Professional Documents

Culture Documents

21946

Uploaded by

Romner CordovaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

21946

Uploaded by

Romner CordovaCopyright:

Available Formats

Description

Field portable, high-production, singlechamber blast machine system, rated at

150 psi, for one operator. Holds 2 cubic

feet of blast media. Equipped with

Millennium pneumatic remote controls.

Components listed on next page.

TECHNICAL DATA SHEET

Contractor

System 2002 CA

with Apollo 600 HP

Respirator

Stock No. 21547

Note: For safe, efficient blasting, read

and follow the owner's manual and seek

training for everyone who will use this

equipment.

Purpose

High-performance blast cleaning

system removes corrosion, mill scale, and

coatings from most surfaces. Produces a

uniform surface texture, and creates a

surface profile to increase bonding for

coatings. See related literature for

additional applications. Machine holds 2

cubic feet of abrasive for up to 30

minutes of continuous blasting at 100 psi

with standard No. 4 nozzle (1/4-inch

orifice).

Contractor System Accessories

Requirements for Operation

These items are required but not included

with this equipment.

Clean, dry, compressed air of

sufficient volume to maintain desired

pressure at the nozzle. See Air

Consumption Chart in Blast Off 2

booklet.

Minimum 30 psi needed to operate

OSHA-required remote control valves

Blast suit and work boots

Abrasive blast media - consult abrasive

supplier for appropriate media for your

application

Compressed air source capable of

delivering 20 cfm (at 90 to 100 psi) of

Grade D breathing-air as defined by the

Compressed Gas Association

Commodity Specification: G-7.1

(www.cganet.com)

Description of Operation

The operator controls blasting from a

remote control handle at the nozzle.

Pressing the handle starts blasting,

releasing it stops blasting. The blast

machine contains abrasive and meters it

into the compressed air stream.

Operator Safety Equipment

2 cu ft Contractor Blast Machine with

CPF-20 Air Filter Installed

Advantages

Approvals and Certifications

Rated for 150-psi working pressure

1-1/2-inch Millennium valve provides

unrestricted air flow

Quantum metering valve maintains

smooth, consistent flow; adjustment

knob allows precise control of media

flow

29-inch width fits through standard

doorways with moisture separator

remove

CPF-20 breathing air filter, installed

Two-wheel integral cart for ease of

moving

Robust handles act as skid for loading

machine into pickup or trailer and

protect valves and piping from

damage

Central hookup point for blast hose and

remote controls

High-efficiency air filter/moisture

separator helps keep abrasive dry

Weather-resistant storage area holds

manuals, paperwork and small parts

State-of-the-art NIOSH-approved

respirator with DLX comfort-fit

suspension.

Blast machine pressure vessel built to

American Society of Mechanical

Engineers (ASME) code for 150-psi

working pressure. Vessel is

hydrostatically tested and National Board

certified.

Apollo 600 helmet is NIOSH-approved

type-CE air fed respirator and is

recognized by OSHA as having an

assigned protection factor (APF) against

lead dust of 1000 times the permissible

exposure limit (PEL).

Remote control system complies with

OSHA regulation 1910.244 (b).

NOTE: Prior to use, ensure that Apollo,

type-CE, continuous-flow, supplied-air

respirator is appropriate for your specific

blasting conditions and requirements.

Related Clemco Literature

Included with Stock No. 21547

Description

Stock No.

Contractor Series Catalog ......................................................21385

Abrasive Blasting Safety Practices ........................................22090

Blast Off 2 ..............................................................................09294

Operator Safety Equipment Product Study ............................07764

Blast Suits & Gloves Technical Data Sheet............................21969

Contractor Blast Machine Owner's Manual ..........................21939

CPF Filter Owners Manual....................................................04143

Options and Accessories

Description

Stock No.

Blast machine cover, 16" ........................................................02335

Electric remote controls....................................................on request

Carbon monoxide alarm, CMS-2............................................22894

Heavy cotton/leather

blast suit ..............S (08920), M (08921), L (08922), XL (08923)

XXL (24201), XXXL (24202)

Seasonal cotton/nylon

blast suit ..............S (22913), M (22914), L (22915), XL (22916),

XXL (22917), XXXL (25022)

(13)

(16)

(9)

(12)

Item

Description

1.

2.

3.

4.

Stock No.

2 cu ft contractor blast machine ..............................21490

1-1/2" Millennium valve ..........................................21336

Quantum abrasive metering valve............................22845

50 ft x 1" Supa blast hose, coupled with

CQPS-1 nylon coupling &

NHP-1 nylon nozzle holder ..............................23480

TMP-4 contractor thread nozzle ..............................23520

Blast hose safety cable ............................................15013

1" Air filter/moisture separator w/manual drain ......22424

16" recessed blast machine screen ..........................03099

Apollo 600 HP DLX helmet w/Clem-Cool ............25194

50 ft x 3/8" respirator hose ......................................04415

CPF-20 air filter........................................................03578

Leather gloves ..........................................................02243

Helmet outer lenses, pkg. of 25 ..............................04361

Helmet intermediate lenses, pkg. of 5......................24943

Nylon ties, (8 provided) ..........................................02195

50 ft twinline hose ....................................................01951

RLX pneumatic handle ............................................10565

Abrasive trap ............................................................02011

Replacement flexible pusher line ............................23674

All-weather machine cover (polyethelene bag) ......15097

Quick coupling gaskets, pkg. of 10..........................21584

Nozzle washers, pkg. of 10 ......................................91024

Abrasive trap screens 6 ea. ......................................02012

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

(-)

(-)

(-)

(-)

(17)

(5)

(8)

(1)

Owners manual

storage area

(10)

(14)

(4)

(15)

(2)

(7)

(6)

(11)

(18)

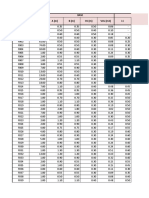

Nominal

Dimensions

Height (floor to highest point):

Width (outside hub to hub):

Length (hose cplg. to handle):

Machine diameter:

Net weight:

Shipping Volume:

Shipping Weight:

Unit

43"

29"

39"

16"

360 lbs

Shipping

(including skid)

55"

35"

40"

(3)

Authorized Distributor:

44.6 cuft

428 lbs

Packaging

Secured on skid and shrink wrapped

ISO 9001:2000 certified. Clemco is committed to continuous product improvement. Specifications are subject to change without notice.

2009 Clemco Industries Corp. One Cable Car Drive Washington, MO 63090 Phone (636) 239-4300 Fax (800) 726-7559

www.clemcoindustries.com

Stock No. 21946

Job No. 1195-1295 Rev. E 06/09

You might also like

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Vaccon Pump CatalogDocument33 pagesVaccon Pump Catalogjaka661100% (1)

- Special Air Services: Aerial Application Agricultural SystemDocument28 pagesSpecial Air Services: Aerial Application Agricultural Systemviorelu99No ratings yet

- Specif-Dust Extraction SystemDocument12 pagesSpecif-Dust Extraction SystemChristopher LloydNo ratings yet

- Maximator High Pressure Compressors MX-SeriesDocument28 pagesMaximator High Pressure Compressors MX-SeriesMaximator TürkiyeNo ratings yet

- Panamax Cargo Hold Cleaning Manual Rev00Document36 pagesPanamax Cargo Hold Cleaning Manual Rev00Cenk ÇobanNo ratings yet

- HH Series Specifications: Heatless Desiccant Compressed Air DryerDocument4 pagesHH Series Specifications: Heatless Desiccant Compressed Air DryerTomás GarduzaNo ratings yet

- ProductsDocument8 pagesProductsLe ChauveNo ratings yet

- Acson Catalogue Air Handling Unit (1201)Document12 pagesAcson Catalogue Air Handling Unit (1201)William Ball50% (4)

- AMS Catalogue Air DifuserDocument12 pagesAMS Catalogue Air DifuserShinigami01001No ratings yet

- Hermatic LRVP CatalogueDocument12 pagesHermatic LRVP CatalogueSunil BawaneNo ratings yet

- ClemcoDocument8 pagesClemcogeraldNo ratings yet

- Valvular de Relevo de PresiónDocument24 pagesValvular de Relevo de Presiónpedrounda1No ratings yet

- Panamax Cargo Hold Cleaning Manual Rev01Document22 pagesPanamax Cargo Hold Cleaning Manual Rev01livslx100% (2)

- PVC Duct Installation GuideDocument10 pagesPVC Duct Installation GuidecitramuaraNo ratings yet

- Design and Size DuctworkDocument6 pagesDesign and Size Ductworkwilderness_666No ratings yet

- Dust Extraction Design ReportDocument13 pagesDust Extraction Design ReportKartik Mendiratta100% (1)

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- AXM Industry EngDocument12 pagesAXM Industry EngHyder AliNo ratings yet

- Gast Compressed Air Systems enDocument11 pagesGast Compressed Air Systems enKrzysiek PodsiadłoNo ratings yet

- Compressor 3Document98 pagesCompressor 3Erick GonzalezNo ratings yet

- Lesoon Equipment Catalogue 2015Document28 pagesLesoon Equipment Catalogue 2015Jason PerezNo ratings yet

- Compressed Air Filters PDFDocument70 pagesCompressed Air Filters PDFdj22500No ratings yet

- Superior Gas Chlorinators BrochureDocument16 pagesSuperior Gas Chlorinators BrochureAqua Technology GroupNo ratings yet

- Vacuum Automation-I (Pumps, Pads, Filter... Etc.) PDFDocument244 pagesVacuum Automation-I (Pumps, Pads, Filter... Etc.) PDFSharath Thimmegowda100% (2)

- Synthetic Yarn Humidification PlantDocument12 pagesSynthetic Yarn Humidification Plantardhendu1No ratings yet

- 230022-H: Supplemental Grilles, Registers, Diffusers and Air Balancing Accessories (15880-H)Document3 pages230022-H: Supplemental Grilles, Registers, Diffusers and Air Balancing Accessories (15880-H)Amin FarukiNo ratings yet

- Guzzler CLDocument2 pagesGuzzler CLgshdavidNo ratings yet

- Technical Proposal for Olympic Pool Filtration SystemDocument10 pagesTechnical Proposal for Olympic Pool Filtration SystemAlma DerajNo ratings yet

- BLASTING TECHNICAL GUIDEDocument16 pagesBLASTING TECHNICAL GUIDESivaratnam Navatharan100% (1)

- Sizing Technical Brief FinalDocument3 pagesSizing Technical Brief FinalBelalNorNo ratings yet

- ARB Compressor DualDocument5 pagesARB Compressor DualSteveNo ratings yet

- 15 Foam MakerDocument8 pages15 Foam MakerMatthew BennettNo ratings yet

- DeltaDocument20 pagesDeltaClaudio TurlherNo ratings yet

- Revised CotmatDocument7 pagesRevised CotmatMayuresh JagtapNo ratings yet

- Mobile Air Compressor Specification (D 33)Document3 pagesMobile Air Compressor Specification (D 33)Elias EliasNo ratings yet

- Ppep PMB Evaluation Wdid 100Document4 pagesPpep PMB Evaluation Wdid 100whalenonNo ratings yet

- Ra13 RuudDocument48 pagesRa13 Ruudramsi17No ratings yet

- Air System ComponentsDocument6 pagesAir System ComponentsEliasNo ratings yet

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDocument6 pagesAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyNo ratings yet

- TankerDocument60 pagesTankerlopezdestructionNo ratings yet

- Appendix - A4-1Document52 pagesAppendix - A4-1soumyasahoo8125No ratings yet

- Daikin Légkezelő KatalógusDocument8 pagesDaikin Légkezelő KatalógusAl Dizdar NazarNo ratings yet

- Book 19 (Ca)Document12 pagesBook 19 (Ca)dirgan_udyanaNo ratings yet

- Hankison HF FiltrosDocument8 pagesHankison HF FiltrosOswaldoNo ratings yet

- Ks MNL Eng 02 03 (Retriever Tks H)Document25 pagesKs MNL Eng 02 03 (Retriever Tks H)chakrapani vagish chandra pandeyNo ratings yet

- 243 C Vent Silencer Brochure (English)Document4 pages243 C Vent Silencer Brochure (English)Adnan RanaNo ratings yet

- Compressed Air SystemsDocument4 pagesCompressed Air Systemsshameer_sanju1049No ratings yet

- Axminster 04 - Compressors, Air Tools & Spraying - p127-p140Document14 pagesAxminster 04 - Compressors, Air Tools & Spraying - p127-p140Pierre799es0% (1)

- CCI DRAG® Compressor RecycleAnti-surge ValveDocument8 pagesCCI DRAG® Compressor RecycleAnti-surge ValvescribdkhatnNo ratings yet

- Air Sentry Dessicant Breathers BrochureDocument14 pagesAir Sentry Dessicant Breathers BrochureNelson PeraltaNo ratings yet

- D 102310 X 012Document8 pagesD 102310 X 012Peter BqkNo ratings yet

- Ccea-Slb001-E4 - 0606 (Ccea 5se - Size 5)Document8 pagesCcea-Slb001-E4 - 0606 (Ccea 5se - Size 5)abioduncityNo ratings yet

- CamTech General Catalog 4 Site 071916Document28 pagesCamTech General Catalog 4 Site 071916Henry Mata100% (1)

- LT32599 10Document38 pagesLT32599 10Angela BaileyNo ratings yet

- Ds Datasheet Erhard Twin Air Air Valves enDocument7 pagesDs Datasheet Erhard Twin Air Air Valves enthawdarNo ratings yet

- PSA Pre-Installation GuideDocument4 pagesPSA Pre-Installation Guiderajesh_rbpNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- California Transparency in Supply Chains Act 2016Document2 pagesCalifornia Transparency in Supply Chains Act 2016Romner CordovaNo ratings yet

- Fuel Pump 2016 2017Document26 pagesFuel Pump 2016 2017Romner CordovaNo ratings yet

- KLINGER Expert 5.1: Powerful Sealing CalculationDocument8 pagesKLINGER Expert 5.1: Powerful Sealing CalculationRomner CordovaNo ratings yet

- Liberacion - Elementos de Concreto Armado 004Document42 pagesLiberacion - Elementos de Concreto Armado 004Romner CordovaNo ratings yet

- Liberacion - Elementos de Concreto Armado 004Document42 pagesLiberacion - Elementos de Concreto Armado 004Romner CordovaNo ratings yet

- Female RJ Line Blanks, Spacers, and Spectacle Blinds (Figure-8's) Per ASME B31.3 - 2010Document1 pageFemale RJ Line Blanks, Spacers, and Spectacle Blinds (Figure-8's) Per ASME B31.3 - 2010Romner CordovaNo ratings yet

- Songs Abracadabra LyricsDocument1 pageSongs Abracadabra Lyricsbitev666No ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IIsammar_10No ratings yet

- A Brief Presentation On Hot and Cold InsulationDocument5 pagesA Brief Presentation On Hot and Cold InsulationMubarik AliNo ratings yet

- Selection of Pipes For A PlantDocument5 pagesSelection of Pipes For A PlantMubarik AliNo ratings yet

- STRUCTURAL PLATFORMS A Small Presentation For The BeginnerDocument4 pagesSTRUCTURAL PLATFORMS A Small Presentation For The BeginnerRomner CordovaNo ratings yet

- Emergency Vents For Storage Tank PDFDocument6 pagesEmergency Vents For Storage Tank PDFRomner CordovaNo ratings yet

- Line Blanks Allowable Pressures Per Asme B31.3 - 2010, Process PipingDocument1 pageLine Blanks Allowable Pressures Per Asme B31.3 - 2010, Process PipingRomner CordovaNo ratings yet

- ASME B31.3 Category M Fluid Service Design RequirementsDocument8 pagesASME B31.3 Category M Fluid Service Design RequirementsRomner CordovaNo ratings yet

- Stress Analysis of GRPDocument5 pagesStress Analysis of GRPRomner CordovaNo ratings yet

- Importance & Impact of Stress Intensification Factor (SIF) : A PresentationDocument6 pagesImportance & Impact of Stress Intensification Factor (SIF) : A PresentationRomner CordovaNo ratings yet

- Slug Flow Analysis Using Dynamic Spectrum Method in Caesar II Part 2 of 2Document4 pagesSlug Flow Analysis Using Dynamic Spectrum Method in Caesar II Part 2 of 2Romner Cordova100% (2)

- Tee ConnectionDocument2 pagesTee ConnectionRomner CordovaNo ratings yet

- Step by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument8 pagesStep by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaNo ratings yet

- Flange Leakage CheckingDocument3 pagesFlange Leakage CheckingKumar RNo ratings yet

- Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument8 pagesMethods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaNo ratings yet

- Emergency Vents For Storage Tank PDFDocument6 pagesEmergency Vents For Storage Tank PDFRomner CordovaNo ratings yet

- Tee ConnectionDocument2 pagesTee ConnectionRomner CordovaNo ratings yet

- Spring Hanger Selection and Design Guidelines For A Piping Engineer Using Caesar IIDocument6 pagesSpring Hanger Selection and Design Guidelines For A Piping Engineer Using Caesar IIRomner CordovaNo ratings yet

- Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument8 pagesMethods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaNo ratings yet

- Stress Analysis of Centrifugal Compressor Connected Piping Systems Using Caesar IIDocument4 pagesStress Analysis of Centrifugal Compressor Connected Piping Systems Using Caesar IIRomner CordovaNo ratings yet

- Step by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument8 pagesStep by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaNo ratings yet

- Selection of Pipes For A PlantDocument5 pagesSelection of Pipes For A PlantMubarik AliNo ratings yet

- STRUCTURAL PLATFORMS A Small Presentation For The BeginnerDocument4 pagesSTRUCTURAL PLATFORMS A Small Presentation For The BeginnerRomner CordovaNo ratings yet

- Emergency Vents For Storage Tank PDFDocument6 pagesEmergency Vents For Storage Tank PDFRomner CordovaNo ratings yet

- Ideal GasesDocument50 pagesIdeal GasesggregresourcesNo ratings yet

- Pressure Test in Piping Systems - Hydro and Pneumatic TestsDocument3 pagesPressure Test in Piping Systems - Hydro and Pneumatic Testssj22No ratings yet

- Ipi 6L20 PDFDocument306 pagesIpi 6L20 PDFартNo ratings yet

- Ulman Part 10Document1,000 pagesUlman Part 10Yana RahmadaniNo ratings yet

- I100Document16 pagesI100Kalai SelvanNo ratings yet

- Vertical Spray Tower (No Packings) : Ka G LDocument6 pagesVertical Spray Tower (No Packings) : Ka G Lsafar bahariNo ratings yet

- PRT Lecture - 16 17Document30 pagesPRT Lecture - 16 17HimaNo ratings yet

- Manara Hydraulic CatalogueDocument8 pagesManara Hydraulic CataloguemujahaddadNo ratings yet

- Interference Effects of Cooling Air-Flows With External AerodynamicsDocument7 pagesInterference Effects of Cooling Air-Flows With External AerodynamicsVyssion100% (1)

- PIC MG-Aguaytia PP GT11 C5 2014 Insp. Final Report Rev00Document39 pagesPIC MG-Aguaytia PP GT11 C5 2014 Insp. Final Report Rev00Jeyson ReynosoNo ratings yet

- 4 - Gas Flow MeasurementDocument46 pages4 - Gas Flow MeasurementHashem HashemNo ratings yet

- Lecture F12Document13 pagesLecture F12Shakeel AhmadNo ratings yet

- Understanding Centrifugal PumpDocument7 pagesUnderstanding Centrifugal PumpjokishNo ratings yet

- Vactor Jet Rodder: Single Piston Water PumpDocument1 pageVactor Jet Rodder: Single Piston Water PumpRocko CallejasNo ratings yet

- Eni 10009E04 PDFDocument64 pagesEni 10009E04 PDFSammyNo ratings yet

- Steam Boiler Systems From Bosch: Highly Efficient and Reliable Process HeatDocument19 pagesSteam Boiler Systems From Bosch: Highly Efficient and Reliable Process Heatnemi90No ratings yet

- HG VolvoProductListing WebDocument4 pagesHG VolvoProductListing Webpiyush sharmaNo ratings yet

- Commulative Difference Final FileDocument914 pagesCommulative Difference Final Filemohsin awanNo ratings yet

- Turbomachinery AerodynamicsDocument21 pagesTurbomachinery AerodynamicsbunnykfaNo ratings yet

- Effect of Operating Variables On The Thermal Efficiency and Work Ratio and Air Rate of Gas TurbineDocument8 pagesEffect of Operating Variables On The Thermal Efficiency and Work Ratio and Air Rate of Gas Turbinejaymil tandel50% (2)

- CADE Technologybrochure AccumulatorsDocument24 pagesCADE Technologybrochure AccumulatorsJose francisco Lazo castroNo ratings yet

- Fluid Mechanics Notes Covers Properties FlowDocument82 pagesFluid Mechanics Notes Covers Properties FlowrajmehaNo ratings yet

- Exflow LeafletDocument4 pagesExflow LeafletazitaggNo ratings yet

- What is a SlugcatcherDocument3 pagesWhat is a Slugcatcherkay50No ratings yet

- Vapor Pressure of Ammonium Nitrate Je60013a020Document2 pagesVapor Pressure of Ammonium Nitrate Je60013a020jerryNo ratings yet

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- What Is HCDPDocument5 pagesWhat Is HCDPfumerojr5164100% (1)

- ME-351 - Applied Thermodynamics II - Course Plan - Rev - 01 PDFDocument4 pagesME-351 - Applied Thermodynamics II - Course Plan - Rev - 01 PDFVimleshKumarSharmaNo ratings yet

- 11.2.1 Clivet DX Modular Air Handling Unit CompressedDocument3 pages11.2.1 Clivet DX Modular Air Handling Unit Compressedirwantino susiloNo ratings yet

- Volume of Water for Test SectionDocument2 pagesVolume of Water for Test SectionFerinoviardi100% (1)