Professional Documents

Culture Documents

Joglekar +estimating and Valuation PDF

Uploaded by

Uday Pandhe0 ratings0% found this document useful (0 votes)

29 views133 pagesOriginal Title

Joglekar-+Estimating-and-Valuation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views133 pagesJoglekar +estimating and Valuation PDF

Uploaded by

Uday PandheCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 133

PRACTICAL INFORMATION

FOR

QUANTITY SURVEYORS

CONTRACT MANAGERS, ARCHITECTS

ENGINEERS AND BUILDERS

by

P.T. JOGLEKAR

AMIS

Superintending Surveyor of Works (Retd)

Military Engineer Services

Professor (Retd.), College of Military Engineering Pune.

First Edition - 1974 (Published by The Institution of Surveyors, New Delhi)

Second Edition - April 1990 (Revised and enlarged)

Third Edition - March 1992 (Revised and enlarged)

Price - Rs. 80/-

‘Second and Third edition published by

Mrs. Mandakini Joglekar

1583, Sadashiv Peth, Flat No.10,

'Shivanandan’, Opp. Maharashtriya Mandal,

Tilak Road, PUNE 411 030.

(Phone No. 434760, PUNE)

All rights reserved by the publisher of the second edition.

DEDICATION

This book stands dedicated

10 the loving memory of my parents

Shri T. M, Joglekar and Smt Umabai Joglekar

Note by the Author

This book is intended and designed for day to day reference, mainly by contract managers

‘and middle order executives of the building industry who deal with quantity surveying, estimating,

analysis of rates, supervision of works, drafting of specifications, checking of interim and final bills,

preparing and defending claims, disputes, etc.

‘The aim has been to collect within the covers of this book the wide ranging and various

kkinds of basic data and information which normally needs a frantic search and poring through a score of

different books and publications. Much thought and discrimination had to be exercised in selecting the

items of information. Too much material packed into a reference book intended for daily use can be as.

harmful as the omission of some vital piece of information,

Every effort has been made to achieve a high degree of reliability of the information

presented. No pains have, been spared in proof-reading and a meticulous correction of the text.

‘The sources of information are quoted at relevant places in the book to motivate the reader

to refer the various Indian Standard Specifications and other authoritative publications in original

whenever more detailed and complete information is needed.

Finally, 1 must thank‘the numerous users of the earlier edition of this book who kept

pressing me to bring out a revised enlarged edition. Without their encouragement and a vociferous

demand by the younger batch of executives, this second edition would not have been possible.

Pune, P. T. Joglekar

03 April 1990

Skriramanavmi

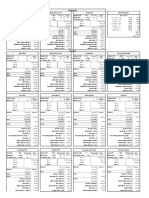

CONTENTS

Description Page Nos Deseription Page Nos

Basie Units = Steel doors, windows, ventilators and fixed

Tights, with area of glazing required per

Length, area, volume and capacity 1 standard unit nas

Weight, temperature and miscellaneous 2

Commercial abbreviations 24

Intemational paper sizes 2

Common Latin/French terms 25 & 26

Shipping measure, American measure 2

‘Measurement of plinth/carpet area 27

Conversion factors 3&4

Contre-ine method for working -out

Conversion of rates 4 quantities 28 & 29

Weights of building materials 5 Caleulating quantity of reinforcement 30.& 31

Weights of stec! sections et Estimating data for oof slopes, root areas,

Tengths of common/hip/valley rafters 2

Round, square and flat steel bars 6

Equal and unequal steel angles 7&8 | Quick methods for estimating material and

Sieel we bars 8 Tabour requirements in

Junior, light and medium stel channels 9 5) Single, double. am

ee encase (Sing, dnl and ur domed

stcal beams 9 & 10 e

Steel column sections 10 (ii) Mutistoreyed oftice buildings 34

Crane rail steel sections 10 eens ae

ii) Internal water supply and sanitary

Plain and chequered stecl plates 10 services for double and four

Plain black steel sheets 10 Mircvod resiental ballings and

Galvanised plan and corrugated steel ar aes el ceca aang a

sheets n

Square and rectangular hollow stecl a ey ae

sections 2 detailed estimates 36 10 38

Shoot ping steel sections 2

Steel wire fabric of square and oblong Analysis of Rates

mesh Ba

Expanded metal sheets “4 Basic and indirect building costs 9 & 40

Hexagonal (chicken wire mesh) neting 15 Working up and submission of tenders 41

Wire cloth, general purposes 15 Working out unit rates 42

Galvanised stel barbed wire 15 Working-costs of tols and plant 8

Structural steel tubes 16

Weight of iron/steeVeopper wire in kg Output of tools and plant 4 1049

per 1000 m 16

Glavanised iron fittings (for roof) 17 | Labour out-put constants for building work 50 to 90

Steel bolts, nuts and rivets 18

Round sire nails 19 | Cement constants 91 0 93

Steel sections for steel doors, windows

fia Genet 19 | Material constants 94 10 5

Equivalent diameters of standard wire gauge Architectural norms/guidelines us

(SWG) and equivalent thicknesses of

Sep cant paste (ea) 17 | Formulae useful in valuation of property 116

‘Weights of aluminium section, for equal and Tables for simplecompound interest et. nt

tnequal angles, tees, channels and beams 20 a Liste 126

Metal rolling shuters a The law relevant othe building industry 127 & 128,

Cast iron manhole covers, gratings, steps and i

floorfoahni traps 2 Bitarety 9

BASIC UNITS

Values of Prefixes of Sub-Multiples and Multiples of Metric Units

Pret Numerical Value

MICROMICRO OR PICO (orp) 10.000 000 000 001 1o*

MILLIMICRO OR NONO (myorn) 0,000 000 001 10%

MICRO é 7) 0.000 001 to

MILL (my 0.001 io?

CENT! ( oot to?

DECI @) oA 10"

DEKA (¢a) 40 10

HECTO () 400 to?

KILO w 4.000 102

MEGA : ) 41.000 000 to

KILOMEGA OR GIGA (kMorG) 4.000 000 000 10°

MEGAMEGA OR TERA (MMorT) | 11000.000 000 000 tor

Length

British Units Metric Units

“12 inches = toot 1 micron = 0.001 milimetre

Steet = tyard 40 millimetres = teentimetre

22 yards = tchain 10 centimetres = tdecimetre

tO chains + furlong 10 decimetres 4 mete

8 furlongs 4 mile 40 metres = tdokametro

5280 feet = Y mile 10 dekametres = thectometre

6080 foot = {nautical mile 10 hectometres = tklometre

@rtish)

Geet = Hathom 1852 metres = 1 nautical mile

(loternational)

Area

British Units Metric Units

1089 sq fost = 1 gunthal 100 eq milimetres 1 sq centimetre

40 gunthas. tacre 400 sqcentimetres =‘ sq.decimetre

49560 sq feat 1 acte 4100 sq decimatres = tsqmetre

"4840 sq yards = tacre 100 sq metres = tareor tq

decametre

640 acres = isqrmile 100 ares, = Theclare or 1 sq

hectomatre

100 hectares = 1 sq kilometre

Volume

1000cu millimetres = 1 eu centimetre

1000 cu centimetres = 4 eudecimetre

1000 cudecimetres = = 1 eu metre

Capacity

British Units Metric Units

60 minims 1 fluid drachm 410 mililires = tcontitve

8 fluid drachms = 4 fluid ounce 10 centiites = docitre

5 fluid ounces = iil 10 deciires 4 ite

= pint 40iitres 1 dekaltre

2pints = iquat 10 dokalitres = thectofire

4 quarts 4 Imp gallon 10 hectoltres = tkiboitre

2 gallons = 1 peck oF 1000 fires

4 pecks 1 bushel tre = 100.028 cu em

B bushels = _tquarter

Wight

Briloh Unit Movi Units

Arcos Unis

18erans SD cies toniligrans are

ieouncss = ipod foconrams > ieee

2epounes 2 ieee togecigams 2 See

‘toaters FT Rind wiht tDgrane = exam

20 hinted weights Hon {o gokagams 2 Thecgam

ro60 grains 2 To necayrams 2 Teepe

se pounds = Sen 1000 grams {nolo tonne

2000 pounds 2 ikaron 200 mires = ima

100 pounds {Stor undid wight

bine’ = 437Sgcins 2 doscog { millgram (mg) = 054 grin

ips ciecareetaa gt sucse cy igen 2 boses

Temperature Conversion

(oF -22)x8 220 ecx8) 432-0

es ee |

ld indian Weight Unite Wisceansovs

(opera 1 domon = 2 Won

Ga Tt Re Nf soe eco ce

© we lL Med 1 gees > 12 donne 144 Noa)

i fuel de see

ttm 22) gues

Weares Ba CSaes

sie unineves |_ see ditineves

70 ertx 1169 | co 24x 488

a socoat” | Se 20% 983

ne worse | 6s 0x04

s wreao | Bs Treas

ae poxer | ts tbe a39

s tuscan | Bee tes xaos

a8 fortes | Be eects

a waxios | Gb Taxiee

DL Hoxz38

Gis Brie

cr Bitta

Shipping Messure Genera

7 ships on ‘oametea | traden = erase er IT

Tise6com | aise

3 [B8008s — mperascond

‘American Mossure bhanardaceteaton porsocand

rien Suologrev)

hundied weight - .

me = 2000 founds | 1 Imperial gaton of water weighs pounds

59 alon Se eed are

wer gaon : 088 Inpgat | 1 cbictot eee as

Amscans express road gradients inprcantages.og. | 1 emecdachage «= ~—=—S—s 7S galonapermin

: 1 Takeepetaee

ee

Refrigeration ( and Air-Conditioning ): One standard ton of retrigeration

rate of 12000 British Thermal Units per hour (equivalent of one

(and air-conditioning denotes the extraction of heat atthe

ton of ice motting in 24 hours)

CONVERSION FACTORS

Multiply By To obtain

‘acres 0.404687 hectares

ones 0.0040469 ‘square kilometres

© centimetres 00328083 feet

centimetres 0.3937 inches

» eubic centimetres 0.00003532 cubic feet

ibic centimetres 0.06102 cubic inches

28317 cubic centimetres *

0.028317 cubic metres

6.22905 gallons, Imperial

cubic feet 02832, hectoitres

cubic feet 283170 lies

cubic inches 16.38716 cubic centimetres,

Veubie metres 353145 cubic feet."

cubic metres 13079 cubic yards

, angular 010174533 radians

degrees, F(less 32 F) 0.5556 degrees, C

degrees, C 18 degrees, F(less 32 F)

foot pounds 0.13826 kilogram metres

feet 30:4801 centimetres

feet 0.304801 metres

fect 304.801 millimetres

gallons, Imperial 0.160538 cubic feet

gallons, Imperial 120091 gallons, U.S.

gallons, Imperial 454596 Titres

gallons, U.S: 0.833702 gallons, Imperial

gallons, U.S. 3.78543 Titres

grams. 0.002046 pounds, avoirdupois

hectares 2.47104 eres

hectares 107638.7 + square feet

hectares 000386101 square miles

horsepower, metric 0.98632 horsepower, U.S.

horsepower, U.S. 1.01387 horsepower, metric,

inches 2.54001 centimetres

inches 00254001 meres

inches 25.4001 millimetres

kilograms 2.20862 pounds

kilograms 000098421 tons (= 2240 Ibs)

Kilogram metres 7233 foot pounds

kilograms per metre 0.671972 pounds per foot

kilograms per sq em 14.2234 pounds per sq inch

kilograms per sq metre 0.204817 pounds per sq foot

kilograms per cubic metre 010624283, pounds per cubic foot

kilometres 0.62137 miles

kilometres 3280.7 feet

lites 0.219975 gallons, Imperial

titres 0.26817 gallons, U.S.

litres 0.035

lives 61.022

metres 3.28083,

metres 39.37

metres 1.09361 yards

miles 1.60935 kilometres

millimetres 0.00328083 feet

millimetres 0.03937 inches

‘ounce (oz) 28.349 grams

pounds (avoirdupois) 453.592 grams

pounds (- do-) 0.453592 kilograms

pounds (- do) 00008464 tons (=2240 pounds)

pounds (- do-) 0.004536 tonne (metric)

pounds per foot 1148816 kilograms per metre

pounds per square foot 4.88241 kilograms per sq metre

pounds per square inch 0.07031 kilograms per sqem

pounds per cubic foot 16.0184 kailograms per cu metre

CONVERSION

FACTORS (Cond.)

a

®

®

®

6)

©

o

©

oe

(10)

an

(12)

03)

4)

5)

06)

an

(a8)

as)

(20)

Multiply By To obtain

Tadians 372578 degrees, angular

square centimetres 0.1550 square inches

square feet 0.00092903, ares

square feet 0.0929034 square metres

square inches —~ ~<645163 — square centimetres

square kilometres 247.104 square acres|

square kilometres 03861 square miles

square metres 10.7639 square feet

square metres. 1.19599 square yards

square miles 2'590, square kilometres

square yards 0.83613, square metres

tons (=2240 pounds) 1016.05 kilograms

tons (~do-) 1.01605 tonne metric

tonne (metric) 2204.62 pounds

tonne (metric) 0.98421 tons (=2240 pounds)

yards 0.914402 metres

CONVERSION OF RATES

To convert Rate per running foot into Rate per running metre

To convert Rate per 10 running feet into Rate per running metrev~

To convert Rate per 100 running feet into Rate per running metre“

To convert Rate per square foot into Rate per square

meure

‘To convert Rate per 10 square feet into Rate per square metre v-

To convert Rate per 100 square feet into Rate per square metro

To convert Rate per cubic foot into Rate per cubic metre

To convert Rate per 100 cubic feet into Rate per cubic metre

To convert Rate per Ib (pound) into Rate per kg

To convert Rate per hundredweight (ewt) into Rate per quintal

To convert Rate per ton into Rate per tonne (Metric)

To convert Ibs/running foot into kgsunning metre

To convert Ibs/square foot into kgs/square metre

To convert Ibs/cubic foot into kesfeubie metre

To conver Ibs/gallon into kgsfitre

To convert Rate per gallon into Rate per litre

To conver Ibs in, into kg/sq em

To convert ton/sq ft into tonne/sq m

‘To convert bending moment from foot-pounds to kilogram-metres

To convert Rate per acre it

Wo Rate per hectare

“Multiply by 3.28 (For vice-versa by 0.3048).

Multiply by 0.328 (For vice-versa by 3.048). “"

Multiply by 0.0328 (For vice-versa by 30.48).

Multiply by 10.764 (For vice-versa by 0.0929). “~

Multiply by 1.0764 (For vice-versa by 0929). ”

Maliply by 0.1076 (For vice-versa by 9:29)

Multiply by 35.315 (For vice-versa by 0.0283), <“~

Multiply by 0.3532 (For vice-versa by 2.83). .

Multiply by 2.2046 (For vice-versa by 0.4536).

Multiply by 1.9684 (For vice-versa by 0.508).

Maltipy by 0.9882 (For vice-versa by 1.016).

Multiply by 1.4881 (For vice-versa by 0.672)

‘Multiply by 4.881 (For vice-versa by 0.205).

Multiply by 16.0184 (For vice-versa by 0.0624).

Multiply by 0.0998 (For vice-versa by 1.002).

‘Multiply by 0.22 (For vice-versa by 4.546).

Multiply by 0.070 (For vice-versa by 14.223).

“Multiply by 10.937 (For vice-versa by 0.0914).

Multiply by 0.138 (For vice-versa by 7.233).

Multiply by 2.471 (For vice-versa by 0.4047).

WEIGHTS OF BUILDING MATERIALS

(Reference S : 1911-1967)

5 ‘Weight in k ‘Weight in

Material pereubic metre Material pe ab meks

‘Accoustical materials Metals

Cork 5 240 | Aluminium, cast 2580 to 27K

Slag wool... 270 | ‘Aluminium, wrought 2640 to 280

| Brass (Copper % :

Aggregate ‘Muntz metal (60 : 40) 822

Broken Stone, dry 1600 0 1870 | Red (90: 10) 850

Broken bricks White (50: 50) 819

Fine 1450 | Yellow (70: 30) :-

Coarse (surkki) 1010 ‘Cast B sha

Foam slag aggregate 700 Drawn 868

Sand, dry, clean 5 1540 to 1600 Rolled 855

Shingle, 3 mm to 38 mm_ - 1460 | Bronze (copper % :

Bell metal (80:20) 873

Bricks Gun metal (90: 10) 8781

Common burt clay 1600 to 1920 | Chromium : 65200 to 6731

Engineering bricks 2160 | Copper, cast 8790 to 89

Pressed bricks 1760 to 1840 | Copper, wrought 8840 to 894

Refractory bricks 1760 to 2000 | Iron, pig TMK

Iron, cast, gray 7030 to 713

Cement (IS : 269) Iron, cast, white 7580 to 772

Ordinary and sluminous 1440 | Iron, wrought 7104

Rapid hardening, 1280 | Lead east, : 3st

| Lead, wrought 11364

‘Cement conerete, plain | Silver, wrought <2 10540 to 10561

Using stone aggregate 2240 0 2400 | Steel, cast mt 785

= | Steel, wrought, mild 78H

Light weight concrete Zinc,cast 00 0 16

Cellular (Siporex’ etc.) 640 | Zinc, wrought 71%

With foam slag agregate 960 1840

Aerated. 760 | Oils, paint, bitumen et

| Bees wax”. 5 964

‘Chemicals Bitumen 104

Gypsum powder 1410 ©1760 | Creosote 1071

Salt, common... 960 | Diesel : 964

Phetiol formaldehyde 1280 | Geo 128

Polysirene 1060 | Paint 2.2 964

Perspex 1200 to 1350 | Paraffin wax 800 to 964

Urea Formaldehyde 1350 0 1380] Petrol... 651

Pitch (1S : 216) 10

Coal Red lead, dry 21K

Coal 850 | Road tar (1S: 215) * tox

Coal dust 700 | Turpentine 86:

Coke, furnace or gas 500 | Vamish 961

Charcoal 300

| Soits

Lime Clay, dry... : 1441

‘Uncalcined stone lumps 1280 to 1440] Earth, dry 212 Nl 110 184

Unslaked, freshly burnt 880 0 1040

Slaked, fresh... 580 0 640 | Timber 1S:399)

Unslaked lime (Kankar ) 1180 | Teak eat

Slaked lime (kankar ) 1020 | Benteak 61:

| Bijasa 801

Stone Bonsum 531

Basalt 2850 to 2960 | Chir 57:

Flint 2590 | Deodar 54

Gneiss 2400 to 2690 | Haldu 67.

Granite 2640 to 2800 | Hollock oul

Laterite 2080 to 2400 | Sal 86.

Limestone 2400 to 2640

Marble 2720 | Water

Quartz 2640 | Fresh 100

Sandstone 2240 to 2400 | Salt : 102.

Slate 2800 | Ice 1

WEIGHTS OF STEEL SECTIONS ETC

HOT-ROLLED ROUND STEEL BARS HOT-ROLLED SQUARE STEEL BARS

(Reference S : 1732-1971) (Referencel +1732 - 1971)

Designation | Weightper | Designation | Weight per | Designation | Weight per | Designation | Weight per

Diameter | Mere | & Diameter | Mee | & Side Width | Mee | & Side Width | Metre

TA ke Tam ig mm kg mam kg

ISRO 5 0.154 ISRO 45 125 IssQ. 5 | 0.196 IssQ. 32 8.04

ISRO 6 0.222 ISRO 50 154 |

ISRO 8 0.395 ISRO 56 193 BSS be Ogee eze IssQ_ 40 12.6

ISRO 10 0617 ISRO 63 2 |

ISRO 12 0.888 ISRO 71 314 Se a IssQ_ 4s 159

ISRO 14 121 ISRO 80 305

ISRO 16 158 ISRO 90 499 eee aed 1ssq 50} 196

ISRO 18 2.00 ISRO 100 6.7 sso. | 13

ISRO 20 247 ISRO 110 746 Roe ae

ISRO 22 298 ISRO 125 963 Issq 16 201 :

ISRO 25 385 ISRO 140 121

ISRO 28 483 ISRO 160 158 IssgQ 20 | 3.14 IssQ 80 50.2

ISRO 32 631 ISRO 180 | 200 |

ISRO 36 799 ISRO 200 | 247 1ssQ 25 | 491 IssQ_ 100 78.5

ISRO 40 985 |

HOT-ROLLEI

STEEL FLATS

(Reference IS :1731 -1971)

Weight per metre of tor-steeliribbedideformedicold twisted steel bars of any nominal diameter

‘given above for respective diameter in ISRO series.

is taken same as

Thickness in mam

waaty"s0 | 40 | 50 | 60 | 80 | 100 | 120] 160 | 180 | 20 | 25 | 32 | «0 | 4 | 50 | wo

‘Weight per Metre Length in kg

10 | 0.236 0.314 0.393 0.471 - : - - - - - - - - - -

14 | 0.330 0.440 0.550 0.659 0.879 . - : : - - - - - . .

20 | 0.471 0.628 0.785 0.942 1.26 157 188 251 283 - - - - - : -

35/0580 O75 Qos 18 137 19 23 a4 333 2 |

Solon? O92 Lis iat 188 236 28) 37 ae an 2D Tt

35 | 0.824 1.1 1.37 . 2.20 3.30 y 495 5.50 687 8.79 - - - -

4/052 126 137 18 251 an Ses 628 tas too 7 DLL

[00 TH th a 28 353 43 Sos G56 FO) ae os DLL

50 | 1.18 157 196 236 3.14 393 471 628 706 785 981 126 157 - . -

S|" 133 zie 35) das ise S18 gor 707 get tos Bs 3 lt

Glia 188 236 28 377 AN S65 154 bas Se2 118 Isl 188 22 2!

65 - 2.04 255 3.06 4.08 5.10 612 816 9.18 10.2 128 163 204 23.0 - 7

| 2 290 233 350 240 S30 659 S79 989 110 137 Ite 20 dT zs 2

1S - 236 2.94 3.53 4.71 589 7.07 942 106 118 14.7 188 236 265 294 -

| 2 28 so Sa TSt 10 13 16 137 201 da es ha

| 2 7 ss at Ses aa 13 27 ial iy be 3 GB 353 424

wo] 2: 353 A bos 789 Gaz We tat Is 196 dea Sle 353 302 fat

110 - - 432 5.18 691 864 104 138 155 173 216 276 345 389 432 518

120 - - 47 565 754 942 113° 15.1 170 188 236 30.1 37.7 424 47.1 565

130 - - - 6.12 816 10.2 122 163 184 204 25.5 327 408 459 S10 612

wo] > 2 2S 8% 110 32 ite Is 220 275 32 440 403 350. os

io] 2 2 fl 8 NR at We ote Be 204 7 Hl 30 Sao oe

to| 2 2 22 too 26 151 20a a6 sa 324 402 502 Ses

wo] 2 2 ll 3S Ma 120 226 54 83 353 a2 Ses ose

200 - - - - - 157 188 25.1 283 314 39.2 S02 628 70.6 - -

250 - - - - - 196 236 314 35.3 39.2 49.1 628 78.5 883 - -

fo) 2 2 fff M8 RS do Ba tt Seo Se 2 we

a a a a eT

HOT-ROLLED STEEL EQUAL ANGLES

(Reference IS: 808 {Part V) 1976

as Size Thickness ‘Weight per n Size ‘Thickness ‘Weight

Designation | mmx mm. aca metre inkg | Designation | gam x mm faa iad

ISA 2020 20x20 +3 09 ISA110110 0x 110 8 13.4

4 1 10 166

2 197

ISA. 2525 | 25x25 3 Ld |

ai ia 16 257

5 18 TSA130130 130 x 130 8 15.9

Isa 3030 | 30x30 3 “4 i nee

3 a 16 307

ISA 3535: | 35x35 3 16 1sA150150 | 150x150 0 ns

5 ae 16 358

a aa 20 441

sa aon | 40x40 3 1g | 18200200 | 200x200 | 369

4 aa 20 60.0

é 35 25 Bo

penta atasets 3 on Supplementary List - Equal Angles

4 27 30x 50x7 | 50x 50 T 315

5 34 x8 8 (5.82

oo 4 7 60x 6x4 | 60x 60 4 3.70

ISA 5080 x

2 a 0x 70x7 | 70x 70 7 738

5 3.8 100x 100x 6.5} 100x100 65 9.99

6 45 x15 1s 21.90

ISA 5555 | 55x55 5 41 [120x120x 8) 120x120 8 14.70

6 49 x10 10 18.20

8 6.4 x12) 12 21.60

10 79 x15 15 26.60

ISA 6060 60x 60 5 45 150x150x15} 150x150 15 33.80

6 5a x18 1B 40.10

3 79 ligoxisoxis| ts0xi80 | 15 4090

x18 8 48.60

ISA 6565 65x65 5 49 x20 20 53.70

§ $8 |00x200%24| 200x200 | 24 7120

10 94 HOT-ROLLED STEEL UNEQUAL ANGLES

1SA 7070 | 70x70 5 33 (Reference IS : 808 (Part V1)-1976)

6 63 Size Thickness] Weight

8 83 | Dssenaion | mmxmm | mm | mentite

10 10.2 ISA 3020 30x20 H IT

75x75 5 57 14

wa 13s 5 53 3 is

8g 89 ISA 4025 40x25 3 15

10 110 4 19

ISA 8080 | 80x80 s B 5 24

10 118 Isa 4530 | 45x30 3 47

12 14.0 4 22

5 23

ISA 9090 90x90 6 82 6 33

3 08 | isn som | sox | 3 7

5. 4 4

2D BS 4 8

1SA100100 | 100x 100 6 92 6 5

8 121 60x40

0 lag | BA 60H | 6x 8 a

2 7 g 58

HOT-ROLLED STEEL UNEQUAL ANGLES - Contd.

aon | atten | S* [ SRG [onenwe | tien | SS | SE

TSA 6545 6 x45 i 41 TSA 12575 [125 x 75) 6

6 49 8

8 64 10

ISA 7045 70x45 5 43 ISA 12595 | 125 x 95) 6

6 52 8

8 67 10

10 83 2

isa 7550 | 75x50 5 47 | isa isos | 150 x 75] 8

6 56 10

8 4 2 :

10 9.0 ISA1SO1IS | 150 x 115) 8 16.3

isa 8050 | 80x50 5 49 10 2041

6 59 12 40

8 17 16 314

ay 94 TSA200100 | 200 x 100) 10 29

ISA 9060 90 x 60 6 68 12 213

8 89 16 358

2 10 | tsa20o1s0 | 200 x 150] 10 269

100 x65 6 15 16 422

ae 8 99 20 52.0

10 122

ISA 10075 | 100x75 6 80

= o 8 10.5

10 130

2 154

HOT-ROLLED STEEL TEE BARS

(Reference IS: 1173-1978)

Size | Thickness] Thickness] Weight per Size | Thickness] Thickness Weight per

Designation} (xb) | of Web | of Flange| Met | Designation | (i xb) | ofWeb | of Flange | Metre

mmxmim | “mm |” mm Kg mmxmm| © mm | ° mm Ke

Normal Tee Bars ‘Slit Light Weight Tee Bars *

ISNT 20 20x 20 4 4 ISLT 200 200 x165 8.0 12.5 28.4

ISNT 30 30x 30 4 4 ISLT 250 250 x180 9.2 141 375

NT 4 40x 40g 6

ISNT 50 50x 50 6 6 Slit Medium Weight Tee Bars **

ISNT 60 60x 60 6 6

NT 75 75x 7509 9 IsMT 50. $0.x 70 45 1. 58

ISNT 100 100 x 100 10 10 ISMT 625 625x 70 5.0 80 67

ISNT150 150x150 10 10 ISMT 75 5.x 75 5.0 8.0 15

ISMT 87.5 875x 85 5.8 9.0 98

Deep Legged Tee Bars ISMT100. 100x100 5:7 108 127

Slit Tee Bars from H-Section ***

ISDT100 100x 50 58 100 81

ISDT150 150x 75 80 6 15.7 ISHT 75 75 x100 84 9.0 153

ISHT 100 100 x20 78 = 90-200

ISHT125 125x250 88 97 214

ISHT150 150 x250 76 10.6 294

* Slit from ISLB 200 and ISLB 500.

'** Slit from MB 100, 125, 150, 175 and 200.

‘"** Slit from ISHB 150, 200, 250 and 300.

HOT ROLLED STEEL CHANNELS

HOT ROLLED STEEL BEAMS

. Depthof | Widdhof | Weight per Depthof | Widthof | Weight

Designation | ‘chamael_ | “Range” | mete” | Designation | "Sean | “tangs | “Steud

mm mm | kg mm mm kg.

JUNIOR CHANNELS JUNIOR BEAMS

(Reference IS : 808 - 1964 - Amendment 3 of 1968) (Reference IS : 808 - 1964 )

ISIC 100 100 4s 58 1S1B 150 150 50 Wa

ISIC 125 125 50 19 ay a a 81

ISIC 150 150 55 99 99

ISIC 175 175 60 112 ieee os be 128

ISIC 200 200 70 140

LIGHT CHANNELS

(Reference IS : 808 - 1964 - Amendment 3 of 1968)

ISLC 75 15 40 57

ISLC 100 100 50 79

ISLC 125 125 65 10.7 *

ISLC 150 150 5 144

ISLC 175 175 8 116

ISLC 200 200 15 206

ISLC 225 225 90 24.0

ISLC 250 250 100 28.0

ISLC 300 300 100 33.1

ISLC 350 350 100 389

ISLC 400 400 100 458

MEDIUM CHANNELS (SLOPING FLANGES)

(Reference IS : 808 (PART Il!) - 1979)

MC 75 15 40 74

MC 100 100 50 9.56

MC 125, 125 65 13.1

MC 125 * 125 66 137

MC 150 150 5 168

MC 150 * 150 16 127

MC 175, 175 1s 196

MC 175 * 175 1 217

MC 200 200 15 223

MC 200 * 200 76 243,

MC 225, 225 80 26.1

MC 225 * 225 83 30.7

MC 250 250 80 30.6

MC 250 * 250 82 342

MC 250 * 250 84 38.1

‘MC 300 300 90 363

MC 300 * 300 2 ALS

MC 300 * 300 94 46.2

MC 350 350 100 42.7

MC 400, 400 100 50.1

NOTE: Weights, dimensions etc of channels with parallel

flanges (MGP series) are same as given above for

‘MC series. The heavier sections in each size are

intended for use in wagon building industry

(marked *),

LIGHT WEIGHT BEAMS

(Reference IS : 808 - 1964 - Amendment 3 of 1968)

ISLB 75

ISLB 100

ISLB 125

ISLB 150

ISLB 175

ISLB 200

ISLB 225

ISLB 250

ISLB 275

ISLB 300

ISLB 325

ISLB 350

ISLB 400

ISLB 450

ISLB 500

ISLB 550

ISLB 600

MB 100

MB 125

MB 150

MB 175

MB 200

MB 225

MB 250

MB 300

MB 350

MB 400

MB 450

MB 500

MB 550

MB 600

15

100

125

150

115

200

225

250

275

300

325

350

400

450

300

550

600

‘MEDIUM WEIGHT BEAMS

(Reference IS : 808 (PART 1) - 1973)

100

125

150

115

200

205

250

300

350

400

450

500

550

600

50

50

5

80

90

100

100

125

140

150

165

165

165

170

180

190

210

70

70

8

85

100

10

125

40

M40

140

150

180

190

210

61

80

ug

142

167

198

235

279

33.0

377

431

495

569

653

750

863

9.5

ns

Ba

15.0

195

254

312

373

46.1

524

616

RA

869.

104

123

10

HOT ROLLED STEEL BEAMS (contd) ‘MS PLATES

: (Reference IS : 1730 (Part I) - 1974)

Designation | Depth ee

mm ho i mum ie mm te

‘WIDE FLANGE BEAMS 5 39.20 n 173.00

(Reference IS : 808-1964) 6 4730 25 19600

7 55.00 28 220.00

ISWB 150, 150 100 170 8 280 32 251.00

ISWB 175 175 125 22.1 10 78.50 36. 283.00

ISWB 200 200 M40 BS 12 94.20 40 314.00

“ 110.00 45 353.00

ISWB 225 25 150 33.9 16 126.00 50 392.00

ISWB 250 250 200 409 18 141.00 56 440.00

ewe 200) Ed td) eel 20 157.00 63 495.00

ISWB 350 350 200 56.9

ISWB 400 400 200 (66.7

eae aw 20 pA STEEL CHEQUERED PLATES

ISWB 500 500 250 952 -

ISWB 550 550 250 125 Standard / Weight per

Twa E00) <0 250 1337 Thickness | square metre

ISWB 600 600 250 1451 mm inkg

5 39

6 47

HOT ROLLED COLUMN SECTIONS 7 55

(ReferenceIS : 808 (PART I) - 1978) 8 6

10 7"

sc100 100 100 200 2 94

SC 120 120 120 262 4 110

16 126

sc.140 140 140 333

SC 160 160 160 419 | Conform tothe weights given in IS: 1730-1961 ‘Dimensions for

steel plate, sheet and strip for structural and general engineering

SC 180 180 180 50.5 aoe

SC 200, 200 200 60.3

sc20 720 220 TA MS PLAIN BLACK SHEETS

S250 250 250 856

Thickness | Weightper | qyickness | Weishtper

CRANE RAIL SECTIONS mm} Sm +

i caaea arama 040 3.4 1.90 14.90

Head [Flange | Tol | Weight to 3 bred ee

Beteniea) wit | wahdeen| apn | perma | 9S 485 | 2k aa

0.90 7.05 2.80 22.00

ISCR 50 50 90 90 298 1.00 785 35, 24.10

ISCR 60 0 105 10s 400 112 8.80 355 27.86

ISCR 80 80 130 130 642 125, 9.80 4.00 3140

IstR 100100 150 150 89.0 140 11.00 430 33.15

ISCR120 120 170 170 118.0 1.60 12.60 465 36.50

ISCR 140 140 170 170 147.0 180 14.10

u

GALVANISED PLAIN STEEL SHEETS

(Reference IS : 277-1977)

‘Weight in kg per sq m of sheet

Class of sheet

and type of zinc coating ‘Thickness of sheets in mm

160 | 1.25 1.00 0.80 0.63

Class 1

750 g of Zine (Spelter) Coating per sq m 1331 10.56 8.60 7.08 5.70

Both Sides Inclusive

Class 2

600 g of Zinc (Spelter) Coating per sq m 1316 1041 8.45 688 535

Both Sides Inclusive

Class 3

430 g of Zinc (Spelter) Coating per sqm 13.01 10.26 8.30 6B 5.40

Both Sides Inclusive

Class 4

315 g of Zinc (Spelter) Coating per sqm 12.94 10.19 822 6.66 532

Both Sides Inclusive

NOTE : Plain sheets of all classes are available in 1.8, 2.2, 2.5, 2.8, and 3 metre length. Class 4 plain sheets are also

available in 3.6 metre length.

Plain sheets of all classes are available in 0.75 and 0,90 metre widths.

CORRUGATED GALVANISED STEEL SHEETS

DEPTH 18 mm NOMINAL

PITCH

75 mm NOMINAL

Weight of corrugated galvanised steel sheets is to be calculated from the area of sheet before corrugation applying

the weight constants given above for plain galvanised sheets,

DETAILS OF CORRUGATION

‘Nominal overall width of sheet

Number of corrugations measured between crowns of

‘uiside comugations

Before ‘After

Comrugation Comugation

mm mm

8 750 660

10 900 800

u 1000 885

Corrugated sheets are available in lengths same as those indicated above for plain sheets,

n

HOLLOW MILD STEEL SECTIONS FOR STRUCTURAL USE

(Reference IS : 4923-1968)

[

+

ped a

Lo

Square Hollow Sections Rectangular Hollow Sections

Depth or with of | Thickness] Welshtper | Dep of | Breadth of ] Thickness | Welghtper

Section (D) Section (D) Section (B) @ metre

mm mm mn mm mm [

254 2.65 40 25 265 234

35 325 on

$03 405 329

32 2.65 2.30 50.8 25.4 2.90 3.04

3.25 2.72 3.25 3.34

4.05 322 405 4.00

38 2.90 303 635 38 2.90 419

335 333 3.65 513

405 399 450 63

45 2.90 3.66 76.2 38, 3.25 5.28

3.65 aa 3.65 586

450 531 450 702

50 2.90 42 162 508 32 594

3.65 5.04 3.65 6.59

450 602 $50 793

85 325 594 90 38 265 496

3.68 659 335 599

450 733 405 79

75 3.25 TAL 100 50, 3.25 TAL

4.03, 8.09 405 809

435, 102 485 102

FE = SHEET PILING SECTIONS:

A ientons ia mn s

(Reference 3: 2314-1963)

Weight | Weightper | Perimeter | Centrevo

per [squaremete | per mete | Conte

Designation | mete | "ofwall | ofwall | distance of

joins

kg kg cm es

Ps 101% 4995. «123.2 23400

ISPS 1625 U 65.37 162.40 308. 402.5

ISPS 202 U—8270 «19570 331 4205

18PS 100F 5520 13800 i 400

U Piling Sections

Overall dimensions in mim

Designation

A B tC

ISPS 1625 U 437 172 13

1SPS 100 FPling Secion ISPS 2222U 458 1945 1“

HARD-DRAWN STEEL WIRE FABRIC

(Reference IS : 1565-1982)

B

Square Mesh

Mesh Size | Diameterof | Weight “Mesh Size Diameter of | Weight

si (Nominal Pitch | Wire per Sh. | (Nominal Pitch Wire per

No. of Wires) | Each Way sqm No. | — of Wires) Each Way sqm

mm mm inkg mm mm inkg

1 50 30 222 2 150 56 257

2 50 38 3.56 2B 150 58 276

3 50 5.0 616 4 150 60 2.96

4 100 34 143 25 150 63 3.27

5 100 36 160 26 150 65 3.48

6 100 40 198 27 150 MW Als

7 100 45 233 2B 150 15 462

8 100 48 284 29 150 80 5.26

9 100 50 3.08 30 150 90 6.65

10 100 53 3.46 31 150 100 8.22

u 100 58 als 32 200 40 098

2 100 65 5.20 33 200 45 126

B 100 70 604 34 200 48 142

4 100 8.0 790 35 200 53 1.74

15 150 3.5 082 36 200 58 2.08

16 150 36 106 37 200 65 2.60

a 150 40 132 38 200 10 3.02

18 150 45 1.66 39 200 80 3.94

9 150 415 185 40 200 9.0 5.30

20 150 50 2.06 4 200 100 6.16

21 150 53 230

Oblong Mesh

Mesh Size | Dia. of Wires Mesh Size | Dia. of Wires

@itch of Wires) Weight per @itch of Wires) Weight per

St t Square metre | SI. ‘Square metre

No. | Main | Cross | Main | Cross No. | Main | Cross | Main | Cross

mm | mm jmm | mm | inkg mm |mm | mm | mm inkg

1 |

2 15 250 5042 249 51 75300 5836 3.04

B os 250-4242 189 375 300 605.0 347

“4 15 250 60 © 50 358 3.80

45 B 300-345-265, 0.96 0 7 30 65 60 426

46 15 300-355 2.65 118 6. 75 300 720 40 436

a7 5 300 40 2.65 145 2 15 30 80 48 573

48 15 300 «40-30 151 6 15 30 90 48 733

49 15 300 45 (35 187 & 15 300 10058 891

50 15 300 4.75 3.5 2.06 6 15 4009.04.95 7.00

51 5 300-4836 216 6 «75 «4009S 56 790

52 B 300 «5042 242 67 75400 10056 an

3 15 30 «5050 2.60 OW =) = 40-05 =i)

54 15 300 «533.15 251 6 715 4001S 4954.97

3s 8 300-5336 258 m 75 40000 74S 446

56 5 30056 3.55 2.83, nN 15 4006340 3.50

4

HARD DRAWN STEEL WIRE FABRIC

EXPANDED METAL SHEETS (XPM)

Oblong. Mesh (Continued) (Reference IS :412 - 1975)

Mesh Size | Dia. of Wires ‘Size of Mesh | Dimensions

itch of Wires) Weight per (Nominal) of Strands Weight per

si. sqm | Ref sqm

No. | Main | Crass | Main | Cross No. | swm | tw | width| Thickness

om | mm | mm | mm kg mm | mm | mm | mm kg

2 10. 150 42 30 146 1 100 2506.25 3.15 3.082

B 10 150° 45 30 1.62 2 100 © 250 50035 2470

aaa 2 25 BS 1

1% 100. 15046, 30 167 A Sy oo ee eS

75° 100 150 4836, 195 5 75° 200 S00 35 3.294

6 75 200 325 315 2141

Cepeda tee enna 19t 7 4 S650 35 8.023

7 100, 150 53 36 2.26 8 40 11s 500 3.15 6.172

i = i) ost = 2h 2.24 9 40 75) 500 35 6.172

10 4000 753.05 224 2.854

eee see a) no 40) 5 3.25315 4.007

80 «100150 6S 40 3.26 2 40 75325 BS 4.007

3 4 «65 3251.60 2.039

Sr 1001807040 oe 4 4007532560 2.039

82 100 2500420 42 153 1s 25 15 325° 3.15 5.529

8 100-250 50a 196 Neh oe 25) eS) ee 325m 822d) 3931

7 25 73 325 1.60 2.808

ee eee ay 125 75-325 1.25 2.194

8 100-250 72050 3.64 IO) 208 Gt) 25 15 7152

1 4 Peer fy ey. iy 7152

dee oe ae 2-20 63.25 2.24 5.086

oy He eee Oe ee 2 20 530 325) 2.04 5.086

8 1003004530 144 3 20 3251.60 3.633,

A 20 ee 50325] 3.633

8 10 300424 145 i ope ty ee Ba

9 100-300 483.6 1.69 2% 2 30 250 125 2.183

1 6100300 210 a ero 5 a sO 25 10 5.037

2% 125° 40 3251.60 5.037

Oo ae ee 190 2 125 50250 1.60 4.000

9 100 30 «5030 1.73 30° «125° 50250125 3.125

31125 40 250125 3.125

ee 2.00 32 «125° 50-250 1.00 2.500

05) ea 100 os 900 158) etna) 234 30125040250 1.00 2.500

96 100 300 60 5.0. 273 4 10 40 3.25 1.60 5.916

35 10 40250125 3.91

ieee OO ae 36 10 40.250 1.00 28733

98 100 3007.0. 4.0 3.35 3709S 8S 3251.60 519)

38 «95285250 1.25 281

a ee oe, 353 39° «95° (85250 1.00 209

100 100300 1m 55 3.64 40 6 25 325° 1.60 7551

Pol seis 1 4h} = 421 44006 5 2501.25 43887

102 «100 300804 442 ee cee eee can

103-100-300 8060 4.69 “43 15 150 1:00 4278

104 1003008065 482

105° 100-300 9.0 48 5.46

106 100 30010058 686

107" 150 250 5042 144

108 150 250 6050 3.30

109 «15025065 SS 3.90

nO 150300 6050 207

Mm 1590300 72050 2.52 ae cenine ont

121503008060 3.49

HEXAGONAL WIRE NETTING 8

(Chick: a wire mesh)

(Reference 5 3150-1982)

Netting is made of annealed mild stee! galvanised wire. The size of aperture is denoted by the distance between parallel

sides of the hexagons formed.

Size of Wire ‘Size of Wire Size of Wire

aperture dia, aperture dia. aperture dia,

mm mm mm mm mm mm

10 0.68 31 0.90 100 1.25

112 (ply 140

140 selvedge)

B 0.63 38 0.90 100 140

0.90 112 G-ply 1.80

125 selvedge)

9 0.63 50 0.90 15 1.40

0.80 125 (1 center

112 strand

3-ply selvedge)

25 080 15 0.90 100 140

0.90 ply 125 (centre 1.60

140 selvedge) strand 180

7 3-ply selvedge)

Note:- The term ‘selvedge’ denotes edge so woven that the end wires do not unravel.

WIRE CLOTH FOR GENERAL PURPOSES

(Reference IS : 1568-1970)

Wire cloth is regularly woven with parallel wires in both directions to produce uniform square meshes or openings, Wire used

for making the cloth can be mild steel, brass, bronze, aluminium alloy or plastics.

i

‘Average Width ‘Nominal Diameter

of Aperture of Wire

oe Apertue CU

170mm 032,04,0.56,08

140 mm 025, 0.32,0.45, 0.63, 0.71

118mm 025, 0.32, 0.41, 0.45, 0.56, 0.63

100 mm 0.22, 0.28, 0.36, 0.5, 0.56

850 microns 0.2, 0.25, 0.32,0.45, 0:50, 0.56

710 microns 018, 025,0.32, 0.45

£600 microns 0.16, 022,0.28, 04

'500 microns 0.14, 02, 0.25, 0.32, 0.36

425 microns 0.14, 0.2, 0.25, 0.28

355 microns 0.125, 0.18, 0.22, 0.25,

300 microns 0.112; 0.16, 0:2, 0.25

250 microns 0.1, 0.14,0.16,0.2

212 microns 01,0.125, 0.14, 0.16, 0.18

180 microns. (0.08, 0.112, 0.125, 0.14

150 microns. 0.071, 0.1, 0.112, 0.125

GALVANISED STEEL BARBED WIRE

(Reference IS :278- 1978)

Size Diameter of Wire in mm Weight of Barbed Wire Distance Between

Designation Line Wire | Wire for barbs in kg per metre ‘Two Barbs

MAX MIN, mm

1 2.50 2.50 0.155 (0.136 75 £12

2 250 250 0120 0.108 150 £12

3 250 200 0125 0.108 75 £12

4 250 2.00 0.103 0.089 150 £12

5 224 2.00 0106 0.097 75 412

6 224 2.00 0085 (0.078 150 £12

16

STEEL TUBES FOR STRUCTURAL PURPOSES.

(Reference IS : 1161 - 1979)

Nominal | Ouiside Thickesss | Weight | Nominal | Outside Thickesss | Weight

Bore | diameter | Cyacy permete | Bore | diameter | Gy... permetre

mm mm mm kg mm mm mm kg

15 213° Light 200 0.962 | 100 143° Light 365 (997

Medium = 2651.22 Medium = 45 21

Heavy 325145 Heavy 4 145

20 269 Light 235142 | 110 1210 Light 45 136

Medium = 265158 Medium 485146

Heavy 325 190 Heavy 54 162

25 337 Light 265 204 | 125 139.7 Light 45 149

Medium = «3.25 2.46 Medium = 485162

Heavy 405 299 Heavy 54 179

32 424 Light 26 261 | 135 1524 Light 45 164

Medium = 3.25 3.15 Medium = 4850177

Heavy 4053.86 Heavy 54 95 |

40 483° Light 29 327 | 150 165.1 Light 45 118

Medium 3.25361 Medium = 485192

Heavy 405443 Heavy 54 112

50 603 Light 29 4a4 | 150 1683 Light 45 181

Light 2 Saseee a7 Medium 485196

Medium 3655.10 Heavy 54 a7

Heavy 45 617 Heavy2 63 253

65 761 Light 325 se | ans 1937 Light 485-226

Medium = 3656153 “Medium = S.4 250

Heavy 45 792 Heavy 59 213

80 889 Light 325 686 | 200 2191 Light 485257

Medium = 4058.48 Medium 56 204

Heavy 485 101 Heavy 59 310

90 1016 Light 365 882 | 25 245 Heavy 59 342

Medium = 4059.75 | 250 2730 - 59 388

Heavy 43516 300 3239 : 63 495

350 3556 : 80 683

WEIGHT OF WIRE IN KILO

Diameter Iron Steel Copper Diameter | Iron Steel Copper

inmm| inmm

0.100 0.06 0.06 0.07 1.000 613 627 698

0125 0.09 0.10 oan 1.250 957 9.80 1090

0.160 ous 0.16 0.18 1.600 15.68 16.04 1786

0.200 024 025 028 2.000 24.51 2508 2791

0.250 038 039 oa 2.500 3829 39.40 4361

0315 061 0.62 0.69 3.150 00:79 os 60.68

0.400 0.98 1.00 142 4.000 98.03, 100.34 111.65

0.500 133 17 174 5.000 153.17 156.78 17445

0.630 243 249 2m 6300 243.18 248.90 276.96

0800 392 401 447 8.000 392.11 40135 446.59

WEIGHTS OF GALVANISED IRON FITTINGS

a

Description of fitings Size in mim Weight in kg of Nos

100 fitings per kg.

Cup-headed sheeting rivets 10x 6 0631 158

2x 6 0709 141

15x 6 0.788 16

Bx 6 0867 ns

Sheet bolts & nats 2x 6 1.104 91

15x 6 Lvs 88

Bx 6 1182 85

x 6 1340 5

31x 6 1497 a

37x 6 1576 3

Roofing screws cone headed 30x 6 1261 ”

56x 6 1497 1

Bx 6 1734 58

5x 6 2207 45

Hook bolts & nuts 87x 75 sou v7

87 x10 7.882 B

100 x75 6463 15

100 x10 8827 n

12x 75 7.094 rs

112 x10 10.088 10

5 x 75 7882 B

125 x10 11823 3

“Limpet washers (cone or circular) 0473 an

Diamond curved washers 30mm or 37 1970 st

mm square.

EQUIVALENT DIAMETERS OF STANDARD WIRE GAUGE

SWwG Millimetes swe Millimetres swG Millimetres

70 27 B 2337 32 02743

co 11785 4 21032 3 0.2540

5/0 10973, 15 1829 Mu 02337

40 10.160 16 11626 35 02134

3/0 9.449 "1 1422 36 0.1930

20 8.839 18 1219 37 0.727

° 8229 19 1016 38 0.1524

1 620 20 ogi 39 0321

2 7910 21 0813 40 0.1219

3 6401 2 ont 41 O18

4 5.893 B 0.610 2 0.1016

5 5385, 24 0559 % 0.0914

6 4377 25 0.508 4 0.0813

7 4470 % 0457 45 oont

8 4.064 21 0.4166 46 0.0610

9 3.658 2 03759 47 0.0508

10 3251 » 0.3554 48 0.0406

u 2946 30 03150 9 0.0305

2 2642 31 0.2946 50 0.0254

SHEET METAL GAUGES - BIRMINGHAM GAUGE (B.G),

Equivalent Thicknesses

Gauge mm Gauge mm Gauge mm | Gauge mm

0 10.07 9 3551 18 1257 2 0.4432

1 8971 10 375 19 1118 28 0.3969

2 7993 1 2927 20 09957 29 03531

3 72 2 2517 2 0.8865 30 03124

4 6350 B 2340 2 0.7938

5 5652 4 1994 3 0.7066

6 5.032 15 1715 m 0.6289

7 4481 16 1588 25 0.5598

8 3.988 0 1412 26 04981

18

+ BOLTS AND NUTS

WEIGHT (IN KILOGRAMS) OF BLACK BOLTS WITH HEXAGON HEAD AND NUTS

(ROUND NECKS)

(Including weight of one Head and one Nut)

EACH

Length in mm fom Diameter of bolt mm

underside of head to

thcend é ~ 1» | « | |» [om

25 0.019 0.048 0.101 0.171 0.278 os “

30 0.020 0.052, 0.107 0.181 0.292 0429 we

35, 0.022, 0.055 0.114 0.190 0.306 0.448 0.633

40 0.024 0.059 0.120 0.200 0.321 0.467 0.657

50 0.025, 0.063 0.126 0.210 0.335 0.487 0.683

S55 0.027 0.066 0.132, 0.220 0.349 0.506 0.709

60 0.029 0.069 0.138 0.230 0.363 0.525 0.734

65 0.030 0.073 0.145 0.240 0.377 0.544 0.759

15 0.031 0.077 “0.151 0.249 0.391 0.564 0.784

90 0.034 0.084 0.164 0.269 0.420 0.602 0.834

100 0.037 0.091 0.177 0.289 0.449 0.641 0.885

110 0.040 0.098 0.189 0.309 0477 0.680 0.936

1s 00s 05-0202 «03290505.

140 007 = 012,021. = 48—S 053387086

150, 0.050 0.119 0.227 0.368, 0.562 0.796 1.087,

160 0.053 0.127 0.240 0.388 0.590 0.834 1.138,

170 0056 033.0252? 1911

190 0.059 0.141 0.265 0.427 0.647 0.912 1.239

200 ous 0278s? 0676981189

220 0.162 0.303 0.486 0.732 1.028 1.390

240 vs 0316 ©0506 «0761-10661

260 : 054 © O88 Lae '382

280 : 056 = oss 1831380

300 a 0.903 1.260 1.693

Weighting of ne

round washer 3 mm thick 0.007 0.008 O.01L 0.018 0.025 0.034

‘Weight in kg of one nut 0.006 0.016 0.034 0.063 0.098 0.145, 0.210

‘Weight in kg of shank

for 35 mm ot tegth 0.006 0.014 00250059 00sT oom anor

RIVETS

WEIGHT (IN KILOGRAMS) OF CUP-HEADED STEEL RIVETS

(ncluding Head)

EACH

‘Length in mm from Diameter of rivet in mm

‘underside of head to

the end 8 2 4 18 2 24

25 0.022 0.044 0.076 0.121 0.179 0.252

7 0.024 0.047 0.081 0.128 0.188 0.265

30 0.026 0.050 0.086 0.135, 0.198 0.278

33 0.028 0.054 0.091 0.142, 0.208 0.290

36 0.030 0.057 0.096 0.149 0.217 0.303

40 . 0.031 0.060 0.101 0.156 0.227 0316

43 0.033 0.063 0.106 0.163 0.237 0.328

46 0.035 0.066 _ Ol 0.171 0.247 0341

50 0.036 0.069 ~ 0.116 0.178 0.256 0.354

25mm of shank only os 0.014 0.025 0.039 0.057 0.077 0.101

‘Wein kg of one head Eg 0.008 0.019 0.037 0.064 0.102 si

19

WEIGHT OF ROUND WIRE NAILS (PLAIN HEAD)

Leng] Diameierof ] Diameter of | AppNo | Length | Diameterof | Diameter of | App No

shank head of nails shank head of nails

mm mm mm er kg mm mm mm per kg.

25 1.60 40 2110 © 2.80 63 350

25 1.80 45 1720 0 315 7 230

5 2.00 50 1430 60 355 80 180

30 1.80 45 1410 80 355 80 140

30 2.00 50 1170 80 400 80 120

40 2.00 50 840 90 3.55 80 10

40 224 36 700 90 450 90 90

40 250 56 640

100 3.55 80 100

50 2.00 50 650 100 400 80 90

50 224 36 600 100 450 90 80

50 250 56 550 100 5.00 100 60

50 280 63 440

50 BAS na 280 125 5.00 100 50

125 5.60 u2 40

6 224 56 540 150 5.60 2 35

o 250 36 440 150 630 126 30

HOT ROLLED STEEL SECTIONS FOR DOORS, WINDOWS & VENTILATORS

(Reference IS : 7482 - 1982)

PURPOSE OR RECOMMENDED USE OF SECTIONS

Designation Designation

& Weight Purpose‘and situation of use & Weight Purpose aid situation of use

per mete (in kg) permetre (in kg)

721.036) Horizontal glazing bars for door side-lights, | F4B (2.28) Central mullion (meeting bar for shutters)

doorsand sashes, sub-dividingbarsforfixed- for windows using F7D as inner frames,

lights, vertical glazing bar for windows, outer frame for open-in windows in rainy

ventilators and doors where metal, area subsiding bas for penile

aluminium or wooden beading is used for ‘windows and top-hung ventilators.

fixing glass

F7D (1419) Innerand outer fraines for windowsandtop-

Ba Vertical glazing bar for EZ frames. Trung ventilators, for our frames for centre

hhung ventilators, and outer frame for door

76 (0.839) Horizontal glazingbarfor standard windows side-lights.

and ventilators

FX8(231) __Outet frames for doors

F2(1.46) Innes frames for open-in windows.

EZ7(1.90) Outer frame for industrial sashes.

3228) Outer frames for open-in windows.

: K11B (1.80) Vertical coupling mullion for all standard

F559) Inner and midddle frames in centre-hung ‘windows. Canbe usedashorizontal coupling

& ventilators. F5 ip used as inner frame for ‘bar when openablewindowsaretobecoupled

F8 (192) botiom-hung venilatorsand sometimes used above fixed ones or between two fixed

as inner frame for open-out windows. windows.

F 8s also used as outer frame for bottom - Can also be used as horizontal coupling

hung ventilators. imullion where windows are not exposed to

weather.

FX6Q@252) Inner frames for doors.

and FZ5 (2.52) K12B(230) Horizontal coupling mullion, also known as

‘weather bar. Especially used when the

‘coupled unit is exposed to rain,

20

ALUMINIUM SECTIONS

ALUMINIUM,

UNEQUAL LEG ANGLES

(Ref IS : 3909-1966)

ISALU Serles (contd)

res semngey mea pens

vg a a a

air

Tin So

TAL Ste

us see iss] peer Wa

a

es z earl

te s 8 8

939 60 40 19

won 0 40 24

et 100 50 34

a9 100 50 39

40x 40 x 4.0 0.84 fea io ret

es e 100 60 47

ae 8 8

ISALT Series 129

epee | me

|S |e

mm on ts 120 %0 61

es 8 &

‘ae

eo # &

50 50 12 150, iv oa

65, 6 16 c ne

aa 200 100 105

som

4 eee

wom | eng Ras

4 aya

wow 8 =] eae

3 - oh per

8

oom) | BEBE 8

150 150 as 30x20 x30 040

7s 175, 12 cee ae

200 200 128 40 x 20 x 3.0 048

a] GREE

Size ‘Weight per mete

mm kg

40x 25 x20 036

40x 25 x30 052

40 x 25 x40 068

50x 25 x30 0.60

50x 25 x 40 079

50x 25 x50 097

50 x 30 x30 064

50x 30x40 084

50x 30x50 1.03

60x 30 x 30 073

60 x 30 x 40 096

60x 30 x50 Lis

60 x 40 x 40 197

60 x 40 x50 131

60 x 40 x 60 15s

80x 40 x40 129

80 x 40 x 60 188

80x 40 x 80 246

100 x 50 x 60 238

100 x 50 x 80 311

100 x 50 x10.0 353

ALUMINIUM CHANNELS

(Ref 15 3921-1966)

ISALC Series

Depth | Width | Thick. | Thick. | Weight

of | of |nessof| ness of| per

Section| Flange | "Web | Flange] mete

mm | mm | mm | mm | “ke

40 20 20 048

40 20 30 0.68

3030 30 088

50 30 40 144

6 30 40° 1B

60 30 60 | 135

60°30 80 195

60 40 60 187

0 40 80 238

30 40 60 210

a 40 50 80 267

8 40 60 100 321

100 40 «5080295

100 4060 1003.55,

100 50 50 80-339

100 50 60 100 4.09

100 50-80 120 498

120 50 50 803.68

20 50 60 100 443

120 6 60 100 498

120 60 80 120 608

150 60 60 100 551

15060 80 120-67

150-80 60 «100659

150 80 80 120 © 807

150 8 100 160. 1026

200 80 80 «120928

200 80 100 160 11.74

200 100 100 160 1347

200 100 120 180 1533

METAL ROLLING SHUTTERS

(Reference IS : 6248 - 1979)

Size of rolling shutters is denoted by clear width x clear height of the opening for which shutter is imtended. Maximum

‘width without intermediate support (guide channel) is 9 metres.

‘Types of shutters are (2) self coiling (push-pull or manual) type upto 8 sq m clear area without ball bearings, and

between 8 to 12 sq m clear area with ball bearings; (b) gear operated (mechanical)type with ball bearings. For clear areas

between 12 and 25 sq m opearted by gear box and crank handle, and between 25 and 35 sq m operated by hand chain and

chain whee! mounted on worm shaft; (c) electrically operated, for clear areas above 35 sq m, upto a maximum of 50 sq m.

Fixing position of hood cover and bracket can be on the inner or outer face of the wall either below or above the

soffit of the opening, with the vertical guide channels fixed beyond the vertical face of the jambs. Fixing position of hood

cover and bracket can also be between the jambs, with the guide channels projecting in the opening or embedded in the

jambs.

Rolling curtain_is built up of interlocking laths shaped out of cold rolled steel strips. ‘The laths are made of strips

not less than 0.9 mm thick for shutters upto 3.5 m with, and not less than 1.2 mm thick for shatters above 3.5 m width

CAST IRON MANHOLE COVERS, GRATINGS, STEPS, TRAPS ETC.

Cast Iron Manhole Covers (Ref IS : 1726 (Parts I to Vil) «1974

HD (Heavy Duty) grade covers are designed for heavy vehicular traffic to withstand a load of 35 tonnes

‘MD (Medium Duty) grade covers are designed for light vehicular traffic as in footpaths/ cycle tacks to withstand a

load of 5 tonnes.

LD (Light Duty) grade covers are designed for pedestriin non-vehicular traffic in domestic premises to withstand a

Toad of 1 tonne.

HD and MD grade covers are specified to have single seal. Option for single or double seal is available in LD grade

covers only. HD grade double triangular covers have a seating frame of square shape in single piece with a circular opening,

and the cover is made up of two triangular pieces forming a square.

Grade /type of Size of clear Weight of ‘Weight of seating of

Ci manhole cover opening in mm cover in kg ‘frame in kg

HD circular 500 (dia) 85 85

560 (ia) 108 100

HD double triangular 500 (dia) ug un

560 (dia) wo us

MD circular 500 (aia) 58 58

560 (dia) a 6

MD rectangular 610x455 80 “a

LD square 455x455 3 7

(ingle seal) 610x610 5 3

LD square 455 x 455 2B 15

(double seal) 610x610 37 1B

LD rectangular 455x610 2B as

(Gingle seal ) @atern 1)

455x610 1s 10

(Pattern 2)

LD rectangular

(Gouble seat) 455x610 29 2B

Cast Iron Gratings ( Re/ IS : $961 - 1970) for drainage of surface water have a scating frame of size 560 x 600 mm

overall, with a hinged grating of size 450 x 490 mm overall fitted in it, The minimum specified weight of grating including

seating frame is 75 kg and is designed for 35 tonne load.

‘Cast Iron Steps for Manholes (Ref IS : 5455 - 1969) can be of Pattern 1 which weigh minimum 4.5 kg per step, are

150 mm wide and of overall length 375 mm of which 125 mm project from the wall. Patten 2 steps weigh minimum 5:3

kk per step, are 165 mm wide and of overall length 385 mm of which 125 mm project from the wall. Both patterns have

raised chequered nonslip ead, are 25 mm thick and have lugs for grip inthe potion intended for embedding inthe wall.

Cast Iron Floor / Nabni traps (Ref IS : 3989 - 1984) are specified to have following characteristics :=

Designation / diameter / size] Diameter of Total Weight (approx.)

Description (nominal bore of outlet) | inlet grating depth of each Wap

Cast iron floor traps 50 mm 100 mm 175 mm 2.5 kg

75 mm 100 mm 225 mm 438 kg

100 mm 200 mm, 296 mm 75 kg

Cast iron nahni traps - 50mm 165 mm 175 mm 55 kg

75 mm 165 mm 225 mm 65 kg

You might also like

- Tech Specifications (HEADS Pro) (Road Design) (Mail)Document32 pagesTech Specifications (HEADS Pro) (Road Design) (Mail)SANDIPNo ratings yet

- Ggps Sandasar Qasim, Battgram OF STEEL REINFORCEMENT (Upto 2nd Bill) S.No Sheet # Part of Building Remarks Steel Used (LBS)Document7 pagesGgps Sandasar Qasim, Battgram OF STEEL REINFORCEMENT (Upto 2nd Bill) S.No Sheet # Part of Building Remarks Steel Used (LBS)syukNo ratings yet

- Assignment Nicmar / Sode Office: Name: Mr. Prabhakar Prakash Shingrut Course: GPCBM Reg. No. 217-04-22-50914-2183Document18 pagesAssignment Nicmar / Sode Office: Name: Mr. Prabhakar Prakash Shingrut Course: GPCBM Reg. No. 217-04-22-50914-2183Prabhakar Shingrut100% (1)

- Reinforcements Cage Bars Pile Description Width Length Length Quantity Concrete (M) Total Length (M)Document15 pagesReinforcements Cage Bars Pile Description Width Length Length Quantity Concrete (M) Total Length (M)Jan Felix DonsalNo ratings yet

- PVC FormulaeDocument4 pagesPVC FormulaessirupaNo ratings yet

- Estimating & CostingDocument10 pagesEstimating & CostingJohn G JoseNo ratings yet

- ROad Construction Tender For African CountriesDocument73 pagesROad Construction Tender For African CountriesmutamanthecontractorNo ratings yet

- Material Cost and Escalation Clauses in Indian ConsDocument14 pagesMaterial Cost and Escalation Clauses in Indian ConsgayaseshaNo ratings yet

- Lec8 Ce151p 2Q 1819 FormworksDocument58 pagesLec8 Ce151p 2Q 1819 FormworksRachelle AndradeNo ratings yet

- The AACE International Journal: Planning and SchedulingDocument8 pagesThe AACE International Journal: Planning and SchedulingHedi ZarkounaNo ratings yet

- Analysis and Execution of Road WorkDocument86 pagesAnalysis and Execution of Road WorkRahul Jha50% (2)

- Cover Letter-Value Engineering ProposalDocument3 pagesCover Letter-Value Engineering ProposalDileesha RoshaneNo ratings yet

- Highway Construction Production Rates and Estimated Contracct TimesDocument95 pagesHighway Construction Production Rates and Estimated Contracct TimesLTE002No ratings yet

- Developments in Formwork: Larsen & Toubro LimitedDocument83 pagesDevelopments in Formwork: Larsen & Toubro LimitedRavi RajanNo ratings yet

- Methods of Approximate Construction Cost Estimation PreparationDocument5 pagesMethods of Approximate Construction Cost Estimation PreparationcivilNo ratings yet

- From WorkDocument42 pagesFrom WorkPrashant SunagarNo ratings yet

- SOR PWD (WB) Building Works 2010Document10 pagesSOR PWD (WB) Building Works 2010Sourabh Mandal0% (1)

- Method For Calculating Schedule Delay ConsideringDocument11 pagesMethod For Calculating Schedule Delay ConsideringGilang ArdiNo ratings yet

- Rawand RCC Bridge PDFDocument20 pagesRawand RCC Bridge PDFsharif mooNo ratings yet

- List of Structure Drawing To Be Taken From HO As On Date 16.01.2023Document1 pageList of Structure Drawing To Be Taken From HO As On Date 16.01.2023SRK QSNo ratings yet

- Doors Windows and VentilationDocument46 pagesDoors Windows and VentilationPrathmesh SheteNo ratings yet

- Cesmm Rev 9Document209 pagesCesmm Rev 9antscarNo ratings yet

- DPRDocument166 pagesDPRRam Narendra NathNo ratings yet

- Gaja Puyal ListDocument9 pagesGaja Puyal ListVijayssc SivaNo ratings yet

- Is SP 27 1987 - 0 PDFDocument130 pagesIs SP 27 1987 - 0 PDFluckyyermalNo ratings yet

- Contract. EthicsDocument27 pagesContract. EthicsNeib Kriszah AlbisNo ratings yet

- Cost Plan SampleDocument3 pagesCost Plan Sampleakg20041100% (1)

- Curriculm of Civil Engg& Allied DisciplineDocument21 pagesCurriculm of Civil Engg& Allied DisciplineAbbasabbasiNo ratings yet

- Formwork Time CalculationDocument17 pagesFormwork Time CalculationFrancois-No ratings yet

- 06 Costing - Labour, Plant and MaterailDocument36 pages06 Costing - Labour, Plant and MaterailMeg TNo ratings yet

- Bar Bending ScheduleDocument5 pagesBar Bending ScheduleAbdulkadirNo ratings yet

- Road ResurfacingDocument16 pagesRoad ResurfacingLovish SinghalNo ratings yet

- Final DissertationDocument65 pagesFinal DissertationDanushka PrädeepNo ratings yet

- Model Estimate For ConstructionDocument4 pagesModel Estimate For ConstructionTarun ChopraNo ratings yet

- Socio-Cultural and Economic Impacts of BRT PeshawarDocument6 pagesSocio-Cultural and Economic Impacts of BRT PeshawarVelumani sNo ratings yet

- CIQS Estimate ClassificationDocument2 pagesCIQS Estimate Classificationttplan800100% (1)

- Estimating Concrete Work II - Estimating Foundation Walls - tcm45-340150Document5 pagesEstimating Concrete Work II - Estimating Foundation Walls - tcm45-340150Tarun ChopraNo ratings yet

- Quantity and Rate Analysis For Reinforced Concrete ConstructionDocument4 pagesQuantity and Rate Analysis For Reinforced Concrete Constructionvenkateswara rao pothinaNo ratings yet

- Chennai MetroDocument30 pagesChennai MetroTamilSelvan Panneerselvam100% (1)

- Estimating Costing VDocument4 pagesEstimating Costing Vशंकर थापाNo ratings yet

- Prepared By: Amrita Chatterjee Swarnendu Bhattacharjee: Adamas Institute of Technology, Civil Engineering, 3 YearDocument79 pagesPrepared By: Amrita Chatterjee Swarnendu Bhattacharjee: Adamas Institute of Technology, Civil Engineering, 3 YearMonjit RoyNo ratings yet

- Construction Project Management GraduatiDocument258 pagesConstruction Project Management GraduatiUzma IlyasNo ratings yet

- Brief Rate AnalysisDocument15 pagesBrief Rate AnalysisSaroj AcharyaNo ratings yet

- Basics of Building ConstructionDocument5 pagesBasics of Building ConstructionSirimilla Mehar100% (1)

- Homework Productivity RateDocument9 pagesHomework Productivity RateMel CoderesNo ratings yet

- BOQDocument32 pagesBOQsowmyaNo ratings yet

- Joglekar Estimating and ValuationDocument133 pagesJoglekar Estimating and Valuationrafay100% (1)

- A Dictionary of Units Part 1Document33 pagesA Dictionary of Units Part 1kapil100% (1)

- Universal Unit of MeasurementDocument3 pagesUniversal Unit of MeasurementAna MarksNo ratings yet

- Unit ConversionsDocument2 pagesUnit Conversionsangry_granNo ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- ScheduleDocument87 pagesScheduleQamrul HasanNo ratings yet

- Rules of Thumb-Chemical EngineeringDocument31 pagesRules of Thumb-Chemical Engineeringintania66No ratings yet

- Technical ManualDocument50 pagesTechnical ManualTerence TanNo ratings yet

- 2Document42 pages2Nhu Nguyen0% (1)

- Units & Conversion Tables: Electus Distribution Reference Data Sheet: UNITCONV PDFDocument1 pageUnits & Conversion Tables: Electus Distribution Reference Data Sheet: UNITCONV PDFutkarsh_maruNo ratings yet

- A Mechanical Engineer's Handbook by ONGCDocument303 pagesA Mechanical Engineer's Handbook by ONGCShantanu Dutta100% (13)

- Conversion FactorsDocument10 pagesConversion FactorsPrashanth Reddy TummuluriNo ratings yet

- Metric Prefixes: ET 106 - Intro. To Engineering Technology Unit ConversionsDocument9 pagesMetric Prefixes: ET 106 - Intro. To Engineering Technology Unit Conversionsbarnibar1No ratings yet

- A - Conversion FactorsDocument14 pagesA - Conversion Factorssaeed65No ratings yet

- Eco Sanitation - Power Point Presentation in Marathi Language.Document30 pagesEco Sanitation - Power Point Presentation in Marathi Language.shrikant100% (6)

- Refuse DisposalDocument23 pagesRefuse Disposalshrikant100% (2)

- 13 Slides.Document13 pages13 Slides.shrikantNo ratings yet

- Poverty EradicationDocument41 pagesPoverty EradicationHarvinder Singh BrarNo ratings yet

- Otji Toilet Sel Builders ManualDocument12 pagesOtji Toilet Sel Builders ManualshrikantNo ratings yet

- Reference Manual SanitationDocument18 pagesReference Manual SanitationshrikantNo ratings yet

- Nirmal Gram Puraskar - Ministry of India.Document98 pagesNirmal Gram Puraskar - Ministry of India.shrikantNo ratings yet

- Structural Systems in ArchitecureDocument24 pagesStructural Systems in Architecureshrikant100% (1)

- Public ToiletsDocument3 pagesPublic ToiletsshrikantNo ratings yet

- Health and Sanitation Report by Arghyam.Document33 pagesHealth and Sanitation Report by Arghyam.shrikantNo ratings yet

- Eco-San Toilets. BangaluruDocument4 pagesEco-San Toilets. BangalurushrikantNo ratings yet

- Sanitation Marts.Document2 pagesSanitation Marts.shrikantNo ratings yet

- GlobalSanitationFund IndiaLaunchWorkshop IndiaWashForum 2009Document64 pagesGlobalSanitationFund IndiaLaunchWorkshop IndiaWashForum 2009shrikantNo ratings yet

- Health and Sanitation Report.Document34 pagesHealth and Sanitation Report.shrikantNo ratings yet

- Report On Sustainabilty of Sanitation Projects in India.Document34 pagesReport On Sustainabilty of Sanitation Projects in India.shrikantNo ratings yet

- Moringa Brochure 2up A4Document2 pagesMoringa Brochure 2up A4shrikantNo ratings yet

- Philosophy For Old Age - George CarlinDocument20 pagesPhilosophy For Old Age - George CarlinSubrahmanya Murali SNo ratings yet

- On Moringa.Document52 pagesOn Moringa.shrikant100% (5)

- Moringa Tree Information.Document16 pagesMoringa Tree Information.shrikantNo ratings yet

- Eco Sanitation 1Document5 pagesEco Sanitation 1shrikantNo ratings yet

- Spanning of Opennings:A Power Point Presentation Prepared by Vaishali Anagal of DR.B N College of Architecture, Pune.Document55 pagesSpanning of Opennings:A Power Point Presentation Prepared by Vaishali Anagal of DR.B N College of Architecture, Pune.shrikant50% (2)

- Moringa Information.Document20 pagesMoringa Information.shrikant0% (1)

- Pre - Fab ToiletsDocument5 pagesPre - Fab ToiletsshrikantNo ratings yet

- Elevators and EscalatorsDocument38 pagesElevators and Escalatorsshrikant100% (11)

- Eco Sanitation 1Document6 pagesEco Sanitation 1shrikantNo ratings yet

- Architects Working Details, Resource Drawings For Students of ArchitectureDocument43 pagesArchitects Working Details, Resource Drawings For Students of ArchitectureshrikantNo ratings yet

- Review of Urine Diversion and Its Use in Agriculture.Document32 pagesReview of Urine Diversion and Its Use in Agriculture.shrikantNo ratings yet

- Power Point Presentation On Timber Joinery.Document56 pagesPower Point Presentation On Timber Joinery.shrikant100% (5)

- Presentation On Foundations.Document32 pagesPresentation On Foundations.shrikant100% (6)

- Vintage Airplane - Feb 1997Document36 pagesVintage Airplane - Feb 1997Aviation/Space History LibraryNo ratings yet

- Ilsco Aluminummechanicallugs CatalogpageDocument5 pagesIlsco Aluminummechanicallugs CatalogpageJhoompieer VFNo ratings yet

- Electrical Wire, Cable, and Cord: 1-99 Ft. $3.84 Per Ft. 100 or More $2.96 Per FTDocument1 pageElectrical Wire, Cable, and Cord: 1-99 Ft. $3.84 Per Ft. 100 or More $2.96 Per FTMiroslaw LabudaNo ratings yet

- Pamphlet - System Earthing - English VersionDocument8 pagesPamphlet - System Earthing - English VersionDhanraj chavanNo ratings yet

- Bulks PDFDocument44 pagesBulks PDFmihai085No ratings yet

- METHOD STATEMENT FOR Installation of LV Power Cables and WiresDocument12 pagesMETHOD STATEMENT FOR Installation of LV Power Cables and Wiresmazen zaloudNo ratings yet

- NASA Workmanship Ref-CRIMPINGDocument27 pagesNASA Workmanship Ref-CRIMPINGkpal525No ratings yet

- QU-BD OneUp and TwoUp Assembly InstructionsDocument67 pagesQU-BD OneUp and TwoUp Assembly InstructionsNeilNo ratings yet

- TR 05 04E 120402 English PDFDocument0 pagesTR 05 04E 120402 English PDFFlores JesusNo ratings yet

- 272 Large Cross-Sections and Composite Screens DesignDocument88 pages272 Large Cross-Sections and Composite Screens DesignepriNo ratings yet

- f6dp30s1Document24 pagesf6dp30s1fcwnv1No ratings yet

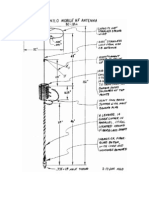

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- 05 50 00 IcDocument44 pages05 50 00 IcÜmit KazanNo ratings yet

- Copper Penn-Crimps Telecommunication Lugs - Type Bblu-2Tc: 2 Hole Long Barrel Lugs For 8 Stranded Thru 2000 MCMDocument2 pagesCopper Penn-Crimps Telecommunication Lugs - Type Bblu-2Tc: 2 Hole Long Barrel Lugs For 8 Stranded Thru 2000 MCMAvoor KhanNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Hardfacing Wires: For Steel Mill RollsDocument16 pagesHardfacing Wires: For Steel Mill RollsRaviTeja BhamidiNo ratings yet

- Haab E3 Duo Electroforming IsDocument6 pagesHaab E3 Duo Electroforming IsPicanol JacquelineNo ratings yet

- Steel Wire Rope - Use & MaintenanceDocument44 pagesSteel Wire Rope - Use & Maintenancesayed salahNo ratings yet

- DL Lebus Bulletin Issue 4Document4 pagesDL Lebus Bulletin Issue 4AmirNo ratings yet

- Cross-Reference - AWG To Metric Size (With Ampacity) of Insulated ConductorsDocument1 pageCross-Reference - AWG To Metric Size (With Ampacity) of Insulated ConductorsJoeDabid94% (16)

- p168 NI Main Control Panel PartsDocument1 pagep168 NI Main Control Panel PartsFRANCISCO JAVIER RUEDA LOPEZNo ratings yet

- DIY Grounding For Nissan 200SX S13Document6 pagesDIY Grounding For Nissan 200SX S13deivs001No ratings yet

- Sace Tmax XT: Circuit-Breaker Terminals and ConnectionDocument28 pagesSace Tmax XT: Circuit-Breaker Terminals and ConnectionPiyakarn BeeNo ratings yet

- Stoody 965GDocument1 pageStoody 965GARTHURS316No ratings yet

- Magnetic Effect of Current - Level - 2 - DTS 2 PDFDocument2 pagesMagnetic Effect of Current - Level - 2 - DTS 2 PDFbrainx MagicNo ratings yet

- M3B10 M8a10 M10a16 M2a10 M4a10 M1a4 M17a16Document1 pageM3B10 M8a10 M10a16 M2a10 M4a10 M1a4 M17a16Hugo GonzalezNo ratings yet

- GB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeDocument2 pagesGB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeArfanAli100% (1)

- Lesson Plan - Electrical Materials and SuppliesDocument5 pagesLesson Plan - Electrical Materials and Supplieswels berdNo ratings yet

- Overhead Contact System De-Icing - System Blue WireDocument8 pagesOverhead Contact System De-Icing - System Blue Wirevahid_dadgaryNo ratings yet