Professional Documents

Culture Documents

Field Density Notes PDF

Field Density Notes PDF

Uploaded by

Reynard Delos SantosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Density Notes PDF

Field Density Notes PDF

Uploaded by

Reynard Delos SantosCopyright:

Available Formats

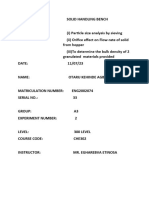

Field Density Test

A.

Rubber-Balloon Method

1) Position the density plate on a flat surface and set the volume measuring apparatus in the

recessed hole in the density plate.

2) Hold the apparatus down firmly in position, open the control valve, pump the balloon

down with the rubber bulb until the water level in the graduated cylinder has reached its

lowest position, and record this volume which is the initial reading.

3) Pump the balloon back into the cylinder by inverting the rubber bulb, and close the

control valve.

4) Place the density plate in a level position on the material to be tested, dig a test hole about

4 in. in diameter and 4 in. deep, retain all the material which is removed from the hole,

then measure and record the mass of the excavated soil.

5) Set the apparatus in the recess in the density plate, hold it down firmly, open the control

valve, pump the balloon into the hole, and record the lowest point reached by the water in

cylinder which is the final reading.

6) Invert the pressure-vacuum bulb and pump the balloon back into the cylinder.

7) Subtract the initial reading from the final reading and obtain the volume of the hole in

cubic feet.

8) Mix the material thoroughly and secure a representative sample of not less than 100 gm

for moisture determination.

9) Make density calculations based on volume of the test hole and dry or wet weight (as

required) of materials removed.

B.

Sand-Cone Method

1) Place the empty sand-cone apparatus upright on a firm level surface, close the valve and

fill the funnel with sand.

2) Open valve and, keeping funnel at least half full of sand, fill the apparatus.

3) Close the valve sharply, empty excess sand, and weigh.

4) Determine the weight of sand required to fill the funnel by seating the inverted apparatus

on a plane surface, opening the valve until the sand stops running, closing the valve

sharply and weighing. (When the base plate is used it should be considered a part of the

funnel).

5) Replace the sand removed in the funnel determination, close the valve and weigh.

6) Seat the density plate, if any, on the test hole, center the sand-cone apparatus, open the

valve and, after the sand has stopped flowing, close the valve.

7) Weigh the apparatus with remaining sand.

8) Determine the volume of the jar and attachment up to and including the valve orifice by

weighing the empty apparatus, filling with water until it appears over the valve, weighing

the filled apparatus, and measuring the temperature of the water.

C.

Nuclear Moisture - Density Measurements

Radioactive materials used in moisture-density devices emit four types of radiation:

alpha particles

beta particles

gamma rays (photons) (for density measurement)

neutrons (for moisture measurement)

1) Density measurement: source of gamma rays is cesium, half life = 30 years

Backscatter: number of backscattered gamma rays detected by the counter is related to

material total density.

Direct Transmission: number of rays directly or indirectly detected by the counter is

dependent on density of material.

2) Moisture measurement: source of neutrons is beryllium which must be bombarded by

americium before it releases the neutrons.

Only backscatter is used. Penetrating power of neutrons depends on material composition rather

than density. They are slowed down most effectively by material containing hydrogen atoms

such as water and polyethylene.

3) Safety - only properly trained, authorized users may handle the equipment. Users must wear

radiation badges to measure cumulative radiation. Safe storage and protection are legally

mandated.

4) Measurement characteristics

Density:

i) Backscatter

ii) Direct transmission

Moisture:

depth of measurement: 2 to 3 inches

range: 70 to 170 lb/cu ft

accuracy 1.5 pcf

depth of measurement: 2 to 8 inches

range: 70 to 170 pcf

accuracy: 0.5 pcf

depth of measurement: 5 inches

range: 0 to 40 lb/cu ft

accuracy 0.25 pcf

You might also like

- Field Density Testing GuideDocument32 pagesField Density Testing Guidenikita6969No ratings yet

- Constant & Falling Head Permeability TestDocument14 pagesConstant & Falling Head Permeability TestIkhwan Z.89% (72)

- T 191Document6 pagesT 191abcd1860100% (2)

- Mapua University: Experiment No. 6 Field Density TestDocument10 pagesMapua University: Experiment No. 6 Field Density TestMike SyNo ratings yet

- Determination of Coefficient of Permeability Using Constant-Head Test and Falling Head TestDocument7 pagesDetermination of Coefficient of Permeability Using Constant-Head Test and Falling Head TestVerra Myza AratNo ratings yet

- Cec 104 Prac-Material Properties ofDocument42 pagesCec 104 Prac-Material Properties ofVietHungCao67% (6)

- Insitu Density TestsDocument9 pagesInsitu Density TestsIsuru Udayanga NanayakkaraNo ratings yet

- D70, Specific GravityDocument3 pagesD70, Specific GravityAldwiNo ratings yet

- 9) Sand Cone MethodDocument6 pages9) Sand Cone MethodPn Ekanayaka100% (1)

- Aashto T 191Document7 pagesAashto T 191Y&Y B&CNo ratings yet

- PQT ProcedureDocument7 pagesPQT ProcedureCak Nhass100% (2)

- La Salle University Ozamiz City: Civil Engineering DepartmentDocument6 pagesLa Salle University Ozamiz City: Civil Engineering DepartmentMark Andykenn Liaga MaglinteNo ratings yet

- ND T 191 - Density of Soil In-Place by The Sand Cone MethodDocument4 pagesND T 191 - Density of Soil In-Place by The Sand Cone MethodAldrin SantosNo ratings yet

- TEST 5: Measurement of Field Density by Sand Cone MethodDocument5 pagesTEST 5: Measurement of Field Density by Sand Cone MethodCE PassajNo ratings yet

- Aashto t191 Density in Place by The Sand Cone Method PDFDocument6 pagesAashto t191 Density in Place by The Sand Cone Method PDFdonyNo ratings yet

- Batstateu Alangilan College of Engineering, Architecture and Fine ArtsDocument5 pagesBatstateu Alangilan College of Engineering, Architecture and Fine ArtsPrince RiveraNo ratings yet

- Ii - Field Density Test: Historical BackgroundDocument4 pagesIi - Field Density Test: Historical BackgroundSean WasilNo ratings yet

- KT 13Document14 pagesKT 13zum marNo ratings yet

- Test Method For Foaming Agents For Use inDocument19 pagesTest Method For Foaming Agents For Use inJunaid AminNo ratings yet

- Field Density Test: A. Calibration of Mechanical DeviceDocument11 pagesField Density Test: A. Calibration of Mechanical DeviceAnn Bernadette PenaflorNo ratings yet

- D70.1737-1-Density of Semi-Solid Bituminous Materials (Pycnometer)Document3 pagesD70.1737-1-Density of Semi-Solid Bituminous Materials (Pycnometer)Devela AvinashNo ratings yet

- Aashto T 310 - InglesDocument10 pagesAashto T 310 - InglesKatherine Quintero OrtízNo ratings yet

- Experiment 20Document8 pagesExperiment 20Tay Joo FangNo ratings yet

- Materials and MethodologyDocument12 pagesMaterials and MethodologyEvan SmithNo ratings yet

- Experiment No. 2 California Bearing RatioDocument7 pagesExperiment No. 2 California Bearing RatioPatricia TubangNo ratings yet

- Laboratory Test and Preparation of Report Use of EquipmentDocument16 pagesLaboratory Test and Preparation of Report Use of Equipmentlsatchithananthan100% (1)

- Chapter 3: Operational Framework 3.1 Research MethodologyDocument6 pagesChapter 3: Operational Framework 3.1 Research MethodologyJhaycEe AsisNo ratings yet

- Aashto T 310 - In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Document6 pagesAashto T 310 - In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Aldrin SantosNo ratings yet

- Blanes ProcedureDocument3 pagesBlanes ProcedureRavishankar HobannaNo ratings yet

- Sand Cone TestDocument14 pagesSand Cone TestRobert Bui0% (1)

- FDT ProcedureDocument2 pagesFDT Procedurepatrick villanuevaNo ratings yet

- Drilling Fluid PartDocument4 pagesDrilling Fluid PartChun SiangNo ratings yet

- Testing of Bituminous MaterialDocument4 pagesTesting of Bituminous MaterialBilal Ahmed BarbhuiyaNo ratings yet

- MODULE 2 Unit 1 (Week 9 and 10) For Lab Soil MechanicsDocument16 pagesMODULE 2 Unit 1 (Week 9 and 10) For Lab Soil MechanicsMark Ruby OpawonNo ratings yet

- Laboratory Test and Preparation of Report Use of EquipmentDocument16 pagesLaboratory Test and Preparation of Report Use of EquipmentEncik ComotNo ratings yet

- Mud Filtration: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab ExperimentDocument5 pagesMud Filtration: University of Zawia Faculty of Oil & Gas Engineering Drilling Fluid Lab Experimentايمن القنونيNo ratings yet

- Lab Manual Soil MechanicsDocument14 pagesLab Manual Soil Mechanicsabhay9911No ratings yet

- Methodologie Essai de Densite in Situ-Atc-sadiolaDocument1 pageMethodologie Essai de Densite in Situ-Atc-sadiolaANISNo ratings yet

- Mud FiltrationDocument5 pagesMud FiltrationMortaza MuhalhalNo ratings yet

- Prosedur Dry Sieve AnalysisDocument2 pagesProsedur Dry Sieve AnalysisxianqianhuiNo ratings yet

- Experiment 1 FoundationDocument6 pagesExperiment 1 FoundationAlfredo Cerdeña Jr.No ratings yet

- Geoinformatics (2) ..Document12 pagesGeoinformatics (2) ..Dinesh SNo ratings yet

- Kenny's Solid Bench FileDocument24 pagesKenny's Solid Bench Fileotaken6No ratings yet

- Candelaria Experiment3 SoilMechLabDocument12 pagesCandelaria Experiment3 SoilMechLabHarley O. CandelariaNo ratings yet

- Geo Lab ReviewerDocument29 pagesGeo Lab ReviewerMay'two Echalas MagawayNo ratings yet

- Constant Falling Head Permeability Test PDFDocument14 pagesConstant Falling Head Permeability Test PDFvinoNo ratings yet

- Reducing Field Sample of Aggregates To Testing SizeDocument17 pagesReducing Field Sample of Aggregates To Testing SizeJan Vindhya Jopson PradesNo ratings yet

- Wet Preparation of Disturbed Soil SamplesDocument8 pagesWet Preparation of Disturbed Soil SamplesMae CostalesNo ratings yet

- ReportDocument11 pagesReportAbdul latif Abdul latifNo ratings yet

- Sand Replacement Method: ObjectiveDocument4 pagesSand Replacement Method: ObjectiveMohamed FarahNo ratings yet

- Laboratory Testing Manual: Soil Mechanic S TestingDocument40 pagesLaboratory Testing Manual: Soil Mechanic S TestingMatthew PagulayanNo ratings yet

- Cone Method: Procedure Procedure For Laboratory WorkDocument3 pagesCone Method: Procedure Procedure For Laboratory WorkDinusha Nilan KumaraNo ratings yet

- Testing of Bituminous MaterialDocument4 pagesTesting of Bituminous MaterialBilal Ahmed BarbhuiyaNo ratings yet

- 1) List of Unit in GTEDocument9 pages1) List of Unit in GTES GONo ratings yet

- 2a6a - Lab 8 - Group 1 (2a6a) - Ecg428 - Mac24Document10 pages2a6a - Lab 8 - Group 1 (2a6a) - Ecg428 - Mac24Izzah AfiqahNo ratings yet

- LAB 14 - One-Dimensional Consolidation - Oedometer - Level 0 - 2ndDocument6 pagesLAB 14 - One-Dimensional Consolidation - Oedometer - Level 0 - 2ndAmirah ShafeeraNo ratings yet

- Soil Mechanics Lab .: Field Dry DensityDocument4 pagesSoil Mechanics Lab .: Field Dry DensityArafa AlmoghrabiNo ratings yet