Professional Documents

Culture Documents

Malaysia Wps Hala Flex

Malaysia Wps Hala Flex

Uploaded by

Keneth Del Carmen0 ratings0% found this document useful (0 votes)

9 views13 pagesMalaysia Wps

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMalaysia Wps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views13 pagesMalaysia Wps Hala Flex

Malaysia Wps Hala Flex

Uploaded by

Keneth Del CarmenMalaysia Wps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

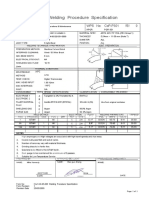

ACFM Engineering & Construction Sdn. Bhd.

Mechanical Erection, Equipment's Structure & Piping Works

WPS Number : AFCM-WPS-01/13,

ReyNo 0

WELDING PROCEDURE SPECIFICATION

‘GTAWISMAW (6G UPHILL)

P-No, 1 - SINGLE VEE

Material Thickness : 1.5 mm to 6.0mm

1.6mm 0 8.22 mm

WELDING CODE & STANDARDS

ASME IX (2013)

TY | DATE [PREPARED AY | REVIEWED RY [APPROVE

Name Name [Sign | Name

ACFM Engineering & Construction Sdn. Bhd.

Mechanical Erection, Equipment's Structure & Piping Works

WELDING PROCEDURE SPECIFICATION (WPS)

In Accordance with Section IX, ASME Boiler and Pressure Vessel Cole

Welding Procedure Spietion No Aronwesoyis Rev: Due _ 20° NoveneR 2013,

Supporting POR No.) AEIEPR-O ae: 20" novEMBER2013

Welling Prces(e) ‘GTAW8 SHAW Type: TANGA

as (Way Preheat (OW 6) i

Soin Tp sincte vee rorzne | Pest Temp. Min AMBIENT — REMOVE MOISTURISED

Ducking MA Catron os | inerpss Temp. Mx 250°C

Daeking Mal (ope) “WA ereonstrin | Prat Manone i

Revie NA | ening

ant we eat Treat (OW-07)

ase tas OW) Tenperaue Rane a

PX Groupe | Time ange

roP.No — Goowpne 4

rb ps7 aa Nh Poi aS COW-HH)

“ASHE SAI06Gr.B [CM] — comtey | %Compaion

a ‘ASHE SALOS Gr. 6 [CNS | ete)

se Mew eke: a

Groowe 15-60mm | 160822 __ | Taing A |

rae SOR mT — | eine, RN

Pipe Dis Rang:

“roo uwuMmeD eet Charteris (WA)

ie ‘UNLIMITED Curent” "DC Polariy—STRAIGHT_| REVERSE

Oe: EACNSHTEMASSINL NOT ECEED BG — | Amp (aap ein | 9-150 Von ans) Toes | 2538

“angst Feeds Size 8 Type

Tier ea (OWI Mas of Met Tas ie GMAW sal

Spe No (SFA) sFasie seas Ekoode Wie edspetrarse IRS

AWS No.(Chss)_ ERVOS 7018 aint

No. 6 [a4 Ate 1 ‘Technique QW)

eco ax (a8) Nk Singer Weave Bad __ som

Hoe Trade Name A Ian ners Cling ‘GRINDING / BRUSHING

Consus e Math ock Gouging ~

One ORel co 16 SAB 58 OR EQUAVALET Cont Teta Wek Disc

Muli o Sing as pre)

estos (OW) Mali Single Hectiss

Fesins)ofGreee nies Gas Cp site

Weking Monession Pat Ovation

rosie) oie NA Travel Spot (Rang) rnin

———_| ening

0° 1)NIA= Not Appeal 2) NI = Not oe ~

fie Cae Tana aT

wat : ‘Ya ange

vrocess [Case [Damier | yc peigy | A Le anes er

lave) cas) | Peo” | Brenan | AMEN || ervey

ROOT eew e 2 es my

HROOTR | craw | enmosc | 24 | 2X | go~ 120 | 10-15 | 60-100 | maxasion

LING &

PLUNGE | swan | eros | 26 | oce | som1s0 | 2532 | cows0o | max2sKymm

age 1661

ACFM Engineering & Construction Sdn. Bhd.

Mechanical Erection, Equipment's Structure & Piping Works

PROCEDURE QUALIFICATION RECORDS

{In Accordance with Section IX, ASME Boiler and Pressure Vessel Code

Procedure Quaiicaton Record No AFCO FRO IS Dae 20 NOvENER 2013

‘Wre Number prow pqR-o0ip13

Wiking recs (es) ‘GiAW 8 SH Trea) nun

“ORNS (aa) ‘BASE METALS (awa)

Maefal Spec. ASMESA105 To. _ASMESA105_

Tygeor Cae 8 to 6

wn pieiGL——ToRN. —— Pai Ge

‘PREHEAT awe)

Probes Tere.

Feria No. Inppass Temp.

‘Weld Nett Anais A. ner

‘Sie of er Meta 230m 26m

Wild Meta Tuctrass 30min ann ‘GAS (aWa08)

Oat EAC SINGLE PASSSHALL NOT ECEED 13.0 mm =

‘POSTWELD HEAT TREATIANT (QW07) snetang ARGO

Temparaure NA Taira NA

Time ae Becking NA

Omer NN

TECHNOL (OWAADY

ave Speed

‘Sting or eave Bead

Osaiaton wa =

sips oil Pass (par aio) MULTI

Sng ort Eecode “SINE

omer = a

Typect Faure & Location

{See etched HTS Report No. MTS18L6-1/13)

7 To | — 6a —| 0a ‘DUCTILE FAILURE - BROKE AT RAGE METAL

12—[ 1905 | see | 17 UCT FAIRE = BROKE AT EASE MEAL

‘GUIDED BEND TESTS (GW-160)~ASTHTASTO" Ta

"est Tempore! 126610 120%

1 inet

ee ese eee (see tated MIS Rear Nb S183)

f (7a | 0 ea acer Ti delet was eee _

sa 7a. cy ACCEPTED, i defect was ebered

Sarat | 0. 2 ACCEPTED. No defect was cbstried

33710. na ACCEPT "eet was cbse

= NESS TEST (QW.170) =:

eet ipsa Vass —— ‘Diop weet

tt Shear —[ fm) |B

coma ee

ICCET-WELD TES (QW=100) ‘OTNER TESTE

Resa Yen |X] Peraitieninio Yes [—K ect et 8a0NES ES fer: sett

Seteacory fe Parental No epost Analisis ——

Husco=Resuts SATISFACTORY [Report Nos MTS/8161-173) | OMner ep EARN RIOD

‘Weer Nane MHD IMRNUDIN FAL ABLOW "Teak Conticiod by RENTRDE TESTING STRUCES SOW BAD

NRICKO. =

rp Labora Test No, —_[RS)IBI61-i/13 THROUGH MTSTOTOLATIT

en

age tof 2

ACFM Engineering & Construction Sdn. Bhd.

Mechanical Erection, Equipment's Structure & Piping Works

ELD PASS RECORD

=F PaLER MEAL cone Tee

races vour | SED | pearwwureaons

NERS oss | Oa | revo | a rn)

DIRT

: caw | wee |e | all, = [2 a or

2 | ew [owes | | utile | = [2 | = one

a A oo

a 12 e

NOTE, ELECTRODE METAL:

".KOBELCO TG-S50[ER705-G), 024mm

2. ROBELGO Ls sze e701, Ozer

Lp SEQUENCE

esas

: atom

eee

23)

Ty 2m

sors |

wr) aaa gy

‘Ween NORD PUNO 7 BRT ee oa

che nn tk a

Stamp

weshe

in accordance with the reqi

Manufacurer

si

Date

‘AL Tid Party! Inspector Examine BodyiGient

‘Signature

Page 20f2

ACFM Engineering & Construction Sdn. Bhd.

Mechanical Erection, Equipment's Structure & Piping Works

WELDER PERFORMANCE QUALIFICATIONS

In Accordance with Section IX, ASME Boiler and Pressure Vessel Cod

Welds Nave NIC 860530236561 _ Stamp No

‘test bescraPrion.

entiation of WPS fotowes arou.wscay/ [5e] Testecupon —] Pretaon wott

‘Spacatn of ase Mata) ‘Sus GE “ene 7aLnm

‘TESTING CONDITIONS AND QUALIFICATION LIMITS

‘Manual or Semiatamate Varabes for Each Process (2.250) Actualalues Range Qustfed

Welang processes) raw

Type rare, seiverste, machine automat) used

‘Bing cts, wed mata ste weld te)

[APP [a] Pepe 1683mm_ (eter dame, ps)

‘tera Pr Noro P-9" SN

Frit oc wecrode pocticatrts) (SFA (hf ony)

Fier Metal or ecrode dastctn(s) (rf ot)

Far Metal Number)

‘Consul ner (STA of PAW) “H

Far ype (slaneal or tx eran (GTAW 0c PAW) ‘SO ‘OUD

Depostticiness fo each press,

Process: _GTAW _Stayers minimum — [=] Yor DE] Wo

Process 2: SMAW _—Stayersminimum — [X_] Yes [—] No

Poston gui (26, 66.2,

Versa! pogresson (pir dow)

‘Type atte gas (OFM) re

{nat as bazcing (GTAW. PAW. GAAWO 2

{rant mode cryin pe a shot eu MAW

(GTAW earn pelt (AC, CEP, OCEN) Deen

Note:

1.5660 nm

15622 mm

2. wir anowrmHour

2, PN 1 through Peo 15F, Po. 34 and P-No. 41 through Poo. 49,

sours

i Banana Camp (a0) sonsacon ia

(HE) somrou, (] tamene tena OW At2 50; waa et maton; [K] saroHe2

sedan arete eitea sal pete ce nan ectesc cocker ete aa

Naceioruemana2 so | Mabotet einen ay

ie et i

See hed Sp os HTB

eratyaeaogegic waite mt(OW01) SATISFACTORY pat ran

fearon acces SRO cai ryocina oa

ioscan) TT eg te cakaeeeR

oe Se bd HTS Rain NoMa AT- TRIES =

Pine penen ey MU a Comey, cu NSE oD

(icienEstse cence. HEME eT SERNCESSO wh, "lary

‘ating sipevsed oy NORZAEDANIN NOHO NOI [AFCH ENGINEERING & CONSTRUCTION SON HD]

Wi crt thatthe statamants inthis record are coroct and that tho tot coupons wore prapared, wold, and testd in accordance wih the

‘eauiramonts of Section ofthe ASIE Bolo ane Pressure Vessel Code.

Page tof

"ty,

ep

PLO 110, Jalan Cyber 5, Kawasan Perindustrian Senai Fasa 3,

81400 Senai, Johor, MALAYSIA. oS ma eonecn tes

‘Te: 607598 8898 Fax: 607-598 3898 Email menuade tesng@yshoocom “7 NS SAME NO z74

TEST REPORT ORIGivac

ot

ot

Mentrade Testing Services Sdn Bhd (co. No. 586617?) WU,

ON (Member of MENTRADE Group) WI 2

Laporatory Test Ho MIS / 18161-1713 ORK

Dato Tested 19 November 2013 TotatPage 4 Paes

customer Engincering & Construction Sdn, Bhd

Suite A-33-2, Menara UOA Bangsar,

No. 5 alan Bangsar Ulam

59000 Kuala Lamp.

Pos ouerno

Your Ret

Dato of Receipt of Fest Kes 18 November 2013

Reterence Code ASME IX :2013

Subject as received)

1: welded stel pipe st sample, Size: 06" Sch 40, marked : WPS No : ACFM-WPS-01/13, Process : GTAW/SMAW, Position : 6G

(Uphill), Joint Type : Single Wee, Welder Name : Molid Imanusin Fauzi Bin Abloh, UC No : $60630-23-6561, material grade : SA106

Gr. By filler mal: ERTHS-G / E7018, for Welding Procedure Qualification Test

Tensile Test : Test Temperature : +25°C; Test Method : ASME IX: 2013,

‘Type of Test Specimen : Reduced Section Trancverse Weld Specimen

Specimen Number risen Z sama ar

[Measured Thickness (ram) 687 a 658 E

Measured With (rm) 9.08 19.05

|Eftective Area rom?) 130.80 132.97

[utimateTensie toed ON) 68.68 z 957

lUtimate Tensile Stess (Nimm?) | ____525 (76.100 psi 524

Location of Fae Broke at base etal Brokat bse mal

Hype of Fae Duele flute Ductile faiure

Bend Test ; Test Method : ASMEIX:2013 Test Temperature +280

Test Specimen Width 38mm —_-Bend Angle : 180 Degree

Tost Specimen Thicknoss——: 7.11 __mm__Former Diameter: 28mm

Type of Bend Face Bend Type of Bend Root Bend

Spectnen | oct Rena Specimen | Result Remarks

[Fi Acct ‘No defect was observed RI ‘Accepted | No defect was obsrved

("8 ‘Accented ‘No defect was observed Ro “Accepied | No defect was observed

Macro-Etch Examination (10X Magnification) Test Method: ASTM E340-00 2005)

Test Specimen Thicknoss T1l___mm__ Test Specimen Width 10mm

Seamer | most Renan Specimen | Result ae

M Accepted No defect was observed - = i ao

“est Conducted By Mr Shara Nizam Bin Neuron

‘est Witessed Oy Mr Mazlam bin Dean of Intelligent Inspection & Engineering Sd, Bhd

Mr alk Arfin of Lloyd's Repister

EipmentUsed

(GOTECH COMPUTERISED UNIVERSAL TESTING MACHINE, Mog -G-700-L0-,

Seal No TCOSMO, Caps: 5008N

(&) Bend Test: Fukunaga Hyuravlic Machine, Model : FEP-IDS, Serial No 608007

Approved Signatory

‘ite pe nmptrntsr conte ponte cay anaes

[

PLO 110, Jalan Cyber 5, Kawasan Perindustrian Senai Fasa 3,

81400 Senai, Johor, MALAYSIA, e

‘Tel: 607-598 8898 Fax: 607-598 3898 Email: mentrade_testing@yahoocom

ote,

oa ier gti

ZS MS nS

SUN, ‘'SAMM NO. 274

Mentrade Testing Services Sdn Bhd (co. no. 5986176) SW,

Ii (Member of MENTRADE Group) SA

“S

TEST REPORT AL

abort Testo MTS /181612/13 reget: 2

bate Teste 19 November 2013, Toialpoge 4 Pages

customer ACEM Engnsering & Construction Sdn. Bh

Suite-32-2, Menara UOA B

No, 5, Jalan Bangsar Utama 1,

39000 Kuala Lumpur

P.O! OuerNo =

Your Ret -

Date of Receipt of Test Kems [x November 2013,

Reference Code ASME IX: 2010

Test Load Appled Livtoker Force Application Tine 10 Second

Suoject os received)

‘One welded steel pipe test sample, Size : 6" Sch 40, marked : WPS No : ACPM-WPS-01/13, Process : GTAW/SMAW, Position : 6G

(Uphild, Joint Type : Single Vee, Welder Name : Molid Imanusin Fauzi Bin Abloh, UC No : 860630-23-6561, material grade : SALD6

Gr. B filler meal : ER7OS-G / E7018, for Welding Proceduce Qualification Test

Hardness Test Location

riers ener

mene

Line 2] y+ 303°

& Nays

HAZ Indentation 0 Smm apart

‘Test Conducted By (Me Shara! Nizam Bin Neaditan

‘Test winessea By [Me Mactan bin Berahim of Intelligent Inspection & Engineering Sdn. Bhd,

Me Zulkili Arifin of Lloyd’s Register

Remake

Equipment Use © AKASHI Viekers Hardness Tester, Model : AVK-C100, Serial No : 190803

Approved Siguatory

Subaila“Chinad, 6.”

Asst, Laboratory Manager

81400 Senai, Johor, MALAYSIA, i-wee rt

Mentrade Testing Services Sdn Bhd (co. No. 586617-P)

y (Member of MENTRADE Group)

PLO 110, Jalan Cyber 5, Kawasan Perindustrian Senai Fasa 3,

= MS ISONEC 17025

“Tel: 607-598 8898 Fax: 607-598 3898 Email: mentrade_testing@yahoocom —“/( as on NO. 274

A

TEST REPORT

Laboratory Testo MTS / 181613 (13 Page No

Date Tested 19 November 2013 Totatrage = 4 Pages

Customer ACFM Engineering & Construction Sén. Bhd,

>. Menara UOA Bangsar,

No, 5, Jalon Bangsar Utams 1

39000 Kula Lumpur

P01 0erNo

Your ret

bate of Recesp of Tes tems 18 November 2013

Relorence Cove ASME IX: 2013

Test Load Applied HvlOket Force Application Time 10 Second

‘Subject as receives)

‘One welded steel pipe test sample, Size : 06" Sch 40, marked : WPS No : ACFM-WPS-O1/13, Process : GTAWISMAW, Position : 6G

(Uphill), Joint Type : Single Vee, Welder Name : Mokd Tmanudin Fawzi Bin Abtoh, VC No : $60630-23-6561, material grade : SALO6

Gr. B, filer metal : ER7OS-G/ E7018, for Welding Procedure Qualification Test

ardaess Test Results: ‘Test Method : ASTM E92 : 1982 (2003)?

gpaaen ae Test Vickers Hardaess Number (HV)

Ldeniietion Location No Line Line 2

1 163 166

Base Metal 2 169 16H

3 161 167

SA106 Gr. B 4 v7 168

WPSNo Heat Aftected Zone [5 170 175

ACEM-WPS.OU/13 (HAZ) 6 17 176

7 176, 180

% 18 162

Process Weld Metal 9 174 159

GTAWISMAW a Ton 3

in 186 170

eat atteved Zone [12 178 173

aan) az) B 168 13

SA106 Ge. B u 166 165,

5 153 ur,

ase Metal 16 169 151

0 152 161

“est Conducted 9 Mr Shah Nizam Bin Neadiran

“eat nese By Mr Mazlam bia Berahim of Itligent Inspection & Engineering Sn. Bhd

Mr Zaki Artin of Loyd’ Register

femarts na

auipment Used [AKASH Vickers Hardness Tester, Model : AVK-C100, Serial No: 190803

Approved Sigaatory/

Mentrade Testing Services Sdn Bhd (Co. o.ss6617P) WU),

SS,

(Member of MENTRADE Group) gS ED

PLO 110, Jalan Cyber 5, Kawasan Perindustrian Senai Fasa 3, Hlac-MRA aces

81400 Senai, Johor, MALAYSIA. CNS SS Meare

‘ ‘Tel: 607-598 8898 Fax: 607-598 3898_ Email: mentrade testing@yzhoocom —“a/q\. SAMMI NO, 274

TEST REPORT ORIGINAL

Laboratory Testo 2 MIS/1BI61-4/ 13 Paseo 4

Date Tested + 19 November 2013 ToulPege = 4 Pages

Customer + ACFM Engineering & Consiistion Sn, Bh

Suite A-33-2, Menara UOA Bangsar,

No, 5, Jalan Bangsar Utama 1

59000 Kuala Lumpur.

POF Order No

Your Ret

Date ot Receipt of Test items =-18 November 2013

Reference Code 5 ASME IX: 2013,

Subject (0s recived)

‘One welded stet pipe test sample, Size = 06" Sch 40, marked : WPS No : ACEM-WPS-01/13, Process : GTAWISMAW, Position 6G

(Uphill, Joint Type : Single Vee, Welder Name : Mohd Imanudin Fauzi Bin Abloh, UC No : 860630-23-6561, material grade : SA106

Gi. B, filler metal : ER7OS-G / E7OIS, for Welding Procedure Qualification Test

Macro-photograph of Sample Marked

WPS No : ACFM.WPS-01/13, Process : GIAW/SMAW, Postion : 6G (Uphill)

Test Conducted By Nizam Bin Ngadiran

Test witnessed By ‘Mr Mazlam bin Berahim of Intelligent

Me ZulkifliAriffin of Lloyd’s Register

nspection & Engineering Sdn. Bhd,

Sf co.no. Ve

ZL (3\ stceire JS

sana Kved wth

Asst. Laboratory Manager

i Tecra Save p08 |

sort,

17-2528434 Emai

RADIOGRAPHIC INSPECTION TEST REPORT

[CLIENT ; ACFM ENGINEERING & CONSTRUCTION 5/B

SUITE A-33-10, MENARA UOA BANGSAR,

NO. 5, JALAN BANGSAR UTAMA 1,

[INSPECTION DATE: 15/11/2013,

[TIME + 2030 t02300 HRS

intelligent_inspection@yahoo.com

IREPORT NO, : IE/RT-5033/1-1/008/2013

INTELLIGENT INSPECTION & ENGINEERING SDN BHD. 1163911)

No. 36&36A, Jalan Lampam 41, Taman Tanjung Puteri

81700 Pasir Gudang, Johor Darul Takzim.

59000 KUALA LUMPUR, MALAYSIA. PROJECT _:seemeLow

[FILM TYPE : FUJI 80 |ACCEPTANCE CRITERIA: ASMEIX(2010)

SIZE/QTY : 4" x15" / 10 |PROCEDURE NO. + IIE/ ASME-RT/ REV-1

Pb SCREEN : YES [TECHNIQUE NO. : DWSI

|SOURCE/STRENGTH = IR 192.7 18 Ci oma TASTM [MATERIAL : CARBON STEEL

SOURCE SIZE : 2x2 mm DESIGNATION :1B

ISFD/FED : 152.4mm IDenstry 12-35 WELDING PROCESS : GrAW/SMAW

[SOD/OFD : 145.3mm/7.0mm SENSITIVITY :2% [POSITION: -

FILM INDENTIFICATION WEDERT osn | OP | WT INTERPRETATION =

xo. m_| ne Jaccerm | wee

PROJECT: ACFM-WPS 01/13

ITEM NO:

MOHD IMANUDIN FAUZI BIN ABLOH

( 860630-23-6561 )

PIPE 1

oo | or | o PG

12

2-0

[TECHNICIANS + MOHD ANUAR/SAIFUL ABIDIN

JASNT LEVEL:

bare: 15/11/2013,

INTERPRETED BY: MOHD}S “APPROVED BY

ASNT LEVEL: 11 i

pate: t6/tij203 || DATE.

a

WT

woLoaasxt 43149

“CLT “OD (GNVTIVHL) FILM SUN THOM <—

cvaeayrnce aprons of

Se

Taoearen |e

nae cs

pox osname,

zo | wo> | eo

a a ere]

S-SOLU STSY SMV | e06891I j ¥z 0SS-9L

[__Noivouev De NOMNOMDEES eVoTEAY | "oR ODE ASE Ty sonwxoiszqaavar

ALVIISLLYAD NOLLIAESNI

131d GHOAVONTS) DNIGTEM TEOM|

wasveounal

‘G11 “Bld 9isldvd YiS¥ ONIGTEM OOT380¥

>noay

ovary

ANBWULYEEL LvaH

onamisos

1931 ss3xouvit

#04831 Lovawn

we 2000

ve NOLISOgWOD WOAH

1

erova t 3e eeeeat

(uw)

oN'oaK noiswania Nouwnoisza saved

BLVOISILYAD NOILI3dSNI

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Safety ManualDocument74 pagesSafety ManualKentDemeterio100% (1)

- Feng Shui Chinese Lucky CharmDocument23 pagesFeng Shui Chinese Lucky CharmKeneth Del CarmenNo ratings yet

- AMO PICE MakatiDocument73 pagesAMO PICE MakatiKeneth Del CarmenNo ratings yet

- Welders Ability Questionnaire and Safety Test: Name - Period - Grade - DateDocument5 pagesWelders Ability Questionnaire and Safety Test: Name - Period - Grade - DateKeneth Del CarmenNo ratings yet

- Sworn Statement: Allan A. MendozaDocument1 pageSworn Statement: Allan A. MendozaKeneth Del CarmenNo ratings yet

- Sworn Statement: Allan A. MendozaDocument1 pageSworn Statement: Allan A. MendozaKeneth Del CarmenNo ratings yet

- Welding Competition-SMAW PlateDocument4 pagesWelding Competition-SMAW PlateKeneth Del CarmenNo ratings yet

- Supplier's Accreditation Form-UpdatedDocument2 pagesSupplier's Accreditation Form-UpdatedKeneth Del Carmen25% (4)

- GMAW WQTDocument1 pageGMAW WQTKeneth Del Carmen100% (2)

- Floating SystemDocument6 pagesFloating SystemKeneth Del CarmenNo ratings yet

- Canteen Policy Support DocumentDocument8 pagesCanteen Policy Support DocumentKeneth Del CarmenNo ratings yet

- Proposal To BatangasDocument3 pagesProposal To BatangasKeneth Del CarmenNo ratings yet

- Cebu Applicant Master ListDocument17 pagesCebu Applicant Master ListKeneth Del CarmenNo ratings yet

- IDD Tier 1 Assessment (Contractor Portion Questionnaire)Document2 pagesIDD Tier 1 Assessment (Contractor Portion Questionnaire)Keneth Del CarmenNo ratings yet

- Line Up For Keppel Subic NewDocument4 pagesLine Up For Keppel Subic NewKeneth Del CarmenNo ratings yet

- FO-R23-001 - R2 Subcontractor Registration FormDocument6 pagesFO-R23-001 - R2 Subcontractor Registration FormKeneth Del CarmenNo ratings yet

- Keppel Eng'g ProposalDocument2 pagesKeppel Eng'g ProposalKeneth Del CarmenNo ratings yet

- Master Line Up For Keppel Subic 1 NewDocument3 pagesMaster Line Up For Keppel Subic 1 NewKeneth Del CarmenNo ratings yet

- RHCM New CompanypolicyDocument40 pagesRHCM New CompanypolicyKeneth Del CarmenNo ratings yet

- Journeyman Welding & Piping Services Intl. Corporation: List of ToolsDocument28 pagesJourneyman Welding & Piping Services Intl. Corporation: List of ToolsKeneth Del CarmenNo ratings yet

- Location of Consumer CanteenDocument1 pageLocation of Consumer CanteenKeneth Del CarmenNo ratings yet

- Cape WPSDocument1 pageCape WPSKeneth Del CarmenNo ratings yet