Professional Documents

Culture Documents

Column1 Column3 Date Item Quantity Unit/no of Uni

Uploaded by

hasnainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column1 Column3 Date Item Quantity Unit/no of Uni

Uploaded by

hasnainCopyright:

Available Formats

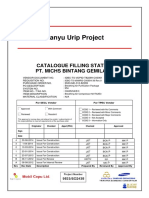

Column1

Column3

date

item

quantity

unit/no of uni

batch no

QC. No

suppliers namsupplier addrelc/invoice no invoice date

mfg.date

exp.date

batch no2

Column9

Column10

Column11

Column12

Column13

Column14

Column15

Column16

Column17

Column18

Goods Receiving Notes

Supplier Name & Adress

#N/A

LC/INVOICE #

DATE

#N/A

BATCH NO.

MFG.DATE:

EXP.DATE:

PHYSICAL CONDITION

DAMAGE

S.NO.

DIRTY

Q.C NO

CLEANED

ITEMS

QUALITY ASSURANCE REPORT

Material Checked and Received By:

SEALED

QUANTITY

RECEIVED

total no of

units

REMAR

APPROVED

Reason for rejection if any:

Material Checked :

Approved

Reject

Assay:

Analyzed by:

Date:

QUALITY ASSURANCE

MANAGER

Quality Control Manager

Instructions:

28. For all material received at the factory ,this form must be prepared once.

29.Supplier must inform as soon as possible for any defect or short shipment in material.

30. All rejected material must placed at designated area

White Copy : Store

Green Copy : QC

22

G.R.N #

DATE

EXP.DATE:

UNSEALED

REMARKS

APPROVED REJECT

aterial.

Conditionally Approved

Date:

You might also like

- Guidelines For Writing Expediting Report 15.03.01 SOP-01 R01 21-06-2019...Document13 pagesGuidelines For Writing Expediting Report 15.03.01 SOP-01 R01 21-06-2019...jeswin80% (5)

- ITP-01 - BackfillingDocument1 pageITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Sop ReceivingDocument6 pagesSop Receivingwaqaas125100% (2)

- SMT Generic Control PlanDocument3 pagesSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- First Article Inspection - Aerospace FormsDocument6 pagesFirst Article Inspection - Aerospace Formssqalopez100% (1)

- Inspection Report TemplateDocument4 pagesInspection Report TemplateBOBNo ratings yet

- In-Line Inspection FORMAT - 1Document3 pagesIn-Line Inspection FORMAT - 1Nishu Jalotia0% (1)

- 21.02.15 Tuv Visit ReportDocument5 pages21.02.15 Tuv Visit ReportssmullaNo ratings yet

- PSWDocument2 pagesPSWLinda G. CordovaNo ratings yet

- IsirDocument4 pagesIsirIkhwandi BdrNo ratings yet

- Material Part Identification ReportDocument3 pagesMaterial Part Identification ReportAshwani DograNo ratings yet

- Form MRIRDocument4 pagesForm MRIRAlbert Wilson PardameanNo ratings yet

- Car Pasien penurunan kesadaran, sulit bernafas, nampak sesak, ada sedikit secret, tidak ada muntahan di rongga mulut, terdengar adanya bunyi aliran udara pernafasan, bunyi auskultasi paru ronkhi, terasa adanya aliran udara pernafasanDocument1 pageCar Pasien penurunan kesadaran, sulit bernafas, nampak sesak, ada sedikit secret, tidak ada muntahan di rongga mulut, terdengar adanya bunyi aliran udara pernafasan, bunyi auskultasi paru ronkhi, terasa adanya aliran udara pernafasanEndar BudiNo ratings yet

- ImirDocument1 pageImirChava TejaNo ratings yet

- InspectionDocument32 pagesInspectionmaruf19900100% (1)

- RfiDocument8 pagesRfiShem BarroNo ratings yet

- Standard Plating Inspection ProcessDocument2 pagesStandard Plating Inspection ProcessPramod Bodne50% (2)

- Sterility Test Failure Investigation FormDocument9 pagesSterility Test Failure Investigation FormmishannakNo ratings yet

- Prototype - Pre-Launch - Production (Circle) Control PlanDocument1 pagePrototype - Pre-Launch - Production (Circle) Control PlanTaufikRasyadiNo ratings yet

- WELD SUMMARY TRACKINGDocument30 pagesWELD SUMMARY TRACKINGThamaraikani Mani100% (1)

- As9102 BlankDocument4 pagesAs9102 Blankshoobi82No ratings yet

- Form SMR.11T.L - LU4-13-05Document2 pagesForm SMR.11T.L - LU4-13-05William ChandraNo ratings yet

- Control FormsDocument22 pagesControl FormsShowki WaniNo ratings yet

- Maintain Training FacilitiesDocument23 pagesMaintain Training FacilitiesChristian James Guevara63% (8)

- Checklist Compressor - SAMPLEDocument1 pageChecklist Compressor - SAMPLESUKhan100% (1)

- Web FormatDocument12 pagesWeb Formatsukoo79No ratings yet

- 021 Form No. TC-G-3 Daily Concrete Report-170707Document1 page021 Form No. TC-G-3 Daily Concrete Report-170707Jaouad Id BoubkerNo ratings yet

- Revision Record Sheet: TitleDocument3 pagesRevision Record Sheet: TitleSanjay MalhotraNo ratings yet

- Std-Insp-0002 (Incoming Material Inspection Procedure)Document3 pagesStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNo ratings yet

- IMIR Report No5Document1 pageIMIR Report No5Chava Teja100% (1)

- Product Complaint Form: Unilever Ghana LTDDocument1 pageProduct Complaint Form: Unilever Ghana LTDCEPHAS DUMORNo ratings yet

- IRN-8108577716-432-01-RIL-Audco-17 Jan 2014Document1 pageIRN-8108577716-432-01-RIL-Audco-17 Jan 2014MuralitclNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Apqp FormsDocument25 pagesApqp FormsgkspNo ratings yet

- LOADER ChecklistsDocument1 pageLOADER ChecklistsSalvacion Jaro100% (1)

- Uncontrolled Copy, Verify Revision Before Using.: Atlantic Inertial SystemsDocument4 pagesUncontrolled Copy, Verify Revision Before Using.: Atlantic Inertial Systemsnetelsrt1298No ratings yet

- Inspection Record For Grouting: Items To InspectDocument1 pageInspection Record For Grouting: Items To InspectJoseph PeterNo ratings yet

- DDDDDocument1 pageDDDDHana TesfayeNo ratings yet

- As 9102 FormsDocument4 pagesAs 9102 Formsmedi38No ratings yet

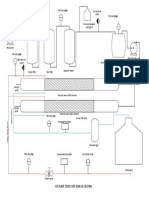

- IDBC-TS-VDPID-T82299-C00001 Rev 4 - P&ID Breathing Air CompressorDocument5 pagesIDBC-TS-VDPID-T82299-C00001 Rev 4 - P&ID Breathing Air CompressorAndiWSutomoNo ratings yet

- Revision Record Sheet: TitleDocument2 pagesRevision Record Sheet: TitleSanjay Malhotra100% (1)

- Test Scenario No. Q10 Quality Management PlaybacksDocument2 pagesTest Scenario No. Q10 Quality Management PlaybacksashumovNo ratings yet

- C5ar Ut RequestDocument4 pagesC5ar Ut RequestRaymond de WeeverNo ratings yet

- Inspection Release NoteDocument1 pageInspection Release NoteNur WijiantoNo ratings yet

- Specific Gravity PDFDocument457 pagesSpecific Gravity PDFvasantnajanNo ratings yet

- SOP 9 IDENTIFICATION AND TRACEABILITYDocument3 pagesSOP 9 IDENTIFICATION AND TRACEABILITYvaishnavi100% (5)

- Phased Ps Wwith P Pap Tracking FormDocument3 pagesPhased Ps Wwith P Pap Tracking FormKurt FinkNo ratings yet

- Inspection Call FORMATDocument1 pageInspection Call FORMATMl JainNo ratings yet

- IMIRDocument2 pagesIMIRRizwanNo ratings yet

- Hydrostatic Test ProcedureDocument3 pagesHydrostatic Test Proceduregstketut100% (6)

- Lyondellbasell Commercial Grade Survey ChecklistDocument11 pagesLyondellbasell Commercial Grade Survey ChecklistJuan Carlos CampilloNo ratings yet

- Needle Detection Report: TotalDocument5 pagesNeedle Detection Report: Totalmizan rohmanNo ratings yet

- Basic Inspection Protocol TitleDocument17 pagesBasic Inspection Protocol TitleCaspian DattaNo ratings yet

- Inspection and Test Plan for Mars CS PackageDocument17 pagesInspection and Test Plan for Mars CS PackageMariah PearsonNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Hasnain Ali: Curriculum VitaDocument3 pagesHasnain Ali: Curriculum VitahasnainNo ratings yet

- 5000 Gallon Plant Tds More The 5000 PPM (Ejaz Sahab)Document10 pages5000 Gallon Plant Tds More The 5000 PPM (Ejaz Sahab)hasnainNo ratings yet

- GPD Ro PlantDocument1 pageGPD Ro PlanthasnainNo ratings yet

- ComplaintsDocument2 pagesComplaintshasnainNo ratings yet

- Dar Ul Uloom 30000GPD PlantDocument1 pageDar Ul Uloom 30000GPD PlanthasnainNo ratings yet

- Has NianDocument1 pageHas NianhasnainNo ratings yet

- JD's (Vertex)Document1 pageJD's (Vertex)hasnainNo ratings yet

- Drawing 1Document1 pageDrawing 1hasnainNo ratings yet

- LeatherDocument30 pagesLeatherBhuva_janaNo ratings yet

- IIDocument1 pageIIhasnainNo ratings yet

- The Chemistry of The Leather IndustryDocument17 pagesThe Chemistry of The Leather Industrymariyyun100% (3)

- Reverse Osmosis: Dr. Ola AbdelwahabDocument15 pagesReverse Osmosis: Dr. Ola Abdelwahabm_alodat6144No ratings yet

- P6 R8.3 TRNGDocument17 pagesP6 R8.3 TRNGhasnainNo ratings yet

- Training Log BookDocument3 pagesTraining Log BookhasnainNo ratings yet

- Take Sample For AnalysisDocument1 pageTake Sample For AnalysishasnainNo ratings yet

- Store First Stage Water If Tds Is Between 1 To 2 MG/LDocument1 pageStore First Stage Water If Tds Is Between 1 To 2 MG/LhasnainNo ratings yet