - BTB - Estimation BOQPo RaksmeyNo ratings yet

- Refrigeration and Air Conditioning - Jordan-PriesterDocument532 pagesRefrigeration and Air Conditioning - Jordan-PriesterJuan Jerez67% (3)

- Masterlife Sra 50: Description Expanding PropertiesDocument2 pagesMasterlife Sra 50: Description Expanding PropertiesSavalia HardikNo ratings yet

- Portland CementDocument88 pagesPortland CementShrey Agarwal75% (4)

- Design of Hydro Mechanical EquipmentDocument316 pagesDesign of Hydro Mechanical EquipmentTarunPatra100% (6)

- Hospitals Design Manual PDFDocument93 pagesHospitals Design Manual PDFHumaneNo ratings yet

- A Fracture Mechanics Model For The Wear of Gear Flanks by PittingDocument7 pagesA Fracture Mechanics Model For The Wear of Gear Flanks by PittingFernando RockerNo ratings yet

- Lifting Lug DesignDocument7 pagesLifting Lug DesignJens SøndergaardNo ratings yet

- 3PS PL 006Document22 pages3PS PL 006ravi00098No ratings yet

- Alemgenet Trade and Industry P.L.C - EthioconstructionDocument4 pagesAlemgenet Trade and Industry P.L.C - EthioconstructionHabtamu Hailemariam AsfawNo ratings yet

- Stylish and Modern LanternsDocument5 pagesStylish and Modern LanternsglaiNo ratings yet

- Electrical Installation Booklet Shipyard Standards: Marine Institute of Memorial University of NewfoundlandDocument81 pagesElectrical Installation Booklet Shipyard Standards: Marine Institute of Memorial University of NewfoundlandHoangNo ratings yet

- 2022-23 AP SyllabusDocument2 pages2022-23 AP SyllabusThrishaNo ratings yet

- Rigid Pavement Design As Per IRC 58 2011 BUC and TDC AnalysisDocument3 pagesRigid Pavement Design As Per IRC 58 2011 BUC and TDC Analysisarvind sharmaNo ratings yet

- High Performance Premium Tile AdhesivesDocument6 pagesHigh Performance Premium Tile Adhesivesshreekumar_scdlNo ratings yet

- SAW Presentation - SSDocument62 pagesSAW Presentation - SSRishabh KumarNo ratings yet

- Improving Chain LubricationDocument5 pagesImproving Chain LubricationAhmadreza AminianNo ratings yet

- Columns Lecture2Document7 pagesColumns Lecture2A KNo ratings yet