Professional Documents

Culture Documents

Cooling Tower

Uploaded by

Raju SubediCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling Tower

Uploaded by

Raju SubediCopyright:

Available Formats

A Cooling Tower is an enclosed device, designed for the evaporative cooling of the water

by the direct contact with air, which must be maintained with reasonable care if it is to be given

peak performance. The cooling tower consists of a RCC structure, fill and fill supports, water

distribution system, fans, gear boxes, drive shafts and motors. The sizing of the tower is done

depending on the amount of the water to be cooled and the degree to which the water is to be

cooled.

The cooling tower in the plant is Induced mechanical draft type with two cells each

including Induced draft fan.

OPERATING PRINCIPLES

Cooling tower operates on the principle of evaporative cooling of water. Hot water from

the plant is distributed and allowed to flow over packing. Air is induced through the packing and

brought in contact with water by means of fans. The intimated contact of water and air causes

evaporation of the water. The water that is evaporated carries away the latent heat of vaporization

from the bulk of the water, thus cooling it. In order to provide heat transfer (bulk of heat by latent

heat and smaller proportion of sensible heat), fills are used.

DESIGN DATA:

Water flow rate

Hot water temperature

Cold water temperature

Design inlet WBT

Number of Cells

5200 m3/hr

42 0C

32 0C

27.5 0C

2

TECHNICAL SPECIFICATION:

Fan Type

Fan Diameter

Axial Flow

9150 mm

Number of Blades

Motor Type

3 phase AC squirrel cage induction motor

Rated motor power

55 kW

Fill pack MOC

PVC and Type: Film flow

Drift eliminator MOC

PVC

COOLING TOWER WORKING PARAMETERS

Loss of water due to evaporation:

Make- up water Needed:

You might also like

- LearnerGuide 1 - CHCCCS015 - CHCCCS023 - HLTAAP001Document145 pagesLearnerGuide 1 - CHCCCS015 - CHCCCS023 - HLTAAP001Raju Subedi80% (5)

- LearnerGuide 4 - Ageing - CHCAGE001 - CHCAGE005 - CHCCCS011Document84 pagesLearnerGuide 4 - Ageing - CHCAGE001 - CHCAGE005 - CHCCCS011Raju Subedi100% (3)

- LearnerGuide 2 - CHCLEG001 - HLTWHS002Document81 pagesLearnerGuide 2 - CHCLEG001 - HLTWHS002Raju Subedi75% (4)

- LearnerGuide 3 - CHCCOM005 - CHCDIV001Document69 pagesLearnerGuide 3 - CHCCOM005 - CHCDIV001Raju Subedi50% (2)

- CONTROL Once The Project Baseline Is Already Prepared. in Most Scenarios, The ChangeDocument2 pagesCONTROL Once The Project Baseline Is Already Prepared. in Most Scenarios, The ChangeRaju SubediNo ratings yet

- LearnerGuide 5 - Ageing - CHCHCS001 - CHCCCS025Document78 pagesLearnerGuide 5 - Ageing - CHCHCS001 - CHCCCS025Raju Subedi100% (1)

- CONTROL Once The Project Baseline Is Already Prepared. in Most Scenarios, The ChangeDocument2 pagesCONTROL Once The Project Baseline Is Already Prepared. in Most Scenarios, The ChangeRaju SubediNo ratings yet

- Assignment 1 - Part BDocument14 pagesAssignment 1 - Part BRaju SubediNo ratings yet

- Module 1A - Introduction To AccountingDocument9 pagesModule 1A - Introduction To AccountingRaju SubediNo ratings yet

- Cruise The Word-AssignmentDocument3 pagesCruise The Word-AssignmentRaju SubediNo ratings yet

- Progressive Office FurnitureDocument10 pagesProgressive Office FurnitureRaju SubediNo ratings yet

- Final Internship ReportDocument54 pagesFinal Internship ReportRaju Subedi71% (7)

- CycloneDocument22 pagesCycloneLetícia Almeida75% (4)

- Junar Juice FinalDocument53 pagesJunar Juice FinalRaju Subedi0% (1)

- Steam GeneratorDocument8 pagesSteam GeneratorRaju SubediNo ratings yet

- Experimental Study of Nanofluid (Sio) Forced Convection Heat Transfer in Automobile RadiatorDocument21 pagesExperimental Study of Nanofluid (Sio) Forced Convection Heat Transfer in Automobile RadiatorRaju SubediNo ratings yet

- LeanDocument33 pagesLeanRaju SubediNo ratings yet

- Department of Thermal Power Engineering: Visvesvaraya Technological UniversityDocument26 pagesDepartment of Thermal Power Engineering: Visvesvaraya Technological UniversityRaju SubediNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Final Exam Calculus 2021 Second BatchDocument2 pagesFinal Exam Calculus 2021 Second BatchOliric NabcihNo ratings yet

- Covalent and Metallic Bonding Mcqs by FMDocument17 pagesCovalent and Metallic Bonding Mcqs by FMfarymemon15No ratings yet

- Philosophy ReviewerDocument9 pagesPhilosophy ReviewerLeinard ManahanNo ratings yet

- Solutions To Practice Problems, Module 2: Engineering MechanicsDocument16 pagesSolutions To Practice Problems, Module 2: Engineering MechanicsShaun Patrick AlbaoNo ratings yet

- Astm c580 Mortar Flexural PDFDocument6 pagesAstm c580 Mortar Flexural PDFMaha MuflehNo ratings yet

- Week 12 Myp 4 HWDocument2 pagesWeek 12 Myp 4 HWAnchal ChadhaNo ratings yet

- Astm F 16Document5 pagesAstm F 16Maki Salim HussainNo ratings yet

- Pavement Engineering Notes 2012Document77 pagesPavement Engineering Notes 2012Mohamed Wehliye90% (10)

- Class 12 Physics Derivations Shobhit NirwanDocument6 pagesClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniNo ratings yet

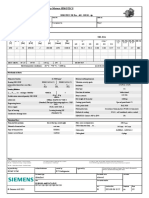

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4Pnadia perezNo ratings yet

- ps11 9Document11 pagesps11 9frak ksaNo ratings yet

- 199-GST-0101-RevA - Electrical MV LV Transformers SpecificationDocument14 pages199-GST-0101-RevA - Electrical MV LV Transformers Specificationdhanny ma100% (1)

- Design of SlabDocument7 pagesDesign of SlabAlam Mohammad Parvez SaifiNo ratings yet

- APPENDIX A B C Pump Specifications Vantage 5000 EN v1.7 July 2019Document14 pagesAPPENDIX A B C Pump Specifications Vantage 5000 EN v1.7 July 2019cerro GranadaNo ratings yet

- Lesson 8 Shear or Diagonal Tension in RC BeamsDocument8 pagesLesson 8 Shear or Diagonal Tension in RC BeamsJoshua John JulioNo ratings yet

- Robotics CH 4 Robot DynamicsDocument40 pagesRobotics CH 4 Robot DynamicsCharlette Alessi InaoNo ratings yet

- Effect of Soil Plug Removal On The Load-Carrying Capacity of Symmetric and Non-Symmetric Pile GroupsDocument25 pagesEffect of Soil Plug Removal On The Load-Carrying Capacity of Symmetric and Non-Symmetric Pile GroupsChandra MouliNo ratings yet

- Ppi-2225cp DatasheetDocument10 pagesPpi-2225cp DatasheetLargaisNo ratings yet

- Overload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleDocument4 pagesOverload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleSuhas KODRENo ratings yet

- DPP-2 (Coulomb's Law and Principle of Superposition)Document6 pagesDPP-2 (Coulomb's Law and Principle of Superposition)Youtuber RSNo ratings yet

- SHORT REPORT - 606 - Liner DisplacementDocument26 pagesSHORT REPORT - 606 - Liner DisplacementwongpeisenNo ratings yet

- Product Specifications: AVA5-50FXDocument3 pagesProduct Specifications: AVA5-50FXhassan329100% (1)

- F4Y Series DatasheetDocument11 pagesF4Y Series DatasheetAizat RomainoNo ratings yet

- Gen Chem 3rd QuarterDocument6 pagesGen Chem 3rd QuarterzafmustaphaNo ratings yet

- An Asymptotic and AlgebraicDocument11 pagesAn Asymptotic and Algebraicjos romNo ratings yet

- Microtrip Line PDFDocument11 pagesMicrotrip Line PDFthap_dinhNo ratings yet

- Comms 4 - FormulaDocument7 pagesComms 4 - Formulaengineeringbsece2fNo ratings yet

- Shell and Tube Heat Exchanger Sample Problem and SolutionDocument9 pagesShell and Tube Heat Exchanger Sample Problem and Solutionlouisealfonzo.chanNo ratings yet

- User Manual DPS - ENDocument60 pagesUser Manual DPS - ENYiannis Steletaris100% (1)

- Accelerated Stability TestingDocument5 pagesAccelerated Stability TestingKevin GaralaNo ratings yet