Professional Documents

Culture Documents

Column

Column

Uploaded by

Ahmed FattouhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column

Column

Uploaded by

Ahmed FattouhCopyright:

Available Formats

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

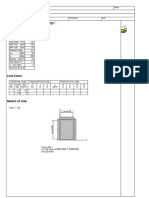

Example: Cantilever column with bi-axial bending

Circular column design by PROKON.

C12

(CirCol Ver W2.6.06 - 07 Apr 2014)

Design code : BS8110 - 1997

General design parameters:

Given:

d = 600 mm

d' = 60 mm

Lo = 6.000 m

fcu = 15 MPa

fy = 450 MPa

750

500

Therefore:

250

4

4

= 282.7103 mm

diax' = dia - d'

= 600 - 60

= 540.000 mm

diay' = dia - d'

= 600 - 60

= 540.000 mm

Assumptions:

(1) The general conditions of clause 3.8.1 are applicable.

(2) The section is symmetrically reinforced.

(3) The specified design axial loads include the self-weight of the column.

(4) The design axial loads are taken constant over the height of the column.

Design approach:

The column is designed using an iterative procedure:

(1) The column design charts are constructed.

(2) An area steel is chosen.

(3) The corresponding slenderness moments are calculated.

(4) The design axis and design ultimate moment is determined .

(5) The steel required for the design axial force and moment is read from

the relevant design chart.

(6) The procedure is repeated until the convergence of the area steel

about the design axis.

(7) The area steel perpendicular to the design axis is read from the relevant

design chart.

(8) The procedure is repeated for each load case.

(9) The critical load case is identified as the case yielding the largest

steel area about the design axis.

750

Y

250

600 2

500

. d 2

Ac =

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Through inspection:

Load case 3 (DL + LL + WL) is critical.

Check column slenderness:

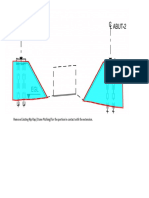

End fixity and bracing for bending about the X-X axis:

At the top end: Condition 4 (free).

At the bottom end: Condition 1 (fully fixed).

The column is unbraced.

x = 2.20

Table 3.22

End fixity and bracing for bending about the Y-Y axis:

At the top end: Condition 4 (free).

At the bottom end: Condition 1 (fully fixed).

The column is unbraced.

y = 2.20

Table 3.22

Effective column height:

lex = x. Lo

= 2.2 6

= 13.200 m

ley = y. Lo

= 2.2 6

= 13.200 m

Column slenderness about both axes:

x =

=

lex

dia

13.2

.6

= 22.000

y =

=

ley

dia

13.2

.6

= 22.000

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Minimum Moments for Design:

Check for mininum eccentricity:

For bi-axial bending, it is only necessary to ensure that the eccentricity

exceeds the minimum about one axis at a time.

3.8.2.4

For the worst effect, apply the minimum eccentricity about the minor axis:

Use emin = 20mm

Mmin = emin. N

= .02 1633

= 32.660 kNm

Check if the column is slender:

3.8.1.3

x = 22.0 > 10

y = 22.0 > 10

The column is slender.

Check slenderness limit:

3.8.1.8

Lo = 6.000 mComparision error60 dia' = 36.000

Slenderness limit not exceeded.

Initial moments:

The initial end moments about the X-X axis:

M1 = Smaller initial end moment = 0.0 kNm

M2 = Larger initial end moment = 127.0 kNm

The initial moment near mid-height of the column :

3.8.3.7

Mi = - 0.4 . M1 + 0.6 . M2

= - 0.4 0 + 0.6 127

= 76.200 kNm

Mi2 = 0.4 . M2

= 0.4 127

= 50.800 kNm

Mi 0.4M2 = 76.2 kNm

The initial end moments about the Y-Y axis:

M1 = Smaller initial end moment = 0.0 kNm

M2 = Larger initial end moment = 42.0 kNm

The initial moment near mid-height of the column :

3.8.3.7

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Mi = - 0.4 . M1 + 0.6 . M2

= - 0.4 0 + 0.6 42

= 25.200 kNm

Mi2 = 0.4 . M2

= 0.4 42

= 16.800 kNm

Mi 0.4M2 = 25.2 kNm

Deflection induced moments:

3.8.3.1

Design ultimate capacity of section under axial load only:

Nuz = 0.4444 . f cu. Ac +

1 . .

f y Asc

1.15

= 0.4444 15000 .28274 +

= 4 549.527 kN

Maximum allowable stress and strain:

Allowable compression stress in steel

f sc =

=

1 .

fy

1.15

1

450

1.15

= 391.304 MPa

Allowable tensile stress in steel

f st =

=

1 .

fy

1.15

1

450

1.15

= 391.304 MPa

Allowable tensile strain in steel

1

450000 .00681

1.15

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

f st

Es

ey =

391.3

200000

= 0.0020

Allowable compressive strain in concrete

ec = 0.0035

For bending about the X-X axis:

Balanced neutral axis depth

xbal =

dia - dcx

ey

1+

cstrain

.6 - .06

.00196

1+

.0035

= 0.3462 mm

Nbal calculated from basic principles using x = xbal = 1348.8 kN

K=

=

Nuz - N

Nuz - Nbal

4 548.7 - 1633

4 548.7 - 1 348.8

= 0.9112

a =

=

1 . lex 2

2000 dia

1

13.2 2

2000

.6

= 0.2420

Therefore:

Madd = N. a. K. dia

= 1633 .242 .91119 .6

= 216.054

For bending about the Y-Y axis:

Date

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Balanced neutral axis depth

xbal =

dia - dc

ey

1+

cstrain

.6 - .06

.00196

1+

.0035

= 0.3462 mm

Nbal calculated from basic principles using x = xbal = 1348.8 kN

K=

=

Nuz - N

Nuz - Nbal

4 548.7 - 1633

4 548.7 - 1 348.8

= 0.9112

a =

=

1 . ley 2

2000 dia

1

13.2 2

2000

.6

= 0.2420

Therefore:

Madd = N. a. K. dia

= 1633 .242 .91119 .6

= 216.054

Design ultimate load and moment:

Design axial load:

Pu = 1633.0 kN

For bending about the X-X axis, the maximum design moment is the greatest of:

(a)

3.8.3.7

3.8.3.2

M = M2 + Madd

= 127 + 216.05

= 343.050 kNm

(d)

3.8.3.2

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

M = emin. N

= .02 1633

= 32.660 kNm

Thus

3.8.3.2

M = 343.1 kNm

Moment distribution along the height of the column for bending about the X-X:

At the top, Mx = 0.0 kNm

Near mid-height, Mx = 238.2 kNm

At the bottom, Mx = 343.1 kNm

Moments about X-X axis( kNm)

Mxbot=127.0 kNm

Initial

Mx=343.1 kNm

Mxmin=32.7 kNm

=

Mxadd=216.1 kNm

Additional

For bending about the Y-Y axis, the maximum design moment is the greatest of:

(a)

Design

3.8.3.7

3.8.3.2

M = M2 + Madd

= 42 + 216.05

= 258.050 kNm

(d)

3.8.3.2

M = emin. N

= .02 1633

= 32.660 kNm

Thus

3.8.3.2

M = 258.1 kNm

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Moment distribution along the height of the column for bending about the Y-Y:

At the top, My = 32.7 kNm

Near mid-height, My = 194.7 kNm

At the bottom, My = 258.1 kNm

Moments about Y-Y axis( kNm)

Mybot=42.0 kNm

Initial

My=258.1 kNm

Mymin=32.7 kNm

=

Myadd=216.1 kNm

Additional

Design of column section for ULS:

Through inspection:

The critical section lies at the bottom end of the column.

The column is bi-axially bent: the moments are therefore added vectorially

to obtain the final design moment:

M' = Mx2 + My2

= 343.05 2 + 258.05 2

= 429.270

Design axial load:

Pu = 1633.0

Design

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

For bending about the design axis:

8000

7000

6000

5000

4000

1200

6%

1100

1000

5%

900

4%

800

3%

700

2%

500

400

1%

300

0%

200

1000

100

2000

600

Axial Load (kN)

3000

-1000

Moment max = 1040 kNm @ 1111kN

Column design chart

-2000

-3000

-4000

-5000

-6000

Bending Moment (kNm)

From the design chart, Asc = 6808 = 2.41%

Design chart for bending about any axis:

8000

7000

6000

5000

4000

-1000

-2000

-3000

-4000

-5000

-6000

Bending Moment (kNm)

1200

6%

1100

1000

5%

900

4%

800

3%

700

2%

500

400

1%

300

0%

200

1000

100

2000

600

Axial Load (kN)

3000

Moment max = 1040 kNm @ 1111kN

Column design chart

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Summary of design calculations:

Design results for all load cases:

Load case

Axis

X-X

Y-Y

2

3

N (kN)

M1 (kNm) M2 (kNm) Mi (kNm) Madd (kNm) Design

M (kNm)

M' (kNm)

Asc (mm)

495.0

0.0

0.0

6.0

3.0

3.6

1.8

71.9

71.9

X-X

Bottom

77.9

74.9

108.0

1131 (0.40%)

X-X

Y-Y

761.0

0.0

0.0

79.0

20.0

47.4

12.0

110.5

110.5

X-X

Bottom

189.5

130.5

230.1

2081 (0.74%)

X-X

Y-Y

1633.0

0.0

0.0

127.0

42.0

76.2

25.2

216.1

216.1

X-X

Bottom

343.1

258.1

429.3

6808 (2.41%)

Load case 3 (DL + LL + WL) is critical.

You might also like

- Steel Section PropertiesDocument2 pagesSteel Section Propertiesman.drakeNo ratings yet

- Code For The Seismic Design of Concrete Structures Ghana PDFDocument85 pagesCode For The Seismic Design of Concrete Structures Ghana PDFHervé KoudouNo ratings yet

- Bolt Clearances 01.01.03Document1 pageBolt Clearances 01.01.03mas ayuNo ratings yet

- SSB05 Detailed Design of Trusses 2010-03-22Document131 pagesSSB05 Detailed Design of Trusses 2010-03-22DN GHNo ratings yet

- Sajai Steels and Project Limited: Company ProfileDocument11 pagesSajai Steels and Project Limited: Company ProfileParvinder KaurNo ratings yet

- Engineering Example of 3D Plate Materials: Sheet Pile Wall in BendingDocument2 pagesEngineering Example of 3D Plate Materials: Sheet Pile Wall in BendingJim Jakson MboeNo ratings yet

- PC 35 R 8Document199 pagesPC 35 R 8rachitmail100% (2)

- British and European SectionsDocument89 pagesBritish and European SectionsgenergiaNo ratings yet

- Faq About PebDocument6 pagesFaq About Pebsaravanan_c1No ratings yet

- Hea - Heb - HemDocument12 pagesHea - Heb - Hemakın ersözNo ratings yet

- Column 1: Made by DateDocument12 pagesColumn 1: Made by DateHafiz KamarudinNo ratings yet

- Abstract of CPWDDocument5 pagesAbstract of CPWDabhishek kumarNo ratings yet

- INFRA Report Final 2-2-2017Document29 pagesINFRA Report Final 2-2-2017AHMED ATIFNo ratings yet

- VRV Electrical RequirementDocument6 pagesVRV Electrical RequirementShrenikShahNo ratings yet

- +foundation DESIGNDocument16 pages+foundation DESIGNjayadushNo ratings yet

- BR101Document1 pageBR101Vladimir ĐorđevićNo ratings yet

- Lux Simulation Report 10.8.2018wDocument12 pagesLux Simulation Report 10.8.2018wChi Kit PhoonNo ratings yet

- Reference Description of Problem Values Units: Infomile SolutionsDocument3 pagesReference Description of Problem Values Units: Infomile SolutionsdhawanaxitNo ratings yet

- BOQ of Factory Building - Civil, CostingDocument17 pagesBOQ of Factory Building - Civil, Costingengineermak2023No ratings yet

- CMU Wall DesignDocument4 pagesCMU Wall DesignamitkuknaNo ratings yet

- Deflection Egyptian CodeDocument3 pagesDeflection Egyptian CodeMagdy BakryNo ratings yet

- Conveyor Truss Connections Calcs - 11Document4 pagesConveyor Truss Connections Calcs - 11René Mella CidNo ratings yet

- Footing Steel Quantity of Morarka CollegeDocument21 pagesFooting Steel Quantity of Morarka CollegeHANISHNo ratings yet

- Allowable Load of Main Components of ScaffoldDocument10 pagesAllowable Load of Main Components of Scaffoldteguh widayatNo ratings yet

- Column PMM EnvelopeDocument23 pagesColumn PMM EnvelopeKutty MansoorNo ratings yet

- Cost Estimate of WarehouseDocument16 pagesCost Estimate of WarehouseAnil SuryawanshiNo ratings yet

- Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and MaterialsDocument6 pagesCode Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and MaterialsAtul GargNo ratings yet

- Specification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeDocument5 pagesSpecification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeSOMNATH JANANo ratings yet

- BS Wind LoadDocument14 pagesBS Wind LoadAreeb Ahmed100% (1)

- Foundation Design of Lamp PostDocument1 pageFoundation Design of Lamp PostMayank AgrawalNo ratings yet

- Break DownDocument67 pagesBreak DownSenthilnathan NagarajanNo ratings yet

- FRP Lighting PolesDocument16 pagesFRP Lighting PolesManish VaghelaNo ratings yet

- Foundation DetailsDocument1 pageFoundation DetailsmohammadNo ratings yet

- RC Piles APIDocument5 pagesRC Piles APIGnabBangNo ratings yet

- A.N Prakash Construction Project Management Consultants Pvt. Ltd. P: 1/1Document1 pageA.N Prakash Construction Project Management Consultants Pvt. Ltd. P: 1/1yogeshNo ratings yet

- Roof Sandwich PanelDocument1 pageRoof Sandwich Panelalden cayagaNo ratings yet

- Wind Load As Per ASCE-7-10 PDFDocument17 pagesWind Load As Per ASCE-7-10 PDFhala94No ratings yet

- Boq For BeamsDocument22 pagesBoq For BeamsgopaltryNo ratings yet

- BOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFDocument2 pagesBOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFVeena NageshNo ratings yet

- Bolt Capacity2Document2 pagesBolt Capacity2abdul kareeNo ratings yet

- Bolt Load Tables To BS449 01.01.03Document1 pageBolt Load Tables To BS449 01.01.03sandeshNo ratings yet

- Modus Operandi - Proflex - Self Supported Roof - All Technical DetailsDocument19 pagesModus Operandi - Proflex - Self Supported Roof - All Technical Detailsuday Ravi100% (1)

- Section TableDocument52 pagesSection TableNurin Irdina RoslanNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignDony DoanxNo ratings yet

- Steel Base Plate DesignDocument5 pagesSteel Base Plate DesignMichael AbandeNo ratings yet

- Sample Showing Typical Details of Pinned Base Plate REV. 1: (ASTM A36M Plate)Document1 pageSample Showing Typical Details of Pinned Base Plate REV. 1: (ASTM A36M Plate)abhinav7373No ratings yet

- Torsion Irregularity Check UBC 97-1630.7 Story Load Case/Combo Label UX Drif Label UX Drif Max DrifDocument2 pagesTorsion Irregularity Check UBC 97-1630.7 Story Load Case/Combo Label UX Drif Label UX Drif Max DrifOmer HayatNo ratings yet

- Steel Beam Marked B6Document27 pagesSteel Beam Marked B6Babu SundararamanNo ratings yet

- Beam Design With Deflection CheckDocument4 pagesBeam Design With Deflection Checkdinesh choudharyNo ratings yet

- RCC62 Retaining WallDocument15 pagesRCC62 Retaining WallRama KrishnaNo ratings yet

- Bahrain Building Regulations (2009)Document81 pagesBahrain Building Regulations (2009)Sogkarimi0% (1)

- Footing DesignDocument7 pagesFooting Designmsiddiq1No ratings yet

- Column Base Design:: Input DataDocument3 pagesColumn Base Design:: Input DataEng HatemNo ratings yet

- Footing Design CalculationDocument45 pagesFooting Design Calculationsam_antony20050% (1)

- FootingDocument14 pagesFootingJaganraj SesurajNo ratings yet

- Pedestal 1Document14 pagesPedestal 1Jaganraj SesurajNo ratings yet

- KRONES Footing Rev 1Document5 pagesKRONES Footing Rev 1donnybtampubolonNo ratings yet

- Design For Isolated Footing 1Document11 pagesDesign For Isolated Footing 1Edilberto ContrerasNo ratings yet

- Rectangular Slab Panel Design:: Input DataDocument8 pagesRectangular Slab Panel Design:: Input DataJohn NjorogeNo ratings yet

- Book 3Document30 pagesBook 3JilJilNo ratings yet

- Need To Extend Our Area As Shown. 187mDocument1 pageNeed To Extend Our Area As Shown. 187mJohn G JoseNo ratings yet

- Student Visa ChecklistDocument1 pageStudent Visa ChecklistJohn G JoseNo ratings yet

- Rishmawi Thesis 2016Document242 pagesRishmawi Thesis 2016John G JoseNo ratings yet

- Untitled PDFDocument1 pageUntitled PDFJohn G JoseNo ratings yet

- 1 PDFDocument1 page1 PDFJohn G JoseNo ratings yet

- Annexure A: Remove Existing Rip Rap (Stone Pitching) For The Portion in Contact With The ExtensionDocument3 pagesAnnexure A: Remove Existing Rip Rap (Stone Pitching) For The Portion in Contact With The ExtensionJohn G JoseNo ratings yet

- Saturday Sunday Monday Tuesday Wednesday Thursday Friday: Holidays and ObservancesDocument2 pagesSaturday Sunday Monday Tuesday Wednesday Thursday Friday: Holidays and ObservancesJohn G JoseNo ratings yet

- AASHTO LRFD Bridge Design Specifications, SI Units, 4th EditionDocument1 pageAASHTO LRFD Bridge Design Specifications, SI Units, 4th EditionJohn G JoseNo ratings yet

- ACAD-D10 & D11 Column Mark at Pier Head Civil 3D ModelDocument1 pageACAD-D10 & D11 Column Mark at Pier Head Civil 3D ModelJohn G JoseNo ratings yet

- Result RET PDFDocument28 pagesResult RET PDFJohn G JoseNo ratings yet

- Route To Site Office From Abu DhabiDocument1 pageRoute To Site Office From Abu DhabiJohn G JoseNo ratings yet

- Comment Compliance SheetDocument1 pageComment Compliance SheetJohn G JoseNo ratings yet

- Reflectors For Reading Level / Coordinate From Sunday MorningDocument1 pageReflectors For Reading Level / Coordinate From Sunday MorningJohn G JoseNo ratings yet

- PT-Anchorage Casting-Test Report: Annexure-6Document2 pagesPT-Anchorage Casting-Test Report: Annexure-6John G JoseNo ratings yet

- Annexure 2: VSL Anchorage (Local Zone)Document1 pageAnnexure 2: VSL Anchorage (Local Zone)John G JoseNo ratings yet

- Baili Scaffolding SystemDocument2 pagesBaili Scaffolding SystemJohn G JoseNo ratings yet

- Shop Drawing: Truck Loading SequenceDocument1 pageShop Drawing: Truck Loading SequenceJohn G JoseNo ratings yet

- Annexure 3: Comparison of Other Designers DrawingsDocument1 pageAnnexure 3: Comparison of Other Designers DrawingsJohn G JoseNo ratings yet

- Atos - AqfrDocument2 pagesAtos - AqfrBillouNo ratings yet

- Technical Manual Ribbed Belt Drives: OptibeltDocument68 pagesTechnical Manual Ribbed Belt Drives: Optibeltvictor perdomoNo ratings yet

- Thermodynamics Test PaperDocument2 pagesThermodynamics Test PaperKrishnaKishoreReddyNo ratings yet

- BURNDY GAR644C SpecsheetDocument2 pagesBURNDY GAR644C SpecsheetSalvador MurilloNo ratings yet

- Advanced Manufacturing Processes: (Mechanical Engineering Group)Document20 pagesAdvanced Manufacturing Processes: (Mechanical Engineering Group)Vikram Kumar100% (1)

- Grade 11 Homework Simple Harmonic MotionDocument1 pageGrade 11 Homework Simple Harmonic MotionMuhammad bilal KhanNo ratings yet

- Iso 10816Document2 pagesIso 10816tuxiboiNo ratings yet

- At451u-Dm 10-09Document1 pageAt451u-Dm 10-09s5548844No ratings yet

- Hec-Ras: Jordan Furnans and Francisco Olivera, Ph.D. Center For Research in Water Resources University of Texas at AustinDocument21 pagesHec-Ras: Jordan Furnans and Francisco Olivera, Ph.D. Center For Research in Water Resources University of Texas at AustinSantos Vilcabana BernillaNo ratings yet

- TH 425Document1 pageTH 425AndreyNo ratings yet

- HHF-1600 Direct-Drive Utilized Pump Parts ListDocument21 pagesHHF-1600 Direct-Drive Utilized Pump Parts ListAhmedNo ratings yet

- 00018Document3 pages00018dexterNo ratings yet

- Kerto S Declaração Conformidade CEDocument3 pagesKerto S Declaração Conformidade CEJoão DiasNo ratings yet

- What Is PressureDocument3 pagesWhat Is PressureJordan MosesNo ratings yet

- Steady State Distillation of A Binary Mixture Under Continuous OperationDocument8 pagesSteady State Distillation of A Binary Mixture Under Continuous OperationClaudia M. DelgadilloNo ratings yet

- 8404-25a Bomco F-1600 7500psiDocument11 pages8404-25a Bomco F-1600 7500psiAnonymous 48jYxR1CNo ratings yet

- NEMA 17 1.8° Hybrid Stepper Motor CatalogDocument2 pagesNEMA 17 1.8° Hybrid Stepper Motor Catalogjose luisNo ratings yet

- Brauduino Controller Build1Document18 pagesBrauduino Controller Build1Marlon G. AguiarNo ratings yet

- Mechanical Engineering SyllabusDocument5 pagesMechanical Engineering SyllabusRahul KarthikNo ratings yet

- 1300-121 Systems One Seed Jet II Closed Center Hydraulic System ManualDocument12 pages1300-121 Systems One Seed Jet II Closed Center Hydraulic System Manualwasihun wodajeNo ratings yet

- T Changer2 2500 PDFDocument2 pagesT Changer2 2500 PDFGm FixoralNo ratings yet

- Napkin I - Specification SheetDocument2 pagesNapkin I - Specification SheetKushagri JoshiNo ratings yet

- Belaz 75310Document2 pagesBelaz 75310Jalil EmadiNo ratings yet

- Csir-Ugc-Net/Jrf - Gate - Physics: V X That Satisfies The Condition (V X VXDocument4 pagesCsir-Ugc-Net/Jrf - Gate - Physics: V X That Satisfies The Condition (V X VXAbhrajit MahapatraNo ratings yet

- Liquid Filling Section MachineryDocument18 pagesLiquid Filling Section MachinerySANJAY100% (1)

- AC Generator Working Principle and PartsDocument2 pagesAC Generator Working Principle and Partsibnuhary100% (1)

- Design of Controller For Inverted Pendulum: Yat-Chen Chen Chih-Chin WenDocument3 pagesDesign of Controller For Inverted Pendulum: Yat-Chen Chen Chih-Chin WenVictor PassosNo ratings yet

- RANGE ROVER SPORT Electrical ReferenceDocument1,157 pagesRANGE ROVER SPORT Electrical ReferenceGeorge Sibiya100% (1)

- Lanci I LancaniciDocument160 pagesLanci I Lancanicimiroslav11No ratings yet