Professional Documents

Culture Documents

Job Safety Analysis PDF

Job Safety Analysis PDF

Uploaded by

Srikanth BammhideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis PDF

Job Safety Analysis PDF

Uploaded by

Srikanth BammhideCopyright:

Available Formats

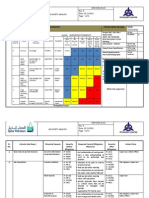

JOB SAFETY ANALYSIS TABLE OF CONTENTS

TO ALL EMPLOYEES - The purpose of the following Job Safety Analysis (JSA) Forms is to create

and maintain an awareness of the hazards that may be prevalent or occur while performing certain

tasks during drilling and how to manage them. It is, by no means, a complete and final

recommendation for any and all drilling work to be performed but is however a working document in

which changes can be made as needed. First and up most important is adherence to The National

Drilling Associations Safety Guide and Terra Testing, Inc. In-house Safety Program. The attached

JSAs complement these Safety Manuals and establishes an awareness amongst our staff.

When signing off on the signature page you are confirming that you have read and understand the

JSAs presented as well as The NDA Safety Guide.

Laurence N. Deutsch, August 19, 2004

SIGNED: LAURENCE N. DEUTSCH, MANAGER OF OPERATIONS

JSA NUMBER

TITLE

JSA NUMBER

MOBILIZATION

TITLE

TTI JSA 001

MOVING DRUMS

TTI JSA 009

DRILL RIG SET UP

TTI JSA 002

HEAT STRESS

TTI JSA 010

SAMPLING OR CORING

TTI JSA 003

HANDLING AUGERS

TTI JSA 011

AIR ROTARY

TTI JSA 004

BLANK

TTI JSA 012

INSTALL WELL MATERIALS

TTI JSA 005

HAND TOOLS

TTI JSA 006

STEAM CLEANERS /

GENERATORS

TTI JSA 007

WELDING & BURNING

TTI JSA 008

Safety First!

Nobody Gets Hurt!

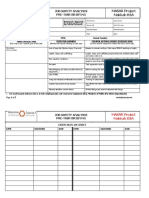

JOB SAFETY ANALYSIS

JSA #: TTI JSA 001

JOB TITLE: MOBILIZATION

EQUIPMENT REQUIRED:

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

ANALYSIS BY: Larry Deutsch-

Support Vehicle, Drill Rig, tooling,

materials, compressors, steam

cleaners, water, generators etc.

Hammerschmitt, Larry Deutsch

Manager

PERSONAL PROTECTIVE EQUIPMENT:

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Not Required

As Needed

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

Loading Support Vehicle and Drill Rig

Load shift and/or loose Materials

Travel

Road Hazards such as wet pavement,

traffic, construction, snow, speed limits

Arrival to project site

Pedestrians, Parking

Project review and sign-in.

Not knowing project conditions or

safety hazards.

JSA Page 1 of 6

Required

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

Tie down and secure all materials or

loads. Inspect load prior to leaving

shop.

Be aware of all conditions while driving.

Keep safe distances from vehicles in

front.

Park only where permitted. Keep rig

from pedestrian traffic until drill site is

setup.

Meet with client and review project

scope. Read, know and sign HASP, if

available.

JOB SAFETY ANALYSIS

JOB TITLE: DRILL RIG SETUP

EQUIPMENT REQUIRED: Rig,

JSA #: TTI JSA 002

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

ANALYSIS BY: Larry Deutsch-

Support Truck, and ancillary equipment Hammerschmitt, Larry Deutsch

PERSONAL PROTECTIVE EQUIPMENT:

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Not Required

Manager

As Needed

Required

Fire Protection

PPE above Level C

Other (list)

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

RECOMMENDED ACTION

Drill Site Set-up

Overhead Electric or underground

utilities causing shock hazard,

explosion or sudden release of

product.

Terrain, public traffic flow, pedestrians.

Lowering rig jacks (Outriggers)

Pinch Points

Verify Rig Kill Switch Operation

Unable to shut down euipment in the

event of an emergency

Raising Derrick

Overhead Electric (shock hazard),

Trees, Canopies, Weather (Lightning)

Unloading augers and tooling from rig

Pinch points, fallen objects, strains

Review private utility locations, request

Utility One Call markouts and

clearances, hand clear to 5 bgs or

other means.

Secure area with cones or tape. Post

signs if necessary. Control public from

entering drill site. Level rig, use correct

blocking, be aware of surroundings.

Keep feet and euipment clear of jacks

when lowering

Check and verify all Kill Switches for

proper operation. Replace if damaged

or unoperable.

Be aware. Check all conditions for

interference with derrick. Refer to

OSHA guidelines for safe working

distances from all electric lines.

Use the buddy system. Do not carry

anything over your lifting capacity. Be

aware of where your feet and hands

are at all times. Use proper lifting

techniques.

Utility Inspection

Think before you Act!

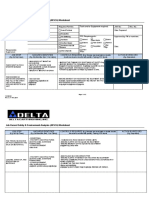

JOB SAFETY ANALYSIS

JOB TITLE: SAMPLING /

CORING

EQUIPMENT REQUIRED: Rig,

augers, Automatic SPT hammer, rods,

split spoons, and hand tools

ANALYSIS BY: Larry Deutsch-

Hammerschmitt, Larry Deutsch

Manager

PERSONAL PROTECTIVE EQUIPMENT:

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

JSA #: TTI - JSA 003

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

Not Required

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

Set H.S.A. drill string and drill to

required depth

As Needed

Required

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

Lifting, pinch points, rotating equipment Use correct lifting techniques, and

mechanical or physical assistance

when needed. Be aware of all pinch

points. Do not trap yourself between

equipment and stationary objects.

Keep hand, feet and clothing clear of

all rotating parts or equipment.

Cleaning soil cuttings from top of

Rotating Equipment, abrasions

Use a shovel at all times. Do not use

borehole

feet or hands to clear cuttings away

from drill string.

Moving equipment, Pinch Points, Worn Inspect all rods, tooling and hammer

Using Automatic SPT hammer,

for excessive wear. Replace when

sampling and hand tools, hoisting, core Tools and Equipment, Wire ropes

needed. Make sure all rod connections

barrels

are flush and tight prior to activating

hammer, When hoisting rods from

borehole, stand clear of upper load

until tension in soil has released. Do

not hang rods more than one rod

length above mast.

JSA Page 2 of 6

JOB SAFETY ANALYSIS

JOB TITLE: HEAT STRESS &

COLD

EQUIPMENT REQUIRED:

JOB SAFETY ANALYSIS

JSA #: TTI - JSA 010

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

ANALYSIS BY: Larry Deutsch-

Hammerschmitt, Larry Deutsch

PERSONAL PROTECTIVE EQUIPMENT:

Not Required

Manager

As Needed

Gloves

Safety Vest

Long Sleeved Shirts

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

POTENTIAL HAZARDS

All Jobs while working in hot

atmospheres or weather

Fatigue, Heat Stress, Heat Stroke

All Jobs while working in cold or

freezing atmospheres or weather

Freezing, Frost Bite

Required

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

Recognize the potential and always

have plenty of liquids available.

Take breaks as required. Provide

cooling and ventilation in enclosed

areas.

Recognize the potential. Wear the

proper PPE and Warm Clothing for the

job.

Take breaks as required.

JSA #: TTI - JSA 004

JOB TITLE: AIR ROTARY

EQUIPMENT REQUIRED: Air

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

ANALYSIS BY: Larry Deutsch-

Compressors, Air Hammer, API rods

and Hand Tools

Hammerschmitt, Larry Deutsch

Manager

PERSONAL PROTECTIVE EQUIPMENT:

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Not Required

As Needed

Required

Fire Protection

PPE above Level C

Other (list)

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

RECOMMENDED ACTION

Set up Air Compressor including

chocking and securing hoses.

Sudden release or whipping of hoses,

movement of equipment

Hoisting hammer and API rods

Damaged or worn wire ropes, lifting,

pinch points

Energizing air lines

Whipping of hoses

GO HOME THE WAY YOU CAME!!

When receiving air compressor make

sure wheels are chocked and the

compressor is secure. Make airline

hose connections and secure with

mechanical safety cable whips.

Inspect all wire ropes for damage or

excessive wear. Replace when

necessary. Use the buddy system. Do

not carry anything over your lifting

capacity. Be aware of where your feet

and hands are at all times. Use proper

lifting techniques.

Stand clear of air hose when

energizing them. Keep others away.

PPE!!!!

ALL the TIME!

JOB SAFETY ANALYSIS

JOB TITLE: HANDLING

JSA #: TTI - JSA 011

AUGERS

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay ANALYSIS BY: Larry DeutschEQUIPMENT REQUIRED:

Hammerschmitt, Larry Deutsch

Manager

Gloves, Safety Glasses, Hard

Hat, Steel Toed Shoes

PERSONAL PROTECTIVE EQUIPMENT:

Not Required

As Needed

Required

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Loading & Unloading at the site

While working with augers up to 4

H.S.A.s

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

Rough Terrain, Wet or Slippery

Conditions

Pinch Points, Struck by, Crushing,

Dropping

While working with augers over 4

H.S.A.s

Pinch Points, Struck by, Crushing,

Dropping

Augers in Motion (ie. drill string)

Cuts, Crushing, Sharps, Strangulation,

Fractures

JSA Page 6 of 6

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

Be aware of your surroundings. Where

Possible place augers on a level, dry

and clean area. Do not step over

augers while carrying or moving them.

Always walk around.

Place augers in a neat group side to

side without stacking to prevent

unwanted shifting of augers. Block

outside augers to prevent movement.

Wear proper safety PPE and Gloves.

Use two hands at all times.

Use the same precautions as above.

Must use two people to carry augers

or assist by crane or other

mechanical means.

NEVER touch rotating augers! Do

not wear loose fitting clothing which

can get caught on augers in motion.

Always use a shovel to remove

cuttings from borehole. KNOW

WHERE RIG KILL SWITCHES ARE

LOCATED MAKE SURE THEY ARE

OPERATIONAL BEFORE DRILLING.

JOB SAFETY ANALYSIS

JOB TITLE: INSTALL WELL

MATERIALS

LOCATION: All Sites

EQUIPMENT REQUIRED: Sand, SUPERVISOR: Drill Foreman, Jay

bentonite, cement, concrete, and procovers

Hammerschmitt, Larry Deutsch

PERSONAL PROTECTIVE EQUIPMENT:

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Installing all well materials

JSA #: TTI JSA 005

ANALYSIS BY: Larry Deutsch-

Not Required

Manager

As Needed

Gloves

Safety Vest

Long Sleeved Shirts

Required

Fire Protection

PPE above Level C

Other (list)

POTENTIAL HAZARDS

RECOMMENDED ACTION

Dust inhalation from sand, concrete or

cement. Burns from cement or

concrete

Use materials in a well ventilated area.

A dust mask may be necessary in

enclosed spaces. Uses proper gloves

when handling cement products. Refer

to MSDSs for additional information

Use proper lifting techniques or

mechanical assistance if available. Be

aware of terrain and ground conditions

while carrying materials.

Strains and falls

JSA Page 3 of 6

JOB SAFETY ANALYSIS

JOB SAFETY ANALYSIS

JSA #: TTI JSA 006

JOB TITLE: HAND TOOLS

EQUIPMENT REQUIRED: All

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

ANALYSIS BY: Larry Deutsch-

Hand Tools

Hammerschmitt, Larry Deutsch

Manager

PERSONAL PROTECTIVE EQUIPMENT:

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Using any and all Hand Tools

Not Required

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

Projectiles from Damaged or worn

tools, Slipping, Straining

As Needed

Required

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

USE THE CORRECT TOOL FOR THE

JOB!

DAMAGE TOOLS Repair or

Replace them.

When using a hammer of any kind

use safety glasses and request all

around you to wear them.

Replace pipe wrench jaws when

needed.

Refer to manufactures manual for

safe operation of any tool.

JOB TITLE: WELDING &

BURNING

EQUIPMENT REQUIRED:

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

Welders, Torches, & Gas Bottles

Hammerschmitt, Larry Deutsch

PERSONAL PROTECTIVE EQUIPMENT:

Not Required

Gloves

Safety Vest

Long Sleeved Shirts

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

POTENTIAL HAZARDS

JSA #: TTI - JSA 008

ANALYSIS BY: Larry DeutschManager

As Needed

Required

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

Trailer Mount Welders

Moving Equipment

Chock wheels to prevent from moving.

Torches and hoses

Damage Hoses Fire Hazard

Operating welder or torches

Eye and body burns and sparks

Transporting and storing Botlles

Explosion

Keep hoses in good condition replace

if necessary

Use proper Safety equipment and

shields to protect from flashes and

sparks.

DO NOT OPERATE NEAR OR

AROUND FUEL TANKS OR

FLAMMABLE PRODUCTS

Store bottles in an upright position and

secure in a stand. Keep bottled gases

secured and separate while

transporting.

STOP - IF IT SEEMS UNSAFE,

It Probably is!

BE ALERT DONT GET HURT!

JOB SAFETY ANALYSIS

JOB TITLE: STEAM

CLEANERS / GENERATORS

EQUIPMENT REQUIRED: Hot

LOCATION: All Sites

SUPERVISOR: Drill Foreman, Jay

Water/Steam Cleaners & Generators

Hammerschmitt, Larry Deutsch

PERSONAL PROTECTIVE EQUIPMENT:

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Electrical Supply

Not Required

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

Shock Hazard

GFIs

Shock Hazard

Steam Cleaner Operation

Hot Water (Scalding), Burns

JSA Page 4 of 6

JOB SAFETY ANALYSIS

JSA #: TTI - JSA 007

ANALYSIS BY: Larry DeutschManager

As Needed

Required

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

Check all extension cords and plugs for

damage. Replace if necessary. Stay

clear of ponded water areas.

Make sure GFI is operable replace if

necessay

Stay clear of burners and coils. Keep

others away also. Keep away from

nozzle end of spayer. Do not point or

clean in the direction of others.

JSA #: TTI - JSA 009

JOB TITLE: MOVING DRUMS

LOCATION: All Sites

EQUIPMENT REQUIRED: Drum SUPERVISOR: Drill Foreman, Jay ANALYSIS BY: Larry DeutschManager

Dolley or Bobcat, Support Truck Hammerschmitt, Larry Deutsch

PERSONAL PROTECTIVE EQUIPMENT:

Not Required

As Needed

Required

Hard Hat

Safety Glasses

Hearing Protection

Steel Toed Boots

BASIC JOB STEPS

Gloves

Safety Vest

Long Sleeved Shirts

POTENTIAL HAZARDS

Fire Protection

PPE above Level C

Other (list)

RECOMMENDED ACTION

Closing Drum

Pinch Points, Cuts

Always wear gloves when placing lid

and ring on open drum

Secure lid using the proper tool for the

job

Moving Drum to Staging Area

Strains, Cuts, Pinch points, Crushing

Use the proper PPE. Never move

drums without a drum dolley or a

mechanical means of assistance such

as a bobcat. Be sure to secure the

drum to the dolley or bobcat.

JSA Page 5 of 6

You might also like

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorMohammed Minhaj100% (1)

- HSE TRA-04 Steel Reinforcement and Shuttering WorksDocument6 pagesHSE TRA-04 Steel Reinforcement and Shuttering WorksQusai Khalil Abu Awad100% (2)

- JSA MasnoryDocument4 pagesJSA Masnorysubhanmusadiq100% (1)

- JSA For Working at HeightDocument1 pageJSA For Working at HeightSafety& Security Supervisor100% (1)

- Construction Job Safety Analysis - Safety Science Y2010Document10 pagesConstruction Job Safety Analysis - Safety Science Y2010Yongsak Yungyuen100% (2)

- JSA For Working at HeightDocument2 pagesJSA For Working at HeightXUE JIANNo ratings yet

- JSA HandToolsDocument2 pagesJSA HandToolsCristina Rican100% (3)

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Hot Work Activities (Cutting)Document9 pagesHot Work Activities (Cutting)Al Mughsar CompanyNo ratings yet

- Pre-Job Safety Assessment: Site InformationDocument2 pagesPre-Job Safety Assessment: Site Informationgueettaf faresNo ratings yet

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- Rigging JSA SafetyDocument5 pagesRigging JSA SafetyaQiLGunawanNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument6 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDocument5 pagesJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanNo ratings yet

- Job Hazard Analysis Site InspectionDocument12 pagesJob Hazard Analysis Site InspectionNonsoufo eze100% (1)

- JHA of Painting PDFDocument3 pagesJHA of Painting PDFTanver Ali100% (1)

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Job Safety Analysis (JSA) - Night Work DateDocument2 pagesJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- JSA Excavation PDFDocument6 pagesJSA Excavation PDFmohamedamine.zemouriNo ratings yet

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 pagesJob Hazard Analysis For Desalination of First Effect Retubingmc chesterNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanChaitanya KolluruNo ratings yet

- Example JSA Job Safety AnalysisDocument13 pagesExample JSA Job Safety AnalysisSiti MaisarahNo ratings yet

- Excavation PermitDocument2 pagesExcavation PermitRajesh Kumar SinghNo ratings yet

- Hydrothermal SolutionsDocument11 pagesHydrothermal SolutionsDedi ApriadiNo ratings yet

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- JSA 08 Gas WeldingDocument1 pageJSA 08 Gas Weldingmuthuswamy77No ratings yet

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- RSP Safety & InspectionDocument39 pagesRSP Safety & InspectionSunil Panicker100% (1)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Site Safety InspectionDocument2 pagesSite Safety InspectionDarius DsouzaNo ratings yet

- JSA. Cleaning ToiletsDocument1 pageJSA. Cleaning ToiletsSajid HussainNo ratings yet

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Handbook SurpacDocument144 pagesHandbook SurpacDedi Apriadi95% (20)

- JOB HAZARD ANALYSIS - Cable TrayDocument10 pagesJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- Retail Marketing MCQ Final.Document38 pagesRetail Marketing MCQ Final.Mujahid Ali100% (3)

- Project No. 074-10 JHA No. 1Document20 pagesProject No. 074-10 JHA No. 1Adel SukerNo ratings yet

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- Alfred Wegener - Continental Drift TheoryDocument177 pagesAlfred Wegener - Continental Drift TheoryDedi Apriadi50% (2)

- Solder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFDocument83 pagesSolder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFQUALITY LABORATORYNo ratings yet

- Job HAzard Analysis Welding Operations MiftahDocument3 pagesJob HAzard Analysis Welding Operations MiftahLukmanElekAe100% (2)

- Job Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Document20 pagesJob Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Barkat Ullah50% (2)

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- Hist C12 Indian History 3Document190 pagesHist C12 Indian History 3kane21232874No ratings yet

- Excavation and TrenchingDocument2 pagesExcavation and TrenchingvikasNo ratings yet

- APtransco PlanningcodeDocument55 pagesAPtransco PlanningcoderajfabNo ratings yet

- Underground Mine Design Surpac SoftwareDocument33 pagesUnderground Mine Design Surpac Softwaretd__1985No ratings yet

- ISO27k Gap Analysis - Executive SummaryDocument9 pagesISO27k Gap Analysis - Executive Summaryjtabeling100% (2)

- QUE$TORDocument19 pagesQUE$TORMichael JoelNo ratings yet

- Excavation (Company Name) : Phase Hazard AnalysisDocument11 pagesExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNo ratings yet

- 2020 Loss Control For TradersDocument8 pages2020 Loss Control For TraderskoushkiNo ratings yet

- 0025 Concerte Poring With Concrete PumpDocument5 pages0025 Concerte Poring With Concrete PumpNibhaNo ratings yet

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- JSA-009a Drilling and Mon Well Construction-SonicDocument4 pagesJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi86% (7)

- Instructional LeadershipDocument17 pagesInstructional LeadershipBeat Emilia33% (3)

- Indonesian HistoryDocument289 pagesIndonesian Historyejohikaru100% (5)

- Electric Start HandbookDocument179 pagesElectric Start HandbookGeronimo JaimeNo ratings yet

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocument5 pagesJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNo ratings yet

- Operating The Man LiftDocument1 pageOperating The Man LiftEllecer anthony Permejo67% (3)

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- Job Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXDocument2 pagesJob Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXJb TiscubNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Anonymous voA5Tb0No ratings yet

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanNo ratings yet

- Water Proofing JHA SummaryDocument1 pageWater Proofing JHA Summarysujith s pNo ratings yet

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- 13.sedimentary BasinsDocument22 pages13.sedimentary BasinsE_Rodriguez20No ratings yet

- Deskripsi Sample GeologiDocument35 pagesDeskripsi Sample GeologiDedi ApriadiNo ratings yet

- Turbidite MuttiDocument47 pagesTurbidite MuttiDedi ApriadiNo ratings yet

- GoethiteDocument1 pageGoethiteDedi ApriadiNo ratings yet

- 8 The Bauxites DiscoveredDocument10 pages8 The Bauxites DiscoveredDedi ApriadiNo ratings yet

- Asera Report 62Document23 pagesAsera Report 62Dedi ApriadiNo ratings yet

- Sentinel Event Notification and Management Policy Final20227484Document19 pagesSentinel Event Notification and Management Policy Final20227484ahamedsahibNo ratings yet

- Company Profile Sample KenyaDocument3 pagesCompany Profile Sample Kenyafrida iluveNo ratings yet

- Preface: Licensing AgreementDocument58 pagesPreface: Licensing AgreementNarcis Patrascu100% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Agus WijayadiNo ratings yet

- Anrlte782Document65 pagesAnrlte782Carlos CelisNo ratings yet

- Mathematics: Profit, Loss, Discount and AverageDocument9 pagesMathematics: Profit, Loss, Discount and AverageVishal JainNo ratings yet

- Auto3D Kit User's Manual - ENGDocument17 pagesAuto3D Kit User's Manual - ENGAnand GovindarajNo ratings yet

- ContourDocument15 pagesContourkaran ahariNo ratings yet

- SAFI SS1 L3 4 Analysis of Tension Members Yielding Rupture Shear Lag 16 and 23-11-2020Document137 pagesSAFI SS1 L3 4 Analysis of Tension Members Yielding Rupture Shear Lag 16 and 23-11-2020esamalnhari77No ratings yet

- Ro1 - Do18 A 2016Document10 pagesRo1 - Do18 A 2016robinrubinaNo ratings yet

- Annex VI - Final Narrative ReportDocument4 pagesAnnex VI - Final Narrative ReporttijanagruNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum Vitaebriton11No ratings yet

- How To Create AStripe AccountDocument5 pagesHow To Create AStripe AccountJarrod GlandtNo ratings yet

- Wastequip Manufacturing Company v. Precision Sewing, Inc.,dba Precision Tarp Et. Al.Document6 pagesWastequip Manufacturing Company v. Precision Sewing, Inc.,dba Precision Tarp Et. Al.PriorSmartNo ratings yet

- Mining Act of 1994Document4 pagesMining Act of 1994Edwin Darvy ValdezNo ratings yet

- CE 111 Finals AnswerDocument20 pagesCE 111 Finals AnswerJulie BajadoNo ratings yet

- 3M India Limited - Annual Report 2015-16Document144 pages3M India Limited - Annual Report 2015-16Ishpreet singhNo ratings yet

- Ffmpeg Codecs ListDocument10 pagesFfmpeg Codecs ListSharbate AzamNo ratings yet

- Deed of DonationDocument2 pagesDeed of DonationDax MonteclarNo ratings yet

- Samsung VP 70Document106 pagesSamsung VP 70nch2No ratings yet