Professional Documents

Culture Documents

Bulletin PVS-80020201-VCD - Vacuum Condensate Drainer

Uploaded by

Teddy Tyssa TarnoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulletin PVS-80020201-VCD - Vacuum Condensate Drainer

Uploaded by

Teddy Tyssa TarnoCopyright:

Available Formats

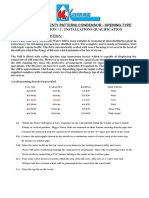

MODEL # 2VCD-20B VACUUM CONDENSATE DRAINER

CATALOG SPECIFICATION SHEET

BULLETIN # PVS-80020201-VCD

PAGE 1 OF 2

IN

(VENT) 15

12

TECHNICAL REFERENCES

Dwg. # 502776 Outline Drawing

Dwg. # 502777 Recommended Drainer Valve Piping GA

Dwg. # 502293 Vacuum Drainer Installation Diagram

5

1

Note:

Refer to system IO&M manual for

integrated operation with the vacuum system.

11

4

12

10

8

(DRAIN) 15

3

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

VACUUM CONDENSATE DRAINER

2VCD-20B

502720

0-7,000 LB/HOUR VARIABLE FLOW

STEAM VACUUM SERVICE, STEAM CONDENSATE

2 PSI [4.1" Hg]

2" NPT IN/OUT, 1/2" NPT VENT/DRAIN

CS BODY, SS INTERNALS

PART NO.

QUANTITY

MATERIAL

502721

1

CS

502722

1

CS

502723

1

CS

502269

2

Aramid/Nitrile

502724

1

SS

502725

1

SS

502726

1

SS

502727

1

SS

90298A537

1

SS

9557K462

1

EPDM

9557K477

1

EPDM

92196A542

16

SS

502347

1

SS

16055T237

1

Vinyl

4513K324

2

CS

MECHANICAL DESIGN

DESIGN PRESSURE

15 PSIG + F.V.

DESIGN TEMPERATURE

200 F / -20 F

MODEL #

PART #

FLOW RANGE

APPLICATION

P

CONNECTIONS

CONSTRUCTION

DESCRIPTION

Drain Chamber

Inlet Cover (Top)

Outlet Cover (Bottom)

Cover Gasket

Ball Float

Valve Stem

Valve Poppet

Valve Seat

Limit Screw

Stem O-Ring

Poppet O-Ring

Cap Screw

Name Plate

Flow Arrow

NPT Plug

The Unique VIP Service Advantage

Value, Integrity, Professionalism & Service

OUT

SPEC.

A513

C1018

C1018

BG3000

A316

A416

A416

A416

A304 (18-8)

D2000

D2000

A304 (18-8)

A304

-A105

MODEL # 2VCD-20B VACUUM CONDENSATE DRAINER

CATALOG SPECIFICATION SHEET

BULLETIN # PVS-80020201-VCD

PAGE 2 OF 2

CAPACITY

The discharge capacity of Unique Systems' condensate drainer is variable by design from 0-7,000 #/hour of water,

depending upon the differential pressure across the valve. Valve operation is completely automatic, self-adjusting to

flow rates specific to vacuum system demands as necessary, without any operator intervention required. The design

condensate flow rate specific to any particular ejector vacuum system can be found on the Condenser Data Sheet

included with the Engineering Documentation Submittal package or the System IO&M Manual. Consult Unique Systems

for more information, if required.

INSTALLATION

The drain valve should be installed in the vertical position, with the flow arrow on the valve body pointing down,

underneath the vacuum condenser. The ideal position is as close to the drain return point as possible, insuring

adequate elevation above the drain return connection. Piping to and from the valve should match the connection size

on the valve. Interconnecting piping should never be smaller than the valve connection size. Unrestricted free-flow of

condensate is critical to the valve's performance. For further details on valve installation reference Dwg. # 502293

Vacuum Condensate Drainer Installation Diagram. The diagram includes more specific information regarding

recommended piping layout.

MAINTENANCE

Unique Systems' Vacuum Condensate Drainer is easy to maintain given the relatively few internal parts comprising the

valve. Before beginning any maintenance or internal inspection of the drainer ensure that the valve is completely

isolated from the process top and bottom. Also ensure that the valve is completely drained through the bottom drain

port. The drainer should be disassembled periodically for inspection and cleaning of the valve seat. A Vacuum

Condensate Drainer in good working order is critical to the performance and operation of the vacuum condenser and

the vacuum system as a whole. Worn or damaged components should be replaced as soon as possible using 2VCD-20B

Repair Kit (Part # 502720-99) in order to ensure proper operation of the valve and the vacuum condenser.

SPARE PARTS

For a complete listing of factory spare parts, please refer to Doc # 2VCD-20B-RSPL Recommended Spare Parts Listing.

www.uniquesystems.com

NOTICE OF PROPRIETARY RIGHTS: This brochure, drawings and/or information shown, is the sole property of Unique Systems, Inc.

Receipt or possession thereof does not confer of transfer any right to make, copy, manufacture and/or sell this or these devices by method shown.

The information contained in this document is subject to change at any time and without prior notice.

No warranties or guarantees of any kind are made or implied by any of the content of this document.

UNIQUE SYSTEMS and its logo are registered trademarks of Unique Systems, Inc.

2009 Unique Systems, Inc.

The Unique VIP Service Advantage

Value, Integrity, Professionalism & Service

You might also like

- Elc MorowaliDocument2 pagesElc MorowaliTeddy Tyssa TarnoNo ratings yet

- 2 - Appendix A1.1 - Scope of Work Temp FacilityDocument1 page2 - Appendix A1.1 - Scope of Work Temp FacilityTeddy Tyssa TarnoNo ratings yet

- Cover and Content of ProposalDocument5 pagesCover and Content of ProposalTeddy Tyssa TarnoNo ratings yet

- Material Resource & Cycle (Dina Hartadi) - GA+5Document39 pagesMaterial Resource & Cycle (Dina Hartadi) - GA+5Teddy Tyssa TarnoNo ratings yet

- Greenship Rating & Certification - Alexander + Yenny Agvira - GA+5Document79 pagesGreenship Rating & Certification - Alexander + Yenny Agvira - GA+5Teddy Tyssa TarnoNo ratings yet

- Benefit Green Building-Nasir-GA+5Document22 pagesBenefit Green Building-Nasir-GA+5Teddy Tyssa TarnoNo ratings yet

- PemanasanGlobal (Charles Wiryawan) - GA+5Document164 pagesPemanasanGlobal (Charles Wiryawan) - GA+5Teddy Tyssa TarnoNo ratings yet

- Design Kriteri Civil WorkDocument10 pagesDesign Kriteri Civil WorkTeddy Tyssa TarnoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- WATER STILL Manesty - ManualDocument4 pagesWATER STILL Manesty - ManualPiyush A JoshiNo ratings yet

- Training Report IpgclDocument50 pagesTraining Report IpgclSahil SinghalNo ratings yet

- Operator Evaluation Programme in Spinning MillDocument43 pagesOperator Evaluation Programme in Spinning MillSENTHIL KUMAR100% (2)

- Nozzle CondDocument8 pagesNozzle CondRevki 'Exiit'No ratings yet

- Efficiency of Geothermal Power Plants - A Worldwide Review-AzDocument13 pagesEfficiency of Geothermal Power Plants - A Worldwide Review-Azbitconcepts9781No ratings yet

- Thermal Power Plant Research PaperDocument10 pagesThermal Power Plant Research PaperManish PrajapatiNo ratings yet

- Myo Docks BrochureDocument9 pagesMyo Docks BrochureJUDONo ratings yet

- Components of Coal-Fired Steam Power PlantDocument5 pagesComponents of Coal-Fired Steam Power PlantDanBenedictAcuzarNo ratings yet

- Evapco Evaporative Condenser Engineering ManualDocument32 pagesEvapco Evaporative Condenser Engineering Manualrodolfocv923590% (1)

- ANNEX - II - Instruments ListDocument7 pagesANNEX - II - Instruments Listjp mishraNo ratings yet

- Worldwide Material 5 EditionDocument2 pagesWorldwide Material 5 Editionhabtsh studioNo ratings yet

- Turbine OperationDocument30 pagesTurbine OperationGanesh Dasara100% (2)

- User Requirements For A Water For Injection SystemDocument42 pagesUser Requirements For A Water For Injection SystemJordi Sos Navarro67% (3)

- Project Report On Thermal PlantDocument58 pagesProject Report On Thermal Plantmenyu198964% (11)

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- Drum FillingDocument31 pagesDrum FillingAnupNandiNo ratings yet

- HI 1.3 For Design and Application PDFDocument96 pagesHI 1.3 For Design and Application PDFmbgs31100% (2)

- Softwares Comparison For Thermal Power PlantDocument6 pagesSoftwares Comparison For Thermal Power PlantarjmandquestNo ratings yet

- Waste Heat Boiler Part 1Document56 pagesWaste Heat Boiler Part 1mulldoctor1100% (2)

- Electrical Interview Questions Part 14Document13 pagesElectrical Interview Questions Part 14Veera RagavanNo ratings yet

- Mapúa University PDFDocument26 pagesMapúa University PDFRodolfo Rey TorresNo ratings yet

- Mechanical Punch ListDocument30 pagesMechanical Punch Listramakrishna100% (2)

- GFL 2001-4 - Water StillDocument1 pageGFL 2001-4 - Water StillwalidNo ratings yet

- Handling of Turbine During EmergencyDocument17 pagesHandling of Turbine During EmergencyManohar TatwawadiNo ratings yet

- Energy Audit - Turbine CycleDocument27 pagesEnergy Audit - Turbine CycleMadhav Pande100% (1)

- Especificaciones Rapidas P7690Document3 pagesEspecificaciones Rapidas P7690ALIB SOUNDNo ratings yet

- Guia Globap GAP ISO 22002-5Document14 pagesGuia Globap GAP ISO 22002-5Miguel Lemus100% (1)

- NTPC Training ReportDocument38 pagesNTPC Training ReportYogesh Kapil100% (3)

- Liquid Ring Vacuum PumpDocument3 pagesLiquid Ring Vacuum PumpSyed HafeezNo ratings yet

- Fuchs WI Cu GB SCRDocument4 pagesFuchs WI Cu GB SCRfurkandarNo ratings yet