Professional Documents

Culture Documents

Chapter 1 Introduction

Uploaded by

Ryan Anthony UmaliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 1 Introduction

Uploaded by

Ryan Anthony UmaliCopyright:

Available Formats

CHAPTER 1 Introduction

1.1 Project Overview

JG Summit Petrochemicals Group (JGSPG) consists of

JG Summit Petrochemical Corporation (JGSPC) and JG Summit

Olefins Corporation (JGSOC) which are both wholly owned

subsidiaries of JG Summit Holdings, Inc (JGSHI). JGSPG has a

250-hectare

fully

integrated,

world-class,

PEZA-accredited

manufacturing complex in Brgy. Simlong, Batangas City, 120

km south of Manila.

JG Summit Petrochemical Corporations has three (3)

polymer plants namely Polyethylene 1, Polyethylene 2 and

Polypropylene

which are

currently

producing

a combined

capacity of 510 kTA of resins per year.

On the other hand JG Summit Olefins Corporation is

producing polymer grade Ethylene and Propylene that are both

exported overseas and used by JGSPC as its main raw material

for producing PE and PP resins.

Power to the entire petrochemical complex is coming

from its own 74MW Diesel power plant located inside the

complex. The power plant also increases its capacity from its

original rating of 47MW through additional generating units.

From 2011 to 2014, PE plants undergo a major debottlenecking project (PE Expansion Project) to increase the

capacity from 200kTA to 320kTA. The Basic Engineering was

handled by JGSPCs Project Engineering group which the author

was part of the team and with its technology vendor from US

while

Detailed

Engineering,

Project

and

Construction

Management were handled by Toyo-Thai Engineering PTE LTD

of Thailand.

Part of the PE Expansion project was the expansion of

the existing substation to cater the additional load requirement

Chapter 1-Introduction

Page 1

such as motors, lightings, instrument and control systems and

process heaters. These additional loads have a combined total

capacity requirement of about 33.3MVA which the existing

substation cannot cater.

Construction of the said plant has been completed last

April 2004 while pre-commissioning, commissioning and startup

activities were completed last June 2014.

Figure1.1 JGSPC (front) and JGSOC (back) Complex

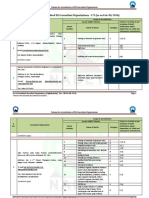

The

substation

of

interest

consist

of

52MVA

13.8kV/6.9kV Delta-wye (solidly grounded) transformer, two(2)

x

3MVA

6.9kV/480V

Delta/wye

transformer,

MV

6.9kV

switchgears, five(5) large induction motors, Power factor

correction capacitors and two(2) spare feeder intended for

future requirement (see Figure 1.2 for Single Line Diagram).

Chapter 1-Introduction

Page 2

Generator

8 sets

8.375MVA

13.8kV

Bus 1

NEW

Polyethylene

Plant no. 2

Estimated equivalent Loads

Momentary:

Z=0.000639 + j 0.019257

p.u (10MVA base)

TRM1

40/52MVA

13.8kV/6.9kV

Interrupting:

Z=0.000685 + j 0.021452

p.u (10MVA base)

Bus 2

TRL3A

3MVA

13.8kV/480

M

PE-KM5806 PE-YM7601

540W

4850W

6.9kV

6.9kV

TRL3B

3MVA

13.8kV/480

PE-KM8601 PE-KM8639

250W

315W

6.9kV

6.9kV

Bus 3

Bus 4

Figure 1.2 System Single Line Diagram

1.2

Project Objectives

This technical report has the following objectives

1.

To determine the positive, negative and zero

sequence impedance network and admittance models from

the point of connection Power Plant Bus (BAC908), Power

transformers and loads;

2.

To perform load flow study by determining the

bus voltages, Load terminal voltages, voltage drop, power

flows, current flow and power factor from Power plant bus

(point of connection) up to each 480V loads;

3.

To perform analysis on the load flow result and

provide recommendation for system improvement.

Chapter 1-Introduction

Page 3

4.

To perform short circuit study for both momentary

and interrupting three(3) phase fault, single line to ground,

line to line and double line to ground fault from the point of

connection at the power plant up to each 480V loads and

determine the minimum and maximum fault current at each

protective devices connection points;

5.

To perform motor starting analysis for medium

voltage motors and low voltage motors that are 100kW and

above by determining the impact of each motor starting

scenario to the power system and evaluate each big motors

starting performance;

6.

To design the time-current coordination of the

overcurrent protective devices and motor overload protective

devices.

1.3

Project Scope and Limitations

As depicted in figure 1.2, this power system study will

from the JGSPCs Power Plant connection point at BAC908

13.8kV feeder, up to the 480V loads. As summarized on table

1.3.1 Load flow study will be conducted from the BAC908

feeder, the 52MVA power transformer, the 6.9kV Motor loads,

the 2 x 3MVA transformer and its 480V loads. Short circuit study

covers from the downstream of BAC908 up to 480V loads. The

Equivalent momentary and interrupting fault impedances at the

connection point were already provided by an earlier study of

the original power system before the PE plant expansion. This

equivalent model will be utilized in the short circuit analysis.

Chapter 1-Introduction

Page 4

Table 1.3.1 Summary of Study Coverage

Analysis Type

Coverage or scope

Load Flow Study

From BAC 908 down to all PE2

power system up to 480V loads

Short Circuit Study

Fault point at TRM1 primary and

secondary, 6.9kV bus, 6.9kV

loads, TRL3A/B primary and

secondary, 480V bus and 480V

loads

Device Coordination Study

From BAC 908 protection down

to all the protective devices of

PE2 power system.

Large Motor Starting Study

Chapter 1-Introduction

All motors 100kW and above

Page 5

Table 1.3.2 Summary of Sub-Study Area

Analysis Type

Sub-Study Area

Power

System 1. Impedance model

Model

2. Admittance Model

3. Load Model

Load Flow Study 1. Bus voltage and Load Voltage Calculation

2. Current and Power Flow Calculation

3. Voltage Drop Calculation

4. Power Factor Calculation

5. Voltage Drop Evaluation

6. Transformer and Bus Bar Loading Evaluation

7. Power Flow Evaluation

Short

Circuit 1. 3-phase fault at various location (Momentary

Study

Symmetrical, Asymmetrical and peak)

2. SLG Fault at various location

3. Line to Line Fault at various Location

4. Double

Line to ground fault

at various

location

Device

1. TCC coordination of all MV Loads and critical

Coordination

Study

Large

LV Loads

2. Grounding System Evaluation

Motor 1. Motor Starting Analysis

Starting Study

Chapter 1-Introduction

Page 6

You might also like

- Islanding Operation of Captive Power PlantsDocument3 pagesIslanding Operation of Captive Power PlantsBhavik Prajapati100% (1)

- SynopsisDocument8 pagesSynopsismanu thomasNo ratings yet

- Brief History of Kothagudem Thermal Power Station:: 1.1 Introduction To ApgencoDocument71 pagesBrief History of Kothagudem Thermal Power Station:: 1.1 Introduction To ApgencoSrikanth SriNo ratings yet

- IeeDocument9 pagesIeeReuban JaysinghNo ratings yet

- Power Flow Monitoring and Analysis For 24.6 MW at 6.9 KV Bus Diesel Power Plant (DPP) Using ETAPDocument6 pagesPower Flow Monitoring and Analysis For 24.6 MW at 6.9 KV Bus Diesel Power Plant (DPP) Using ETAP陆华林No ratings yet

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiNo ratings yet

- GHTP Lehra MohabbatDocument23 pagesGHTP Lehra MohabbatDivanshu Garg40% (5)

- Wind Generation System For Charging BatteriesDocument6 pagesWind Generation System For Charging BatteriesAmit RanjanNo ratings yet

- A Power Quality Case Study-A Cement Industry PDFDocument8 pagesA Power Quality Case Study-A Cement Industry PDFgtgreatNo ratings yet

- Technicical SpecificationsDocument22 pagesTechnicical SpecificationsSaurabh PariharNo ratings yet

- Integration of Variable Speed Hydropower Generation and VSC HVDC - AbbDocument10 pagesIntegration of Variable Speed Hydropower Generation and VSC HVDC - AbbDeepak GehlotNo ratings yet

- TS-2 Plant Description JAC - 1002Document2 pagesTS-2 Plant Description JAC - 1002Ramesh-NairNo ratings yet

- PM Assignment 2 NotesDocument7 pagesPM Assignment 2 NotesRamawaty SukmaaNo ratings yet

- On The Black Start of Offshore Wind Power Plants With Diode Rectifier BasedDocument10 pagesOn The Black Start of Offshore Wind Power Plants With Diode Rectifier Basednabilhoque601No ratings yet

- 11ref PDFDocument4 pages11ref PDFRevuNo ratings yet

- Floating Production Storage and OffloadingDocument10 pagesFloating Production Storage and OffloadingbhuvanaNo ratings yet

- Load Shedding Philosophy ExplainedDocument35 pagesLoad Shedding Philosophy Explainedchinnarao100% (1)

- PLC Controlled Diesel GeneratorDocument8 pagesPLC Controlled Diesel GeneratorPaiman KoplaxNo ratings yet

- Protection and Design of Distributed Energy Generation System (Microgrid)Document6 pagesProtection and Design of Distributed Energy Generation System (Microgrid)Neha BandhuNo ratings yet

- A New Controller Scheme For Photovoltaics PowerDocument10 pagesA New Controller Scheme For Photovoltaics PowerHakan PolatkanNo ratings yet

- A Maximum Power Point Tracking System With Parallel Connection For PV Stand-Alone ApplicationsDocument10 pagesA Maximum Power Point Tracking System With Parallel Connection For PV Stand-Alone ApplicationsJidhin JayanNo ratings yet

- Ynynd11 Transformer ConnectionsDocument6 pagesYnynd11 Transformer ConnectionsGurunadha Rao RamachandraNo ratings yet

- Mặt trờiDocument6 pagesMặt trờiDuy ThanhNo ratings yet

- The PEM Fuel Cell System With DC/DC Boost Converter: Design, Modeling and SimulationDocument5 pagesThe PEM Fuel Cell System With DC/DC Boost Converter: Design, Modeling and SimulationIDESNo ratings yet

- ProjectDocument86 pagesProjectrajuNo ratings yet

- Preparation & Characterization LiFePO4 Battery BankDocument6 pagesPreparation & Characterization LiFePO4 Battery BankAgung Sugeng RiyadiNo ratings yet

- Design of Low Inductance Switching Power Cell For GaN HEMT Based InverterDocument11 pagesDesign of Low Inductance Switching Power Cell For GaN HEMT Based InverterArmandinho CaveroNo ratings yet

- Solar PV Hybrid Power Plants For Petrol SystemDocument27 pagesSolar PV Hybrid Power Plants For Petrol SystemLakshmi NarayananNo ratings yet

- Trep Case StudyDocument24 pagesTrep Case StudyXie TiaNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Presented By: 1. Y.Madhu Sudhan Reddy, 07BM1A0234, 4 EEE 2. S.Srinivasulu, 07BM1A0236, 4 EEEDocument8 pagesPresented By: 1. Y.Madhu Sudhan Reddy, 07BM1A0234, 4 EEE 2. S.Srinivasulu, 07BM1A0236, 4 EEESiva KonakallaNo ratings yet

- Solar Photo Voltaic Water Pumping: Harnessing Maximum PowerDocument8 pagesSolar Photo Voltaic Water Pumping: Harnessing Maximum PowerIDESNo ratings yet

- Power GenerationDocument16 pagesPower GenerationBert De BorjaNo ratings yet

- Report For Four Week Training at Guru Hargobind Thermal Plant (GHTP) Lehra MohabbatDocument23 pagesReport For Four Week Training at Guru Hargobind Thermal Plant (GHTP) Lehra MohabbatLovepreet SinghNo ratings yet

- Performance Analysis of MPPT Charge Controller WitDocument6 pagesPerformance Analysis of MPPT Charge Controller WitMunkh-Erdene TseveenNo ratings yet

- Escholarship UC Item 9t12q4fbDocument159 pagesEscholarship UC Item 9t12q4fbnewintechNo ratings yet

- Microturbine FuzzyDocument7 pagesMicroturbine FuzzyTariq KhanNo ratings yet

- MATLAB Modeling of Solar/Wind Hybrid Energy SystemDocument4 pagesMATLAB Modeling of Solar/Wind Hybrid Energy SystemMahar Nadir AliNo ratings yet

- Control of PEM Fuel Cell Distributed Generation SystemsDocument10 pagesControl of PEM Fuel Cell Distributed Generation SystemsRushikeshKatkarNo ratings yet

- Dual-Input LLCDocument11 pagesDual-Input LLCVishal PusadkarNo ratings yet

- Comparative Analysis of Transient Operation of Two Different Embedded Gas Turbine Power PlantsDocument0 pagesComparative Analysis of Transient Operation of Two Different Embedded Gas Turbine Power PlantsvcharlesNo ratings yet

- Generator Capability Study For Offshore Oil PlatformDocument8 pagesGenerator Capability Study For Offshore Oil Platformmohammad mostajeranNo ratings yet

- Islanding Scheme Operation: A Project Report OnDocument24 pagesIslanding Scheme Operation: A Project Report OnSooraj Surendran SugathaNo ratings yet

- Emergency Generator Sizing and Motor Starting AnalysisDocument6 pagesEmergency Generator Sizing and Motor Starting AnalysisK.RamachandranNo ratings yet

- Complete 5kVA Off-Grid Solar System for Daily 12kWhDocument7 pagesComplete 5kVA Off-Grid Solar System for Daily 12kWhMuhammad Sharif JanjuaNo ratings yet

- 61 - DieselEngine Black StartDocument12 pages61 - DieselEngine Black StartLincoln Eng100% (1)

- Selection of Power From Shore For An Offshore Oil and Gas DevelopmentDocument29 pagesSelection of Power From Shore For An Offshore Oil and Gas DevelopmentKURNIAWANNo ratings yet

- Generation Interconnection Combined Feasibility/Impact Study ReportDocument9 pagesGeneration Interconnection Combined Feasibility/Impact Study ReporteddisonfhNo ratings yet

- Regulated Output Voltage Double Switch Buck-Boost Converter For Photovoltaic Energy ApplicationDocument11 pagesRegulated Output Voltage Double Switch Buck-Boost Converter For Photovoltaic Energy ApplicationEduardo Cairolli de NovaesNo ratings yet

- Energies 13 04205Document18 pagesEnergies 13 04205osw2306No ratings yet

- Durgapur Institute of Advanced Technology & Management: A Maharatna CompanyDocument23 pagesDurgapur Institute of Advanced Technology & Management: A Maharatna CompanySushant KumarNo ratings yet

- Design and Implementation of A Feasible Microgrid Model in BrazilDocument9 pagesDesign and Implementation of A Feasible Microgrid Model in Brazilel_ruso__83No ratings yet

- Performance Test of Axial Turbine-Generator Magnet Permanent On-Grid System Prototype For Very Low Head ApplicationDocument11 pagesPerformance Test of Axial Turbine-Generator Magnet Permanent On-Grid System Prototype For Very Low Head Applicationveerabhadrappa kokatanurNo ratings yet

- STATCOM and Capacitor Banks in A Fixed Speed Wind Farm 2014 Energy ProcediaDocument11 pagesSTATCOM and Capacitor Banks in A Fixed Speed Wind Farm 2014 Energy Procediakrit_kasemNo ratings yet

- Grid Power Integration Technologies For Offshore Ocean Wave EnergyDocument8 pagesGrid Power Integration Technologies For Offshore Ocean Wave EnergyCarla CoronaNo ratings yet

- JPS19-231 - Lead Acid Batteries For Airport Ground-SupportDocument4 pagesJPS19-231 - Lead Acid Batteries For Airport Ground-Supportcarlosalberto.camargoNo ratings yet

- Control Strategy For HVDC Interconnected DC-based Offshore Wind FarmDocument6 pagesControl Strategy For HVDC Interconnected DC-based Offshore Wind FarmTruong HoaNo ratings yet

- Transient Stability Analysis of Taiwan Power System's Power Grid Connected With A High-Capacity Offshore Wind FarmDocument6 pagesTransient Stability Analysis of Taiwan Power System's Power Grid Connected With A High-Capacity Offshore Wind FarmAnbert Einstein-Huu Hao NguyenNo ratings yet

- Optim 2014 BanuDocument6 pagesOptim 2014 BanuIoan-Viorel BanuNo ratings yet

- S1E1 Process Measurement-PressureDocument61 pagesS1E1 Process Measurement-PressureRyan Anthony UmaliNo ratings yet

- Royal Prince Dasma Electrical Plan 1Document2 pagesRoyal Prince Dasma Electrical Plan 1Ryan Anthony UmaliNo ratings yet

- Royal Prince Dasma Electrical Plan 1Document2 pagesRoyal Prince Dasma Electrical Plan 1Ryan Anthony UmaliNo ratings yet

- 33 Chapter 8 Fire PumpDocument37 pages33 Chapter 8 Fire PumpRyan Anthony UmaliNo ratings yet

- CPC 100 MPD 600 Article Diagnostic Testing of Cast Resin Transformers 2018 ENUDocument13 pagesCPC 100 MPD 600 Article Diagnostic Testing of Cast Resin Transformers 2018 ENUManoj ShahNo ratings yet

- 29-Chapter 5 Protection Coordination-Objectives and Methodology Part 2Document14 pages29-Chapter 5 Protection Coordination-Objectives and Methodology Part 2Ryan Anthony UmaliNo ratings yet

- Graduate Programs Course Descriptions - 0 PDFDocument7 pagesGraduate Programs Course Descriptions - 0 PDFstephen villaruzNo ratings yet

- CPC 100 MPD 600 Article Diagnostic Testing of Cast Resin Transformers 2018 ENUDocument13 pagesCPC 100 MPD 600 Article Diagnostic Testing of Cast Resin Transformers 2018 ENUManoj ShahNo ratings yet

- Draft DC Declaring The Commercial Operation of Ewdo and Providing Further PoliciesDocument3 pagesDraft DC Declaring The Commercial Operation of Ewdo and Providing Further PoliciesRyan Anthony UmaliNo ratings yet

- 33-Chapter 8-Fire Pump EvaluationDocument42 pages33-Chapter 8-Fire Pump EvaluationRyan Anthony UmaliNo ratings yet

- Board Presentation-Power System Analysis of 52mva SubstationDocument23 pagesBoard Presentation-Power System Analysis of 52mva SubstationRyan Anthony Umali100% (1)

- 28A-LV Settings MCC8Document1 page28A-LV Settings MCC8Ryan Anthony UmaliNo ratings yet

- 33 Chapter 8 Fire PumpDocument37 pages33 Chapter 8 Fire PumpRyan Anthony UmaliNo ratings yet

- Pec ReviewerDocument1 pagePec ReviewerRyan Anthony UmaliNo ratings yet

- TER-Ryan Anthony K. UmaliDocument444 pagesTER-Ryan Anthony K. UmaliRyan Anthony Umali100% (3)

- 22-Chapter 4 Short Circuit Analysis Working-InT LLDocument4 pages22-Chapter 4 Short Circuit Analysis Working-InT LLRyan Anthony UmaliNo ratings yet

- 33-Chapter 8-Conclusion and RecommendationDocument4 pages33-Chapter 8-Conclusion and RecommendationRyan Anthony UmaliNo ratings yet

- 17-Chapter 4 Short Circuit Analysis Working-MOM SLGDocument14 pages17-Chapter 4 Short Circuit Analysis Working-MOM SLGRyan Anthony UmaliNo ratings yet

- 16-Chapter 4 Short Circuit Analysis Working-MOM 3phaseDocument15 pages16-Chapter 4 Short Circuit Analysis Working-MOM 3phaseRyan Anthony UmaliNo ratings yet

- 15-Chapter 4 Short Circuit Analysis-Objectives and MethodologyDocument4 pages15-Chapter 4 Short Circuit Analysis-Objectives and MethodologyRyan Anthony UmaliNo ratings yet

- 32 Chapter 7 Arc Flash AnalysisDocument20 pages32 Chapter 7 Arc Flash AnalysisRyan Anthony UmaliNo ratings yet

- 12-Chapter 3 3.1-3.2 Load Flow AnalysisDocument5 pages12-Chapter 3 3.1-3.2 Load Flow AnalysisRyan Anthony UmaliNo ratings yet

- 33-Chapter 8-Conclusion and RecommendationDocument4 pages33-Chapter 8-Conclusion and RecommendationRyan Anthony UmaliNo ratings yet

- 19-Chapter 4 Short Circuit Analysis Working-MOM DLGDocument15 pages19-Chapter 4 Short Circuit Analysis Working-MOM DLGRyan Anthony UmaliNo ratings yet

- 13-Chapter 3.3.1 Load Flow Analysis Case 1Document46 pages13-Chapter 3.3.1 Load Flow Analysis Case 1Ryan Anthony UmaliNo ratings yet

- 30 Chapter 5 Cable EvaluationDocument4 pages30 Chapter 5 Cable EvaluationRyan Anthony UmaliNo ratings yet

- 18-Chapter 4 Short Circuit Analysis Working-MOM LLDocument9 pages18-Chapter 4 Short Circuit Analysis Working-MOM LLRyan Anthony UmaliNo ratings yet

- 19-Chapter 4 Short Circuit Analysis Working-MOM DLGDocument15 pages19-Chapter 4 Short Circuit Analysis Working-MOM DLGRyan Anthony UmaliNo ratings yet

- Process Flow Sheets - Flow Chart SymbolsDocument6 pagesProcess Flow Sheets - Flow Chart SymbolsKHUSHI GUPTANo ratings yet

- CPI201T 12 PetroChemical IndustryDocument64 pagesCPI201T 12 PetroChemical IndustryPortia ShilengeNo ratings yet

- SaudiDocument52 pagesSaudiTarun AggarwalNo ratings yet

- Hexagon PPM L-T Chiyoda C2 Engineering Analysis Case Study USDocument2 pagesHexagon PPM L-T Chiyoda C2 Engineering Analysis Case Study USktejankarNo ratings yet

- Our Company OrpicDocument6 pagesOur Company OrpicErik AlfiandyNo ratings yet

- 6 MarchDocument51 pages6 MarchmaritsyaditaaNo ratings yet

- Refining & Chemicals: Training CoursesDocument185 pagesRefining & Chemicals: Training CoursesJean-Louis KouassiNo ratings yet

- Eia Saudiarabien Petroch 1Document15 pagesEia Saudiarabien Petroch 1moheauNo ratings yet

- TGM - Petrochemical Complexes - 160910 - NK PDFDocument240 pagesTGM - Petrochemical Complexes - 160910 - NK PDFChristina george babyNo ratings yet

- EPC Execution of Borealis Ethane Tank Project TGE enDocument20 pagesEPC Execution of Borealis Ethane Tank Project TGE enLEENo ratings yet

- Petrochemicals PresentationDocument27 pagesPetrochemicals PresentationVarunKumarNo ratings yet

- China, SE Asia and Turkey Polyolefins: Impact On Increasing Global CapacityDocument30 pagesChina, SE Asia and Turkey Polyolefins: Impact On Increasing Global CapacitySam Cheng100% (1)

- Lummus Technology: Most Broad, Diversified Technology PortfolioDocument2 pagesLummus Technology: Most Broad, Diversified Technology PortfolioSARFRAZ ALINo ratings yet

- The Chemicals Subsectorv1Document13 pagesThe Chemicals Subsectorv1Makhosonke MkhonzaNo ratings yet

- +++ Fundamentals of Petroleum RefiningDocument6 pages+++ Fundamentals of Petroleum Refiningnadjib62No ratings yet

- Permitting Requirements PD 1586Document65 pagesPermitting Requirements PD 1586Leslie Balneg RubinNo ratings yet

- ChillRex02 Weekly Report Week 8 (6 January)Document13 pagesChillRex02 Weekly Report Week 8 (6 January)Sharifah NurriedaNo ratings yet

- Venkat ResumeDocument3 pagesVenkat ResumevenkiksaNo ratings yet

- Jowy P Deauna Updated CV 2022Document4 pagesJowy P Deauna Updated CV 2022Reychelle Ann Quinto RodriguezNo ratings yet

- Petrochemical Projects in the Gulf RegionDocument2 pagesPetrochemical Projects in the Gulf RegionGuillermoAlvarez84100% (1)

- CE4102 Petrochemical Processes Lecture 3 Olefins ProductionDocument27 pagesCE4102 Petrochemical Processes Lecture 3 Olefins ProductionAgus WahyudhiNo ratings yet

- Moscow Refining, Gas & Petrochemical WeekDocument11 pagesMoscow Refining, Gas & Petrochemical Weekdheeraj sehgalNo ratings yet

- Polyolefin in IranDocument12 pagesPolyolefin in Irantotpityi100% (1)

- User ManualDocument1 pageUser ManualManuel CantoralNo ratings yet

- PVC Fact BookDocument20 pagesPVC Fact BookevoidNo ratings yet

- Chemical Billionaire's Bid For Fossil Fuel Empire: Ineos Corporate ProfileDocument14 pagesChemical Billionaire's Bid For Fossil Fuel Empire: Ineos Corporate ProfileFood and Water Watch100% (1)

- Accredited Consultants PDFDocument142 pagesAccredited Consultants PDFShantanu EksambekarNo ratings yet

- Tahrir ProjectDocument12 pagesTahrir Projectingbarragan87No ratings yet

- TK 4153 Perancangan Proses Teknik Kimia (Chemical Process Design)Document30 pagesTK 4153 Perancangan Proses Teknik Kimia (Chemical Process Design)Nur Irfana Mardiyah DiyahlikebarcelonaNo ratings yet

- One Night at The Call CenterDocument11 pagesOne Night at The Call CenterSampat PrajapatiNo ratings yet