Professional Documents

Culture Documents

80 20 Internal Bond Tester

Uploaded by

Hazeq AzaharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

80 20 Internal Bond Tester

Uploaded by

Hazeq AzaharCopyright:

Available Formats

Internal Bond Tester

Model 80-20

The Internal Bond Tester is designed to determine the internal bond strength of a variety of Paper and Board materials

according to TAPPI T 569. The instrument design is based on a falling pendulum which creates a high speed impact on a

paper specimen. The paper specimen is sandwiched between two double-coated tape substrates. The pendulum impact

measures the total energy required to delaminate the internal fibers of a specimen in a Z type direction into two separate

piles. The system also incorporates an automatic sample preparation station which allows five specimens to be accurately

prepared simultaneously. The Prep Station requires a filtered air supply meeting IG4 Industrial Grade Air: ISO Class 1-4-1.

FEATURES

APPLICATIONS

Storage and editing of up to 500 readings

Newsprint, Fine Paper, Liner Board, Book Stock,

Selectable units (ft.lb/in, J/m and kgcm)

Carton Board, Medium, Coatings, Laminates

RS-232 serial output

STANDARDS

Report printout with built-in printer

Conforms to TAPPI standard T 569

Magnetic hammer release

Automatic calibration

Automatic specimen hold-down during test sequence

Settable limits, statistics-average, standard deviation, high/low results

Safe automated sample cutting procedure eliminates manual use of cutting knives

5.7 inch LCD color display with 320 x 240 resolution

15 Character alphanumeric keypad

6 function keys for easy test setup

10 soft key icons allow simple intuitive navigation of test functions

Internal Bond Tester

Model 80-20

5.7 inch LCD color display

with 320 x 240 resolution

Test result display

Software Program

15 character alphanumeric keypad

Setup Menu

FEATURES

Screen display

Provides a web-like page navigation menu-driven user interface

Normal Mode

Set pressure: using the + and - keys, set the compression forces from 50 to 200 psi

Duration: sets the amount of time (in seconds) the set pressure will be applied to the samples

Threshold: defines what % of set pressure to begin countdown of dwell time (duration)

Calibration mode

Internal Bond Tester

Model 80-20

Sample Prep Station

A SAFE operation precision Sample Prep Station with digital display and direct

read out in kPa and psi units is available to prepare up to five test pieces at a

time. The Sample Prep Station provides a consistent adhesive transfer when

pressing the test specimen between the double-sided tape and aluminum

platens.

Unlike other sample prep stations, the TMI Ibond prep station has a safety

feature which does not require the operator to cut individual test specimens

with a box cutting knives after the specimen is pressed. The specimen cutting

operation is performed automatically by the instrument.

Included with the Sample Prep Station are five aluminum platens with a sample

size of 25.4 x 25.4 mm (1.0 x 1.0 inches). The clamping pressure is adjustable

from 345 kPa (50 psi) to 1379 kPa (200 psi). During the pressing operation, a

selectable dwell time can be set by the operator from 0 - 4 seconds. The factory

setting is 3 seconds in accordance with TAPPI T 569. The system is designed

with a reinforced anvil to prevent deflection during sample preparation.

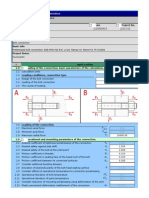

a steel anvil

b double coated tape

c specimen

d double coated tape

e aluminum platen

Reinforced anvil system prevents sample

deflection during preparation

Ordering Information

Figure shows specimen sandwiched between two

double-coated tape substrates

80-01-03-0001

120 +/- 10% VAC, 50/60 Hz for 120 VAC Sample Prep Station

80-01-03-0002

220 +/- 5% VAC, 50/60 Hz for 220 VAC Sample Prep Station

Specifications (applies to both models)

Pneumatic clamping force

50-200 psi

Dwell time

1 to 4 seconds

Sample Press Timer

user adjustable 1-4 seconds

Aluminum platens (five)

sample size of 25.4 x 25.4 mm (1.0 x 1.0 inches)

Sample thickness range

up to 1.25 mm (0.050 inches)

Clamping pressure adjustment

345 kPa (50 psi) to 1379 kPa (200 psi)

Clamping pressure resolution

7 Kpa (1 psi)

Clamping pressure control

at 690 kPa (100psi) is better than 21 kPa (7 psi)

at 1034 kPa (150psi) is better than 34 kPa (5 psi)

Weight

22.7 kg (50 lb)

Dimensions (W x D x H)

33.5 x 26.7 x 37.1 cm (13.2 x 10.5 x 14.6 in)

Air Requirements

Filtered air supply meeting IG4 Industrial Grade Air: ISO Class 1-4-1

Standards

Meets TAPPI T569 om 07: Internal bond strength (Scott type). This method defines a

test that measures the energy required to rapidly delaminate a sheet-type specimen.

Internal Bond Tester

Model 80-20

Magnetic

hammer release

Pendulum

Alphanumeric

keypad

Built-in printer

LCD color display

Function keys

Adjustable feet

Ordering Information

Model

80-20-00-0003

Ranges

0 841 J/m (0 - 400 ft.lb x 10-3)

0 1575 J/m (0 - 750 ft.lb x 10-3)

0 2100 J/m (0 - 1000 ft.lb x 10-3)

Pendulum Release

Magnetic

Peak/Angular Resolution

0.04

Results directly in

ft.lb/in, J/m, kgcm

Statistics

Average, Standard Deviation, Minimum, Maximum and Calibrate function

Pendulums (Must be ordered separately, please specify)

80-20-04

0.4 ft.lb/in pendulum assembly (standard range)

80-20-02

0.75 ft.lb/in pendulum assembly

80-20-03

1.0 ft.lb/in pendulum assembly

Specifications

Weight

23 kg (51 lb)

Dimensions (W x D x H)

53.3 x 40 x 60.3 cm (21 x 15.7 x 23.7 in)

Air

Instrument quality 700 kPa

Electrical

90-264 VAC 50/60 Hz

Standards

TAPPI T 569

Internal bond strength (Scott type). This method defines a test that measures

the energy required to rapidly delaminate a sheet-type specimen.

2015 Testing Machines, Inc. All rights reserved. Specifications subject to change.

Testing Machines, Inc.

Messmer Bchel (Bchel BV)

PT. TMI Asia

TMI Trading (Shanghai) Co., Ltd.

Delaware, USA

The TMI Group of Companies

Phone: (302) 613-5600 Fax: (302) 613-5619

info@testingmachines.com

West Java, Indonesia

Veenendaal, Netherlands

Shanghai, China

Visit us on the web at: www.testingmachines.com

FIBRO System AB

Stockholm, Sweden

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Dodge Ram Truck 2005 1500,2500, 3500 Service Repair Manual - IntroductionDocument14 pagesDodge Ram Truck 2005 1500,2500, 3500 Service Repair Manual - Introductionthomas ruldu40% (5)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BoltCon - 02Document105 pagesBoltCon - 02Marinel1955100% (1)

- PD Iso-Tr 9464-2023 - (2023-11-29 - 10-17-32 Am)Document74 pagesPD Iso-Tr 9464-2023 - (2023-11-29 - 10-17-32 Am)Luís SilvaNo ratings yet

- Stress, Strain and Relation ExerciseDocument7 pagesStress, Strain and Relation ExerciseHazeq AzaharNo ratings yet

- EXP-MN-SI020-EN-R0 - Measurements in Instrumentation PDFDocument114 pagesEXP-MN-SI020-EN-R0 - Measurements in Instrumentation PDFbali100% (3)

- Esas 12Document8 pagesEsas 12Marche SebastianNo ratings yet

- Astm D323Document10 pagesAstm D323Nayth Andres GalazNo ratings yet

- First-Order Process Time Delay 2002Document47 pagesFirst-Order Process Time Delay 2002Hazeq Azahar100% (1)

- Experiment 6 - Kla DeterminationDocument4 pagesExperiment 6 - Kla DeterminationHazeq AzaharNo ratings yet

- Start-Up Cost: (1 To 1.5 PAGES)Document3 pagesStart-Up Cost: (1 To 1.5 PAGES)Hazeq AzaharNo ratings yet

- R. E. S. H.E.H.S: (12) United States Patent (10) Patent No.: US 6, 177,600 B1Document11 pagesR. E. S. H.E.H.S: (12) United States Patent (10) Patent No.: US 6, 177,600 B1Hazeq AzaharNo ratings yet

- 2 in 1 Correction Highlighter With Pen: Problem/IssuesDocument1 page2 in 1 Correction Highlighter With Pen: Problem/IssuesHazeq AzaharNo ratings yet

- United States Patent (10) Patent No.: US 8.471,082 B2Document10 pagesUnited States Patent (10) Patent No.: US 8.471,082 B2Hazeq AzaharNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentHazeq AzaharNo ratings yet

- Assignment 1 Cpe614 051018Document2 pagesAssignment 1 Cpe614 051018Hazeq AzaharNo ratings yet

- Irradiationpreservationoffoods 141110012437 Conversion Gate02Document129 pagesIrradiationpreservationoffoods 141110012437 Conversion Gate02Hazeq AzaharNo ratings yet

- Assignment 2 Chemical Engineering Thermodynamics/ThermodynamicsDocument1 pageAssignment 2 Chemical Engineering Thermodynamics/ThermodynamicsHazeq AzaharNo ratings yet

- Search Results: Membrane Test Unit - Membrane - Membrane Technology - ScribdDocument4 pagesSearch Results: Membrane Test Unit - Membrane - Membrane Technology - ScribdHazeq AzaharNo ratings yet

- 11 Design of FootingDocument6 pages11 Design of FootingMarieday LopezNo ratings yet

- Victaulic FittingDocument188 pagesVictaulic FittingThomas CuralliNo ratings yet

- Engineering Conversion SheetDocument4 pagesEngineering Conversion SheetVan Lian ChinNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- Gases and The Kinetic-Molecular TheoryDocument54 pagesGases and The Kinetic-Molecular TheoryCassey ToyuNo ratings yet

- General Specifications: EJA510E and EJA530E Absolute and Gauge Pressure TransmitterDocument11 pagesGeneral Specifications: EJA510E and EJA530E Absolute and Gauge Pressure Transmitteryosue riveraNo ratings yet

- Republic of The Philippines: Battery - 1Document8 pagesRepublic of The Philippines: Battery - 1Aileen AntipoloNo ratings yet

- Tasintu PaturatDocument104 pagesTasintu PaturatpipestressNo ratings yet

- Fyzika A1Document2 pagesFyzika A1DannydajaNo ratings yet

- Solar Roll PE55 PDFDocument2 pagesSolar Roll PE55 PDFLong TomahawkNo ratings yet

- Fluid Mechanics - Lecture Notes - SCI 3114Document84 pagesFluid Mechanics - Lecture Notes - SCI 3114Sharlene Cecil PagoboNo ratings yet

- Ideal Gas LawDocument16 pagesIdeal Gas LawJomari ValenzuelaNo ratings yet

- MicroCal P200Document4 pagesMicroCal P200Paul Chiriacescu100% (1)

- Plascore - PN1 - Honeycomb PDFDocument2 pagesPlascore - PN1 - Honeycomb PDFIverton FariasNo ratings yet

- 3 Barton-Bandis Joint Model: 3.1 BackgroundDocument40 pages3 Barton-Bandis Joint Model: 3.1 BackgroundRakshit MishraNo ratings yet

- Lecture 2-Normal Stress Under Axial Loading PDFDocument12 pagesLecture 2-Normal Stress Under Axial Loading PDFomed RekaniNo ratings yet

- Material PA 4112: Revision Index Revision DateDocument2 pagesMaterial PA 4112: Revision Index Revision DateFábioNo ratings yet

- Introduction To Engineering Analysis 4th Edition Hagen Solutions ManualDocument27 pagesIntroduction To Engineering Analysis 4th Edition Hagen Solutions ManualJesseHallmzgxy100% (16)

- Coldroom Brochure 2020 (Email Version)Document12 pagesColdroom Brochure 2020 (Email Version)MOHAMED FAHMIE SYAFIQ BIN AHMAD BAKRI (LKIM)No ratings yet

- DERAKANE 411-45 Epoxy Vinyl Ester Resin: April 2005Document3 pagesDERAKANE 411-45 Epoxy Vinyl Ester Resin: April 2005benNo ratings yet

- 04 - CPL 3101-15Document16 pages04 - CPL 3101-15Kiplgat ChelelgoNo ratings yet

- Product Data Sheet UP GM 203Document1 pageProduct Data Sheet UP GM 203Ravindra ErabattiNo ratings yet

- Liquid Pressure and Pascals LawDocument16 pagesLiquid Pressure and Pascals Lawitsamazing496No ratings yet

- Artigo 3 e 4Document10 pagesArtigo 3 e 4Eunice FidelisNo ratings yet