Professional Documents

Culture Documents

2720 (Part-IXL) PDF

2720 (Part-IXL) PDF

Uploaded by

Soundar PachiappanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2720 (Part-IXL) PDF

2720 (Part-IXL) PDF

Uploaded by

Soundar PachiappanCopyright:

Available Formats

IS : 2720 ( Part XL1 \- 1977

( Reaffirmed 1987 )

Indian Standard

( Reaffirmed 1997 )

METHODS OF TEST FOR SOILS

PART XLI

MEASUREMENT

OF SWELLING

PRESSURE OF SOILS

(Third

Reprint

hlARCH 1994)

UDC 624,131..414.3

@ Copyright1978

BUREAU

i)F

INDIAN

STANDARDS

MANAK UHAVAN, 9 RAHADUR SHAH ZAFAR MARG

NEW DELHI

--._.

110002

IS : 2720 ( Part XL1 ) - 1977

Indian Standard

METHODS

PART XLI

OF TEST FOR SOILS

MEASUREMENT

OF SWELLING

PRESSURE OF SOILS

Soil Engineering

Sectional

Committee,

BDC 23

Representing

Chairman

Cent;raorkBct$lding

PR~F DINESH MOHAN

Research

Institute

( CSIR ),

Members

Works

Department,

Public

Government

Uttar Pradesh

Snnr D. C. CHATURVEDI ( Altematc )

ADDITIONAL DIRECTOR RESEAI~CR Railway Board ( Ministry of Railways )

( RDSO )

ADDITIONALClfrEr ENGINEER

of

DEPUTY DIRECTOR RESEARcIf

( RDSO ) ( Alternate )

University of Jodhpur, Jodhpur

PROF ALAS SlXoit

Engineer-in-Chiefs

Branch, Army Headquarters

LT-COL AVTAU SINQII

MAJ V.K.

RANITKAR(

Alternate)

Cementation Co Ltd, Calcutta

DE A. BANERJKT.:

SRRI S. GUPTA ( Altrmate )

Irrigation Department, Government of Punjab

CHIEF ENGINEER ( D & R )

DIRECTOR

IPRI

) ( Alternote )

personal capacity

( P-820,

P .New A&ore,

Calcutta 700053 )

In personal capacity

( 5, Hungnford

Street, 12/l

SHRI A. G. DASTIDAR

Hungerford Court, Calcutta 700017 )

Irrigation Research Institute, Khagaul, Patna

SHRI l7. L. DEWAN

Indian Geotechnical Society, New Delhi

DH G. S. DHILLON

Asia Foundations & Construction ( g) Ltd, Bombay

SHRI A. H. DIVANJI

SIIRI A. N. JANQLE ( Alternate )

Indian Institute of Technology, New Delhi

DR SHASHI K. GKLHATI

DIG G. V. RIO ( Alternate)

National Buildings Organization, New Delhi

SBRI v. G. l-I1201,15

Snnr S. H. BALCHANDANI( Alternhte )

Public Works Department, Government of Punjab

SHRI 0. P. MALHOTRA

Roads Wing ( Ministry of Shippibg & Transport ),

SIIKI J. S. MAI~YA

New Delhi

SHRI N. SEN ( Alternate )

Central Water Commission, New Delhi

SHRI R.S. h~ELPO;TE

D~F+CTYDIHECTO~ ( CSMRS ) ( Al&mutt )

SHRI K. N. DADINA

In

( Continued on pugs 2 )

BUREAU

@ Copyright 1978

OF

INDIAN

STANDARDS

This publication is protected under the IndiM CopFig@ Act_{ XIV of. 1957 ) and

reproduction in whole or in part by any mean) utcept wrth wrttten permtsston of the

publisher shall be deemed to be an infringement of copyrlght under the said Act.

IS : 2720 ( Part XL1 ) - 1977

( Confinuedfrom

page 1 )

Members

Representing

SRRI T. K. NATARAJAN

Central

Road

Research

Institute

( CSIR ),

New Delhi

REPRESENTATIVE

Hindustan Construction Co Ltd, Bombay

RES~ARCII OFFICER

Building & Roads Research Laboratory, Chandigarh

SIIRI K. R. %XENA

Engineering Research Laboratories, Hyderahad

SEcRETAlly

Central Board of Irrigation & Power, New Delhi

DICPC.TY

SECRETARY (rlllernnte)

*DR S~rn~~sr~El~

PIL4IcAsM

University of Roorkcc, Roorkee

DR GOPAL RANJAN (&fern&)

SHRIILD.

SHARMA

Irrigation Research Institute, Roorkee

SUPERINTENDINGENGINEER

Public

Works

Department,

Government

of

Tamil Nadu

EXECUTIVE ENGINEER ( Alternate )

Concrete Association of India, Bombay

SHRI U. T. UNWALLA

SHIU T. M. MENON ( Alternafc )

SRILI H. C. VEK.\ZA

All India Instruments Manufacturers

& Dealers

Association, Bombay

SHRI V. K. VASUDEVAN ( Alternate )

&RI I>. AJ~THA SIMHA,

Director General, IS1 ( Ex-o&cio Member )

Dirrctor ( Civ Engg )

.4

0.1

Sta

the

Cit

Secretary

Deputy

Soi1

Testing

Procedures

SHRI G. RAMAN

Director ( Civ Engg ), IS1

8.~ Equipment

Subcommittee,

BDC 23 : 3

Convener

PWF

ALAM SINQH

University of Jodhpur,

Jodhpur

stu

thi

PU

so

tes

SW

Members

Central

Building

Research

Institute

( CSIR ),

Roorkee

LT-COL AVTAR SINGH

Engineer-in-Chiefs

Branch, Army Headquarters

MA,J V. K. KANITXAR

( Alfernnte)

Irrigation Research Institute, Khagaul, Patna

SAXI R. L. DEWAN

DEPUTY DIRECTOR RESEARCH Railway Board ( Ministry of Railways )

( SOIL MECHANICS-I ) ( RDSO )

DIRECTOR

ASSISTANT

RESEARCH

( SOIL MECHANICS I ) ( RDSO ) ( Alternate )

Beas Project, Talwara Township

DIRECTOR ( I & (2 )

SHRI K. S. PRE~I ( Alternate)

Geologists Syndicate Pvt Ltd, Calcutta

SERI H. K. GUHA

SRR1 N. N. BHATTAC~ARAYA ( Alternate )

Indian Institute of Technology, New Delhi

SHRISKASHI K.GULRATI

United Technical Consultants ( P) Ltd, New Delhi

SHRI R. K. JAIN

DR P. K. DE ( Alternnte )

SHRI AMAR

0.2

OfI

SINGX~

( Continrrcdon page 15 )

*Also represents Institution of Engineers ( India ),

exi

Wf

the

z:

Pr

da

0. .

(a:

mi

PO

Pr

SU

ch

O.!

ins

in

fie

IS : 2720 ( Part

XL1 ) - 1977

Indian Standard

METHODS OF TEST FOR SOILS

PART XLI

MEASUREMENT

OF SWELLING

PRESSURE OF SOILS

0.

FOREWORD

0.1 This Indian

Standard

( Part XL1 ) was adopted

by the Indian

Standards

Institution

on 30 December

1977, after the draft finalized

by

the Soil Engineering.Sectional

Committee

had been approved

by the

Civil Engineering

Division Council.

0.2 With a view to establish

uniform

procedures

for the determination

of different characteiistics

of soils and also for facilitating

comparative

studies of the results, the Indian

Standards

Institution

has brought

out

this Indian

Standard

methods

of test for soils ( IS : 2720 ) which is

Fortvone parts of this standard

have been published

published

in parts.

so far.

This part IS : 2720 ( Part XLI ) deals with the method

of

test for determination

of swelling pressure of soils. The main purpose of

swelling pressure test is to determine

the intrinsic

swelling pressure of the

expansive

soil tested.

The expansive

clays increase in their volume

when they come in contact

with water owing to surface properties

of

these clay types.

Light structures

founded on these type of clays popularly

known in India as black cotton soil, experience severe structural

damage due to the swelling

of the subsoil.

Since the intrinsic

swelling

pressure is to be associated

with the design of structures

against such

damages, measurement

of swelling pressure assumes importance.

0.3 The

swelling

pressure is dependent

upon several

factors namely

(a) the type and amount of clay in the soil and the nature of the clay

mineral,

(b) the initial water content and dry density, (c) the nature of

pore fluid, (d) the stress history of the soil including

the confining

pressure and (e) drying and wetting

cycles to which the soils have been

subjected

to. Besides, the dependence

of swelling pressure on volume

change makes a precise measurement

of swelling pressure difficult.

0.4 In the formulation

of this standard

due weightage has been given to

international

co-ordination

among the standards

and practices prevailing

in different

countries

in addition

to relating

it to the practices

in the

field in this country.

3

IS : 2720 ( Part XL1 ) - 1977

0.5 In reporting

the result of a test or analysis made in accordance

with

this standard,

if the final value, observed or calculated,

is to be rounded

off, it shall be done in accordance

with IS : 2-1960*.

1. SCOPE

1.1 This standard

covers the laboratory

method

of conducting

onedimensional

swelling pressure test using either fixed or the floating rings

on both undisturbed

or remoulded

soils in the partially

saturated

condition

to determine

thbLswelling

pressure of the soil. Two methods,

namely, consolidometer

method in which the volume change of the soil

is permitted

and the corresponding

pressure required

to bring back the

soil to its original volume is measured and the constant

volume method

in which the volume change is prevented

and the con/sequent pressure is

measured are covered.

2. TERMINOLOGY

2.0 For the pupose of this standard,

the following

definition

2.1 Swelling Pressure - The pressure which the expansive

if the soil is not allowed to swell or the volume change

is arrested.

shall apply.

soil exerts,

of the soil

a

C

S

tl

b

n

Pa

SECTION

3. APPARATUS

CONSOLIDOMETER

METHOD

AND EQUIPMENT

3.1 Coqsolidometer - A device to hold the sample in a ring either

fixed or floating with porous stones ( or ceramic discs ) on each face of

the sample. A consolidometer

shall also provide means for submerging

the sample, for applying

a vertical

load and for measuring

the change

in the thickness of the specimen..

The provision

for fixing of the dial

gauge shall be rigid; in no case shall the dial gauge be fixed to a

cantilevered

arm. Suitable

provision

shall be made to enable the dial

gauge to be fixed in such a way that the dial gauge records accurately

the

vertical expansion of the specimen.

3.1.1 Specimen Dicimctw -The

specimen shall be 60 mm in diameter

( specimens of diameters

50, 70 and 100 mm may also be used in special

case ).

*Rules

for

rounding off numerical values ( w&d

4

).

3

2

3

3s

ir

P

3

tr.

ri*

3.

cc

3.

IS : 2720 ( Part XL1 ) - 1977

3.1.2 Specimen Thickness - The specimen shall be at least 20 mm thick

in all cases. However, the thickness shall not be less than 10 times the

maximum diameter of the grain in the soil specimen. The diameter to

thickness ratio shall be a minimum of 3.

which is non3 1.3 Ring - The ring shall be made of a material

corrosive in relation to tht? soil tested. The inner surface shall be highly

polished or coated with a thin coating of silicon grease or with a lowfriction material.

The thickness of the ring shall be such that under

assumed hydrostatic

stress conditions

in the sample the change

in

diameter of the ring will not exceed 003 percent under the maximum

load applied during the test. The ring shall have one edge bevelled

suitably so that the sample is pressed into the ring with least disturbance.

The ring shall be placed with its cutting edge upwards in the consolidometer and clamped

with a special clamp which should in no way

damage the sharp edge. The clamp should be made circular with

central hole equal in diameter

of the porous stone and should be

perfectly concentric with the sample. The ring shall be provided with

a collar of internal diameter same as that of the ring and of effective

height 20 mm. The collar shall rest securely on the specimen ring.

carbide

or

3.1.4 Porous Stones - The stones shall be of silicon

aluminium

oxide and of medium grade. It shall have a high permeability

compared to that of the soil being tested. The diameter of the top stone

shall be 0.2 to 0.5 mm less than the internal diameter of the ring. The

thickness of the stone shall be a minium of 15 mm. The top stone shall

be loaded through a corrosion-resistant

plate of sufficient rigidity and of

minimum thickness 10 mm to prevent breakage of the stone. The loading

plate &all have suitable holes for free drainage of water.

3.2 Dial Gauge 20 mm.

3.3 Water

accurate

Reservoir

to 001 mm

with

a traverse

of at

least

To keep the soil sample submerged.

3.4 Moisture Room - For storing samples and for preparing samples

in climates where there is. likelihood

of excessive moisture loss during

preparation ( optional ).

knife, spatula, etc for

3.5 Soil Trimming

Tools - Fine wire-saw,

trimming sample to fit into the inside diameter of the consolidometer

ring with minimum disturbances.

3.6 Oven

corroding

- thermostatically

material to maintain

3.7 Desiccator -

controlled

oven with interior of nonthe temperature between 105 and 110C.

With any desiccating

5

agent other than sulphuric

acid.

IS : 2720 ( Part XL1 ) - 1977

3.8 Balance

3.9 Containers

4. PREPARATION

sensitive

-

to 0.01 g.

for water

content

determination.

OF TEST SPECIMEN

4.1 Preparation

of Specimen from Undisturbed Soil Samples The container

ring shall be cleaned and weighed empty. From one end of

the undisturbed

soil sample about 30 mm, or more if desired, of the soil

sample, if desired shall be cut off and rejected.

The specimen shall be cut

off either from the undisturbed

tube sample or from block sample the latter

generally

being more representative

of the field conditions.

In either

case the consolidation

ring should be gradually

inserted

in the sample

by pressing with hands and carefully removing

the material

around

the

ring. The soil specimen so cut shall project as far as 10 mm on either

side of the ring. The specimen shall then be trimmed

smooth and flush

with the top and bottom of the ring. Any voids in the specimen caused

due to removal of gravel or limestone

pieces, shall be filled back by

pressing lightly the loose soil in the voids, care being taken to see that

the specimen

is not affected. The container

ring shall be wiped clear

of any soil sticking

to the outside and weighed

again with the soil.

The whole process should be quick to ensure minimum

loss of moisture

and if possible

shall be carried

cut in the moisture

room.

Three

representative

specimens

from the soil trimming

shall be taken in

moisture

content

cans and their

moisture

content

determined

in

acc:ordance with IS : 2720 ( Part XI )-1973*.

S

*

1

S

S

;:

t

t

i

I

I

(

(

4.2 Preparation

of Specimen from Disturbed

Soil Sample? - In

case where

it is necessary td use disturbed

soil samples the soil sample

shall b& compacted

to the desired (field ) density and water content

it1 a

standard

compaction

proctor

mould.

Samples of suitable

sizes are cut

from it as given in 4.11.

NI)TE 1 - Since thr >wcllinq pr(~ssure of tllr: so11 is very much influtnccd

by its

initial

water

content

and dr).density

it shall be ensured

that in the case of

undisturbed

soil samp!es, the sprcmx-n

shall be coil&ted

from the field for trst dttriog

the driest season of the yrar, ,namely,

April, May and June,

so that the swelling

pressure wcordrd

shall iw rnaxlmtrm.

ho the case of remoulded

shrinkage

limit or field water

maximum.

soil samples,

content.

SO

the initial water content

shall be at the

that the swelling pressure

recorded

shall be

of test for soils: Part

1

S

~o,r~;: 2 - The desiccated

soil ohtained

from the field rouplcd

with smaller

thickn~ss of consr~lidation

ring make the undisturbed

soil specimen

always

in danger

of

bt-ing disturbed

durinfi

trimming:

hence great care shall be taken to handle

the

specbmen delicately

with the least pressure applied to the soil.

*Methods

11 Determination

of water

content

( second rcuision ).

1

I

s

IS:2720 ( Part XL1 ) - 1977

5. PROCEDURE

5.1 Assembly

5.1.1 The porous stones shall be saturated.

All surfaces

of the

consolidometer

which are to be enclosed shall be moistened.

The porous

stones shall be saturated

by boiling

in distilled

water for at least

15 minutes.

The consolidometer

shall be assembled

with the soil

specimen

(in the ring)

and porous stones at top and bottom

of the

specimen,

providing

a filter paper rendered

wet ( Whatman

No. 1 or

equivalent)

between

the soil specimen

and the porous stone.

The

loading block shall then be positioned centrally on the top porous stone.

5.1.2 This assembly shall then be mounted on the loading frame such

that, the.load

when applied is transmitted

to the soil specimen through

the loading cap. The assembly shall be so centred that the load applied

is axial.

5.1.3 In the case of the lever loading system, the apparatus

shall be

properly counterbalanced.

If a jack with load measurements

by platform

scales is used as the loading

systems the tare weight with the empty

consolidation

apparatus,

excluding

those parts which will be on top of

the soil specimen,

which rest on the platfortn shall be determined

before

filling the ring with the soil and this tare weight shall be added to the

computed scale loads required to give the desired pressures at the time

of loading the soil specimen.

5.1.4 The

heave of the

adjusted

in

release run,

holder with the dial gauge to record the progressive vertical

specimen under no load, shall then be screwed in place and

such a way that the dial gauge is near the end of its

allowing small margin for the compression

of the soil, if any.

5.1.5 An initial setting load of 50 gf/cms ( this includes the weight of

the porous stone and the loading pad ) shall be placed on the loading

hanger and the initial reading of the dial gauge shall be noted.

5.1.6 The system shall be connected

to a water reservoir

with the

level of water in the reservoir being at about the same level as the soil

specimen and water allowed to flow in the sample.

The soil shall then

be allowed to swell.

5.2

Procedure

5.2.1 The free swell readings

shown by the dial gauge under the

at different

seating load of 5 kN/ms ( 0.05 kgf/ cm% ) shall be recorded

time intervals.

For the purpose of record form 1 given in Appendix

A

shall be used and the total readings noted at total elapsed time since

starting shown therein.

7

IS I 2720 ( Part XL1 ) - 1977

5.2.2 The dial gauge readings shall be taken till equilibrium is reached.

This is ensured by making a plot of swelling dial reading UCMUS

time in

hours, which plot becomes asymptotic with abscissa ( time scale ). The

equilibrium swelling is normally reached over a period of 6 to 7 days in

general for all expansive soils.

5.2.3 The swollen sample shall then be subjected to consolidation

under different pressures as given in form 2 irl Appendix

A.

The

compression dial readings shall be recorded till the dial readings attain

a steady state for each load applied over the specimen. The consolidation

loads shall be applied till the specimen attains its original volume.

6. CALCULATIONS

AND REPORT

&I The observations shall be recorded suitably. Two forms recommended

for recording

are given in Appendix A.

6.2 Calculations - The observed swelling dial reading recorded in

form 1 of Appendix A sh@l be plotted with elapsed time as abscissa and

shelling dial reading as .ordinates on natural scale. A smooth c!lrve

shall be drawn joining these points. If the curve so drawn becomes

asymptotic with the abscissa, the swelling has reached its maximum and

hence the swelling phase shall be stopped, and the consolidation phase

shall be started. The compression readings shall be tabulated as in form 2

of Appendix A and a plot of change in thickness of expanded specimen

as ordinates and consolidation

pressure applied as abscissa in semilogarithmic scale shall be made. The swelling pressure exerted by the

soil specimen under zero swelling condition shall be obtained by interpolation and expressed in kN/ms (kgf/cms).

SECTION

7. APPARATUS

AND

CONSTANT

7.3 Moisture

accurate

consolidometer

to 0.002

mm

shall

conform

with a traverse

to

the

of at least

Room

7.4 Soil Trimming

7.5 Balance -

METHOD

EQUIPMENT

7.1 Consolidometer - The

requirements given in 3.1.

7.2 Dial Gauge 10 mm.

VOLUME

Tools -shall

be in conformity

with 3.5.

sensitive to 0.01 g.

controlled

oven with interior

if non7.6 Oven - thermostatically

corroding material to maintain temperature between 105 to 110C.

8

IS : 2720 ( Part XL1 ) - 1977

-

7.7 Desiccator

7.8 Moisture

7.9 Loading

CVith any desiccating

Content

agent

other than suiphuric

acid.

Cans

Unit of 5 000 kg Capacity

7.10 High Sensitive

Proving

8. PREPARATION

OF SOIL

Strain

controlled

type.

Ring of 200 kg Capacity

SPECIMEN

8.1 Preparation

of Specimen

as specified in 4.1.

from

Undisturbed

8.2 Preparation

specified in 4.2.

from

Disturbed

of Specimen

Soil Samples

Soil Samples

as

9. PROCEDURE

9.1 Assembly

9.1.1 The consolidation

specimen ring with the specimen shall be kept

in between

two porous stones saturated

in boiling water providing

;L

filter paper ( Whatman

No. 1 or equivalent

) between the soil specimel\

and the porous stone.

The loading

block shall then bc positiorlr*(l

centrally

on the top of the porous stone.

9.1.2 This assembly shall then be placed on the platen of the loading

unit as shown in Fig. 1. The load measuring

proving ring tip attached

to the load frame shall be placed in contact

with the consolidation

cell

without any eccentricity.

A direct strain measuring

dial gauge shall be

fitted to the cell. The specimen shall be inundated

with distilled water

and allowed to swell.

8.2 Detailed Procedure

for the Test - The initial

reading of the

proving ring shall be noted. The swelling of the specimen with increasing

volume shall be obtained

in the strain measuring

load gauge. To keep

the specimen at constant volume, the platen shall be so adjusted that the

dial gauge always show the original

reading.

This adjustment

shall be

done at every 01 mm of swell or earlier. The duration

of test shall

conform to the requirements

given in 5.2.2. The assembly shall then be

dismantled

and the soil specimen extracted

from the consolidation

ring

to determine

final

moisture

content

in accordance

with IS : 2720

( Part IX )-1973*.

10.CALCULATIONS

10.1 The observations

Appendix

B.

AND REPORT

shall

be recorded

*Determination of water content ( second reuision).

9

suitably

in the form

given

in

IS : 2720 ( Part XLL ) - 1977

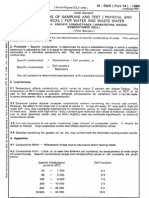

,/-GUlDE

ROD

REACTION

PROVING

PISTON

BEAM

RING

DIRECT

STRAIN

MEASURING

DIAL GAUGE

ROD

BRASS CAP

{PERFORATELY

~CONSOLIOOMEtER

CELL

MAGNETIC

SOlL

BASE

SAMPLE

ANVIL

NOTE

--

minimises

The above is only an illustrative

volume changes may be preferred.

FIG. 1

set up.

Any suitable

apparatus

which

SET-UP FOR MEASURINGSWELLINGPRESSUREIN THE

CONSTANTVOLUME METHOD

10.2 Calculations - The difference between the final and initial dial

readings of the proving ring gives total load in terms of division which

when multiplied by the calibration factor gives the total load. This when

divided by the cross-sectional area of the soil specimen gives the swell

pressure expressed in kN/m2 ( kgf/cm2 ).

Final dial reading Swelling pressure in

Initial dial reading

kN/m2 ( kgf/cm2 ) = Area of the specimen

10

x Calibration factor

of proving

ring

IS : 2720 ( Part XLI ) - 1977

APPENDIX

A

( Clauses 5.2.1, 5.2.3, 6.1 and 6.2 )

SWELLING PRESSUREMy;;$;

FORM

CONSOLIDOMETER

Dated:

Project:

Tested

1.

Details

by:

of soils sample

i) Location

ii) Boring

iii)

No.

Depth

iv) \isual

description

v) Liquid

Plasticity

vi)

2.

of soil

limit

index

Percentage

of soil fraction

below 0002 mm

Details

of soil specimen

i) Undisturbed

ii) Specific

or remoulded

gravity

of the soil

-_

NATURAL%KSITY

Test

Description

Weight ofcontainerring + wet specimen

Weight

of container

Diameter

tainer

of

lest II

CONTENT

Description

____

Weight of container

+ wet soil

--

1 Before1 After

II-/_

Test 1 Test /

I

/

I

LVright of containor -\- dry soil

\Vcight of container

of

Weight

in g/ml

Weight

Initial thickness

soil sample

Wet density

con-

__-I

MOISTURE

of water

of dry soil

IS I 2720 ( Part XL1 ) - 1977

Dry density

in g/ml

Moisture

percent

Date

Time

of starting

Elapsed time

in hours

Swelling

leading

dial

05

1

2

4

8

12

16

20

24

36

48

60

72

96

120

144

12

content

in

IS : 2720 ( Part XL1 ) - 1977

FORM

DATA SHEET FOR SWELL - COMPRESSION

Pressure

in kgf/cm*

~______.

( O*O-O~05)

Increment

Compression

in kN/mP

TEST

Change in Thickless of Expanded

Specimen

O-5

( o-05-0* 10 )

(O-10-0*25 )

( O-25-0-50.)

5-10

10-25

25-50

50-100

( o-50- 1*oo )

( 1.oo-2.00 )

100-200

200-400

( 2*00-4.00 )

( 4*00-8.00 )

400-800

800-l 600

( 8~00-16~00)

APPENDIX

B

( Clause 10.1 )

SWELL PRESSURE TEST BY CONSTANT

Project:

VOLUME METHOD

Dated:

Tested

1.

Details of soil samples

9 Location

ii) Boring No.

iii) Depth

of soil

iv) Visual description

Liquid

limit

v)

Plasticity index

vi) Percentage of soil fraction

below 0.002 mm

by:

18 I 2720 ( Part XL1 ) - 1977

2.

Details

of the soil specimen

i) Undisturbed

of remoulded

ii) Specific gravity

NATURAL

of the soil

DENSITY

MOISTURE

CONTENT

Test I

Description

Test II

I

----\

Before

Description

Test

__._-

1 After

Test

Weight of container

+ wet soil

Weight of container ring

+ wet specimen

Weight of con.

tainer

Diameter

of

container

Initial thickness of

sample

Wet density

in g/ml

Weight of container

+ dry soil

Weight

of container

Weight

of water

Weight

of

dry

Moisture content

percent

soil

in

Dry density

in g/ml

SWELL

Date

Strain

Dial

Gauge

Reading

Before

Adjustment

Time

--

Pro+ing

Ring

Reading

PRESSURE

DATA

Differences

Load

?g

in kg/

cm

1

--_

--

-.

-14

IS : 2720 ( Part XL1 ) - 1917

( Continuedfrom pIIge 2 )

Replcsrnting

Members

SRI&I 0.

Building & Roads Research Laboratory, Chandigarh

P. MALEOTRA

RESEAIWR OFFICER ( BLDG &

ROADS ) ( Alternate )

Central Water Commission, New Delhi

SHRI R. S. MELKOTE

DEPUTY DIRECTOZ ( CSMRS

) deib$e

)

Road

Research

Institute

SHRI P. JAQANNATBA RAO

SRRI N. SEN

SHRI P. K. THOMAS ( Albnaie

SHRI M. M. D. SETH

DR B. L. DHAWAN

SHRI V. V. S. RAO

( ANemare )

SHRI H. C. VERMA

Panel

for

Part

( CSIR ),

New Delhi

Ministry of Shipping & Transport ( Roads Wing ),

New Delhi

)

Public

Works

Department,

Government

of

Uttar Pradesh

In personal capacity ( F-24, Green Park, New Delhi)

Associated

Instruments

Manufacturers

(I ) Pvt Ltd,

New Delhi

the Preparation

of Draft on Methods

of Test for Soils:

XL1 Measurement

of Swelling Pressure of Soils,

BDC23:3:Pl

DR V. DAKSHNAIUURTKY

Indian Institute of Technology,

15

Madras

BUREAU

OF

INDIAN

STANDARDS

Headquarters:

Manak Bhavan,

Telephones:

9 Bahadur Shah Zafar Marg,

331

01 31,

331

NEW DELHI

Telegrams:

( Common

13 75

110002

Manaksanstha

to all Offices)

Telephone

Regional Offices:

: Manak Bhavan, 9 Bahadur Shah Zafar Marg.

Central

331 01 31

331 13 75

I

36 24 99

NEW DELHI 110002

: 1 /14 C. I. T. Scheme VII M, V. I. P. Road,

Maniktola, CALCUTTA

700054

Northern

: SC0 445-446,

Sector 35-C,

CHANDIGARH

160036

*Eastern

Southern

: C. I. T. Campus,

tWestern

: Manakalaya,

BOMBAY

MADRAS

E9 MIDC,

400093

600113

Marol,

Andheri

21843

3 16 41

41 24 42

41 25 19

c 41 2916

( East ), 632 92 95

I

Branch Offices:

Pushpak, Nurmohamed

Shaikh Marg, Khanpur,

AHMADABAD

380001

+,Peenya Industrial Area

BANGALORE 560058

1st Stage, Bangalore

2 63 48

Tumkur Road

Gangotri Complex, 5th Floor, Bhadbhada Road, T. T. Nagar,

BHCPAL 462003

Plot No. 82;83. Lewis Road, BHUBANESHWAR

751002

5315. Ward No. 29, R.G. Barua Road, 5th Byelane,

GUWAHATI

781003

5-8-566

L. N. Gupta Marg ! Nampallv Station Road ),

HYDERABAD

500001

R14 Yudhister

117/418

Marg. C Scheme,

B Sarvodaya

JAIPUR

Nagar, KANPUR

I 2 63

(38 49

138 49

667

5 36 27

3 31 77

23 1083

63471

6 98

21 68

{ 21 82

6 23

/6 21

16 21

302005

208005

Patliputra Industrial Estate, PATNA 800013

T.C. No. 14/l 421. Universitv P.O.. Palayam

TRIVANDRUM

695035

49

55

56

16

32

76

92

05

04

17

inspection Offices ( With Sale Point ):

Pushpanjali, First Floor, 205-A West High Court Road,

2 51 71

Shankar Nagar Square, NAGPUR 440010

Institution of Engineers ( India ) Building, 1332 Shivaji Nagar,

5 24 35

PUNE 411005

-*Sales CFse in Calcutta is a? 5 Chowringhse Approach, P. 0. Princep 27 68 00

Street. Calcut[r 700072

tSales Office in Bombay is at Novelty Chambers, Grant Road,

Bombay 400n07

ZSales Otflcein Bangslorz is at Unity Building, Naresimharaja Squa!e,

Bangaloru 560002

keprography

Unit,

MS,

New

Delhi

89 65 28

22 36 71

) Indl;l

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Laboratory 1 - Identification of Minerals and RocksDocument25 pagesLaboratory 1 - Identification of Minerals and RocksMohammad Nurhassanal Jinal86% (7)

- Opencast Mining MethodDocument7 pagesOpencast Mining MethodjaypadoleNo ratings yet

- Concrete Centre SamplingDocument1 pageConcrete Centre SamplingEmir MuslićNo ratings yet

- Is 1077 - 1992 Common Burnt Clay Buil. Bricks Spec.Document6 pagesIs 1077 - 1992 Common Burnt Clay Buil. Bricks Spec.rambinodNo ratings yet

- 811Document31 pages811rambinodNo ratings yet

- SP16-Design Aid For RC To IS456-1978Document252 pagesSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- 460 (Part-1)Document15 pages460 (Part-1)rambinod67% (3)

- 460 (Part-2)Document16 pages460 (Part-2)rambinod0% (1)

- 460 (Part-3)Document10 pages460 (Part-3)rambinod100% (1)

- Is 455Document10 pagesIs 455Ravi ChandranNo ratings yet

- IS 3370 Part 3Document15 pagesIS 3370 Part 3SourabhAdikeNo ratings yet

- Hume Pipe Is 458-2003Document33 pagesHume Pipe Is 458-2003Bishwanath Sanfui100% (4)

- 3025 44Document6 pages3025 44rambinodNo ratings yet

- 3025 51Document8 pages3025 51rambinodNo ratings yet

- 3025 20Document1 page3025 20rambinodNo ratings yet

- Mlvss & Mlss Is-3025 - 18Document2 pagesMlvss & Mlss Is-3025 - 18Anuraj20No ratings yet

- UDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IDocument4 pagesUDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IrambinodNo ratings yet

- 3025 16Document2 pages3025 16rambinodNo ratings yet

- Sub Grade PrepDocument3 pagesSub Grade Prepgrace evaristoNo ratings yet

- Retaining Wall CalculationDocument1 pageRetaining Wall CalculationNurmuliana Abdul WahabNo ratings yet

- The KCL - Polymer Mud - More Than Words!Document16 pagesThe KCL - Polymer Mud - More Than Words!Upender DhullNo ratings yet

- Dr. Decuypere's Nutrient Charts Fruit Chart : Click On The Buttons Below To Visit Each ChartDocument28 pagesDr. Decuypere's Nutrient Charts Fruit Chart : Click On The Buttons Below To Visit Each Chartmani_77No ratings yet

- What Is Chlorite?Document6 pagesWhat Is Chlorite?Angelo CorteroNo ratings yet

- BhimkundDocument11 pagesBhimkundDnyanal NandoskarNo ratings yet

- Undisturbed Samples of London Clay-Bishop & WebbDocument31 pagesUndisturbed Samples of London Clay-Bishop & WebbAnonymous GnfGTwNo ratings yet

- EP-June 30,2010Document7 pagesEP-June 30,2010Bobby CalanogNo ratings yet

- MOBPLS BC Activities Aug 2023 For ChartDocument8 pagesMOBPLS BC Activities Aug 2023 For ChartRoudell BautistaNo ratings yet

- BS SieveDocument2 pagesBS SieveAnonymous 2FDTST37uNo ratings yet

- GATE IIT (GT Test - 1)Document3 pagesGATE IIT (GT Test - 1)RadhaAnanthalekshmiNo ratings yet

- Stratigraphy and Structure Across The Blue Ridge and Inner Piedmont in Central VirginiaDocument27 pagesStratigraphy and Structure Across The Blue Ridge and Inner Piedmont in Central VirginiastephenNo ratings yet

- © 2015 Pearson Education LTDDocument77 pages© 2015 Pearson Education LTDCamille AndreaNo ratings yet

- Soil Correlations: Caltrans Geotechnical ManualDocument5 pagesSoil Correlations: Caltrans Geotechnical ManualHandi ThomasNo ratings yet

- Feldspar - An WEB 2011Document2 pagesFeldspar - An WEB 2011Nazanin SabetNo ratings yet

- My Geo NotesDocument21 pagesMy Geo NotesKuyeri Tafadzwa Dave100% (1)

- Complete Your Responses in A Color Other Than Black or Red.: Homework 7-Igneous Rocks and VolcanoesDocument3 pagesComplete Your Responses in A Color Other Than Black or Red.: Homework 7-Igneous Rocks and VolcanoesGil GameshNo ratings yet

- Earth Science: Quarter 1-ModuleDocument51 pagesEarth Science: Quarter 1-ModuleBoison Prince ChristianNo ratings yet

- Urban Soils and Tree Health - David DechantDocument66 pagesUrban Soils and Tree Health - David DechantJonathan German AlacioNo ratings yet

- Interpretation of Effective Stress Friction Angle From In-Situ Tests - MayneDocument10 pagesInterpretation of Effective Stress Friction Angle From In-Situ Tests - MayneTargetRockNo ratings yet

- Shear Strength Degradation of Vibrated Dry SandsDocument10 pagesShear Strength Degradation of Vibrated Dry SandsSelda DurmazNo ratings yet

- The Cycles Questions Rewritten From Original WorksheetDocument2 pagesThe Cycles Questions Rewritten From Original WorksheetAmyNo ratings yet

- 391 TESe PDFDocument5 pages391 TESe PDFFernando FanteNo ratings yet

- Well Log and Seismic Data Analysis Using Rock Physics TemplatesDocument7 pagesWell Log and Seismic Data Analysis Using Rock Physics TemplatesJulio Enrique Rodriguez FloresNo ratings yet

- Angle of Repose DataDocument1 pageAngle of Repose DataMark Carlton100% (1)

- ADM - Grade 11 - Quarter1 (S1112ES-Ic-17)Document24 pagesADM - Grade 11 - Quarter1 (S1112ES-Ic-17)josephine alcantara100% (1)

- Science: Quarter 1 - Module 5Document21 pagesScience: Quarter 1 - Module 5danica royalesNo ratings yet

- Litoestratigrafía Detallada de Parana Etendeka, Basalto Serra GeralDocument21 pagesLitoestratigrafía Detallada de Parana Etendeka, Basalto Serra GeralJuan TurraNo ratings yet